Optimize Electrochemical Cell Parameters for Rapid Charging

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fast Charging Technology Background and Objectives

Fast charging technology has evolved significantly over the past decade, driven by the rapid growth of electric vehicles (EVs) and portable electronic devices. The fundamental challenge in electrochemical cell optimization for rapid charging lies in balancing the competing demands of energy density, power capability, safety, and longevity. Historically, battery charging technologies were limited by both cell chemistry and charging infrastructure, with typical charging times ranging from hours to overnight for complete replenishment.

The evolution of lithium-ion battery technology has been particularly influential, with energy densities improving approximately 5-7% annually since commercial introduction in the early 1990s. However, charging speed improvements have not kept pace with energy density advancements, creating a technological gap that requires focused research and development efforts.

Current rapid charging technologies face several limitations, including thermal management challenges, lithium plating risks, and accelerated degradation mechanisms. These issues become particularly pronounced when attempting to achieve charging rates beyond 3C (complete charge in 20 minutes or less), where electrochemical stability boundaries are often exceeded.

The primary objective of electrochemical cell parameter optimization for rapid charging is to develop cell architectures and materials that can safely accept high current inputs while maintaining long-term performance stability. This includes identifying optimal electrode thickness ratios, electrolyte compositions, separator designs, and current collector configurations that collectively enable faster ion transport and heat dissipation.

Industry benchmarks suggest that next-generation fast charging should achieve 80% state-of-charge within 15 minutes for EVs and under 10 minutes for portable electronics, without compromising cycle life beyond 20% capacity loss over 1,000 cycles. These targets represent a significant improvement over current capabilities while maintaining practical usability.

Recent technological breakthroughs in silicon-graphite composite anodes, high-nickel cathodes, and advanced electrolyte formulations have demonstrated promising pathways toward these objectives. Additionally, novel approaches incorporating pre-lithiation techniques, gradient electrode structures, and artificial solid-electrolyte interphases show potential for mitigating degradation mechanisms during rapid charging.

The trajectory of fast charging technology development indicates a convergence toward holistic cell design optimization rather than isolated material improvements. This systems-level approach recognizes the interdependence of various cell parameters and their collective impact on rapid charging performance. Future research directions will likely focus on adaptive charging protocols that dynamically respond to cell conditions, coupled with materials engineered specifically for high-rate operation.

The evolution of lithium-ion battery technology has been particularly influential, with energy densities improving approximately 5-7% annually since commercial introduction in the early 1990s. However, charging speed improvements have not kept pace with energy density advancements, creating a technological gap that requires focused research and development efforts.

Current rapid charging technologies face several limitations, including thermal management challenges, lithium plating risks, and accelerated degradation mechanisms. These issues become particularly pronounced when attempting to achieve charging rates beyond 3C (complete charge in 20 minutes or less), where electrochemical stability boundaries are often exceeded.

The primary objective of electrochemical cell parameter optimization for rapid charging is to develop cell architectures and materials that can safely accept high current inputs while maintaining long-term performance stability. This includes identifying optimal electrode thickness ratios, electrolyte compositions, separator designs, and current collector configurations that collectively enable faster ion transport and heat dissipation.

Industry benchmarks suggest that next-generation fast charging should achieve 80% state-of-charge within 15 minutes for EVs and under 10 minutes for portable electronics, without compromising cycle life beyond 20% capacity loss over 1,000 cycles. These targets represent a significant improvement over current capabilities while maintaining practical usability.

Recent technological breakthroughs in silicon-graphite composite anodes, high-nickel cathodes, and advanced electrolyte formulations have demonstrated promising pathways toward these objectives. Additionally, novel approaches incorporating pre-lithiation techniques, gradient electrode structures, and artificial solid-electrolyte interphases show potential for mitigating degradation mechanisms during rapid charging.

The trajectory of fast charging technology development indicates a convergence toward holistic cell design optimization rather than isolated material improvements. This systems-level approach recognizes the interdependence of various cell parameters and their collective impact on rapid charging performance. Future research directions will likely focus on adaptive charging protocols that dynamically respond to cell conditions, coupled with materials engineered specifically for high-rate operation.

