How to Test Electrochemical Cell Safety in Thermal Conditions

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Cell Safety Testing Background and Objectives

Electrochemical cells, particularly lithium-ion batteries, have become ubiquitous in modern society, powering everything from portable electronics to electric vehicles and grid-scale energy storage systems. As energy density requirements continue to increase, ensuring the safety of these cells under various operating conditions has become paramount. Thermal conditions represent one of the most critical safety concerns, as elevated temperatures can trigger catastrophic failures including thermal runaway, venting, fires, and explosions.

The evolution of electrochemical cell safety testing can be traced back to the early 1990s when the first commercial lithium-ion batteries were introduced. Initial safety protocols were relatively basic, focusing primarily on overcharge protection and short circuit prevention. As the technology proliferated and incidents occurred, testing methodologies evolved significantly, incorporating more sophisticated thermal abuse tests and standardized protocols.

Recent high-profile incidents involving battery fires in consumer electronics, electric vehicles, and energy storage systems have heightened awareness of thermal safety issues. These events have accelerated the development of more rigorous testing standards and regulations across industries. The global transition toward electrification further emphasizes the critical importance of robust thermal safety testing protocols.

Current thermal safety testing aims to evaluate cell behavior under various thermal stress conditions, including external heating, internal short circuits, thermal propagation, and thermal cycling. The primary objective is to understand failure mechanisms, establish safety margins, and develop mitigation strategies to prevent catastrophic failures. Testing must account for diverse cell chemistries, form factors, and applications, each presenting unique safety challenges.

Industry standards such as UL 1642, IEC 62133, UN 38.3, and SAE J2464 provide frameworks for thermal safety testing, though many experts argue that these standards have not kept pace with rapidly evolving battery technologies. This gap has prompted research institutions and manufacturers to develop supplementary testing protocols that address emerging concerns.

The ultimate goal of thermal safety testing is to develop cells that can withstand abuse conditions without catastrophic failure. This includes designing cells with improved thermal stability, implementing effective thermal management systems, and developing advanced safety features such as shutdown separators, pressure relief mechanisms, and flame-retardant electrolytes.

Looking forward, the field is moving toward more predictive testing methodologies that can accurately simulate real-world conditions and failure modes. Advanced diagnostic techniques, including in-situ monitoring and non-destructive evaluation methods, are being integrated into testing protocols to provide deeper insights into failure mechanisms and early warning indicators.

The evolution of electrochemical cell safety testing can be traced back to the early 1990s when the first commercial lithium-ion batteries were introduced. Initial safety protocols were relatively basic, focusing primarily on overcharge protection and short circuit prevention. As the technology proliferated and incidents occurred, testing methodologies evolved significantly, incorporating more sophisticated thermal abuse tests and standardized protocols.

Recent high-profile incidents involving battery fires in consumer electronics, electric vehicles, and energy storage systems have heightened awareness of thermal safety issues. These events have accelerated the development of more rigorous testing standards and regulations across industries. The global transition toward electrification further emphasizes the critical importance of robust thermal safety testing protocols.

Current thermal safety testing aims to evaluate cell behavior under various thermal stress conditions, including external heating, internal short circuits, thermal propagation, and thermal cycling. The primary objective is to understand failure mechanisms, establish safety margins, and develop mitigation strategies to prevent catastrophic failures. Testing must account for diverse cell chemistries, form factors, and applications, each presenting unique safety challenges.

Industry standards such as UL 1642, IEC 62133, UN 38.3, and SAE J2464 provide frameworks for thermal safety testing, though many experts argue that these standards have not kept pace with rapidly evolving battery technologies. This gap has prompted research institutions and manufacturers to develop supplementary testing protocols that address emerging concerns.

The ultimate goal of thermal safety testing is to develop cells that can withstand abuse conditions without catastrophic failure. This includes designing cells with improved thermal stability, implementing effective thermal management systems, and developing advanced safety features such as shutdown separators, pressure relief mechanisms, and flame-retardant electrolytes.

Looking forward, the field is moving toward more predictive testing methodologies that can accurately simulate real-world conditions and failure modes. Advanced diagnostic techniques, including in-situ monitoring and non-destructive evaluation methods, are being integrated into testing protocols to provide deeper insights into failure mechanisms and early warning indicators.

