Electrochemical Cell Vs Photovoltaic Cell: Energy Output Analysis

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical and Photovoltaic Cell Technology Evolution

The evolution of electrochemical and photovoltaic cell technologies represents two distinct yet parallel paths in energy conversion systems. Electrochemical cells, dating back to Alessandro Volta's pioneering work in 1800, have undergone significant transformations from simple zinc-copper configurations to today's sophisticated lithium-ion batteries. This evolutionary trajectory has been characterized by continuous improvements in energy density, cycle life, and safety features.

Photovoltaic technology, while conceptually understood since Becquerel's discovery of the photovoltaic effect in 1839, only gained practical significance with Bell Labs' development of the first silicon solar cell in 1954. The subsequent decades witnessed a progression from first-generation crystalline silicon cells to second-generation thin-film technologies, and now to emerging third-generation concepts including perovskite cells and multi-junction architectures.

The technological convergence points between these two energy conversion mechanisms have become increasingly evident. Both technologies have benefited from advances in materials science, particularly in nanomaterials and interface engineering. The development of photoelectrochemical cells represents a hybrid approach that leverages principles from both domains, demonstrating how innovation often occurs at technological intersections.

Energy density evolution has followed distinctly different patterns. Electrochemical cells have seen exponential improvements, with lithium-ion technology achieving approximately 250-300 Wh/kg, representing a nearly tenfold increase from lead-acid predecessors. Photovoltaic efficiency has improved more gradually, from about 6% for early silicon cells to beyond 25% for modern commercial modules, with laboratory multi-junction cells exceeding 45% efficiency.

Manufacturing scalability has been a critical factor in both technologies' commercial viability. Electrochemical cell production has benefited from decades of industrial optimization, while photovoltaic manufacturing has undergone a remarkable cost reduction curve, with module prices falling by approximately 99% since 1976, enabling grid parity in many markets worldwide.

Recent technological convergence has manifested in integrated energy systems that combine storage capabilities of electrochemical cells with the generation capacity of photovoltaic technology. This integration addresses the intermittency challenge inherent to solar power, creating more resilient and flexible energy solutions. The emergence of building-integrated photovoltaics with integrated battery storage exemplifies this trend toward holistic energy system design.

Looking forward, both technologies face similar challenges in sustainability and resource constraints. Research directions increasingly focus on abundant, non-toxic materials and circular economy approaches to ensure long-term viability and minimal environmental impact as deployment scales continue to expand globally.

Photovoltaic technology, while conceptually understood since Becquerel's discovery of the photovoltaic effect in 1839, only gained practical significance with Bell Labs' development of the first silicon solar cell in 1954. The subsequent decades witnessed a progression from first-generation crystalline silicon cells to second-generation thin-film technologies, and now to emerging third-generation concepts including perovskite cells and multi-junction architectures.

The technological convergence points between these two energy conversion mechanisms have become increasingly evident. Both technologies have benefited from advances in materials science, particularly in nanomaterials and interface engineering. The development of photoelectrochemical cells represents a hybrid approach that leverages principles from both domains, demonstrating how innovation often occurs at technological intersections.

Energy density evolution has followed distinctly different patterns. Electrochemical cells have seen exponential improvements, with lithium-ion technology achieving approximately 250-300 Wh/kg, representing a nearly tenfold increase from lead-acid predecessors. Photovoltaic efficiency has improved more gradually, from about 6% for early silicon cells to beyond 25% for modern commercial modules, with laboratory multi-junction cells exceeding 45% efficiency.

Manufacturing scalability has been a critical factor in both technologies' commercial viability. Electrochemical cell production has benefited from decades of industrial optimization, while photovoltaic manufacturing has undergone a remarkable cost reduction curve, with module prices falling by approximately 99% since 1976, enabling grid parity in many markets worldwide.

Recent technological convergence has manifested in integrated energy systems that combine storage capabilities of electrochemical cells with the generation capacity of photovoltaic technology. This integration addresses the intermittency challenge inherent to solar power, creating more resilient and flexible energy solutions. The emergence of building-integrated photovoltaics with integrated battery storage exemplifies this trend toward holistic energy system design.

Looking forward, both technologies face similar challenges in sustainability and resource constraints. Research directions increasingly focus on abundant, non-toxic materials and circular economy approaches to ensure long-term viability and minimal environmental impact as deployment scales continue to expand globally.

