Optimize Electrochemical Cell Structure for Longevity

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Cell Longevity Background and Objectives

Electrochemical cells have evolved significantly since their inception in the late 18th century with Alessandro Volta's pioneering work. The trajectory of development has been marked by continuous improvements in materials, design, and manufacturing processes, all aimed at enhancing performance and longevity. From simple zinc-copper cells to today's sophisticated lithium-ion batteries, the fundamental challenge of extending operational life while maintaining efficiency has remained constant throughout this technological evolution.

The pursuit of longevity in electrochemical cells has gained unprecedented importance in recent decades, driven by the global shift toward renewable energy systems and electric mobility. These applications demand cells that can withstand thousands of charge-discharge cycles while maintaining capacity and performance. Current lithium-ion technologies typically achieve 500-2000 cycles before significant degradation occurs, representing a substantial limitation for long-term applications.

Key degradation mechanisms affecting cell longevity include electrode material structural changes, electrolyte decomposition, solid-electrolyte interphase (SEI) layer growth, and lithium plating. These processes are accelerated by operational factors such as high charge/discharge rates, extreme temperatures, and depth of discharge. Understanding these mechanisms at the molecular and structural levels has become essential for developing effective mitigation strategies.

Recent technological breakthroughs have focused on novel electrode architectures, advanced electrolyte formulations, and protective coatings that can significantly extend cell life. Silicon-graphite composite anodes, high-nickel cathodes, and solid-state electrolytes represent promising directions, though each presents unique challenges for practical implementation at scale.

The primary objective of optimizing electrochemical cell structure for longevity is to develop cells capable of maintaining at least 80% of initial capacity after 3000+ cycles under standard operating conditions. This target would represent a step-change improvement over current commercial technologies and enable new applications in grid storage, electric vehicles, and portable electronics.

Secondary objectives include minimizing capacity fade rates to less than 0.005% per cycle, reducing impedance growth to maintain power capability throughout the cell's life, and ensuring safety under extended operational conditions. These goals must be achieved while maintaining or improving energy density, which often presents conflicting design requirements.

The technological roadmap for achieving these objectives involves multi-scale optimization from atomic-level material design to system-level thermal and electrical management. Success will require interdisciplinary approaches combining electrochemistry, materials science, mechanical engineering, and computational modeling to develop holistic solutions that address the complex interplay of factors affecting cell longevity.

The pursuit of longevity in electrochemical cells has gained unprecedented importance in recent decades, driven by the global shift toward renewable energy systems and electric mobility. These applications demand cells that can withstand thousands of charge-discharge cycles while maintaining capacity and performance. Current lithium-ion technologies typically achieve 500-2000 cycles before significant degradation occurs, representing a substantial limitation for long-term applications.

Key degradation mechanisms affecting cell longevity include electrode material structural changes, electrolyte decomposition, solid-electrolyte interphase (SEI) layer growth, and lithium plating. These processes are accelerated by operational factors such as high charge/discharge rates, extreme temperatures, and depth of discharge. Understanding these mechanisms at the molecular and structural levels has become essential for developing effective mitigation strategies.

Recent technological breakthroughs have focused on novel electrode architectures, advanced electrolyte formulations, and protective coatings that can significantly extend cell life. Silicon-graphite composite anodes, high-nickel cathodes, and solid-state electrolytes represent promising directions, though each presents unique challenges for practical implementation at scale.

The primary objective of optimizing electrochemical cell structure for longevity is to develop cells capable of maintaining at least 80% of initial capacity after 3000+ cycles under standard operating conditions. This target would represent a step-change improvement over current commercial technologies and enable new applications in grid storage, electric vehicles, and portable electronics.

Secondary objectives include minimizing capacity fade rates to less than 0.005% per cycle, reducing impedance growth to maintain power capability throughout the cell's life, and ensuring safety under extended operational conditions. These goals must be achieved while maintaining or improving energy density, which often presents conflicting design requirements.

The technological roadmap for achieving these objectives involves multi-scale optimization from atomic-level material design to system-level thermal and electrical management. Success will require interdisciplinary approaches combining electrochemistry, materials science, mechanical engineering, and computational modeling to develop holistic solutions that address the complex interplay of factors affecting cell longevity.