Market Demand Analysis for Thermal Safety Testing Solutions

The global market for electrochemical cell thermal safety testing solutions has experienced significant growth in recent years, primarily driven by the rapid expansion of electric vehicles, portable electronics, and energy storage systems. Market research indicates that the thermal safety testing equipment market reached approximately $1.2 billion in 2022, with projections suggesting a compound annual growth rate of 8.7% through 2030.

Consumer electronics manufacturers represent the largest market segment, accounting for roughly 35% of the total demand. This is closely followed by automotive manufacturers at 30%, energy storage system developers at 20%, and aerospace and defense industries at 10%. The remaining 5% is distributed across various other sectors including medical devices and industrial applications.

Regulatory requirements have become increasingly stringent worldwide, particularly following several high-profile battery failure incidents. The UN 38.3 test for lithium batteries, IEC 62133 standard, and UL 1642 certification have become mandatory requirements in most markets, creating substantial demand for comprehensive thermal safety testing solutions. Additionally, the implementation of the European Battery Directive and similar regulations in Asia has further accelerated market growth.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea where major battery manufacturing facilities are concentrated. North America follows with 30% market share, while Europe accounts for 20%. The remaining 5% is distributed across other regions, with emerging markets showing the highest growth potential.

Customer requirements have evolved significantly, with manufacturers now demanding more sophisticated testing solutions that can simulate real-world conditions. There is growing interest in accelerated testing methodologies that can reduce time-to-market while maintaining reliability. Additionally, there is increasing demand for testing equipment that can handle larger battery packs and modules rather than just individual cells.

Cost considerations remain a significant factor influencing market dynamics. High-end thermal safety testing equipment can cost between $100,000 to $500,000, creating barriers for smaller manufacturers. This has led to the emergence of testing service providers who offer specialized testing capabilities on a contract basis, representing a growing segment within the overall market.

Future market growth is expected to be driven by innovations in fast-charging technologies, solid-state batteries, and the increasing energy density of cells, all of which introduce new thermal management challenges requiring advanced testing methodologies.

Consumer electronics manufacturers represent the largest market segment, accounting for roughly 35% of the total demand. This is closely followed by automotive manufacturers at 30%, energy storage system developers at 20%, and aerospace and defense industries at 10%. The remaining 5% is distributed across various other sectors including medical devices and industrial applications.

Regulatory requirements have become increasingly stringent worldwide, particularly following several high-profile battery failure incidents. The UN 38.3 test for lithium batteries, IEC 62133 standard, and UL 1642 certification have become mandatory requirements in most markets, creating substantial demand for comprehensive thermal safety testing solutions. Additionally, the implementation of the European Battery Directive and similar regulations in Asia has further accelerated market growth.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea where major battery manufacturing facilities are concentrated. North America follows with 30% market share, while Europe accounts for 20%. The remaining 5% is distributed across other regions, with emerging markets showing the highest growth potential.

Customer requirements have evolved significantly, with manufacturers now demanding more sophisticated testing solutions that can simulate real-world conditions. There is growing interest in accelerated testing methodologies that can reduce time-to-market while maintaining reliability. Additionally, there is increasing demand for testing equipment that can handle larger battery packs and modules rather than just individual cells.

Cost considerations remain a significant factor influencing market dynamics. High-end thermal safety testing equipment can cost between $100,000 to $500,000, creating barriers for smaller manufacturers. This has led to the emergence of testing service providers who offer specialized testing capabilities on a contract basis, representing a growing segment within the overall market.

Future market growth is expected to be driven by innovations in fast-charging technologies, solid-state batteries, and the increasing energy density of cells, all of which introduce new thermal management challenges requiring advanced testing methodologies.

Current Thermal Safety Testing Technologies and Challenges

The thermal safety testing of electrochemical cells has evolved significantly over the past decade, with several standardized methodologies now established across the industry. Current testing technologies primarily fall into three categories: controlled thermal chamber testing, accelerated rate calorimetry (ARC), and thermal abuse testing with physical deformation. These methods aim to simulate various real-world conditions that cells might encounter during operation or in failure scenarios.

Controlled thermal chamber testing represents the most widely adopted approach, where cells are subjected to gradually increasing temperatures in specialized environmental chambers. These chambers can precisely control temperature ramps from ambient to beyond 200°C while monitoring cell parameters including voltage, internal pressure, and surface temperature. The primary challenge with this method lies in the slow heating rates, which may not accurately represent rapid thermal events in real-world scenarios.