Market Analysis of Energy Conversion Technologies

The global energy conversion technology market is experiencing significant growth, driven by increasing energy demands and the transition towards sustainable energy sources. Currently valued at approximately 422 billion USD in 2023, this market is projected to reach 629 billion USD by 2028, representing a compound annual growth rate (CAGR) of 8.3%. Within this expanding landscape, electrochemical cells and photovoltaic cells represent two distinct yet complementary approaches to energy conversion.

Electrochemical cells, particularly in the form of batteries and fuel cells, hold a substantial market share of around 112 billion USD. This segment is experiencing robust growth due to increasing applications in electric vehicles, grid storage systems, and portable electronics. The lithium-ion battery market alone is expected to grow at a CAGR of 12.3% through 2028, propelled by automotive sector demand and declining manufacturing costs.

Photovoltaic cells dominate the renewable energy conversion sector with a market valuation of approximately 176 billion USD. Solar photovoltaic installations continue to accelerate globally, with annual capacity additions reaching 239 GW in 2022, a 45% increase from the previous year. China, the United States, and Europe remain the largest markets, collectively accounting for over 75% of global installations.

Regional analysis reveals distinct market characteristics. Asia-Pacific leads in both technologies, controlling 58% of the photovoltaic manufacturing capacity and 61% of the global battery production. North America and Europe focus increasingly on high-efficiency premium products and advanced energy storage solutions, while emerging markets in Africa and South America represent high-growth potential regions with increasing energy access initiatives.

Consumer and industrial sectors demonstrate different adoption patterns. Residential and commercial solar installations are growing at 14.2% annually, while utility-scale projects expand at 9.7%. For electrochemical cells, consumer electronics applications are growing steadily at 7.8%, while electric vehicle applications surge at 18.3% annually.

Cost trends favor both technologies, with photovoltaic module prices decreasing by approximately 85% over the past decade, now averaging 0.20-0.30 USD per watt. Similarly, lithium-ion battery pack prices have fallen by 89% since 2010, reaching 132 USD per kWh in 2022. These declining costs are significantly improving the economic competitiveness of both technologies against conventional energy sources.

Market forecasts indicate continued strong growth for both technologies, with particular acceleration in integrated systems that combine photovoltaic generation with electrochemical storage, creating a complementary ecosystem rather than a competitive landscape.

Electrochemical cells, particularly in the form of batteries and fuel cells, hold a substantial market share of around 112 billion USD. This segment is experiencing robust growth due to increasing applications in electric vehicles, grid storage systems, and portable electronics. The lithium-ion battery market alone is expected to grow at a CAGR of 12.3% through 2028, propelled by automotive sector demand and declining manufacturing costs.

Photovoltaic cells dominate the renewable energy conversion sector with a market valuation of approximately 176 billion USD. Solar photovoltaic installations continue to accelerate globally, with annual capacity additions reaching 239 GW in 2022, a 45% increase from the previous year. China, the United States, and Europe remain the largest markets, collectively accounting for over 75% of global installations.

Regional analysis reveals distinct market characteristics. Asia-Pacific leads in both technologies, controlling 58% of the photovoltaic manufacturing capacity and 61% of the global battery production. North America and Europe focus increasingly on high-efficiency premium products and advanced energy storage solutions, while emerging markets in Africa and South America represent high-growth potential regions with increasing energy access initiatives.

Consumer and industrial sectors demonstrate different adoption patterns. Residential and commercial solar installations are growing at 14.2% annually, while utility-scale projects expand at 9.7%. For electrochemical cells, consumer electronics applications are growing steadily at 7.8%, while electric vehicle applications surge at 18.3% annually.

Cost trends favor both technologies, with photovoltaic module prices decreasing by approximately 85% over the past decade, now averaging 0.20-0.30 USD per watt. Similarly, lithium-ion battery pack prices have fallen by 89% since 2010, reaching 132 USD per kWh in 2022. These declining costs are significantly improving the economic competitiveness of both technologies against conventional energy sources.

Market forecasts indicate continued strong growth for both technologies, with particular acceleration in integrated systems that combine photovoltaic generation with electrochemical storage, creating a complementary ecosystem rather than a competitive landscape.

