How to Reduce Self-Discharge in Electrochemical Cells

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Cell Self-Discharge Background and Objectives

Electrochemical cells have revolutionized portable energy storage since their inception in the late 18th century with Alessandro Volta's pioneering work. The evolution of these cells has been marked by significant milestones, from the development of lead-acid batteries in the 1850s to the commercialization of lithium-ion batteries in the 1990s. Throughout this technological progression, self-discharge has remained a persistent challenge that limits the efficiency and practical utility of electrochemical energy storage systems.

Self-discharge refers to the spontaneous reduction in stored charge when a battery is left in open-circuit conditions, effectively representing energy loss without any external load. This phenomenon occurs due to various internal chemical reactions and physical processes within the cell, including electrolyte decomposition, electrode corrosion, shuttle effects of active materials, and internal short circuits caused by dendrite formation or impurities.

The significance of addressing self-discharge has grown exponentially with the proliferation of portable electronics, electric vehicles, and grid-scale energy storage systems. Modern applications increasingly demand batteries with extended shelf life, minimal maintenance requirements, and reliable performance after periods of inactivity. The economic implications are substantial, as self-discharge directly impacts the usable energy capacity, operational lifetime, and overall cost-effectiveness of energy storage solutions.

Recent technological trends indicate a shift toward more sophisticated approaches to mitigate self-discharge. These include advanced electrode surface treatments, electrolyte additives that form stable passivation layers, and novel separator materials that inhibit shuttle effects. Computational modeling and in-situ characterization techniques have enabled deeper understanding of the underlying mechanisms, facilitating more targeted interventions.

The primary technical objectives in this domain include reducing self-discharge rates to below 1% per month for consumer electronics applications and below 3% per month for grid-scale storage systems. Additionally, solutions must maintain compatibility with existing manufacturing processes, avoid significant increases in production costs, and not compromise other critical performance parameters such as energy density, power capability, and cycle life.

Achieving these objectives requires a multidisciplinary approach combining electrochemistry, materials science, and engineering. The ideal solution would address the fundamental causes of self-discharge rather than merely mitigating symptoms, potentially revolutionizing the longevity and reliability of next-generation energy storage technologies while enabling new applications previously limited by self-discharge constraints.

Self-discharge refers to the spontaneous reduction in stored charge when a battery is left in open-circuit conditions, effectively representing energy loss without any external load. This phenomenon occurs due to various internal chemical reactions and physical processes within the cell, including electrolyte decomposition, electrode corrosion, shuttle effects of active materials, and internal short circuits caused by dendrite formation or impurities.

The significance of addressing self-discharge has grown exponentially with the proliferation of portable electronics, electric vehicles, and grid-scale energy storage systems. Modern applications increasingly demand batteries with extended shelf life, minimal maintenance requirements, and reliable performance after periods of inactivity. The economic implications are substantial, as self-discharge directly impacts the usable energy capacity, operational lifetime, and overall cost-effectiveness of energy storage solutions.

Recent technological trends indicate a shift toward more sophisticated approaches to mitigate self-discharge. These include advanced electrode surface treatments, electrolyte additives that form stable passivation layers, and novel separator materials that inhibit shuttle effects. Computational modeling and in-situ characterization techniques have enabled deeper understanding of the underlying mechanisms, facilitating more targeted interventions.

The primary technical objectives in this domain include reducing self-discharge rates to below 1% per month for consumer electronics applications and below 3% per month for grid-scale storage systems. Additionally, solutions must maintain compatibility with existing manufacturing processes, avoid significant increases in production costs, and not compromise other critical performance parameters such as energy density, power capability, and cycle life.

Achieving these objectives requires a multidisciplinary approach combining electrochemistry, materials science, and engineering. The ideal solution would address the fundamental causes of self-discharge rather than merely mitigating symptoms, potentially revolutionizing the longevity and reliability of next-generation energy storage technologies while enabling new applications previously limited by self-discharge constraints.

Market Analysis for Low Self-Discharge Battery Technologies

The global market for low self-discharge battery technologies has experienced significant growth in recent years, driven by increasing demand for reliable energy storage solutions across multiple sectors. The market size for advanced battery technologies with reduced self-discharge characteristics was valued at approximately $12.5 billion in 2022 and is projected to reach $28.7 billion by 2030, representing a compound annual growth rate (CAGR) of 10.9%.