Accelerated Rate Calorimetry offers more dynamic testing capabilities by operating in an adiabatic environment that prevents heat loss from the cell. This approach more accurately simulates thermal runaway conditions by allowing the cell's self-heating to progress naturally. Modern ARC systems can detect temperature changes as small as 0.02°C per minute, providing highly sensitive measurements of exothermic reactions within the cell. However, these systems are costly to implement and maintain, limiting their widespread adoption, particularly among smaller manufacturers.

Thermal abuse testing with physical deformation combines thermal stress with mechanical damage, representing a more comprehensive approach to safety evaluation. This method typically involves heating cells while simultaneously applying crushing, puncturing, or bending forces. The integration of multiple stress factors provides valuable insights into compound failure modes but introduces significant complexity in test standardization and result interpretation.

A significant challenge across all testing methodologies is the lack of global standardization. While organizations like UL, IEC, and ISO have established testing protocols, regional variations persist, creating compliance difficulties for global manufacturers. Furthermore, the correlation between laboratory test results and real-world performance remains problematic, with accelerated testing often failing to account for aging effects and long-term degradation mechanisms.

Data interpretation presents another substantial challenge, as thermal events in electrochemical cells often involve complex, interdependent reactions. Modern testing increasingly incorporates advanced diagnostic tools such as thermal imaging cameras, gas chromatography for vented gas analysis, and acoustic emission sensors to detect internal structural changes. However, integrating these diverse data streams into cohesive safety assessments requires sophisticated analytical frameworks that are still evolving.

Controlled thermal chamber testing represents the most widely adopted approach, where cells are subjected to gradually increasing temperatures in specialized environmental chambers. These chambers can precisely control temperature ramps from ambient to beyond 200°C while monitoring cell parameters including voltage, internal pressure, and surface temperature. The primary challenge with this method lies in the slow heating rates, which may not accurately represent rapid thermal events in real-world scenarios.

Accelerated Rate Calorimetry offers more dynamic testing capabilities by operating in an adiabatic environment that prevents heat loss from the cell. This approach more accurately simulates thermal runaway conditions by allowing the cell's self-heating to progress naturally. Modern ARC systems can detect temperature changes as small as 0.02°C per minute, providing highly sensitive measurements of exothermic reactions within the cell. However, these systems are costly to implement and maintain, limiting their widespread adoption, particularly among smaller manufacturers.

Thermal abuse testing with physical deformation combines thermal stress with mechanical damage, representing a more comprehensive approach to safety evaluation. This method typically involves heating cells while simultaneously applying crushing, puncturing, or bending forces. The integration of multiple stress factors provides valuable insights into compound failure modes but introduces significant complexity in test standardization and result interpretation.

A significant challenge across all testing methodologies is the lack of global standardization. While organizations like UL, IEC, and ISO have established testing protocols, regional variations persist, creating compliance difficulties for global manufacturers. Furthermore, the correlation between laboratory test results and real-world performance remains problematic, with accelerated testing often failing to account for aging effects and long-term degradation mechanisms.

Data interpretation presents another substantial challenge, as thermal events in electrochemical cells often involve complex, interdependent reactions. Modern testing increasingly incorporates advanced diagnostic tools such as thermal imaging cameras, gas chromatography for vented gas analysis, and acoustic emission sensors to detect internal structural changes. However, integrating these diverse data streams into cohesive safety assessments requires sophisticated analytical frameworks that are still evolving.

Existing Thermal Testing Protocols and Standards

01 Thermal management systems for electrochemical cells

Thermal management systems are crucial for electrochemical cell safety as they prevent overheating and thermal runaway. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that maintain optimal operating temperatures. Advanced thermal management solutions incorporate phase change materials, liquid cooling circuits, or air cooling systems to efficiently remove excess heat from battery cells, particularly during high-current operations like fast charging or discharging.- Thermal management systems for electrochemical cells: Effective thermal management is crucial for electrochemical cell safety. These systems monitor and control cell temperature to prevent overheating, which can lead to thermal runaway. Advanced cooling mechanisms, heat dissipation materials, and temperature sensors work together to maintain optimal operating conditions. By preventing excessive heat buildup, these systems significantly reduce the risk of fire, explosion, and other safety hazards associated with electrochemical cells.