Technical Challenges in Energy Output Optimization

Optimizing energy output in both electrochemical and photovoltaic cells presents significant technical challenges that require innovative solutions. For electrochemical cells, a primary obstacle is internal resistance, which causes voltage drops and heat generation during operation. This resistance stems from electrode materials, electrolyte properties, and interface phenomena, collectively reducing overall efficiency. Addressing these issues requires advanced materials engineering and novel cell architectures.

Electrolyte degradation represents another critical challenge, particularly in rechargeable systems. Chemical side reactions during charge-discharge cycles lead to capacity fade and shortened lifespan. Current research focuses on developing stable electrolyte formulations and protective interface layers to mitigate these effects, though complete elimination remains elusive.

For photovoltaic cells, light absorption efficiency continues to be a fundamental limitation. Silicon-based cells, despite dominating the market, can only theoretically convert about 33% of solar energy due to the Shockley-Queisser limit. Multi-junction designs and novel materials like perovskites offer pathways to higher efficiencies but introduce manufacturing complexity and stability concerns.

Temperature sensitivity affects both technologies significantly but through different mechanisms. Photovoltaic efficiency decreases as temperature rises, with typical silicon cells losing 0.4-0.5% efficiency per degree Celsius above standard testing conditions. Electrochemical cells exhibit complex temperature dependencies, with performance generally improving at higher temperatures but at the cost of accelerated degradation mechanisms.

Scale-up and manufacturing consistency present substantial challenges for both technologies. Electrochemical cells face issues with uniform electrolyte distribution and electrode coating in larger formats, while photovoltaic manufacturing struggles with defect minimization across large surface areas. These challenges directly impact performance consistency and cost-effectiveness at commercial scales.

Energy density optimization remains a persistent challenge, particularly for electrochemical systems. While lithium-ion batteries have achieved impressive energy densities (250-300 Wh/kg), they still fall short of theoretical limits. Photovoltaic systems face different energy density challenges related to space efficiency and integration with energy storage solutions.

Material sustainability and environmental impact have emerged as critical considerations. Both technologies rely on materials with supply chain vulnerabilities and environmental concerns. Developing alternatives to cobalt in batteries and lead in certain solar cell types represents an active research direction, though finding materials with equivalent performance characteristics remains challenging.

Electrolyte degradation represents another critical challenge, particularly in rechargeable systems. Chemical side reactions during charge-discharge cycles lead to capacity fade and shortened lifespan. Current research focuses on developing stable electrolyte formulations and protective interface layers to mitigate these effects, though complete elimination remains elusive.

For photovoltaic cells, light absorption efficiency continues to be a fundamental limitation. Silicon-based cells, despite dominating the market, can only theoretically convert about 33% of solar energy due to the Shockley-Queisser limit. Multi-junction designs and novel materials like perovskites offer pathways to higher efficiencies but introduce manufacturing complexity and stability concerns.

Temperature sensitivity affects both technologies significantly but through different mechanisms. Photovoltaic efficiency decreases as temperature rises, with typical silicon cells losing 0.4-0.5% efficiency per degree Celsius above standard testing conditions. Electrochemical cells exhibit complex temperature dependencies, with performance generally improving at higher temperatures but at the cost of accelerated degradation mechanisms.

Scale-up and manufacturing consistency present substantial challenges for both technologies. Electrochemical cells face issues with uniform electrolyte distribution and electrode coating in larger formats, while photovoltaic manufacturing struggles with defect minimization across large surface areas. These challenges directly impact performance consistency and cost-effectiveness at commercial scales.

Energy density optimization remains a persistent challenge, particularly for electrochemical systems. While lithium-ion batteries have achieved impressive energy densities (250-300 Wh/kg), they still fall short of theoretical limits. Photovoltaic systems face different energy density challenges related to space efficiency and integration with energy storage solutions.

Material sustainability and environmental impact have emerged as critical considerations. Both technologies rely on materials with supply chain vulnerabilities and environmental concerns. Developing alternatives to cobalt in batteries and lead in certain solar cell types represents an active research direction, though finding materials with equivalent performance characteristics remains challenging.