Consumer electronics continues to be the largest application segment, accounting for nearly 45% of the market share. This dominance stems from the growing consumer preference for devices with longer shelf life and reduced maintenance requirements. Particularly, portable electronic devices, wearables, and smart home devices are driving significant demand for batteries that can maintain charge over extended periods of non-use.

The industrial sector represents the second-largest market segment, with applications in backup power systems, remote monitoring equipment, and industrial IoT devices. This sector values batteries that can maintain operational readiness with minimal maintenance, creating a strong demand pull for low self-discharge solutions.

Emerging application areas showing rapid growth include medical devices, automotive electronics, and renewable energy storage systems. The medical device segment, in particular, is expected to grow at a CAGR of 12.3% through 2030, as reliability and longevity become critical factors in implantable and wearable medical technologies.

Geographically, Asia-Pacific dominates the market with approximately 42% share, led by manufacturing powerhouses like China, Japan, and South Korea. North America follows with 28% market share, driven by technological innovation and high adoption rates in consumer and industrial applications.

Key market drivers include increasing adoption of IoT devices requiring long-term power solutions, growing demand for reliable backup power systems, and the expanding market for electric vehicles and renewable energy storage. Additionally, regulatory pressures to reduce electronic waste are pushing manufacturers toward longer-lasting battery solutions.

Market challenges include price sensitivity, especially in consumer segments, technical limitations in achieving ultra-low self-discharge rates without compromising other performance parameters, and competition from alternative energy storage technologies. The premium pricing of low self-discharge batteries remains a significant barrier to wider adoption in cost-sensitive applications.

Customer preferences are increasingly shifting toward batteries that offer not only low self-discharge rates but also high energy density, fast charging capabilities, and environmental sustainability. This multi-parameter optimization challenge is reshaping product development strategies across the industry.

Consumer electronics continues to be the largest application segment, accounting for nearly 45% of the market share. This dominance stems from the growing consumer preference for devices with longer shelf life and reduced maintenance requirements. Particularly, portable electronic devices, wearables, and smart home devices are driving significant demand for batteries that can maintain charge over extended periods of non-use.

The industrial sector represents the second-largest market segment, with applications in backup power systems, remote monitoring equipment, and industrial IoT devices. This sector values batteries that can maintain operational readiness with minimal maintenance, creating a strong demand pull for low self-discharge solutions.

Emerging application areas showing rapid growth include medical devices, automotive electronics, and renewable energy storage systems. The medical device segment, in particular, is expected to grow at a CAGR of 12.3% through 2030, as reliability and longevity become critical factors in implantable and wearable medical technologies.

Geographically, Asia-Pacific dominates the market with approximately 42% share, led by manufacturing powerhouses like China, Japan, and South Korea. North America follows with 28% market share, driven by technological innovation and high adoption rates in consumer and industrial applications.

Key market drivers include increasing adoption of IoT devices requiring long-term power solutions, growing demand for reliable backup power systems, and the expanding market for electric vehicles and renewable energy storage. Additionally, regulatory pressures to reduce electronic waste are pushing manufacturers toward longer-lasting battery solutions.

Market challenges include price sensitivity, especially in consumer segments, technical limitations in achieving ultra-low self-discharge rates without compromising other performance parameters, and competition from alternative energy storage technologies. The premium pricing of low self-discharge batteries remains a significant barrier to wider adoption in cost-sensitive applications.

Customer preferences are increasingly shifting toward batteries that offer not only low self-discharge rates but also high energy density, fast charging capabilities, and environmental sustainability. This multi-parameter optimization challenge is reshaping product development strategies across the industry.

Current Challenges in Self-Discharge Reduction

Self-discharge remains one of the most significant challenges in electrochemical cell technology, limiting the shelf life and reliability of energy storage systems. Current lithium-ion batteries typically experience self-discharge rates of 2-10% per month, while supercapacitors may lose 20-40% of their charge in just 30 days. This phenomenon substantially impacts applications requiring long-term energy storage, particularly in medical devices, remote sensors, and backup power systems.

