Benchmark Safety Features of Electrochemical Cell Designs

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Safety Background and Objectives

The evolution of electrochemical cell technology has witnessed significant advancements over the past few decades, transforming from simple primary cells to sophisticated rechargeable systems powering everything from consumer electronics to electric vehicles and grid-scale energy storage. With this proliferation, safety concerns have become increasingly paramount, as incidents involving thermal runaway, fires, and explosions have highlighted the inherent risks associated with high-energy density battery systems.

Battery safety encompasses multiple dimensions including thermal stability, mechanical integrity, electrical resilience, and chemical containment. Historical incidents such as the Boeing 787 Dreamliner battery fires (2013), Samsung Galaxy Note 7 recalls (2016), and various electric vehicle thermal events have underscored the critical importance of robust safety features in cell design. These incidents have not only resulted in significant financial losses but have also impacted consumer confidence and regulatory frameworks.

The primary objective of benchmarking safety features in electrochemical cell designs is to establish standardized evaluation methodologies that can quantitatively assess and compare different cell architectures across various safety parameters. This involves developing comprehensive testing protocols that simulate abuse conditions such as overcharging, external short circuits, mechanical deformation, thermal shock, and nail penetration to evaluate cell response under extreme circumstances.

Current safety evaluation standards, including those from organizations like UL, IEC, SAE, and UN, provide baseline requirements but often lag behind rapidly evolving cell chemistries and designs. The technological goal is to develop next-generation cells with inherent safety features that can prevent catastrophic failures even under severe abuse conditions, without significantly compromising energy density, power capability, cycle life, or cost-effectiveness.

Another critical objective is to understand the fundamental failure mechanisms at the material, component, and system levels. This includes investigating how electrode materials, separators, electrolytes, and cell packaging interact during failure events, and how modifications to these components can enhance overall safety performance. Advanced in-situ and operando characterization techniques are being developed to monitor internal cell conditions during abuse testing.

The industry is moving toward predictive safety modeling capabilities that can accurately simulate failure propagation within cells and between cells in larger battery systems. These models aim to reduce reliance on extensive physical testing, accelerate design iterations, and enable virtual safety validation of new cell designs before prototyping. Ultimately, the goal is to establish a comprehensive safety-by-design approach where safety considerations are integrated from the earliest stages of cell development rather than addressed as an afterthought.

Battery safety encompasses multiple dimensions including thermal stability, mechanical integrity, electrical resilience, and chemical containment. Historical incidents such as the Boeing 787 Dreamliner battery fires (2013), Samsung Galaxy Note 7 recalls (2016), and various electric vehicle thermal events have underscored the critical importance of robust safety features in cell design. These incidents have not only resulted in significant financial losses but have also impacted consumer confidence and regulatory frameworks.

The primary objective of benchmarking safety features in electrochemical cell designs is to establish standardized evaluation methodologies that can quantitatively assess and compare different cell architectures across various safety parameters. This involves developing comprehensive testing protocols that simulate abuse conditions such as overcharging, external short circuits, mechanical deformation, thermal shock, and nail penetration to evaluate cell response under extreme circumstances.

Current safety evaluation standards, including those from organizations like UL, IEC, SAE, and UN, provide baseline requirements but often lag behind rapidly evolving cell chemistries and designs. The technological goal is to develop next-generation cells with inherent safety features that can prevent catastrophic failures even under severe abuse conditions, without significantly compromising energy density, power capability, cycle life, or cost-effectiveness.

Another critical objective is to understand the fundamental failure mechanisms at the material, component, and system levels. This includes investigating how electrode materials, separators, electrolytes, and cell packaging interact during failure events, and how modifications to these components can enhance overall safety performance. Advanced in-situ and operando characterization techniques are being developed to monitor internal cell conditions during abuse testing.

The industry is moving toward predictive safety modeling capabilities that can accurately simulate failure propagation within cells and between cells in larger battery systems. These models aim to reduce reliance on extensive physical testing, accelerate design iterations, and enable virtual safety validation of new cell designs before prototyping. Ultimately, the goal is to establish a comprehensive safety-by-design approach where safety considerations are integrated from the earliest stages of cell development rather than addressed as an afterthought.