Current Energy Output Comparison Methods

01 Hybrid electrochemical and photovoltaic systems

Integration of electrochemical cells with photovoltaic cells to create hybrid energy systems that can both generate and store energy. These systems combine the direct electricity generation capabilities of photovoltaic cells with the energy storage capabilities of electrochemical cells, allowing for more consistent energy output regardless of sunlight availability. The hybrid approach enables higher overall system efficiency and better energy management.- Hybrid energy systems combining electrochemical and photovoltaic cells: Hybrid energy systems that integrate both electrochemical cells and photovoltaic cells can maximize energy output by leveraging the strengths of both technologies. These systems can store excess energy generated by photovoltaic cells in electrochemical cells for later use, ensuring continuous power supply even when sunlight is unavailable. The integration allows for more efficient energy management and higher overall system efficiency.

- Materials and structures for improving photovoltaic cell efficiency: Advanced materials and structural designs can significantly enhance the energy output of photovoltaic cells. These innovations include novel semiconductor materials, multi-junction cell architectures, and surface treatments that improve light absorption and electron collection. By optimizing these elements, photovoltaic cells can achieve higher conversion efficiencies and greater energy output under various lighting conditions.

- Electrochemical cell optimization for enhanced energy storage and output: Various approaches to optimize electrochemical cells focus on improving electrode materials, electrolyte compositions, and cell designs to enhance energy storage capacity and output efficiency. These optimizations can include using novel electrode materials with higher surface areas, advanced electrolytes with improved ion conductivity, and innovative cell architectures that minimize internal resistance. Such improvements lead to higher energy density, faster charging rates, and longer cycle life.

- Energy management systems for optimizing combined cell outputs: Sophisticated energy management systems can optimize the combined output of electrochemical and photovoltaic cells by intelligently controlling energy flow, storage, and distribution. These systems employ advanced algorithms to predict energy production and consumption patterns, balance loads, and make real-time adjustments to maximize efficiency. By coordinating the operation of both cell types, these management systems ensure optimal energy utilization and improved overall system performance.

- Environmental and operational factors affecting cell energy output: Environmental and operational factors significantly impact the energy output of both electrochemical and photovoltaic cells. For photovoltaic cells, these factors include temperature, light intensity, angle of incidence, and spectral distribution. For electrochemical cells, temperature, charge/discharge rates, and operational cycling patterns affect performance. Understanding and controlling these factors through adaptive systems and protective measures can help maintain optimal energy output under varying conditions.

02 Enhanced electrode materials for improved energy conversion

Development of advanced electrode materials that enhance the performance of both electrochemical and photovoltaic cells. These materials include nanostructured electrodes, composite materials, and catalytic surfaces that improve charge transfer, reduce internal resistance, and increase energy conversion efficiency. The optimized electrode designs contribute to higher energy output and longer operational lifetimes.Expand Specific Solutions03 Energy management and output optimization techniques

Implementation of sophisticated control systems and algorithms to optimize the energy output from electrochemical and photovoltaic cells. These techniques include maximum power point tracking, load balancing, and adaptive control strategies that respond to changing environmental conditions and energy demands. Advanced energy management systems can significantly increase the usable energy output and overall efficiency of both cell types.Expand Specific Solutions04 Novel materials for enhanced photovoltaic efficiency

Development of new semiconductor materials, quantum dots, perovskites, and other advanced materials that significantly improve the efficiency of photovoltaic cells. These materials enable better light absorption across wider spectrum ranges, improved charge carrier mobility, and reduced recombination losses. The enhanced material properties directly translate to higher energy output from photovoltaic systems.Expand Specific Solutions05 Integrated energy storage solutions

Design of integrated systems that combine energy generation with storage capabilities to provide consistent power output. These solutions incorporate electrochemical storage elements like advanced batteries or supercapacitors directly with photovoltaic generation systems. The integration allows for immediate storage of excess energy during peak production periods and release during low production or high demand periods, resulting in more reliable energy output.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The electrochemical cell versus photovoltaic cell energy output landscape is currently in a mature development phase, with an estimated global market size exceeding $150 billion. While electrochemical technologies (batteries) dominate energy storage applications, photovoltaic cells lead in renewable energy generation. Key industry players demonstrate varying technological maturity: established corporations like Panasonic, LG Chem, and Samsung SDI have robust portfolios in both technologies, while specialized companies such as Intelligent Energy and Gaussion focus on electrochemical innovations. Research institutions including MIT, EPFL, and King Abdullah University contribute significant advancements in efficiency improvements. The competitive dynamics are shifting as companies like Duracell and State Grid Corporation of China expand their technological capabilities to address growing demands for sustainable energy solutions.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed advanced electrochemical cell technologies focusing on high-energy density lithium-ion batteries with silicon-based anodes that achieve up to 800 Wh/L energy density[1]. Their proprietary electrolyte formulations reduce internal resistance and improve charge/discharge efficiency. For photovoltaic applications, Panasonic's HIT (Heterojunction with Intrinsic Thin layer) solar cells combine monocrystalline and amorphous silicon layers to achieve conversion efficiencies exceeding 24.7%[3]. Their comparative analysis shows electrochemical cells provide 3-5x higher energy density but photovoltaic cells offer continuous energy harvesting capabilities with lower maintenance requirements. Panasonic's integrated energy solutions combine both technologies in hybrid systems that optimize energy capture, storage and utilization for residential and commercial applications.