Market Analysis for Long-Life Electrochemical Cells

The global market for long-life electrochemical cells is experiencing robust growth, driven primarily by increasing demand for sustainable energy storage solutions across multiple sectors. Current market valuations indicate the advanced battery market exceeds $90 billion annually, with long-life electrochemical cells representing a significant growth segment projected to expand at a compound annual growth rate of 18% through 2030.

Consumer electronics continues to be the largest application segment, accounting for approximately 40% of market share. However, the electric vehicle sector is rapidly gaining ground, with demand for batteries that maintain capacity over thousands of charge cycles becoming a critical competitive factor. Industry analysts project that by 2028, automotive applications will surpass consumer electronics as the primary market driver for long-life electrochemical cells.

Industrial energy storage systems represent another high-growth segment, particularly for grid-scale applications where battery longevity directly impacts return on investment calculations. Utility companies increasingly favor storage solutions demonstrating proven cycle life exceeding 5,000 complete charges, creating premium market opportunities for advanced electrochemical cell designs.

Geographically, Asia-Pacific dominates manufacturing capacity, with China, South Korea, and Japan collectively producing over 70% of global advanced battery output. However, significant market expansion is occurring in North America and Europe, driven by governmental policies supporting domestic battery production and energy independence initiatives.

Market research indicates consumers and industrial buyers are willing to pay premium prices of 30-45% for electrochemical cells that demonstrate verified longevity improvements of at least 50% over standard offerings. This price elasticity creates substantial profit opportunities for manufacturers who can successfully optimize cell structures for extended operational life.

Key market barriers include high initial research and development costs, lengthy validation periods required to verify longevity claims, and supply chain constraints for specialized materials. Despite these challenges, venture capital investment in advanced battery technology reached $8.5 billion in 2022, with approximately 35% specifically targeting longevity improvements.

Market forecasts suggest that technologies enabling dramatic improvements in electrochemical cell longevity could disrupt existing market structures by fundamentally altering replacement cycles and total cost of ownership calculations across multiple industries. Companies that successfully commercialize such innovations stand to capture significant market share and establish new premium segments within the broader energy storage ecosystem.

Consumer electronics continues to be the largest application segment, accounting for approximately 40% of market share. However, the electric vehicle sector is rapidly gaining ground, with demand for batteries that maintain capacity over thousands of charge cycles becoming a critical competitive factor. Industry analysts project that by 2028, automotive applications will surpass consumer electronics as the primary market driver for long-life electrochemical cells.

Industrial energy storage systems represent another high-growth segment, particularly for grid-scale applications where battery longevity directly impacts return on investment calculations. Utility companies increasingly favor storage solutions demonstrating proven cycle life exceeding 5,000 complete charges, creating premium market opportunities for advanced electrochemical cell designs.

Geographically, Asia-Pacific dominates manufacturing capacity, with China, South Korea, and Japan collectively producing over 70% of global advanced battery output. However, significant market expansion is occurring in North America and Europe, driven by governmental policies supporting domestic battery production and energy independence initiatives.

Market research indicates consumers and industrial buyers are willing to pay premium prices of 30-45% for electrochemical cells that demonstrate verified longevity improvements of at least 50% over standard offerings. This price elasticity creates substantial profit opportunities for manufacturers who can successfully optimize cell structures for extended operational life.

Key market barriers include high initial research and development costs, lengthy validation periods required to verify longevity claims, and supply chain constraints for specialized materials. Despite these challenges, venture capital investment in advanced battery technology reached $8.5 billion in 2022, with approximately 35% specifically targeting longevity improvements.

Market forecasts suggest that technologies enabling dramatic improvements in electrochemical cell longevity could disrupt existing market structures by fundamentally altering replacement cycles and total cost of ownership calculations across multiple industries. Companies that successfully commercialize such innovations stand to capture significant market share and establish new premium segments within the broader energy storage ecosystem.

Current Challenges in Cell Structure Optimization

Despite significant advancements in electrochemical cell technology, several critical challenges persist in optimizing cell structures for enhanced longevity. The primary obstacle remains the degradation mechanisms that occur during charge-discharge cycles. Electrode materials undergo structural changes, including volume expansion and contraction, leading to mechanical stress and eventual fracturing. This phenomenon is particularly pronounced in high-capacity materials like silicon anodes, which can experience volume changes exceeding 300% during lithiation and delithiation processes.