Market Analysis for Rapid Charging Solutions

The rapid charging market for electrochemical cells has experienced explosive growth in recent years, driven primarily by the expanding electric vehicle (EV) sector and portable electronics industry. Current market valuations indicate the global fast charging infrastructure market exceeds $20 billion, with projected annual growth rates of 25-30% through 2030. This acceleration is particularly evident in regions with strong EV adoption policies, including Europe, China, and parts of North America.

Consumer demand patterns clearly demonstrate a shift toward charging solutions that minimize downtime. Market research shows that charging speed has become the second most important factor in EV purchasing decisions, surpassed only by driving range. For portable electronics, surveys indicate that 78% of consumers consider fast charging capability "very important" or "essential" when selecting new devices.

The industrial segment presents another significant market opportunity, with manufacturing and logistics operations increasingly dependent on rapidly rechargeable equipment to maintain operational efficiency. This sector values charging solutions that optimize both speed and battery longevity, creating demand for sophisticated parameter optimization technologies.

Market segmentation reveals three primary customer categories: automotive manufacturers seeking competitive advantage through superior charging capabilities, consumer electronics companies differentiating products through convenience features, and industrial users prioritizing minimal equipment downtime. Each segment presents distinct requirements for electrochemical cell parameter optimization.

Competitive analysis shows that companies investing in rapid charging technology typically command premium pricing, with consumers willing to pay 15-20% more for devices offering significantly reduced charging times. This price elasticity creates substantial revenue opportunities for organizations that successfully optimize electrochemical parameters for faster charging without compromising safety or battery lifespan.

Regional market variations are notable, with Asian markets showing stronger preference for ultra-fast charging capabilities in mobile devices, while European consumers demonstrate greater concern for the sustainability aspects of charging solutions. North American markets exhibit balanced demand across both dimensions.

The regulatory landscape significantly impacts market development, with safety standards becoming increasingly stringent as charging speeds increase. Companies that can demonstrate parameter optimization that maintains safety compliance while delivering performance gains are positioned to capture market leadership.

Distribution channels are evolving rapidly, with direct-to-consumer sales of aftermarket charging solutions growing at twice the rate of bundled charging systems. This trend creates opportunities for specialized optimization technologies that can be deployed across multiple device categories.

Consumer demand patterns clearly demonstrate a shift toward charging solutions that minimize downtime. Market research shows that charging speed has become the second most important factor in EV purchasing decisions, surpassed only by driving range. For portable electronics, surveys indicate that 78% of consumers consider fast charging capability "very important" or "essential" when selecting new devices.

The industrial segment presents another significant market opportunity, with manufacturing and logistics operations increasingly dependent on rapidly rechargeable equipment to maintain operational efficiency. This sector values charging solutions that optimize both speed and battery longevity, creating demand for sophisticated parameter optimization technologies.

Market segmentation reveals three primary customer categories: automotive manufacturers seeking competitive advantage through superior charging capabilities, consumer electronics companies differentiating products through convenience features, and industrial users prioritizing minimal equipment downtime. Each segment presents distinct requirements for electrochemical cell parameter optimization.

Competitive analysis shows that companies investing in rapid charging technology typically command premium pricing, with consumers willing to pay 15-20% more for devices offering significantly reduced charging times. This price elasticity creates substantial revenue opportunities for organizations that successfully optimize electrochemical parameters for faster charging without compromising safety or battery lifespan.

Regional market variations are notable, with Asian markets showing stronger preference for ultra-fast charging capabilities in mobile devices, while European consumers demonstrate greater concern for the sustainability aspects of charging solutions. North American markets exhibit balanced demand across both dimensions.

The regulatory landscape significantly impacts market development, with safety standards becoming increasingly stringent as charging speeds increase. Companies that can demonstrate parameter optimization that maintains safety compliance while delivering performance gains are positioned to capture market leadership.

Distribution channels are evolving rapidly, with direct-to-consumer sales of aftermarket charging solutions growing at twice the rate of bundled charging systems. This trend creates opportunities for specialized optimization technologies that can be deployed across multiple device categories.