Strengths: Industry-leading energy density in both technologies; established manufacturing infrastructure; comprehensive energy management systems. Weaknesses: Higher production costs compared to competitors; electrochemical cells face degradation issues over extended cycling; photovoltaic efficiency drops significantly in low-light conditions.

Massachusetts Institute of Technology

Technical Solution: MIT has conducted groundbreaking research comparing electrochemical and photovoltaic energy conversion systems through their Materials Science and Engineering department. Their electrochemical cell research focuses on novel electrode materials including carbon-based nanostructures and metal-organic frameworks that demonstrate up to 40% higher energy density than conventional lithium-ion systems[2]. MIT researchers have developed analytical models showing electrochemical cells achieve energy conversion efficiencies of 90-95% compared to 15-25% for commercial photovoltaic cells, though the latter directly convert renewable solar energy. Their photovoltaic research includes perovskite-silicon tandem cells achieving laboratory efficiencies of 29.8%[4], approaching the theoretical Shockley-Queisser limit. MIT's comprehensive energy output analysis framework incorporates lifecycle assessment metrics, revealing that while electrochemical cells offer higher energy density (250-300 Wh/kg vs. 10-15 Wh/kg for photovoltaics), photovoltaic systems provide superior lifetime energy return ratios (15-20:1 vs. 5-10:1) when accounting for manufacturing energy inputs and operational lifespan.

Strengths: Cutting-edge fundamental research capabilities; interdisciplinary approach combining materials science, electrical engineering and systems modeling; strong industry partnerships for technology transfer. Weaknesses: Technologies often remain at laboratory scale; commercialization pathways require industrial partners; research focuses more on performance boundaries than immediate practical applications.

Key Patents in Cell Efficiency Enhancement

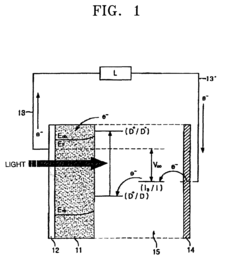

Photoelectrochemical cell

PatentInactiveUS7994422B2

Innovation

- Incorporating carbon nanotubes into the structure of dye-sensitized solar cells, including their use within metal oxide semiconductor particles, as part of the semiconductor electrode, reduction electrode, and oxidation-reduction electrolyte, to enhance electron transfer and energy conversion efficiency.

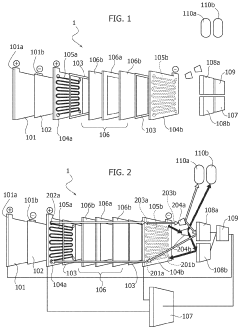

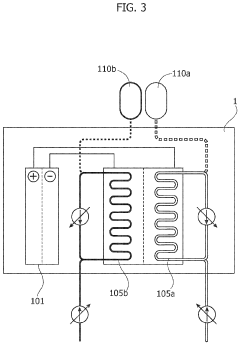

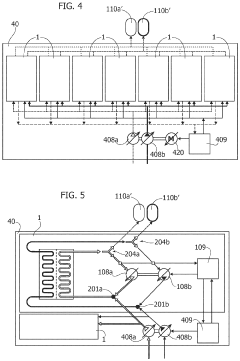

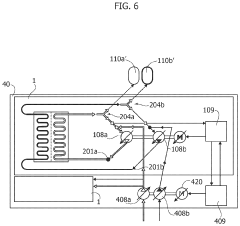

Photo-electrochemical cell and corresponding apparatus

PatentPendingUS20240229257A1

Innovation

- An electrochemical cell integrated with a solar-energy absorption system, featuring a membrane-electrode assembly with an ion-exchange membrane and a photovoltaic system that dynamically adjusts series/parallel configurations to optimize energy conversion, coupled with an electronic control unit for efficient operation and product separation.