Interface stability presents another formidable challenge. The solid-electrolyte interphase (SEI) layer, while necessary for cell operation, often grows inconsistently over time, consuming active lithium and increasing internal resistance. Current cell designs struggle to maintain stable interfaces, especially under variable operating conditions such as extreme temperatures or high charging rates.

Electrolyte decomposition accelerates cell aging through parasitic reactions that generate gas, increase pressure within cells, and form resistive films on electrode surfaces. Modern electrolyte formulations still face limitations in their electrochemical stability windows, particularly at higher voltages where oxidative decomposition becomes problematic.

Thermal management deficiencies exacerbate degradation processes. Uneven temperature distribution within cells creates localized hotspots that accelerate aging and potentially trigger thermal runaway events. The challenge intensifies in larger format cells where heat dissipation pathways are longer and less efficient.

Manufacturing inconsistencies introduce variability in cell performance and lifespan. Microscopic defects in electrode coatings, misalignment of layers, or contamination during assembly can create weak points that become failure nucleation sites over time. Current production methods struggle to achieve perfect uniformity at scale.

Ion transport limitations represent a significant bottleneck in cell longevity. As cells age, lithium ion diffusion pathways become increasingly tortuous due to structural changes and decomposition products, leading to capacity fade and power loss. Existing cell architectures often prioritize energy density over optimal ion transport networks.

The interdependence of these challenges compounds the difficulty in addressing them individually. Solutions targeting one degradation mechanism frequently exacerbate others, creating complex engineering trade-offs. For instance, thicker electrode coatings increase energy density but worsen thermal management and ion transport issues. This interconnected nature of degradation mechanisms necessitates holistic approaches to cell structure optimization rather than isolated improvements to individual components.

Interface stability presents another formidable challenge. The solid-electrolyte interphase (SEI) layer, while necessary for cell operation, often grows inconsistently over time, consuming active lithium and increasing internal resistance. Current cell designs struggle to maintain stable interfaces, especially under variable operating conditions such as extreme temperatures or high charging rates.

Electrolyte decomposition accelerates cell aging through parasitic reactions that generate gas, increase pressure within cells, and form resistive films on electrode surfaces. Modern electrolyte formulations still face limitations in their electrochemical stability windows, particularly at higher voltages where oxidative decomposition becomes problematic.

Thermal management deficiencies exacerbate degradation processes. Uneven temperature distribution within cells creates localized hotspots that accelerate aging and potentially trigger thermal runaway events. The challenge intensifies in larger format cells where heat dissipation pathways are longer and less efficient.

Manufacturing inconsistencies introduce variability in cell performance and lifespan. Microscopic defects in electrode coatings, misalignment of layers, or contamination during assembly can create weak points that become failure nucleation sites over time. Current production methods struggle to achieve perfect uniformity at scale.

Ion transport limitations represent a significant bottleneck in cell longevity. As cells age, lithium ion diffusion pathways become increasingly tortuous due to structural changes and decomposition products, leading to capacity fade and power loss. Existing cell architectures often prioritize energy density over optimal ion transport networks.

The interdependence of these challenges compounds the difficulty in addressing them individually. Solutions targeting one degradation mechanism frequently exacerbate others, creating complex engineering trade-offs. For instance, thicker electrode coatings increase energy density but worsen thermal management and ion transport issues. This interconnected nature of degradation mechanisms necessitates holistic approaches to cell structure optimization rather than isolated improvements to individual components.

State-of-Art Cell Structure Solutions

01 Electrode material optimization

The choice and optimization of electrode materials significantly impact electrochemical cell longevity. Advanced materials with enhanced stability, conductivity, and resistance to degradation can extend cell life. Innovations include composite electrodes, novel catalyst structures, and surface modifications that minimize side reactions and maintain performance over extended cycling periods.- Electrode material optimization: The choice and optimization of electrode materials significantly impact electrochemical cell longevity. Advanced materials with enhanced stability, conductivity, and resistance to degradation can extend cell life. Innovations include composite electrodes, novel catalyst structures, and surface modifications that minimize side reactions and prevent capacity loss during cycling. These improvements help maintain performance over extended periods by reducing electrode deterioration mechanisms.