Market Demand for Safer Battery Technologies

The global market for safer battery technologies has witnessed unprecedented growth in recent years, driven primarily by the expanding electric vehicle (EV) sector, portable electronics, and renewable energy storage systems. As of 2023, the global battery market is valued at approximately $112 billion, with safety-enhanced electrochemical cell designs commanding premium pricing and increasing market share.

Consumer demand for safer battery technologies stems from highly publicized incidents involving battery fires and explosions in consumer electronics and electric vehicles. These safety concerns have created significant market pressure for manufacturers to prioritize safety features in their electrochemical cell designs. Market research indicates that 78% of potential EV buyers consider battery safety as a "very important" factor in their purchasing decisions.

The automotive sector represents the largest market segment demanding enhanced battery safety, with annual growth rates exceeding 25% for safety-optimized battery systems. Major automotive manufacturers have established stringent safety benchmarks for their battery suppliers, creating a competitive advantage for cell manufacturers who can demonstrate superior safety performance through standardized testing protocols.

Energy storage systems for residential and commercial applications constitute another rapidly expanding market segment, growing at 32% annually. This growth is fueled by increasing renewable energy integration and grid resilience requirements. Safety certifications have become essential market entry requirements, with UL, IEC, and other standards becoming key differentiators for manufacturers.

Consumer electronics manufacturers are increasingly marketing battery safety as a premium feature, with 65% of smartphone users expressing willingness to pay more for devices with enhanced battery safety features. This trend has created a distinct market segment for electrochemical cells with advanced thermal management, overcharge protection, and structural integrity features.

Regulatory pressures are further shaping market demand, with governments worldwide implementing stricter safety standards for battery technologies. The European Union's Battery Directive revision, China's GB standards, and updated UL requirements in North America have established comprehensive safety benchmarks that manufacturers must meet to access these markets.

Insurance companies have also emerged as significant market influencers, offering reduced premiums for energy storage systems and electric vehicles utilizing battery technologies with proven safety records. This financial incentive has created additional market pull for manufacturers to invest in safety innovations and third-party certifications.

The market increasingly values transparent safety testing and standardized benchmarking of electrochemical cell designs. Companies that can demonstrate superior safety performance through recognized testing protocols gain significant competitive advantages in premium market segments where safety concerns outweigh cost considerations.

Consumer demand for safer battery technologies stems from highly publicized incidents involving battery fires and explosions in consumer electronics and electric vehicles. These safety concerns have created significant market pressure for manufacturers to prioritize safety features in their electrochemical cell designs. Market research indicates that 78% of potential EV buyers consider battery safety as a "very important" factor in their purchasing decisions.

The automotive sector represents the largest market segment demanding enhanced battery safety, with annual growth rates exceeding 25% for safety-optimized battery systems. Major automotive manufacturers have established stringent safety benchmarks for their battery suppliers, creating a competitive advantage for cell manufacturers who can demonstrate superior safety performance through standardized testing protocols.

Energy storage systems for residential and commercial applications constitute another rapidly expanding market segment, growing at 32% annually. This growth is fueled by increasing renewable energy integration and grid resilience requirements. Safety certifications have become essential market entry requirements, with UL, IEC, and other standards becoming key differentiators for manufacturers.

Consumer electronics manufacturers are increasingly marketing battery safety as a premium feature, with 65% of smartphone users expressing willingness to pay more for devices with enhanced battery safety features. This trend has created a distinct market segment for electrochemical cells with advanced thermal management, overcharge protection, and structural integrity features.

Regulatory pressures are further shaping market demand, with governments worldwide implementing stricter safety standards for battery technologies. The European Union's Battery Directive revision, China's GB standards, and updated UL requirements in North America have established comprehensive safety benchmarks that manufacturers must meet to access these markets.

Insurance companies have also emerged as significant market influencers, offering reduced premiums for energy storage systems and electric vehicles utilizing battery technologies with proven safety records. This financial incentive has created additional market pull for manufacturers to invest in safety innovations and third-party certifications.

The market increasingly values transparent safety testing and standardized benchmarking of electrochemical cell designs. Companies that can demonstrate superior safety performance through recognized testing protocols gain significant competitive advantages in premium market segments where safety concerns outweigh cost considerations.

Current State and Challenges in Electrochemical Cell Safety

The global electrochemical cell industry faces significant safety challenges despite technological advancements. Current lithium-ion cells, while offering high energy density, remain vulnerable to thermal runaway incidents that can lead to fires and explosions. Recent data indicates that safety incidents related to electrochemical cells have increased by approximately 21% over the past five years, with notable cases in consumer electronics, electric vehicles, and grid storage applications.