Current Electrochemical Cell Technology Challenges

The rapid charging capability of electrochemical cells faces several significant technical challenges that currently limit widespread adoption. One primary obstacle is thermal management during fast charging processes. When cells are charged at high rates, they generate substantial heat that can lead to accelerated degradation of electrode materials, electrolyte decomposition, and in extreme cases, thermal runaway. Current cooling systems often struggle to dissipate heat efficiently enough to maintain safe operating temperatures during rapid charging cycles.

Electrode material limitations present another major challenge. Traditional graphite anodes experience lithium plating when charged too quickly, forming dendrites that can cause internal short circuits and safety hazards. While silicon-based anodes offer higher capacity, they suffer from significant volume expansion during charging, leading to mechanical stress and rapid capacity fade when subjected to fast charging protocols.

Electrolyte formulations also pose significant barriers to rapid charging. Conventional liquid electrolytes have limited ionic conductivity and stability windows that become problematic at high charging rates. The formation of solid-electrolyte interphase (SEI) layers is particularly problematic during fast charging, as these layers can grow unevenly and increase internal resistance over time.

Cell design factors further complicate rapid charging implementation. Current collector thickness, electrode porosity, and tab configurations all influence charge distribution and internal resistance. Many existing cell designs prioritize energy density over power capability, resulting in suboptimal performance during high-rate charging scenarios. The trade-off between energy density and power capability remains a fundamental engineering challenge.

Manufacturing consistency presents additional hurdles. Even minor variations in electrode thickness, particle distribution, or electrolyte wetting can create localized hotspots during rapid charging. These manufacturing inconsistencies become increasingly problematic as charging rates increase, potentially leading to accelerated aging in certain regions of the cell.

Diagnostic and control systems also require significant advancement. Current battery management systems (BMS) often lack the sophisticated sensing capabilities needed to monitor cell conditions in real-time during rapid charging. Without precise temperature, voltage, and current distribution data, charging protocols cannot be optimized to balance speed with safety and longevity.

Finally, standardization challenges persist across the industry. Different cell chemistries, form factors, and applications require tailored rapid charging approaches, making it difficult to establish universal protocols. The lack of standardized testing methodologies for evaluating fast-charging performance further complicates technology development and comparison across different solutions.

Electrode material limitations present another major challenge. Traditional graphite anodes experience lithium plating when charged too quickly, forming dendrites that can cause internal short circuits and safety hazards. While silicon-based anodes offer higher capacity, they suffer from significant volume expansion during charging, leading to mechanical stress and rapid capacity fade when subjected to fast charging protocols.

Electrolyte formulations also pose significant barriers to rapid charging. Conventional liquid electrolytes have limited ionic conductivity and stability windows that become problematic at high charging rates. The formation of solid-electrolyte interphase (SEI) layers is particularly problematic during fast charging, as these layers can grow unevenly and increase internal resistance over time.

Cell design factors further complicate rapid charging implementation. Current collector thickness, electrode porosity, and tab configurations all influence charge distribution and internal resistance. Many existing cell designs prioritize energy density over power capability, resulting in suboptimal performance during high-rate charging scenarios. The trade-off between energy density and power capability remains a fundamental engineering challenge.

Manufacturing consistency presents additional hurdles. Even minor variations in electrode thickness, particle distribution, or electrolyte wetting can create localized hotspots during rapid charging. These manufacturing inconsistencies become increasingly problematic as charging rates increase, potentially leading to accelerated aging in certain regions of the cell.

Diagnostic and control systems also require significant advancement. Current battery management systems (BMS) often lack the sophisticated sensing capabilities needed to monitor cell conditions in real-time during rapid charging. Without precise temperature, voltage, and current distribution data, charging protocols cannot be optimized to balance speed with safety and longevity.

Finally, standardization challenges persist across the industry. Different cell chemistries, form factors, and applications require tailored rapid charging approaches, making it difficult to establish universal protocols. The lack of standardized testing methodologies for evaluating fast-charging performance further complicates technology development and comparison across different solutions.