The primary mechanism driving self-discharge involves unwanted redox reactions at electrode-electrolyte interfaces. These parasitic reactions occur continuously even when the cell is not in use, gradually depleting stored energy. Despite decades of research, completely eliminating these reactions has proven elusive due to their thermodynamic favorability in the high-energy electrochemical environments necessary for energy storage.

Material impurities present a significant technical barrier to reducing self-discharge. Even trace contaminants at parts-per-million levels can catalyze side reactions or form microscopic conductive pathways between electrodes. Current purification technologies struggle to achieve the ultra-high purity levels required while maintaining economic viability for mass production.

Electrode surface stability represents another major challenge. Surface reconstruction, dissolution, and film formation processes continuously modify electrode interfaces during cycling and storage. These dynamic changes create new reaction sites and pathways for self-discharge. Existing surface stabilization approaches often compromise other performance metrics like power density or cycle life.

Electrolyte decomposition further complicates self-discharge reduction efforts. Modern high-voltage battery systems operate beyond the electrochemical stability windows of most electrolytes, leading to gradual decomposition that generates reactive species. These decomposition products can shuttle between electrodes, facilitating charge transfer and accelerating self-discharge rates.

Temperature sensitivity exacerbates these challenges, with self-discharge rates typically doubling with every 10°C increase. This creates a complex engineering problem where solutions must function across wide temperature ranges from -40°C to 60°C depending on the application environment. Current thermal management systems add significant weight, cost, and complexity to battery systems.

The measurement and characterization of self-discharge itself presents methodological difficulties. Accurate quantification requires extremely sensitive instrumentation and carefully controlled test conditions over extended periods. This slows the research feedback loop and complicates the evaluation of potential solutions, creating a bottleneck in the development process.

The primary mechanism driving self-discharge involves unwanted redox reactions at electrode-electrolyte interfaces. These parasitic reactions occur continuously even when the cell is not in use, gradually depleting stored energy. Despite decades of research, completely eliminating these reactions has proven elusive due to their thermodynamic favorability in the high-energy electrochemical environments necessary for energy storage.

Material impurities present a significant technical barrier to reducing self-discharge. Even trace contaminants at parts-per-million levels can catalyze side reactions or form microscopic conductive pathways between electrodes. Current purification technologies struggle to achieve the ultra-high purity levels required while maintaining economic viability for mass production.

Electrode surface stability represents another major challenge. Surface reconstruction, dissolution, and film formation processes continuously modify electrode interfaces during cycling and storage. These dynamic changes create new reaction sites and pathways for self-discharge. Existing surface stabilization approaches often compromise other performance metrics like power density or cycle life.

Electrolyte decomposition further complicates self-discharge reduction efforts. Modern high-voltage battery systems operate beyond the electrochemical stability windows of most electrolytes, leading to gradual decomposition that generates reactive species. These decomposition products can shuttle between electrodes, facilitating charge transfer and accelerating self-discharge rates.

Temperature sensitivity exacerbates these challenges, with self-discharge rates typically doubling with every 10°C increase. This creates a complex engineering problem where solutions must function across wide temperature ranges from -40°C to 60°C depending on the application environment. Current thermal management systems add significant weight, cost, and complexity to battery systems.

The measurement and characterization of self-discharge itself presents methodological difficulties. Accurate quantification requires extremely sensitive instrumentation and carefully controlled test conditions over extended periods. This slows the research feedback loop and complicates the evaluation of potential solutions, creating a bottleneck in the development process.

Existing Self-Discharge Reduction Solutions

01 Electrolyte composition to reduce self-discharge

Specific electrolyte compositions can significantly reduce self-discharge rates in electrochemical cells. These compositions may include additives that form protective films on electrode surfaces, preventing unwanted side reactions. Optimized electrolyte formulations can stabilize the electrode-electrolyte interface, inhibit shuttle mechanisms, and reduce parasitic reactions that contribute to capacity loss during storage. These improvements extend the shelf life and reliability of batteries in various applications.- Electrolyte composition to reduce self-discharge: Specific electrolyte compositions can significantly reduce self-discharge rates in electrochemical cells. These compositions may include additives that form protective films on electrode surfaces, preventing unwanted reactions that lead to capacity loss. Advanced electrolyte formulations can also improve the stability of the electrode-electrolyte interface, reducing parasitic reactions that contribute to self-discharge during storage or operation.