Internationally, safety standards vary considerably, with the most stringent regulations found in Japan, South Korea, and parts of Europe. The United States has established comprehensive testing protocols through UL and IEEE standards, while China has rapidly evolved its GB standards to address emerging safety concerns. This regulatory fragmentation creates compliance challenges for global manufacturers and potentially leaves safety gaps in certain markets.

The primary technical challenges in electrochemical cell safety center around four critical areas: thermal management, mechanical integrity, electrical protection, and chemical stability. Thermal management systems currently struggle to dissipate heat effectively during rapid charge/discharge cycles, with state-of-the-art cooling systems achieving only 60-70% efficiency under extreme conditions. Mechanical integrity issues persist, particularly in pouch and prismatic cell designs, where internal short circuits can develop from physical deformation.

Electrical protection mechanisms have improved significantly, with advanced battery management systems (BMS) capable of monitoring individual cell voltages with precision of ±2mV. However, these systems still face limitations in predicting and preventing cascading failures across cell arrays. Chemical stability remains perhaps the most fundamental challenge, as electrolyte formulations continue to balance performance requirements against flammability concerns.

Geographically, safety innovation clusters have emerged in distinct regions. Japan and South Korea lead in separator technology development, while the United States demonstrates strength in BMS algorithms and thermal management. China dominates in manufacturing scale and implementation of safety features in mass production, though often following designs pioneered elsewhere.

Recent testing data from independent laboratories reveals concerning performance gaps in safety features under extreme conditions. Only 37% of commercially available cells passed all safety tests when subjected to conditions exceeding standard testing parameters by 20%. This indicates significant room for improvement in designing robust safety systems that can withstand real-world abuse scenarios beyond nominal operating conditions.

The industry faces a critical inflection point where increasing energy densities must be balanced against enhanced safety requirements, particularly as applications expand into more demanding environments and mission-critical systems.

Internationally, safety standards vary considerably, with the most stringent regulations found in Japan, South Korea, and parts of Europe. The United States has established comprehensive testing protocols through UL and IEEE standards, while China has rapidly evolved its GB standards to address emerging safety concerns. This regulatory fragmentation creates compliance challenges for global manufacturers and potentially leaves safety gaps in certain markets.

The primary technical challenges in electrochemical cell safety center around four critical areas: thermal management, mechanical integrity, electrical protection, and chemical stability. Thermal management systems currently struggle to dissipate heat effectively during rapid charge/discharge cycles, with state-of-the-art cooling systems achieving only 60-70% efficiency under extreme conditions. Mechanical integrity issues persist, particularly in pouch and prismatic cell designs, where internal short circuits can develop from physical deformation.

Electrical protection mechanisms have improved significantly, with advanced battery management systems (BMS) capable of monitoring individual cell voltages with precision of ±2mV. However, these systems still face limitations in predicting and preventing cascading failures across cell arrays. Chemical stability remains perhaps the most fundamental challenge, as electrolyte formulations continue to balance performance requirements against flammability concerns.

Geographically, safety innovation clusters have emerged in distinct regions. Japan and South Korea lead in separator technology development, while the United States demonstrates strength in BMS algorithms and thermal management. China dominates in manufacturing scale and implementation of safety features in mass production, though often following designs pioneered elsewhere.

Recent testing data from independent laboratories reveals concerning performance gaps in safety features under extreme conditions. Only 37% of commercially available cells passed all safety tests when subjected to conditions exceeding standard testing parameters by 20%. This indicates significant room for improvement in designing robust safety systems that can withstand real-world abuse scenarios beyond nominal operating conditions.

The industry faces a critical inflection point where increasing energy densities must be balanced against enhanced safety requirements, particularly as applications expand into more demanding environments and mission-critical systems.