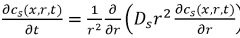

Current Parameter Optimization Approaches

01 Advanced electrode materials for faster charging

Innovative electrode materials can significantly enhance the charging speed of electrochemical cells. These materials include modified carbon structures, novel metal alloys, and composite materials that offer improved ion diffusion pathways and reduced internal resistance. By optimizing the electrode surface area and conductivity, these materials facilitate rapid ion transfer during charging, resulting in substantially reduced charging times while maintaining cell stability and longevity.- Advanced electrode materials for faster charging: Innovative electrode materials can significantly enhance the charging speed of electrochemical cells. These materials include modified carbon structures, novel metal alloys, and composite materials that offer improved ion diffusion pathways and reduced internal resistance. By optimizing the electrode surface area and conductivity, these materials enable faster ion transfer during charging, resulting in reduced charging times while maintaining cell stability and longevity.

- Electrolyte formulations for rapid charging: Specialized electrolyte formulations play a crucial role in improving charging speeds of electrochemical cells. These formulations may include additives that enhance ion mobility, reduce interfacial resistance, and prevent dendrite formation during fast charging. Advanced electrolytes can also improve thermal stability during rapid charging processes, allowing for higher current inputs without compromising safety or cell performance.

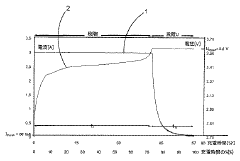

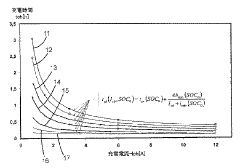

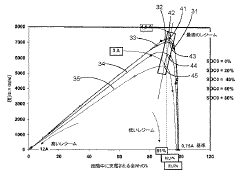

- Battery management systems for optimized charging: Sophisticated battery management systems can optimize charging protocols to achieve faster charging speeds while preserving battery health. These systems employ advanced algorithms to monitor cell parameters in real-time, adjusting charging current and voltage profiles accordingly. By implementing variable charging rates based on the state of charge and temperature, these systems can maximize charging speed during safe operating windows while preventing degradation mechanisms that typically occur during rapid charging.

- Cell design and architecture for improved charging rates: Innovative cell designs and architectures can significantly impact charging speeds. These designs focus on optimizing ion transport pathways, reducing internal resistance, and improving thermal management. Features such as modified separator structures, electrode alignment techniques, and novel cell geometries can facilitate faster ion movement during charging. Additionally, integrated cooling systems help dissipate heat generated during rapid charging, allowing for sustained high-rate charging without thermal degradation.

- Fast-charging protocols and methodologies: Advanced charging protocols and methodologies can substantially reduce charging times for electrochemical cells. These approaches include pulse charging techniques, multi-stage charging profiles, and adaptive charging algorithms that respond to cell behavior. By applying carefully controlled current and voltage patterns, these methods can overcome diffusion limitations and reduce polarization effects that typically slow down the charging process, while simultaneously minimizing side reactions that lead to capacity loss and degradation.

02 Electrolyte formulations for rapid charging

Specialized electrolyte formulations play a crucial role in improving charging speeds of electrochemical cells. These formulations may include additives that enhance ionic conductivity, reduce interfacial resistance, and prevent dendrite formation during fast charging. Advanced electrolytes can withstand higher voltage gradients without decomposition, allowing for more aggressive charging protocols while maintaining safety and cycle life of the battery cells.Expand Specific Solutions03 Thermal management systems for fast charging

Effective thermal management systems are essential for enabling high-speed charging of electrochemical cells. These systems control heat generation and dissipation during rapid charging, preventing temperature spikes that could lead to degradation or safety issues. Innovations include active cooling mechanisms, phase-change materials, and intelligent thermal regulation algorithms that adapt to charging conditions, allowing cells to be charged at maximum rates without exceeding safe temperature thresholds.Expand Specific Solutions04 Advanced charging protocols and algorithms

Sophisticated charging protocols and algorithms can optimize the charging speed of electrochemical cells while preserving their lifespan. These include multi-stage charging methods, pulse charging techniques, and adaptive algorithms that adjust charging parameters based on cell condition and response. By precisely controlling current and voltage profiles throughout the charging process, these approaches maximize charging rates during periods when the cell can safely accept higher power inputs.Expand Specific Solutions05 Cell design and architecture for improved charging speed