- Electrode material modifications: Modifications to electrode materials can minimize self-discharge in electrochemical cells. These modifications include surface treatments, doping with specific elements, or using composite materials that enhance stability. By reducing reactivity with the electrolyte and improving structural integrity, these modified electrode materials can significantly decrease the rate of self-discharge, extending the shelf life and operational efficiency of the cells.

- Battery management systems for self-discharge control: Advanced battery management systems can monitor and control self-discharge in electrochemical cells. These systems employ algorithms to detect early signs of self-discharge and implement preventive measures. Features may include intelligent charging protocols, temperature management, and voltage monitoring to minimize conditions that accelerate self-discharge. Some systems also incorporate periodic maintenance cycles to preserve battery capacity during long storage periods.

- Separator designs to minimize internal short circuits: Innovative separator designs can effectively reduce self-discharge caused by internal short circuits in electrochemical cells. These separators feature enhanced mechanical strength, thermal stability, and ion selectivity. Some designs incorporate ceramic coatings or polymer composites that prevent dendrite growth while maintaining high ionic conductivity. By physically preventing electrode contact and filtering out impurities, these separators significantly reduce self-discharge rates.

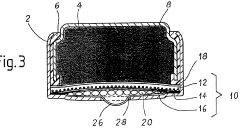

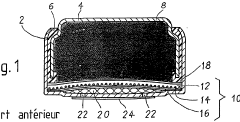

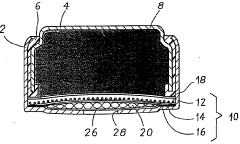

- Cell construction techniques for improved sealing: Advanced cell construction techniques focus on improving the sealing of electrochemical cells to prevent moisture ingress and electrolyte leakage, both of which contribute to self-discharge. These techniques include precision manufacturing methods, innovative gasket materials, and hermetic sealing technologies. Some approaches involve multi-layer encapsulation or specialized crimping methods to ensure long-term integrity of the cell housing, thereby minimizing environmental factors that accelerate self-discharge.

02 Electrode material modifications

Modifications to electrode materials can effectively minimize self-discharge in electrochemical cells. These include surface treatments, doping with specific elements, or incorporating stabilizing compounds that reduce reactivity with the electrolyte. Novel electrode structures with enhanced stability can prevent dissolution of active materials and suppress unwanted redox reactions at the electrode surface. These approaches maintain the integrity of the electrode-electrolyte interface during storage periods.Expand Specific Solutions03 Advanced separator technologies

Innovative separator designs and materials play a crucial role in reducing self-discharge rates. These separators can feature selective ion transport properties, reduced ionic resistance, and enhanced mechanical stability. Some advanced separators incorporate functional coatings that trap or neutralize impurities that would otherwise contribute to self-discharge. These technologies effectively isolate electrodes while maintaining necessary ionic conductivity for cell operation.Expand Specific Solutions04 Battery management systems for self-discharge control

Sophisticated battery management systems can monitor and mitigate self-discharge in electrochemical cells. These systems employ algorithms to detect early signs of self-discharge and implement preventive measures such as periodic refreshing cycles or voltage maintenance protocols. Some systems include temperature control mechanisms, as higher temperatures accelerate self-discharge rates. Advanced monitoring capabilities allow for real-time assessment of battery health and prediction of remaining useful life.Expand Specific Solutions05 Novel cell designs to minimize parasitic reactions

Innovative cell architectures can fundamentally address self-discharge mechanisms. These designs may include improved sealing techniques to prevent moisture ingress, optimized internal pressure systems, or novel current collector configurations that minimize corrosion. Some approaches incorporate sacrificial materials that preferentially react with contaminants before they can cause self-discharge. These structural innovations work synergistically with material improvements to extend the storage life of electrochemical cells.Expand Specific Solutions

Leading Battery Manufacturers and Research Institutions

The self-discharge reduction in electrochemical cells market is in a growth phase, with increasing demand driven by energy storage applications. The global market is expanding rapidly as battery technologies become critical for renewable energy integration and electric mobility. Technologically, the field shows varying maturity levels across different approaches. Leading players like Sion Power are advancing lithium-sulfur technology with their Licerion® innovation, while established manufacturers such as CATL, BYD, and VARTA Microbattery focus on improving conventional lithium-ion batteries. Research institutions like Dalian Institute of Chemical Physics and companies including Leclanché and FDK are developing novel electrolyte formulations and electrode materials. The competitive landscape features both specialized battery manufacturers and diversified corporations like Robert Bosch and DuPont, indicating the strategic importance of self-discharge reduction across multiple industries.