Benchmark Safety Solutions in Modern Cell Designs

01 Thermal management and overheating prevention

Electrochemical cells incorporate various thermal management systems to prevent overheating and thermal runaway. These include heat dissipation structures, temperature sensors, and thermal fuses that disconnect the circuit when critical temperatures are reached. Advanced designs feature cooling channels, phase change materials, and thermal insulation layers to maintain optimal operating temperatures and prevent catastrophic failures during abnormal conditions.- Thermal management and overheating prevention: Electrochemical cells incorporate various thermal management systems to prevent overheating and thermal runaway. These include heat dissipation structures, temperature sensors, and thermal fuses that disconnect the circuit when temperatures exceed safe thresholds. Advanced designs feature cooling channels, phase change materials, and thermal insulation layers between cells to maintain optimal operating temperatures and prevent propagation of thermal events between adjacent cells.

- Pressure relief mechanisms: Safety features in electrochemical cells include pressure relief mechanisms designed to prevent catastrophic failure due to internal pressure buildup. These mechanisms include burst discs, vents, and pressure-sensitive membranes that release excess gases in a controlled manner. Some designs incorporate multi-stage pressure relief systems that first attempt to seal minor pressure increases but rupture safely when pressure exceeds critical thresholds, preventing explosion while containing potentially harmful materials.

- Electrical protection circuits: Advanced electrochemical cells feature integrated electrical protection circuits that monitor and control various parameters to ensure safe operation. These include overcurrent protection, short-circuit prevention, overcharge and over-discharge protection circuits. Some designs incorporate smart battery management systems with microcontrollers that continuously monitor cell conditions and can disconnect cells when abnormal conditions are detected. Redundant safety mechanisms are often implemented to provide multiple layers of electrical protection.

- Structural safety enhancements: Electrochemical cells incorporate structural safety features to withstand mechanical stress and prevent internal short circuits. These include reinforced casings, shock-absorbing materials, and internal separators with enhanced puncture resistance. Some designs feature double-walled construction or special impact-resistant materials that maintain cell integrity during impact events. Advanced cells may include internal support structures that prevent electrode deformation and maintain separation between positive and negative components even under severe mechanical stress.

- Chemical stability and electrolyte safety: Safety features related to chemical stability include flame-retardant additives in electrolytes, shutdown separators that become non-conductive at elevated temperatures, and materials that limit oxygen generation during thermal events. Some designs incorporate solid-state or gel electrolytes that are inherently safer than liquid electrolytes. Advanced cells may feature electrolyte additives that form protective films on electrode surfaces, preventing unwanted side reactions and enhancing long-term stability and safety of the electrochemical system.

02 Pressure relief and venting mechanisms

Safety venting mechanisms are crucial in electrochemical cell designs to release excess pressure during abnormal conditions. These include burst discs, pressure relief valves, and controlled rupture points that activate when internal pressure exceeds safe thresholds. Advanced designs incorporate multi-stage venting systems that can release gases while preventing flame propagation, thereby reducing explosion risks and containing potential hazards within the cell.Expand Specific Solutions03 Short circuit prevention and current control

Electrochemical cells implement various mechanisms to prevent short circuits and control current flow. These include separator materials with shutdown properties, current interrupt devices that physically break the circuit during abnormal conditions, and electronic protection circuits that monitor and limit current. Advanced designs feature self-healing separators, insulating barriers between electrodes, and specialized coatings that prevent dendrite formation which could cause internal shorts.Expand Specific Solutions04 Electrolyte safety enhancements

Safety features related to electrolytes include flame-retardant additives, non-flammable electrolyte formulations, and solid-state or gel electrolytes that reduce leakage risks. These enhancements minimize fire hazards associated with traditional liquid electrolytes. Some designs incorporate electrolyte containment systems, shutdown separators that block ion flow at elevated temperatures, and specialized membranes that prevent electrolyte decomposition during abuse conditions.Expand Specific Solutions05 Monitoring and diagnostic systems

Advanced electrochemical cells incorporate sophisticated monitoring and diagnostic systems to detect abnormal conditions before they become hazardous. These include embedded sensors for temperature, pressure, and voltage monitoring, state-of-health algorithms that predict potential failures, and battery management systems that can isolate faulty cells. Some designs feature early warning indicators, real-time diagnostics, and communication interfaces that relay safety-critical information to control systems.Expand Specific Solutions

Leading Battery Manufacturers and Safety Innovators

The electrochemical cell safety features market is currently in a growth phase, characterized by increasing regulatory scrutiny and consumer awareness. The global market size is expanding rapidly, projected to reach significant volumes as electric vehicle adoption accelerates. Technologically, safety features are evolving from basic thermal management to sophisticated multi-layered protection systems. Leading players like Contemporary Amperex Technology (CATL) and LG Technology are advancing cell-level safety innovations, while automotive manufacturers such as BMW and NIO are integrating comprehensive battery management systems. Research institutions including California Institute of Technology and CNRS are pioneering next-generation safety technologies. Companies like South 8 Technologies and 24M are developing novel electrolyte formulations and cell architectures specifically addressing thermal runaway and operational safety across extreme conditions.