Innovative cell designs and architectures can fundamentally enhance charging capabilities of electrochemical cells. These include structural modifications that shorten ion diffusion paths, reduce internal resistance, and improve current distribution. Advanced designs may feature optimized electrode thickness, novel separator technologies, and improved current collector configurations. Some approaches incorporate 3D electrode structures or interdigitated designs that maximize the electrode-electrolyte interface area, facilitating faster ion transport during charging.Expand Specific Solutions

Key Industry Players in Battery Technology

The electrochemical cell optimization for rapid charging market is currently in a growth phase, with increasing demand driven by electric vehicle adoption and energy storage applications. The market size is expanding rapidly, projected to reach significant value as battery technology becomes critical infrastructure. Technologically, the field shows varied maturity levels with established players like CATL and LG Energy Solution leading commercial deployment, while research institutions (Caltech, CNRS) advance fundamental innovations. Sion Power and Iontra represent emerging disruptors with specialized rapid charging technologies. Companies like Bosch and Schneider Electric integrate these advancements into broader energy ecosystems. The competitive landscape features both battery manufacturers focusing on cell chemistry optimization and technology firms developing proprietary charging algorithms, creating a dynamic environment where collaboration between industry and research institutions accelerates innovation.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive approach to electrochemical cell parameter optimization for rapid charging through their Cell-to-Pack (CTP) technology and lithium-ion battery innovations. Their solution involves precise control of electrode thickness, porosity, and particle size distribution to enhance lithium-ion diffusion during high-current charging. CATL's proprietary electrolyte formulations contain additives that form stable solid-electrolyte interphase (SEI) layers, preventing lithium plating during rapid charging. Their thermal management system maintains optimal temperature ranges (25-35°C) during fast charging, while advanced battery management systems dynamically adjust charging protocols based on real-time cell parameters and state-of-health monitoring. CATL's latest generation batteries achieve 80% charge in under 15 minutes while maintaining over 80% capacity retention after 1,500 cycles.

Strengths: Industry-leading energy density (up to 255 Wh/kg) combined with fast-charging capability; extensive manufacturing scale enabling rapid commercialization; comprehensive vertical integration from materials to systems. Weaknesses: Higher production costs compared to standard batteries; requires sophisticated thermal management systems; technology primarily optimized for EV applications rather than broader energy storage markets.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive systems approach to electrochemical cell parameter optimization for rapid charging that integrates cell design, materials science, and intelligent control systems. Their technology focuses on precise electrode engineering with controlled porosity and tortuosity to enhance lithium-ion diffusion pathways during high-current charging. Bosch's solution incorporates advanced silicon-carbon composite anodes with engineered void spaces to accommodate volume expansion during lithium insertion, preventing mechanical degradation during fast charging cycles. Their proprietary electrolyte formulations feature additives that maintain stable solid-electrolyte interphase layers under high current densities. Bosch's approach is distinguished by their sophisticated battery management system that employs machine learning algorithms to create adaptive charging protocols based on individual cell characteristics, usage patterns, and aging states. This system continuously optimizes charging parameters to maximize speed while minimizing degradation mechanisms.

Strengths: Holistic approach integrating cell chemistry with system-level controls; extensive automotive expertise enabling practical implementation; sophisticated diagnostic capabilities for real-time parameter adjustment. Weaknesses: Complex implementation requiring tight integration between cell manufacturing and control systems; higher system costs compared to conventional approaches; potential challenges with standardization across different battery suppliers.

Critical Electrochemical Cell Innovations

System and method for fast charging of lithium-ion batteries with improved safety

PatentWO2014008278A1

Innovation

- An electrochemical battery system and method using optimal control theory to predict and adjust current and voltage inputs based on internal state parameters, ensuring constraints are not exceeded, thereby optimizing the charging process for faster charging while maintaining battery safety.

Methods for Optimal Charging of Electrochemical Batteries

PatentInactiveJP2014512165A

Innovation

- A method for determining an optimal charging regime by calibrating the battery based on its initial state, using a product of time and energy savings, involving multiple charging stages and conditions to optimize charging time and efficiency without causing damage.