Sion Power Corp.

Technical Solution: Sion Power has developed a proprietary lithium-sulfur (Li-S) battery technology with advanced electrolyte formulations specifically designed to minimize self-discharge. Their approach incorporates protective layers on the lithium anode that prevent polysulfide shuttle effects, a primary cause of self-discharge in Li-S cells. The company's Licerion® technology utilizes a protected lithium anode architecture with specialized electrolyte additives that form stable interfaces, significantly reducing parasitic reactions that lead to capacity loss during storage. Their multi-layer protection system includes ceramic-based barriers and engineered polymers that physically block lithium dendrite formation while simultaneously preventing electrolyte decomposition at the electrode surface. Recent advancements have shown self-discharge rates below 2% per month, compared to 8-10% in conventional lithium-sulfur systems.

Strengths: Exceptional energy density (500 Wh/kg) while maintaining low self-discharge rates; scalable manufacturing process compatible with existing production equipment; significantly longer shelf life than conventional Li-S cells. Weaknesses: Higher production costs compared to standard lithium-ion; temperature sensitivity can affect self-discharge performance in extreme conditions; protective layers may gradually degrade over extended cycling.

VARTA Microbattery GmbH

Technical Solution: VARTA has developed a sophisticated multi-layered approach to reducing self-discharge in their CoinPower® series and other advanced lithium-ion cells. Their technology focuses on precision engineering at the electrode-electrolyte interface to minimize parasitic reactions. VARTA's solution incorporates ultra-high purity electrode materials with controlled surface chemistry that reduces reactive sites where unwanted side reactions typically occur. Their proprietary electrolyte formulation includes a blend of functional additives that selectively form protective films on electrode surfaces, creating stable passivation layers that prevent continuous electrolyte decomposition. The company employs advanced manufacturing techniques with exceptionally low moisture contamination (below 5ppm) throughout the production process, eliminating a key catalyst for self-discharge reactions. VARTA's cells feature engineered particle morphologies with reduced surface area to volume ratios, decreasing the total interface area where parasitic reactions can occur. Their formation protocols include specialized voltage holding steps at critical potentials where interface stabilization occurs most effectively. Independent testing has shown self-discharge rates below 1% per month in their premium cell lines, with some specialized products maintaining over 95% capacity after 12 months of storage at room temperature.

Strengths: Exceptional consistency across mass-produced cells with minimal variation in self-discharge characteristics; maintains performance across wide temperature range (-20°C to 60°C); compatible with demanding applications requiring long shelf life. Weaknesses: Premium manufacturing processes increase production costs; some specialized additives have limited availability, creating supply chain challenges; requires precise charging protocols to maintain optimal performance.

Key Patents and Research in Self-Discharge Prevention

Method for reducing self-discharge in electrochemical cells

PatentInactiveJP2015502640A

Innovation

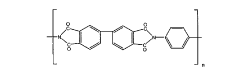

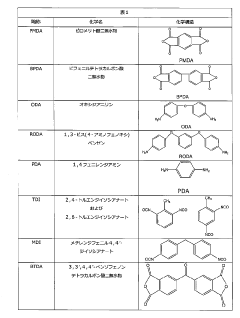

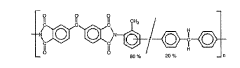

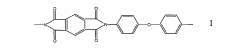

- The use of a porous separator made from a nanoweb containing a plurality of nanofibers composed of wholly aromatic polyimide with a high degree of imidization (>0.51) is inserted between the cathode and anode to reduce self-discharge rate and variability.