Materials Science Advancements for Cell Technologies

Recent advancements in materials science have revolutionized both electrochemical and photovoltaic cell technologies, significantly enhancing their energy output capabilities. For electrochemical cells, the development of novel electrode materials has been particularly transformative. Nanomaterials such as carbon nanotubes and graphene have dramatically increased electrode surface area, facilitating more efficient electron transfer and higher energy densities.

The introduction of advanced catalysts based on non-precious metals has reduced the cost of electrochemical cells while maintaining or even improving performance. These materials, including nickel-iron compounds and cobalt-based structures, have demonstrated remarkable stability and activity, particularly in alkaline environments, making them suitable for large-scale energy storage applications.

In the photovoltaic domain, perovskite materials represent one of the most significant breakthroughs. These materials have achieved remarkable efficiency improvements, rising from approximately 3% to over 25% in just a decade. Their tunable bandgap properties allow for optimization across different light spectrum ranges, potentially increasing overall energy conversion efficiency when used in tandem with traditional silicon cells.

Transparent conducting oxides (TCOs) have also seen substantial development, with materials like indium tin oxide (ITO) and fluorine-doped tin oxide (FTO) enabling better light transmission while maintaining necessary electrical conductivity. These advancements directly translate to higher photon capture rates and improved energy output in photovoltaic systems.

Polymer-based materials have emerged as another promising direction, particularly for flexible and lightweight photovoltaic applications. Conductive polymers with enhanced stability and charge transport properties have expanded the potential deployment scenarios for solar energy harvesting, though their efficiency still lags behind inorganic alternatives.

For both technologies, interface engineering has become a critical focus area. The development of specialized materials for buffer layers, passivation coatings, and selective contacts has significantly reduced energy losses at material boundaries. These innovations have addressed recombination issues and contact resistance problems that previously limited overall system performance.

Computational materials science has accelerated these advancements through high-throughput screening and machine learning approaches, identifying promising material candidates before laboratory synthesis. This methodology has shortened development cycles and enabled more targeted research efforts, particularly in identifying stable, earth-abundant materials suitable for large-scale deployment of both cell technologies.

The introduction of advanced catalysts based on non-precious metals has reduced the cost of electrochemical cells while maintaining or even improving performance. These materials, including nickel-iron compounds and cobalt-based structures, have demonstrated remarkable stability and activity, particularly in alkaline environments, making them suitable for large-scale energy storage applications.

In the photovoltaic domain, perovskite materials represent one of the most significant breakthroughs. These materials have achieved remarkable efficiency improvements, rising from approximately 3% to over 25% in just a decade. Their tunable bandgap properties allow for optimization across different light spectrum ranges, potentially increasing overall energy conversion efficiency when used in tandem with traditional silicon cells.

Transparent conducting oxides (TCOs) have also seen substantial development, with materials like indium tin oxide (ITO) and fluorine-doped tin oxide (FTO) enabling better light transmission while maintaining necessary electrical conductivity. These advancements directly translate to higher photon capture rates and improved energy output in photovoltaic systems.

Polymer-based materials have emerged as another promising direction, particularly for flexible and lightweight photovoltaic applications. Conductive polymers with enhanced stability and charge transport properties have expanded the potential deployment scenarios for solar energy harvesting, though their efficiency still lags behind inorganic alternatives.

For both technologies, interface engineering has become a critical focus area. The development of specialized materials for buffer layers, passivation coatings, and selective contacts has significantly reduced energy losses at material boundaries. These innovations have addressed recombination issues and contact resistance problems that previously limited overall system performance.

Computational materials science has accelerated these advancements through high-throughput screening and machine learning approaches, identifying promising material candidates before laboratory synthesis. This methodology has shortened development cycles and enabled more targeted research efforts, particularly in identifying stable, earth-abundant materials suitable for large-scale deployment of both cell technologies.