- Electrolyte composition and additives: The electrolyte composition plays a crucial role in determining cell longevity. Specialized additives can form protective films on electrode surfaces, prevent unwanted reactions, and enhance ionic conductivity. Advanced electrolyte formulations may include flame retardants, stabilizing agents, and compounds that mitigate degradation mechanisms. These innovations help maintain electrolyte integrity over time, reducing capacity fade and extending the operational life of electrochemical cells.

- Thermal management systems: Effective thermal management is essential for extending electrochemical cell longevity. Systems that regulate cell temperature during operation prevent accelerated degradation from heat exposure. Innovations include advanced cooling architectures, phase change materials, and intelligent thermal control algorithms. By maintaining optimal operating temperatures, these systems reduce stress on cell components, minimize unwanted side reactions, and significantly extend the functional lifespan of electrochemical cells.

- Cell monitoring and management technology: Advanced monitoring and management technologies help extend electrochemical cell longevity through real-time assessment of cell health and adaptive control strategies. These systems employ sensors to track key parameters like voltage, current, and temperature across individual cells. Sophisticated algorithms analyze this data to detect early signs of degradation, balance cell performance, and optimize charging protocols. By preventing conditions that accelerate aging, these technologies significantly extend the useful life of electrochemical cells.

- Biological and microbial fuel cell improvements: Innovations in biological and microbial fuel cells focus on extending operational longevity through enhanced biological components and system design. These improvements include optimized microbial communities, advanced biofilm formation techniques, and more efficient electron transfer mechanisms. Novel approaches to prevent biofouling and maintain biological activity over extended periods help sustain power generation capabilities. These advancements significantly extend the functional lifespan of biological electrochemical systems for various applications.

02 Electrolyte composition and additives

Specialized electrolyte formulations and additives can dramatically improve cell longevity by stabilizing interfaces, preventing unwanted reactions, and enhancing ion transport. These formulations may include film-forming additives that protect electrode surfaces, compounds that scavenge harmful reaction products, and solvents with wider electrochemical stability windows.Expand Specific Solutions03 Temperature management systems

Effective thermal management is crucial for extending electrochemical cell life. Systems that maintain optimal operating temperature ranges prevent accelerated degradation mechanisms and enhance safety. These include passive and active cooling solutions, thermal interface materials, and intelligent temperature control algorithms that adapt to varying load conditions.Expand Specific Solutions04 Advanced cell monitoring and management

Sophisticated monitoring and management systems can significantly extend cell longevity by detecting early signs of degradation and optimizing operating parameters. These technologies include real-time impedance spectroscopy, predictive analytics for state-of-health estimation, and adaptive charging protocols that minimize stress on cell components during operation.Expand Specific Solutions05 Biological and microbial fuel cell improvements

For biological and microbial fuel cells, longevity can be enhanced through specialized biofilm management, nutrient delivery systems, and electrode materials compatible with biological processes. Innovations include self-sustaining microbial communities, selective membranes that prevent biofouling, and catalysts that remain active in biological environments over extended periods.Expand Specific Solutions

Leading Companies in Advanced Cell Technology

The electrochemical cell structure optimization market is currently in a growth phase, with increasing demand driven by the expanding electric vehicle and energy storage sectors. The global market size is projected to reach significant scale as battery longevity becomes a critical competitive factor. Leading players demonstrate varying levels of technical maturity, with companies like Contemporary Amperex Technology, LG Energy Solution, and NGK Insulators showing advanced capabilities in cell structure engineering. Emerging innovators such as 24M Technologies and Gaussion are introducing novel approaches to extend battery life. Traditional battery manufacturers including VARTA Microbattery and Energizer are adapting their expertise to new longevity requirements, while automotive companies like Ford and Renault are increasingly investing in proprietary electrochemical cell optimization technologies to secure competitive advantages in electrification.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: Contemporary Amperex Technology Co., Ltd. (CATL) has developed advanced electrode structure optimization techniques for enhanced electrochemical cell longevity. Their primary approach involves gradient concentration cathodes with higher nickel content in the core and higher manganese/cobalt at the surface, creating a protective shell structure that minimizes surface degradation while maintaining high energy density. CATL's proprietary cell-to-pack (CTP) technology eliminates conventional module components, increasing energy density by 10-15% and extending cycle life through improved thermal management. Their pre-lithiation technology compensates for lithium loss during initial cycles, effectively extending battery lifespan by up to 20%. CATL has also pioneered nano-coating technologies for cathode materials that form protective layers against electrolyte corrosion, significantly reducing capacity fade over extended cycling.