Electrochemical cell protected against self-discharge

PatentInactiveFR2671231A1

Innovation

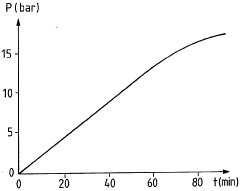

- Incorporating a gas-impermeable sheet, preferably made of metal, between the gas diffusion electrode and the orifices in the cell housing, which can be designed to automatically tear under internal pressure during use or manually pierced by the user, depending on the cell type, to maintain cell integrity and prevent self-discharge.

Environmental Impact of Battery Longevity Improvements

Reducing self-discharge in electrochemical cells directly contributes to significant environmental benefits through extended battery longevity. When batteries maintain their charge for longer periods, their effective lifespan increases substantially, reducing the frequency of replacement and disposal. This translates to fewer batteries entering waste streams annually, decreasing the environmental burden of toxic materials like lead, cadmium, and lithium compounds that can leach into soil and water systems.

The manufacturing process for batteries is resource-intensive, requiring substantial energy inputs and raw material extraction. Each improvement in self-discharge rates that extends battery life by even 10% can reduce manufacturing demand proportionally, leading to decreased mining activities for critical materials like lithium, cobalt, and nickel. These extraction processes are associated with habitat destruction, water pollution, and carbon emissions in mining regions across South America, Africa, and Asia.

Carbon footprint analyses demonstrate that the production phase accounts for 70-80% of a battery's lifetime environmental impact. Advanced technologies that reduce self-discharge can extend useful life from 3-5 years to 7-10 years for consumer applications, effectively halving the carbon emissions per year of service. For grid storage applications, longevity improvements from reduced self-discharge could prevent thousands of tons of CO2 emissions annually per installation.

Waste reduction benefits are equally compelling. Current global battery waste exceeds 11 million tons annually, with only 5% properly recycled in many regions. Batteries with improved self-discharge characteristics require less frequent replacement, potentially reducing this waste stream by 20-30% if widely implemented. This would significantly decrease the environmental contamination from improper disposal practices prevalent in developing nations.

Water conservation represents another critical environmental benefit. Battery production requires approximately 500 liters of water per kWh of capacity. Extending battery life through reduced self-discharge means fewer replacement units and consequently less water consumption. In water-stressed regions where lithium extraction occurs, such as Chile's Atacama Desert, these savings could help preserve fragile ecosystems and indigenous communities' water access.

Finally, improved battery longevity supports circular economy principles by maximizing resource utilization before recycling becomes necessary. When batteries maintain their charge more effectively, they remain viable for secondary applications even after their primary use ends, creating cascading environmental benefits through multiple life cycles before materials must be recovered through recycling processes.

The manufacturing process for batteries is resource-intensive, requiring substantial energy inputs and raw material extraction. Each improvement in self-discharge rates that extends battery life by even 10% can reduce manufacturing demand proportionally, leading to decreased mining activities for critical materials like lithium, cobalt, and nickel. These extraction processes are associated with habitat destruction, water pollution, and carbon emissions in mining regions across South America, Africa, and Asia.

Carbon footprint analyses demonstrate that the production phase accounts for 70-80% of a battery's lifetime environmental impact. Advanced technologies that reduce self-discharge can extend useful life from 3-5 years to 7-10 years for consumer applications, effectively halving the carbon emissions per year of service. For grid storage applications, longevity improvements from reduced self-discharge could prevent thousands of tons of CO2 emissions annually per installation.

Waste reduction benefits are equally compelling. Current global battery waste exceeds 11 million tons annually, with only 5% properly recycled in many regions. Batteries with improved self-discharge characteristics require less frequent replacement, potentially reducing this waste stream by 20-30% if widely implemented. This would significantly decrease the environmental contamination from improper disposal practices prevalent in developing nations.

Water conservation represents another critical environmental benefit. Battery production requires approximately 500 liters of water per kWh of capacity. Extending battery life through reduced self-discharge means fewer replacement units and consequently less water consumption. In water-stressed regions where lithium extraction occurs, such as Chile's Atacama Desert, these savings could help preserve fragile ecosystems and indigenous communities' water access.

Finally, improved battery longevity supports circular economy principles by maximizing resource utilization before recycling becomes necessary. When batteries maintain their charge more effectively, they remain viable for secondary applications even after their primary use ends, creating cascading environmental benefits through multiple life cycles before materials must be recovered through recycling processes.