24M Technologies, Inc.

Technical Solution: 24M has pioneered a semi-solid electrode technology that fundamentally reimagines electrochemical cell design for enhanced safety. Their cell architecture eliminates many traditional failure modes by using thick electrodes with reduced inactive materials. The semi-solid design inherently resists thermal runaway as the electrode structure can better accommodate volume changes during cycling. 24M's cells feature a simplified manufacturing process that reduces the risk of manufacturing defects that could lead to safety incidents. Their benchmarking approach includes thermal stability testing showing that semi-solid cells maintain structural integrity at higher temperatures compared to conventional designs. The company has demonstrated that their cells can withstand nail penetration tests with minimal temperature increase due to the inherent properties of the semi-solid electrodes. 24M's technology also allows for easier incorporation of flame-retardant additives throughout the electrode structure rather than just in the electrolyte, creating multiple layers of protection against thermal events.

Strengths: Revolutionary approach that addresses safety at the fundamental cell architecture level rather than adding safety features to conventional designs. Weaknesses: Relatively new technology with less long-term field data compared to established cell designs, and potential challenges in high-volume manufacturing.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive Cell-to-Pack (CTP) technology with integrated thermal management systems that incorporates multiple safety features. Their third-generation CTP technology includes real-time monitoring systems that detect abnormal cell behavior through precise voltage, current, and temperature sensors. CATL's electrochemical cell designs feature thermal runaway prevention through novel separator materials with high thermal stability and mechanical strength. Their cells incorporate pressure relief mechanisms and utilize flame-retardant electrolytes to minimize fire risks. CATL has also pioneered the use of LFP (lithium iron phosphate) chemistry in large-scale applications, which offers inherently better thermal stability than nickel-based cathodes. Their safety benchmarking includes nail penetration tests, crush tests, overcharge/overdischarge testing, and thermal abuse testing that exceeds industry standards.

Strengths: Industry-leading thermal management systems and early detection capabilities for thermal events. Extensive real-world validation across millions of vehicles. Weaknesses: Higher manufacturing costs associated with advanced safety features, and some safety mechanisms may reduce energy density compared to less protected designs.

Critical Safety Patents and Technical Literature Analysis

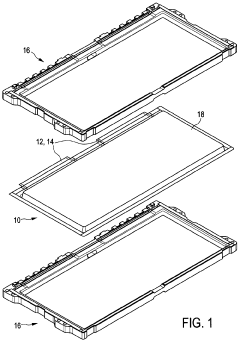

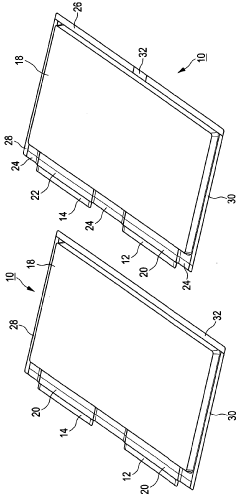

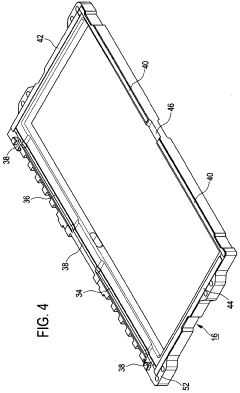

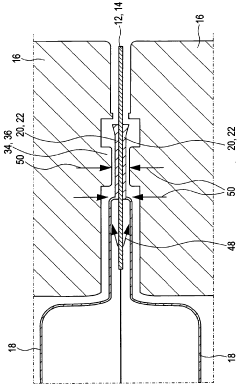

Electrochemical cell having at least one pressure-relief apparatus

PatentWO2012022448A1

Innovation

- The electrochemical cell design incorporates a frame element with a support web spaced close to the sealing seam of the casing, allowing for controlled pressure relief through a pressure relief device that vents gases or electrolytes away from the current collector and battery management system, preventing damage and ensuring safety.