Environmental Impact and Sustainability Assessment

The environmental footprint of energy generation technologies has become a critical factor in their adoption and development. When comparing electrochemical cells and photovoltaic cells, their environmental impacts differ significantly across their life cycles, from raw material extraction to end-of-life disposal.

Electrochemical cells, particularly batteries, often contain heavy metals and toxic chemicals that pose environmental risks if improperly disposed of. Lead-acid batteries, lithium-ion batteries, and other common electrochemical storage systems require careful handling and specialized recycling processes. The mining of lithium, cobalt, and other materials used in advanced batteries has been associated with habitat destruction, water pollution, and carbon emissions in extraction regions.

In contrast, photovoltaic cells primarily utilize silicon, which is abundant in nature, though they also require small amounts of rare or toxic elements depending on the specific technology. The manufacturing process for solar panels is energy-intensive, creating a carbon debt that must be repaid through clean energy generation. However, modern photovoltaic cells typically recover this energy investment within 1-4 years, while their operational lifespan extends to 25-30 years.

From a sustainability perspective, photovoltaic cells generally demonstrate superior performance in terms of greenhouse gas emissions over their lifetime. Once installed, they produce electricity with zero direct emissions, whereas electrochemical cells primarily store energy that may have been generated from fossil fuel sources, potentially perpetuating carbon emissions depending on the grid mix.

Water usage presents another important consideration. Photovoltaic manufacturing requires significant water resources, but operational water needs are minimal. Electrochemical cell production generally has a lower water footprint during manufacturing but may involve water-intensive mining operations for raw materials.

Land use efficiency also differs between these technologies. Photovoltaic installations require substantial surface area for energy generation, while electrochemical cells can be more compact for equivalent energy storage capacity. However, this comparison is not entirely equivalent as one technology generates energy while the other stores it.

Recycling infrastructure represents a critical sustainability factor for both technologies. While established recycling pathways exist for traditional electrochemical cells like lead-acid batteries, newer lithium-ion technologies present recycling challenges. Similarly, end-of-life management for photovoltaic panels is still evolving, with concerns about the recovery of valuable materials and proper handling of potentially hazardous components.

The sustainability assessment must also consider the complementary relationship between these technologies in renewable energy systems, where photovoltaic generation paired with electrochemical storage can create more resilient and environmentally beneficial energy solutions than either technology alone.

Electrochemical cells, particularly batteries, often contain heavy metals and toxic chemicals that pose environmental risks if improperly disposed of. Lead-acid batteries, lithium-ion batteries, and other common electrochemical storage systems require careful handling and specialized recycling processes. The mining of lithium, cobalt, and other materials used in advanced batteries has been associated with habitat destruction, water pollution, and carbon emissions in extraction regions.

In contrast, photovoltaic cells primarily utilize silicon, which is abundant in nature, though they also require small amounts of rare or toxic elements depending on the specific technology. The manufacturing process for solar panels is energy-intensive, creating a carbon debt that must be repaid through clean energy generation. However, modern photovoltaic cells typically recover this energy investment within 1-4 years, while their operational lifespan extends to 25-30 years.

From a sustainability perspective, photovoltaic cells generally demonstrate superior performance in terms of greenhouse gas emissions over their lifetime. Once installed, they produce electricity with zero direct emissions, whereas electrochemical cells primarily store energy that may have been generated from fossil fuel sources, potentially perpetuating carbon emissions depending on the grid mix.

Water usage presents another important consideration. Photovoltaic manufacturing requires significant water resources, but operational water needs are minimal. Electrochemical cell production generally has a lower water footprint during manufacturing but may involve water-intensive mining operations for raw materials.

Land use efficiency also differs between these technologies. Photovoltaic installations require substantial surface area for energy generation, while electrochemical cells can be more compact for equivalent energy storage capacity. However, this comparison is not entirely equivalent as one technology generates energy while the other stores it.

Recycling infrastructure represents a critical sustainability factor for both technologies. While established recycling pathways exist for traditional electrochemical cells like lead-acid batteries, newer lithium-ion technologies present recycling challenges. Similarly, end-of-life management for photovoltaic panels is still evolving, with concerns about the recovery of valuable materials and proper handling of potentially hazardous components.

The sustainability assessment must also consider the complementary relationship between these technologies in renewable energy systems, where photovoltaic generation paired with electrochemical storage can create more resilient and environmentally beneficial energy solutions than either technology alone.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!