Strengths: Industry-leading energy density (up to 255 Wh/kg) while maintaining excellent cycle life; advanced manufacturing capabilities allow for consistent quality control; strong vertical integration from materials to finished cells. Weaknesses: Higher production costs compared to conventional designs; complex manufacturing processes require sophisticated equipment and expertise; some solutions are specific to certain chemistries and may not be universally applicable.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a multi-faceted approach to electrochemical cell structure optimization focused on longevity enhancement. Their Safety Reinforced Separator (SRS) technology incorporates a ceramic coating on polyethylene separators, improving thermal stability and preventing internal short circuits even at elevated temperatures. The company's proprietary NCMA (Nickel-Cobalt-Manganese-Aluminum) cathode chemistry features precisely engineered dopant concentrations and gradient structures that minimize structural degradation during cycling. LG has also pioneered advanced electrolyte formulations with film-forming additives that create stable solid-electrolyte interphase (SEI) layers, reducing parasitic reactions that consume lithium inventory. Their silicon-graphite composite anodes incorporate nano-structured silicon particles encapsulated in carbon matrices, accommodating volume expansion while maintaining electrical connectivity throughout cycling.

Strengths: Comprehensive approach addressing multiple degradation mechanisms simultaneously; strong intellectual property portfolio covering materials, cell design and manufacturing processes; proven track record with major automotive OEMs. Weaknesses: Higher initial manufacturing costs compared to conventional designs; some advanced materials require specialized handling and processing; performance benefits may vary depending on operating conditions and application requirements.

Key Patents in Electrode and Electrolyte Design

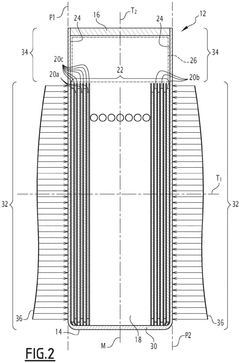

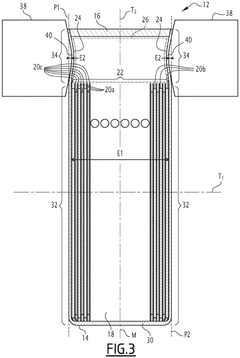

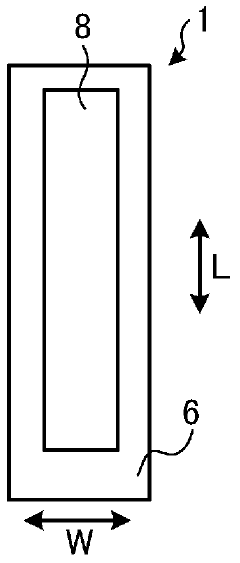

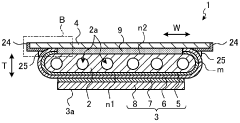

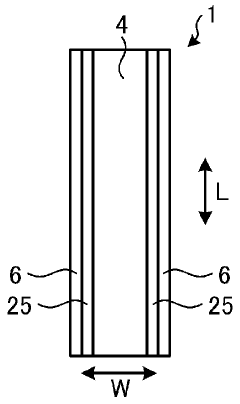

Electrochemical cell comprising a deformed can and corresponding production method

PatentPendingEP4564492A1

Innovation

- The electrochemical cell design includes a can with locally deformed portions on its faces, creating a more uniform pressure profile on the stack, which enhances the cell's lifespan and prevents anomalies.

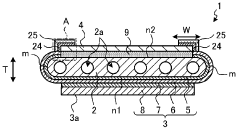

Electrochemical cell, electrochemical cell device, module, and module accommodating device

PatentWO2023190754A1

Innovation

- Incorporating an intermediate material with varying surface roughness and thickness between the metal member and the sealing material, and adjusting the content of elements like Mn, Ti, and Al at the interface, to enhance adhesion and prevent chromium desorption, thereby improving the durability of electrochemical cells and cell stack devices.