Electrochemical cell having at least one pressure-relief apparatus

PatentInactiveEP2606520A1

Innovation

- An electrochemical cell design featuring a frame element with a support web spaced close to the sealing seam of the casing, allowing for controlled pressure relief through a pressure relief device that vents gases away from the current collector and battery management system, thereby preventing material discharge and enhancing safety.

Regulatory Standards and Compliance Requirements

The regulatory landscape for electrochemical cell safety is governed by a complex framework of international, regional, and national standards. IEC 62133 serves as the cornerstone international standard, establishing comprehensive safety requirements for portable sealed secondary cells and batteries containing alkaline or non-acid electrolytes. This standard addresses critical safety aspects including electrical, mechanical, and environmental considerations across the entire product lifecycle.

In the United States, UL 1642 provides detailed specifications for lithium batteries used in various applications, while UL 2054 covers household and commercial batteries. These standards are complemented by UN 38.3, which outlines mandatory transportation testing requirements for lithium-based cells and batteries, including altitude simulation, thermal testing, vibration, shock, and external short circuit tests.

European regulations center around the EN 62133 standard, which mirrors the IEC framework but includes additional provisions aligned with EU directives. The Battery Directive 2006/66/EC establishes requirements for battery disposal and recycling, while the REACH and RoHS directives impose restrictions on hazardous substances in battery manufacturing.

Asian markets maintain distinct regulatory frameworks. Japan enforces the JIS C 8714 standard for secondary lithium cells, while China implements GB 31241 with stringent safety requirements for portable electronic products. South Korea's KC certification program mandates compliance with specific safety standards before market entry.

Compliance verification typically involves a multi-stage process including design review, prototype testing, production sample evaluation, and ongoing quality assurance. Third-party certification from recognized bodies such as UL, TÜV, or SGS is often required to demonstrate regulatory adherence. Documentation requirements include detailed test reports, technical construction files, and declarations of conformity.

Emerging regulatory trends indicate a shift toward more stringent thermal runaway prevention requirements, enhanced transportation safety protocols, and increased focus on end-of-life management. The evolving nature of electrochemical technology has prompted regulatory bodies to develop more specific standards for next-generation battery chemistries, including solid-state, sodium-ion, and flow batteries.

Companies developing electrochemical cells must implement robust regulatory monitoring systems to track evolving standards across global markets. Early integration of compliance considerations into the design process can significantly reduce certification timelines and costs while ensuring market access.

In the United States, UL 1642 provides detailed specifications for lithium batteries used in various applications, while UL 2054 covers household and commercial batteries. These standards are complemented by UN 38.3, which outlines mandatory transportation testing requirements for lithium-based cells and batteries, including altitude simulation, thermal testing, vibration, shock, and external short circuit tests.

European regulations center around the EN 62133 standard, which mirrors the IEC framework but includes additional provisions aligned with EU directives. The Battery Directive 2006/66/EC establishes requirements for battery disposal and recycling, while the REACH and RoHS directives impose restrictions on hazardous substances in battery manufacturing.

Asian markets maintain distinct regulatory frameworks. Japan enforces the JIS C 8714 standard for secondary lithium cells, while China implements GB 31241 with stringent safety requirements for portable electronic products. South Korea's KC certification program mandates compliance with specific safety standards before market entry.

Compliance verification typically involves a multi-stage process including design review, prototype testing, production sample evaluation, and ongoing quality assurance. Third-party certification from recognized bodies such as UL, TÜV, or SGS is often required to demonstrate regulatory adherence. Documentation requirements include detailed test reports, technical construction files, and declarations of conformity.

Emerging regulatory trends indicate a shift toward more stringent thermal runaway prevention requirements, enhanced transportation safety protocols, and increased focus on end-of-life management. The evolving nature of electrochemical technology has prompted regulatory bodies to develop more specific standards for next-generation battery chemistries, including solid-state, sodium-ion, and flow batteries.

Companies developing electrochemical cells must implement robust regulatory monitoring systems to track evolving standards across global markets. Early integration of compliance considerations into the design process can significantly reduce certification timelines and costs while ensuring market access.