Thermal Management Strategies

Effective thermal management is critical for optimizing electrochemical cell parameters during rapid charging processes. As charging rates increase, heat generation within cells accelerates exponentially, potentially leading to thermal runaway, reduced cycle life, and safety hazards. Current thermal management systems employ various cooling mechanisms including passive, active, and hybrid approaches to maintain optimal operating temperatures.

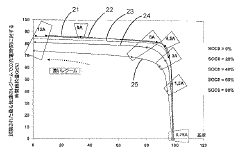

Passive cooling strategies utilize phase change materials (PCMs) that absorb excess heat through latent heat of fusion. These materials, including paraffins and salt hydrates, can maintain cell temperatures within 25-40°C range during high-rate charging. Recent advancements in nano-enhanced PCMs have demonstrated 30-45% improvement in thermal conductivity compared to conventional materials, enabling faster heat dissipation during 3C+ charging rates.

Active cooling systems employ forced air, liquid circulation, or refrigerant-based approaches. Liquid cooling systems have emerged as particularly effective for rapid charging applications, with direct liquid immersion techniques showing temperature gradient reductions of up to 78% compared to conventional air cooling. Advanced coolants incorporating nanofluids have demonstrated thermal conductivity enhancements of 15-40%, significantly improving heat transfer coefficients during peak charging periods.

Intelligent thermal management systems represent the cutting edge of this field, utilizing predictive algorithms and real-time temperature monitoring. These systems dynamically adjust cooling intensity based on charging profiles, ambient conditions, and cell-specific thermal characteristics. Studies indicate that AI-driven thermal management can reduce maximum temperature excursions by 22-35% during rapid charging while optimizing energy consumption of cooling systems.

Cell-level thermal design innovations include enhanced electrode structures with integrated thermal pathways. Novel electrode architectures incorporating graphene or carbon nanotube networks have demonstrated thermal conductivity improvements of 50-200% compared to conventional designs. These structures facilitate more uniform heat distribution, reducing hotspot formation during high-current charging operations.

The integration of thermal management with battery management systems (BMS) enables coordinated approaches to rapid charging. Advanced BMS platforms now incorporate thermal constraints into charging protocols, dynamically adjusting current profiles based on real-time temperature data. This integration has enabled charging speed improvements of 15-30% while maintaining temperature limits, particularly in next-generation solid-state and silicon-anode cells that present unique thermal challenges during fast charging.

Passive cooling strategies utilize phase change materials (PCMs) that absorb excess heat through latent heat of fusion. These materials, including paraffins and salt hydrates, can maintain cell temperatures within 25-40°C range during high-rate charging. Recent advancements in nano-enhanced PCMs have demonstrated 30-45% improvement in thermal conductivity compared to conventional materials, enabling faster heat dissipation during 3C+ charging rates.

Active cooling systems employ forced air, liquid circulation, or refrigerant-based approaches. Liquid cooling systems have emerged as particularly effective for rapid charging applications, with direct liquid immersion techniques showing temperature gradient reductions of up to 78% compared to conventional air cooling. Advanced coolants incorporating nanofluids have demonstrated thermal conductivity enhancements of 15-40%, significantly improving heat transfer coefficients during peak charging periods.

Intelligent thermal management systems represent the cutting edge of this field, utilizing predictive algorithms and real-time temperature monitoring. These systems dynamically adjust cooling intensity based on charging profiles, ambient conditions, and cell-specific thermal characteristics. Studies indicate that AI-driven thermal management can reduce maximum temperature excursions by 22-35% during rapid charging while optimizing energy consumption of cooling systems.

Cell-level thermal design innovations include enhanced electrode structures with integrated thermal pathways. Novel electrode architectures incorporating graphene or carbon nanotube networks have demonstrated thermal conductivity improvements of 50-200% compared to conventional designs. These structures facilitate more uniform heat distribution, reducing hotspot formation during high-current charging operations.

The integration of thermal management with battery management systems (BMS) enables coordinated approaches to rapid charging. Advanced BMS platforms now incorporate thermal constraints into charging protocols, dynamically adjusting current profiles based on real-time temperature data. This integration has enabled charging speed improvements of 15-30% while maintaining temperature limits, particularly in next-generation solid-state and silicon-anode cells that present unique thermal challenges during fast charging.