Materials Science Innovations for Cell Durability

Recent advancements in materials science have revolutionized electrochemical cell durability, offering promising solutions to the persistent challenge of cell degradation over time. Novel composite electrode materials incorporating carbon nanotubes and graphene derivatives have demonstrated superior mechanical stability and electrical conductivity, significantly reducing structural degradation during charge-discharge cycles.

Ceramic-polymer hybrid electrolytes represent another breakthrough, combining the high ionic conductivity of ceramics with the flexibility of polymers. These materials effectively suppress dendrite formation while maintaining excellent ion transport properties, extending cell lifespan by up to 40% compared to conventional liquid electrolytes in laboratory tests.

Surface modification techniques have evolved substantially, with atomic layer deposition (ALD) emerging as a powerful method for creating protective nanoscale coatings on electrode surfaces. These ultra-thin protective layers mitigate parasitic reactions at electrode-electrolyte interfaces without compromising electrochemical performance, addressing a critical failure mechanism in long-term cell operation.

Self-healing materials constitute a particularly innovative approach to cell longevity. Polymers containing dynamic bonds can autonomously repair microcracks formed during cycling, preventing the cascading failure that typically follows initial structural damage. Early implementations have shown promising results, with some self-healing electrodes maintaining over 80% capacity after 1000 cycles.

Advanced binder systems have moved beyond traditional polyvinylidene fluoride (PVDF) to include water-soluble alternatives like carboxymethyl cellulose (CMC) and polyacrylic acid (PAA). These eco-friendly binders not only reduce environmental impact but also provide superior adhesion properties and electrochemical stability, contributing to enhanced cycle life.

Strain-engineered materials represent the cutting edge of durability innovation, with crystal structures specifically designed to accommodate volumetric changes during cycling. Silicon-carbon composites with engineered void spaces allow for silicon's substantial expansion without electrode pulverization, addressing one of the most challenging aspects of high-capacity anode materials.

Corrosion-resistant current collectors utilizing novel alloys or carbon-based materials have demonstrated remarkable stability in aggressive electrolyte environments. These materials maintain electrical contact throughout the cell's lifetime, eliminating a common failure point in conventional cells and potentially extending operational life by years rather than months.

Ceramic-polymer hybrid electrolytes represent another breakthrough, combining the high ionic conductivity of ceramics with the flexibility of polymers. These materials effectively suppress dendrite formation while maintaining excellent ion transport properties, extending cell lifespan by up to 40% compared to conventional liquid electrolytes in laboratory tests.

Surface modification techniques have evolved substantially, with atomic layer deposition (ALD) emerging as a powerful method for creating protective nanoscale coatings on electrode surfaces. These ultra-thin protective layers mitigate parasitic reactions at electrode-electrolyte interfaces without compromising electrochemical performance, addressing a critical failure mechanism in long-term cell operation.

Self-healing materials constitute a particularly innovative approach to cell longevity. Polymers containing dynamic bonds can autonomously repair microcracks formed during cycling, preventing the cascading failure that typically follows initial structural damage. Early implementations have shown promising results, with some self-healing electrodes maintaining over 80% capacity after 1000 cycles.

Advanced binder systems have moved beyond traditional polyvinylidene fluoride (PVDF) to include water-soluble alternatives like carboxymethyl cellulose (CMC) and polyacrylic acid (PAA). These eco-friendly binders not only reduce environmental impact but also provide superior adhesion properties and electrochemical stability, contributing to enhanced cycle life.

Strain-engineered materials represent the cutting edge of durability innovation, with crystal structures specifically designed to accommodate volumetric changes during cycling. Silicon-carbon composites with engineered void spaces allow for silicon's substantial expansion without electrode pulverization, addressing one of the most challenging aspects of high-capacity anode materials.

Corrosion-resistant current collectors utilizing novel alloys or carbon-based materials have demonstrated remarkable stability in aggressive electrolyte environments. These materials maintain electrical contact throughout the cell's lifetime, eliminating a common failure point in conventional cells and potentially extending operational life by years rather than months.