Thermal Management Systems and Failure Mode Analysis

Thermal management systems in electrochemical cells represent a critical safety component that directly impacts performance, longevity, and catastrophic failure prevention. Current benchmark designs implement multi-layered approaches to thermal regulation, with passive and active cooling strategies working in tandem. Passive systems utilize phase change materials and thermal interface materials strategically positioned between cells, while active systems employ liquid cooling circuits, forced air convection, and thermoelectric cooling elements that respond dynamically to temperature fluctuations.

Industry leaders have established temperature thresholds between 15-45°C as optimal operational ranges, with sophisticated management systems designed to maintain cells within these parameters even under extreme ambient conditions or high discharge rates. Advanced thermal management architectures now incorporate dedicated cooling channels within cell casings and specialized heat-dissipating electrode substrates that distribute thermal energy more uniformly across the cell structure.

Failure mode analysis reveals thermal runaway as the predominant catastrophic failure mechanism in electrochemical cells, typically initiated through four primary pathways: internal short circuits, external short circuits, overcharging, and mechanical damage. Each pathway generates distinct thermal signatures that modern monitoring systems can detect through predictive algorithms. Benchmark safety designs now incorporate multiple redundant protection mechanisms including thermal fuses, current interrupt devices (CIDs), and pressure relief mechanisms calibrated to specific cell chemistries.

Statistical analysis of failure incidents indicates that approximately 72% of thermal events begin with localized hotspot formation that subsequently propagates through adjacent cells. Leading manufacturers have responded by implementing cell-to-cell thermal isolation barriers and intumescent materials that expand upon heating to prevent thermal propagation. These physical barriers demonstrate 85-92% effectiveness in containing single-cell thermal events based on standardized testing protocols.

Real-time monitoring systems represent another critical safety benchmark, with contemporary designs featuring distributed temperature sensors with response times under 500 milliseconds and temperature resolution of ±0.5°C. These systems interface with battery management systems (BMS) that employ predictive thermal models to anticipate potential failure conditions before critical thresholds are breached. The most advanced systems utilize machine learning algorithms that continuously refine thermal behavior predictions based on operational data, enabling preemptive cooling activation or load reduction.

Emerging benchmark designs are now incorporating self-healing thermal management features, including microencapsulated phase change materials that automatically respond to temperature fluctuations and thermally-triggered shutdown separators that irreversibly interrupt ionic transport when temperature thresholds are exceeded. These innovations represent significant advancements in passive safety systems that function independently of electronic control systems.

Industry leaders have established temperature thresholds between 15-45°C as optimal operational ranges, with sophisticated management systems designed to maintain cells within these parameters even under extreme ambient conditions or high discharge rates. Advanced thermal management architectures now incorporate dedicated cooling channels within cell casings and specialized heat-dissipating electrode substrates that distribute thermal energy more uniformly across the cell structure.

Failure mode analysis reveals thermal runaway as the predominant catastrophic failure mechanism in electrochemical cells, typically initiated through four primary pathways: internal short circuits, external short circuits, overcharging, and mechanical damage. Each pathway generates distinct thermal signatures that modern monitoring systems can detect through predictive algorithms. Benchmark safety designs now incorporate multiple redundant protection mechanisms including thermal fuses, current interrupt devices (CIDs), and pressure relief mechanisms calibrated to specific cell chemistries.

Statistical analysis of failure incidents indicates that approximately 72% of thermal events begin with localized hotspot formation that subsequently propagates through adjacent cells. Leading manufacturers have responded by implementing cell-to-cell thermal isolation barriers and intumescent materials that expand upon heating to prevent thermal propagation. These physical barriers demonstrate 85-92% effectiveness in containing single-cell thermal events based on standardized testing protocols.

Real-time monitoring systems represent another critical safety benchmark, with contemporary designs featuring distributed temperature sensors with response times under 500 milliseconds and temperature resolution of ±0.5°C. These systems interface with battery management systems (BMS) that employ predictive thermal models to anticipate potential failure conditions before critical thresholds are breached. The most advanced systems utilize machine learning algorithms that continuously refine thermal behavior predictions based on operational data, enabling preemptive cooling activation or load reduction.

Emerging benchmark designs are now incorporating self-healing thermal management features, including microencapsulated phase change materials that automatically respond to temperature fluctuations and thermally-triggered shutdown separators that irreversibly interrupt ionic transport when temperature thresholds are exceeded. These innovations represent significant advancements in passive safety systems that function independently of electronic control systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!