- Safety mechanisms for preventing short circuits: Various safety mechanisms are implemented to prevent short circuits in electrochemical cells. These include separator designs that maintain physical isolation between electrodes, current interrupt devices that activate when abnormal conditions are detected, and protective coatings that enhance electrical insulation. These mechanisms help prevent internal short circuits that could otherwise lead to rapid discharge, overheating, and potentially catastrophic failure of the cell.

- Pressure relief and venting systems: Electrochemical cells incorporate pressure relief and venting systems to safely manage gas buildup during abnormal operating conditions. These systems include burst discs, pressure relief valves, and controlled rupture mechanisms that activate when internal pressure exceeds safe thresholds. By providing controlled pathways for gas release, these systems prevent explosive cell rupture while containing potentially hazardous materials, significantly enhancing overall cell safety.

- Battery management systems for monitoring and control: Advanced battery management systems (BMS) continuously monitor critical parameters of electrochemical cells including voltage, current, temperature, and state of charge. These systems implement protective algorithms that can detect abnormal conditions and take corrective actions such as disconnecting cells, limiting charging rates, or activating cooling systems. By providing real-time monitoring and intelligent control, BMS technology significantly improves the safety profile of electrochemical cells during operation.

- Flame-retardant and safety-enhanced electrolyte formulations: Specialized electrolyte formulations enhance electrochemical cell safety by incorporating flame-retardant additives, reducing flammability, and improving thermal stability. These formulations may include non-flammable solvents, fire-suppressing compounds, and additives that form protective solid-electrolyte interphase layers. By addressing the inherent flammability risks of conventional electrolytes, these advanced formulations significantly reduce fire hazards while maintaining electrochemical performance.

02 Safety mechanisms for preventing short circuits

Various safety mechanisms are implemented to prevent short circuits in electrochemical cells. These include separator designs with shutdown capabilities, current interrupt devices, and protective coatings on electrodes. Some designs incorporate physical barriers between electrodes or special electrolyte formulations that become non-conductive under abnormal conditions. These mechanisms help isolate electrical pathways when potential short circuit conditions are detected, preventing catastrophic failure.Expand Specific Solutions03 Pressure relief and containment systems

Pressure relief and containment systems are essential safety features in electrochemical cells that manage internal pressure buildup during abnormal conditions. These systems include venting mechanisms, burst discs, and reinforced cell casings that can safely release excess gases while containing potentially hazardous materials. Advanced designs incorporate multi-stage pressure relief that activates at different thresholds to provide controlled response to varying levels of pressure buildup, preventing explosive rupture of cells.Expand Specific Solutions04 Monitoring and diagnostic systems for early fault detection

Sophisticated monitoring and diagnostic systems enable early detection of potential safety issues in electrochemical cells. These systems track parameters such as voltage, current, temperature, and internal resistance to identify abnormal patterns indicating developing faults. Advanced battery management systems employ algorithms that can predict failure modes before they become critical, allowing preventive measures to be taken. Some systems incorporate reference electrodes or specialized sensors that provide additional data points for more accurate diagnostics.Expand Specific Solutions05 Electrolyte and separator innovations for enhanced safety

Innovations in electrolyte formulations and separator materials significantly improve electrochemical cell safety. These include flame-retardant additives, solid-state electrolytes, and ceramic-reinforced separators that reduce fire risks. Some advanced designs incorporate self-healing separators or electrolytes that solidify upon impact or puncture. Gel polymer electrolytes and composite separators with thermal shutdown properties provide additional safety layers by preventing ion transport under unsafe conditions, effectively shutting down the cell before catastrophic failure occurs.Expand Specific Solutions

Key Industry Players in Battery Safety Testing Equipment

The electrochemical cell safety testing market in thermal conditions is currently in a growth phase, with increasing demand driven by electric vehicle and energy storage expansion. Market size is projected to reach significant volumes as regulatory requirements tighten globally. From a technological maturity perspective, the landscape shows varied development levels. Research institutions like CNRS and Caltech are advancing fundamental safety methodologies, while commercial players demonstrate different specialization levels. LG Energy Solution, BYD, and Toyota lead with comprehensive thermal safety protocols, while companies like CAMX Power and Element Energy focus on innovative material-based approaches. Automotive manufacturers (BMW, Bosch) are integrating advanced thermal management systems, creating a competitive ecosystem balancing established testing frameworks with emerging predictive technologies.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive thermal safety testing protocol for electrochemical cells that combines multiple methodologies. Their approach includes accelerating rate calorimetry (ARC) to measure heat generation during thermal runaway, thermal abuse testing in environmental chambers where cells are subjected to extreme temperature cycling (from -40°C to 85°C), and nail penetration tests conducted at various temperatures to simulate internal short circuits under different thermal conditions. The company has pioneered the use of infrared thermography during testing to create detailed thermal maps of cell behavior during failure events. Their Battery Management System (BMS) is specifically designed to incorporate thermal safety parameters with real-time monitoring capabilities that can detect abnormal temperature gradients across cell arrays. LG has also implemented a multi-stage thermal propagation test methodology that evaluates how thermal events in a single cell affect adjacent cells in module configurations.