Safety Standards and Testing Protocols for Battery Self-Discharge

The safety standards and testing protocols for battery self-discharge are critical components in the evaluation and certification of electrochemical cells. International organizations such as IEC (International Electrotechnical Commission) and IEEE (Institute of Electrical and Electronics Engineers) have established comprehensive standards that specifically address self-discharge characteristics. These standards typically require batteries to maintain a minimum percentage of their rated capacity after specified storage periods under controlled temperature conditions.

Key testing protocols include the IEC 61960 standard for lithium secondary cells, which mandates specific self-discharge rate measurements at various temperatures and states of charge. Similarly, the UL 1642 standard incorporates self-discharge evaluation as part of its safety assessment framework for lithium batteries. These protocols typically involve charging cells to full capacity, storing them for predetermined periods (often 7, 14, or 28 days), and then measuring the remaining capacity.

Temperature-controlled testing environments are essential for standardized self-discharge evaluation, as self-discharge rates can increase exponentially with temperature. Most standards require testing at multiple temperature points, typically including 25°C (standard condition), 45°C (accelerated condition), and sometimes -10°C (low-temperature performance).

Advanced testing methodologies have emerged to provide more accurate measurements of self-discharge rates. Potentiostatic and galvanostatic techniques allow for precise monitoring of current and voltage changes during storage periods. Differential voltage analysis has proven particularly valuable for detecting subtle self-discharge mechanisms that might be missed by conventional capacity measurements.

Safety certification bodies increasingly require manufacturers to demonstrate long-term self-discharge stability through accelerated aging tests. These tests simulate years of storage in compressed timeframes by exposing cells to elevated temperatures while monitoring capacity retention. The correlation between accelerated testing and real-world performance must be validated through statistical models and historical data.

For emerging battery technologies with novel chemistries, specialized testing protocols are being developed to address unique self-discharge mechanisms. These protocols often incorporate electrochemical impedance spectroscopy (EIS) to characterize internal resistance changes related to self-discharge processes. Additionally, post-mortem analysis of cells after extended storage periods provides valuable insights into degradation mechanisms that contribute to self-discharge.

Compliance with these standards and protocols is becoming increasingly important as battery applications expand into critical sectors such as medical devices, automotive systems, and grid storage, where unexpected capacity loss due to self-discharge could have serious consequences.

Key testing protocols include the IEC 61960 standard for lithium secondary cells, which mandates specific self-discharge rate measurements at various temperatures and states of charge. Similarly, the UL 1642 standard incorporates self-discharge evaluation as part of its safety assessment framework for lithium batteries. These protocols typically involve charging cells to full capacity, storing them for predetermined periods (often 7, 14, or 28 days), and then measuring the remaining capacity.

Temperature-controlled testing environments are essential for standardized self-discharge evaluation, as self-discharge rates can increase exponentially with temperature. Most standards require testing at multiple temperature points, typically including 25°C (standard condition), 45°C (accelerated condition), and sometimes -10°C (low-temperature performance).

Advanced testing methodologies have emerged to provide more accurate measurements of self-discharge rates. Potentiostatic and galvanostatic techniques allow for precise monitoring of current and voltage changes during storage periods. Differential voltage analysis has proven particularly valuable for detecting subtle self-discharge mechanisms that might be missed by conventional capacity measurements.

Safety certification bodies increasingly require manufacturers to demonstrate long-term self-discharge stability through accelerated aging tests. These tests simulate years of storage in compressed timeframes by exposing cells to elevated temperatures while monitoring capacity retention. The correlation between accelerated testing and real-world performance must be validated through statistical models and historical data.

For emerging battery technologies with novel chemistries, specialized testing protocols are being developed to address unique self-discharge mechanisms. These protocols often incorporate electrochemical impedance spectroscopy (EIS) to characterize internal resistance changes related to self-discharge processes. Additionally, post-mortem analysis of cells after extended storage periods provides valuable insights into degradation mechanisms that contribute to self-discharge.

Compliance with these standards and protocols is becoming increasingly important as battery applications expand into critical sectors such as medical devices, automotive systems, and grid storage, where unexpected capacity loss due to self-discharge could have serious consequences.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!