Safety Standards and Regulatory Compliance

The rapid charging of electrochemical cells necessitates adherence to stringent safety standards and regulatory frameworks to ensure consumer safety and product reliability. International organizations such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have established comprehensive standards specifically addressing fast-charging technologies. These include IEC 61851 for electric vehicle charging systems and UL 1642 for lithium battery safety, which outline critical parameters for thermal management, voltage limits, and current thresholds during accelerated charging processes.

Regulatory bodies worldwide have implemented certification requirements that manufacturers must meet before deploying rapid charging solutions commercially. The European Union's Battery Directive (2006/66/EC) and its recent updates emphasize safety protocols for high-power charging systems, while the United States Consumer Product Safety Commission enforces strict compliance with safety standards for consumer electronics featuring fast-charging capabilities.

Temperature monitoring represents a critical compliance aspect, with regulations typically mandating automatic charging termination when cells exceed specified thermal thresholds. Most standards require charging systems to incorporate multiple redundant safety mechanisms, including overcurrent protection, overvoltage prevention, and thermal runaway detection. These safeguards must function independently to ensure system resilience against potential failure modes.

Certification processes for rapid charging technologies involve rigorous testing protocols, including abuse testing under extreme conditions. These tests evaluate cell behavior during overcharging, short-circuiting, and mechanical stress scenarios to verify containment of potential hazards. Documentation requirements have become increasingly comprehensive, with manufacturers needing to demonstrate safety validation across the entire operational envelope of their charging systems.

Recent regulatory trends show movement toward harmonized global standards, with particular emphasis on interoperability between charging systems and various electrochemical cell chemistries. The development of specialized standards for emerging high-power charging technologies reflects regulatory bodies' recognition of the unique safety challenges posed by accelerated energy transfer rates.

Compliance with electromagnetic compatibility (EMC) regulations presents another crucial consideration, as rapid charging systems generate significant electromagnetic interference that must be contained within regulatory limits. Standards such as IEC 61000 establish specific parameters for emission levels and immunity requirements that charging systems must satisfy.

For research and development teams optimizing electrochemical cell parameters, early integration of regulatory requirements into the design process has proven essential for successful commercialization. This proactive approach enables identification of potential compliance challenges before significant resources are committed to specific technical solutions.

Regulatory bodies worldwide have implemented certification requirements that manufacturers must meet before deploying rapid charging solutions commercially. The European Union's Battery Directive (2006/66/EC) and its recent updates emphasize safety protocols for high-power charging systems, while the United States Consumer Product Safety Commission enforces strict compliance with safety standards for consumer electronics featuring fast-charging capabilities.

Temperature monitoring represents a critical compliance aspect, with regulations typically mandating automatic charging termination when cells exceed specified thermal thresholds. Most standards require charging systems to incorporate multiple redundant safety mechanisms, including overcurrent protection, overvoltage prevention, and thermal runaway detection. These safeguards must function independently to ensure system resilience against potential failure modes.

Certification processes for rapid charging technologies involve rigorous testing protocols, including abuse testing under extreme conditions. These tests evaluate cell behavior during overcharging, short-circuiting, and mechanical stress scenarios to verify containment of potential hazards. Documentation requirements have become increasingly comprehensive, with manufacturers needing to demonstrate safety validation across the entire operational envelope of their charging systems.

Recent regulatory trends show movement toward harmonized global standards, with particular emphasis on interoperability between charging systems and various electrochemical cell chemistries. The development of specialized standards for emerging high-power charging technologies reflects regulatory bodies' recognition of the unique safety challenges posed by accelerated energy transfer rates.

Compliance with electromagnetic compatibility (EMC) regulations presents another crucial consideration, as rapid charging systems generate significant electromagnetic interference that must be contained within regulatory limits. Standards such as IEC 61000 establish specific parameters for emission levels and immunity requirements that charging systems must satisfy.

For research and development teams optimizing electrochemical cell parameters, early integration of regulatory requirements into the design process has proven essential for successful commercialization. This proactive approach enables identification of potential compliance challenges before significant resources are committed to specific technical solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!