Strengths: Advanced thermal imaging capabilities provide detailed visualization of heat distribution during failure events, allowing for better safety design. Their multi-level testing approach from cell to pack level ensures comprehensive safety evaluation. Weaknesses: Their testing protocols are highly specialized and require expensive equipment, making implementation costly. Some of their thermal abuse tests have been criticized for not fully representing real-world failure conditions.

BYD Co., Ltd.

Technical Solution: BYD has developed the Blade Battery technology with an integrated thermal safety testing methodology specifically designed for large-format LFP (lithium iron phosphate) cells. Their testing protocol includes a unique nail penetration test performed at elevated temperatures (up to 60°C) to simulate worst-case thermal abuse scenarios. BYD employs thermal shock cycling where cells are rapidly transferred between extreme temperature environments (-40°C to 130°C) to evaluate structural integrity and safety performance. Their approach includes proprietary thermal runaway propagation prevention technology that undergoes rigorous validation through controlled thermal abuse tests. BYD has implemented a "thermal gradient stress test" where different sections of the same cell are maintained at different temperatures to evaluate the cell's resistance to thermal gradient-induced stress. The company also conducts extended high-temperature storage tests (60°C for 6 months) combined with regular performance and safety evaluations to assess long-term thermal stability and aging effects on safety performance.

Strengths: Their Blade Battery design has demonstrated exceptional thermal stability in nail penetration tests even at elevated temperatures. The focus on thermal propagation prevention provides enhanced safety for large battery packs. Weaknesses: Testing methodology is heavily optimized for their specific LFP chemistry and form factor, potentially limiting applicability to other battery technologies. Their thermal gradient stress tests may not fully represent all real-world thermal conditions experienced in various applications.

Critical Technologies in Thermal Runaway Prevention

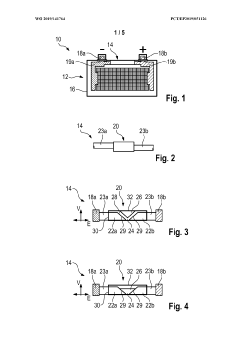

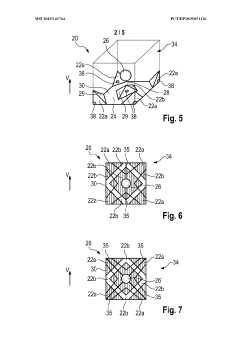

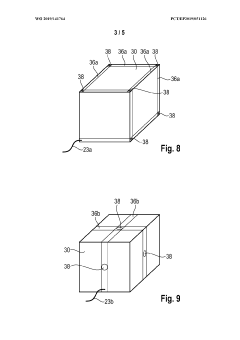

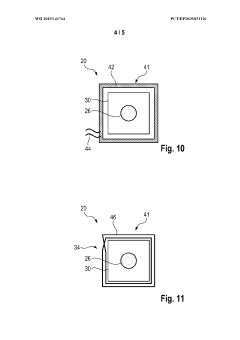

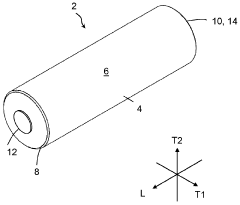

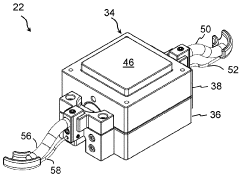

Test device for an electrochemical cell, module comprising a test device, and method for testing an electrochemical cell

PatentWO2019141764A1

Innovation

- A test device with a switching mechanism that bridges cathodic and anodic sub-electrodes using a conductive contact substance, which transitions from a non-conductive to a conductive state upon temperature increase or mechanical release, allowing for controlled short-circuit creation and monitoring of current flow within the cell.