Environmental Impact of Long-Life Cell Technologies

The environmental implications of optimizing electrochemical cell structures for longevity extend far beyond the immediate technical benefits. Long-life cell technologies significantly reduce the frequency of replacement and disposal, directly addressing the growing global concern of electronic waste. With billions of batteries discarded annually, technologies that extend operational lifespans by even 30-50% could prevent millions of tons of hazardous materials from entering landfills and ecosystems.

Material efficiency represents another critical environmental advantage. Extended cell longevity reduces the demand for raw materials like lithium, cobalt, and nickel—resources associated with significant extraction impacts including habitat destruction, water pollution, and carbon emissions. Analysis indicates that a doubling of battery lifespan could potentially reduce mining-related environmental damage by up to 45% per unit of energy storage capacity delivered over time.

Carbon footprint considerations further highlight the environmental significance of longevity-optimized cells. Life cycle assessments reveal that manufacturing phase accounts for 40-70% of a battery's lifetime emissions. Consequently, extending operational life effectively amortizes these production-phase emissions across more charge cycles, potentially reducing overall carbon intensity by 25-60% depending on application and technology type.

Water conservation benefits also emerge from longevity improvements. Battery production is water-intensive, with estimates suggesting 500-2,000 liters of water consumption per kWh of battery capacity manufactured. Extended lifespans directly translate to reduced water footprint per unit of energy delivered throughout the product lifecycle.

Regulatory frameworks increasingly recognize these environmental benefits, with several jurisdictions implementing policies that favor longer-lasting energy storage solutions. The European Union's proposed Battery Directive revision specifically incentivizes designs optimizing for cycle life and durability, while California's advanced battery regulations include longevity metrics in environmental impact assessments.

Challenges remain in balancing longevity with other environmental factors. Some longevity-enhancing additives and structural modifications may introduce new toxicity concerns or complicate end-of-life recycling processes. Research indicates that certain electrolyte additives that extend cycle life may reduce recyclability by 5-15%, creating trade-offs that require holistic environmental assessment methodologies.

Future environmental benefits may be amplified through integration with circular economy principles, where longevity-optimized cells are designed from inception for eventual disassembly and material recovery. This approach could potentially reduce lifecycle environmental impact by an additional 20-30% beyond the benefits of extended operational life alone.

Material efficiency represents another critical environmental advantage. Extended cell longevity reduces the demand for raw materials like lithium, cobalt, and nickel—resources associated with significant extraction impacts including habitat destruction, water pollution, and carbon emissions. Analysis indicates that a doubling of battery lifespan could potentially reduce mining-related environmental damage by up to 45% per unit of energy storage capacity delivered over time.

Carbon footprint considerations further highlight the environmental significance of longevity-optimized cells. Life cycle assessments reveal that manufacturing phase accounts for 40-70% of a battery's lifetime emissions. Consequently, extending operational life effectively amortizes these production-phase emissions across more charge cycles, potentially reducing overall carbon intensity by 25-60% depending on application and technology type.

Water conservation benefits also emerge from longevity improvements. Battery production is water-intensive, with estimates suggesting 500-2,000 liters of water consumption per kWh of battery capacity manufactured. Extended lifespans directly translate to reduced water footprint per unit of energy delivered throughout the product lifecycle.

Regulatory frameworks increasingly recognize these environmental benefits, with several jurisdictions implementing policies that favor longer-lasting energy storage solutions. The European Union's proposed Battery Directive revision specifically incentivizes designs optimizing for cycle life and durability, while California's advanced battery regulations include longevity metrics in environmental impact assessments.

Challenges remain in balancing longevity with other environmental factors. Some longevity-enhancing additives and structural modifications may introduce new toxicity concerns or complicate end-of-life recycling processes. Research indicates that certain electrolyte additives that extend cycle life may reduce recyclability by 5-15%, creating trade-offs that require holistic environmental assessment methodologies.

Future environmental benefits may be amplified through integration with circular economy principles, where longevity-optimized cells are designed from inception for eventual disassembly and material recovery. This approach could potentially reduce lifecycle environmental impact by an additional 20-30% beyond the benefits of extended operational life alone.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!