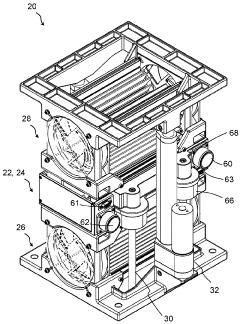

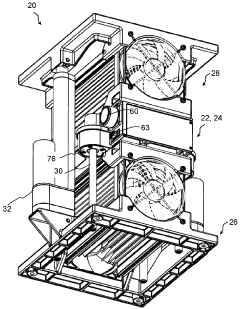

Apparatus, system and method for testing an electrochemical cell under a controlled temperature condition

PatentWO2024000070A1

Innovation

- An apparatus and system utilizing a pair of Peltier modules with a cell-contacting member and heat sink members to maintain a substantially isothermal state or controlled temperature condition, featuring a concave cylindrical cell-contacting surface and adjustable linear actuators for precise temperature control, along with temperature and heat flux sensors for feedback-based power control.

Regulatory Compliance Requirements for Battery Safety

The regulatory landscape for electrochemical cell safety testing under thermal conditions is complex and continuously evolving. Major international standards organizations have established comprehensive frameworks that manufacturers must adhere to before bringing battery products to market. The International Electrotechnical Commission (IEC) has developed IEC 62133 for portable batteries and IEC 61960 for lithium-ion cells, both containing specific thermal safety test requirements including thermal abuse, thermal cycling, and high-temperature endurance tests.

In the United States, UL 1642 and UL 2054 standards govern cell-level and battery pack safety respectively, with detailed protocols for thermal runaway prevention and management. The UN Transportation Testing (UN 38.3) is mandatory for shipping lithium batteries internationally, requiring cells to undergo rigorous thermal tests including thermal cycling between extreme temperatures (-40°C to +75°C) and altitude simulation.

European regulations are primarily guided by EN 62133, which harmonizes with IEC standards but includes additional requirements specific to the European market. The EU Battery Directive (2006/66/EC) further regulates battery disposal and recycling considerations related to thermal degradation products.

Asian markets have established their own certification systems, with Japan's JIS C8714 and China's GB/T 31241 standards implementing stringent thermal safety requirements. These standards often exceed international minimums, particularly for consumer electronics applications.

Industry-specific regulations add another layer of compliance requirements. Medical device batteries must meet ISO 13485 and IEC 60601-1 standards, which include specialized thermal safety parameters. Automotive applications are governed by ISO 26262 and UN ECE R100, with particular emphasis on thermal management systems for large-format cells.

Recent regulatory trends show increasing focus on abuse testing beyond normal operating conditions, with requirements for thermal propagation testing becoming more common. Regulatory bodies are also moving toward harmonization of standards, though regional differences persist. The emergence of new battery chemistries has prompted regulatory updates, with standards organizations working to develop appropriate testing protocols for solid-state batteries and other next-generation technologies.

Compliance documentation requirements have become more comprehensive, with detailed thermal test reports, risk assessments, and failure mode analyses now standard components of regulatory submissions. Manufacturers must maintain traceability throughout the testing process and provide evidence of compliance with all applicable thermal safety standards.

In the United States, UL 1642 and UL 2054 standards govern cell-level and battery pack safety respectively, with detailed protocols for thermal runaway prevention and management. The UN Transportation Testing (UN 38.3) is mandatory for shipping lithium batteries internationally, requiring cells to undergo rigorous thermal tests including thermal cycling between extreme temperatures (-40°C to +75°C) and altitude simulation.

European regulations are primarily guided by EN 62133, which harmonizes with IEC standards but includes additional requirements specific to the European market. The EU Battery Directive (2006/66/EC) further regulates battery disposal and recycling considerations related to thermal degradation products.

Asian markets have established their own certification systems, with Japan's JIS C8714 and China's GB/T 31241 standards implementing stringent thermal safety requirements. These standards often exceed international minimums, particularly for consumer electronics applications.

Industry-specific regulations add another layer of compliance requirements. Medical device batteries must meet ISO 13485 and IEC 60601-1 standards, which include specialized thermal safety parameters. Automotive applications are governed by ISO 26262 and UN ECE R100, with particular emphasis on thermal management systems for large-format cells.

Recent regulatory trends show increasing focus on abuse testing beyond normal operating conditions, with requirements for thermal propagation testing becoming more common. Regulatory bodies are also moving toward harmonization of standards, though regional differences persist. The emergence of new battery chemistries has prompted regulatory updates, with standards organizations working to develop appropriate testing protocols for solid-state batteries and other next-generation technologies.

Compliance documentation requirements have become more comprehensive, with detailed thermal test reports, risk assessments, and failure mode analyses now standard components of regulatory submissions. Manufacturers must maintain traceability throughout the testing process and provide evidence of compliance with all applicable thermal safety standards.

Environmental Impact of Battery Thermal Testing Procedures

Battery thermal testing procedures, while essential for safety evaluation, carry significant environmental implications that warrant careful consideration. The testing processes often involve high energy consumption, particularly when simulating extreme temperature conditions. Test chambers that can reach temperatures from -40°C to over 100°C require substantial power inputs, contributing to carbon emissions when powered by non-renewable energy sources. A typical thermal abuse test facility can consume between 50-200 kWh per test cycle, equivalent to the daily electricity usage of multiple households.

The disposal of tested batteries presents another environmental challenge. Thermal testing frequently results in damaged or destroyed cells containing hazardous materials such as lithium, cobalt, nickel, and electrolyte solvents. Without proper waste management protocols, these materials can contaminate soil and water systems. Research indicates that a single improperly disposed lithium-ion battery can contaminate approximately 1,000 liters of groundwater.

Thermal testing procedures also generate atmospheric emissions. When batteries undergo thermal runaway during testing, they release toxic gases including hydrogen fluoride, carbon monoxide, and various volatile organic compounds. These emissions require sophisticated filtration and scrubbing systems to prevent environmental release. Studies have shown that a medium-sized lithium-ion cell undergoing complete thermal runaway can produce up to 5 liters of toxic gas mixture.

Water usage represents another environmental concern in battery testing facilities. Cooling systems and fire suppression equipment essential for thermal testing safety consume significant water resources. Advanced testing facilities may require 500-1,000 gallons of water per day for operation and emergency preparedness.

The environmental footprint extends to the manufacturing of specialized testing equipment. Thermal chambers, calorimeters, and safety monitoring systems require resource-intensive production processes and contain materials with their own environmental impact profiles. The average thermal test chamber has an embodied carbon footprint equivalent to manufacturing several household appliances.

Progressive testing facilities are implementing more sustainable practices, including closed-loop cooling systems, renewable energy sources, and improved battery recycling protocols. Some organizations have reported reducing their environmental impact by 30-40% through these measures. The industry is also exploring computational modeling and simulation techniques to reduce the number of physical tests required, potentially decreasing the overall environmental footprint of battery safety validation while maintaining rigorous safety standards.

The disposal of tested batteries presents another environmental challenge. Thermal testing frequently results in damaged or destroyed cells containing hazardous materials such as lithium, cobalt, nickel, and electrolyte solvents. Without proper waste management protocols, these materials can contaminate soil and water systems. Research indicates that a single improperly disposed lithium-ion battery can contaminate approximately 1,000 liters of groundwater.

Thermal testing procedures also generate atmospheric emissions. When batteries undergo thermal runaway during testing, they release toxic gases including hydrogen fluoride, carbon monoxide, and various volatile organic compounds. These emissions require sophisticated filtration and scrubbing systems to prevent environmental release. Studies have shown that a medium-sized lithium-ion cell undergoing complete thermal runaway can produce up to 5 liters of toxic gas mixture.

Water usage represents another environmental concern in battery testing facilities. Cooling systems and fire suppression equipment essential for thermal testing safety consume significant water resources. Advanced testing facilities may require 500-1,000 gallons of water per day for operation and emergency preparedness.

The environmental footprint extends to the manufacturing of specialized testing equipment. Thermal chambers, calorimeters, and safety monitoring systems require resource-intensive production processes and contain materials with their own environmental impact profiles. The average thermal test chamber has an embodied carbon footprint equivalent to manufacturing several household appliances.

Progressive testing facilities are implementing more sustainable practices, including closed-loop cooling systems, renewable energy sources, and improved battery recycling protocols. Some organizations have reported reducing their environmental impact by 30-40% through these measures. The industry is also exploring computational modeling and simulation techniques to reduce the number of physical tests required, potentially decreasing the overall environmental footprint of battery safety validation while maintaining rigorous safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!