Electrochemical Cell Efficiency in High-Temperature Applications

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Cell Technology Evolution and Objectives

Electrochemical cells have undergone significant evolution since their inception in the late 18th century with Alessandro Volta's pioneering work. The trajectory of development has been marked by continuous improvements in materials, design configurations, and operational parameters. Early electrochemical cells were primarily focused on basic energy generation, while modern iterations have expanded into diverse applications including energy storage, conversion, and specialized industrial processes under extreme conditions.

High-temperature electrochemical cells represent a specialized branch that has gained prominence over the past four decades. These systems operate at temperatures exceeding 500°C, enabling unique reaction kinetics and thermodynamic advantages that conventional low-temperature cells cannot achieve. The historical development of these high-temperature systems can be traced through several key technological waves, beginning with solid oxide fuel cells (SOFCs) in the 1970s, followed by molten carbonate fuel cells (MCFCs), and more recently, advanced ceramic-based systems designed specifically for extreme thermal environments.

The primary technical objective in high-temperature electrochemical cell development centers on maximizing efficiency while maintaining operational stability. Current research aims to achieve electrical efficiency exceeding 70% in combined heat and power applications, representing a significant improvement over the 45-60% range commonly observed in today's commercial systems. Additionally, there is a focused effort to extend operational lifespans beyond 80,000 hours while maintaining performance degradation rates below 0.25% per 1,000 hours of operation.

Material science advancements have been instrumental in pushing the boundaries of what's possible in high-temperature electrochemical applications. The evolution from traditional ceramic electrolytes to advanced composite structures incorporating nanomaterials has enabled significant improvements in ionic conductivity and thermal stability. Concurrently, electrode materials have progressed from simple metal-based structures to sophisticated multi-functional catalytic surfaces that can withstand thermal cycling while maintaining electrochemical performance.

Looking forward, the technological roadmap for high-temperature electrochemical cells is focused on several critical objectives: reducing system costs to below $1,000/kW for commercial viability, developing materials capable of withstanding temperatures up to 1000°C with minimal degradation, achieving start-up times under 30 minutes for greater operational flexibility, and integrating advanced manufacturing techniques such as 3D printing and atomic layer deposition to create previously impossible cell architectures with optimized mass transport properties.

The convergence of computational modeling, advanced materials science, and precision manufacturing techniques is expected to drive the next generation of breakthroughs in this field, potentially enabling applications in sectors ranging from distributed power generation to carbon capture and chemical synthesis under extreme conditions.

High-temperature electrochemical cells represent a specialized branch that has gained prominence over the past four decades. These systems operate at temperatures exceeding 500°C, enabling unique reaction kinetics and thermodynamic advantages that conventional low-temperature cells cannot achieve. The historical development of these high-temperature systems can be traced through several key technological waves, beginning with solid oxide fuel cells (SOFCs) in the 1970s, followed by molten carbonate fuel cells (MCFCs), and more recently, advanced ceramic-based systems designed specifically for extreme thermal environments.

The primary technical objective in high-temperature electrochemical cell development centers on maximizing efficiency while maintaining operational stability. Current research aims to achieve electrical efficiency exceeding 70% in combined heat and power applications, representing a significant improvement over the 45-60% range commonly observed in today's commercial systems. Additionally, there is a focused effort to extend operational lifespans beyond 80,000 hours while maintaining performance degradation rates below 0.25% per 1,000 hours of operation.

Material science advancements have been instrumental in pushing the boundaries of what's possible in high-temperature electrochemical applications. The evolution from traditional ceramic electrolytes to advanced composite structures incorporating nanomaterials has enabled significant improvements in ionic conductivity and thermal stability. Concurrently, electrode materials have progressed from simple metal-based structures to sophisticated multi-functional catalytic surfaces that can withstand thermal cycling while maintaining electrochemical performance.

Looking forward, the technological roadmap for high-temperature electrochemical cells is focused on several critical objectives: reducing system costs to below $1,000/kW for commercial viability, developing materials capable of withstanding temperatures up to 1000°C with minimal degradation, achieving start-up times under 30 minutes for greater operational flexibility, and integrating advanced manufacturing techniques such as 3D printing and atomic layer deposition to create previously impossible cell architectures with optimized mass transport properties.

The convergence of computational modeling, advanced materials science, and precision manufacturing techniques is expected to drive the next generation of breakthroughs in this field, potentially enabling applications in sectors ranging from distributed power generation to carbon capture and chemical synthesis under extreme conditions.

Market Analysis for High-Temperature Electrochemical Applications

The high-temperature electrochemical cell market is experiencing significant growth, driven primarily by increasing demand for clean energy solutions and industrial applications requiring efficient high-temperature operations. The global market for high-temperature electrochemical technologies was valued at approximately $4.2 billion in 2022 and is projected to reach $7.8 billion by 2028, representing a compound annual growth rate of 10.8%.

Solid oxide fuel cells (SOFCs) constitute the largest segment within this market, accounting for nearly 45% of the total market share. These cells operate at temperatures between 600-1000°C and find extensive applications in stationary power generation, distributed energy systems, and combined heat and power (CHP) units. The SOFC market alone is expected to grow at 12.3% annually through 2030, outpacing other electrochemical technologies.

Molten carbonate fuel cells (MCFCs) represent another significant segment, operating at temperatures around 650°C and particularly valued for their fuel flexibility and carbon capture capabilities. This segment currently holds approximately 20% of the market share and is gaining traction in industrial and utility-scale applications.

Geographically, Asia-Pacific dominates the market with 38% share, led by significant investments in Japan, South Korea, and China. North America follows at 32%, with Europe accounting for 25% of the global market. The remaining 5% is distributed across other regions, with notable growth observed in Middle Eastern countries investing in alternative energy technologies.

Key industry verticals driving demand include power generation (36%), industrial processing (28%), transportation (18%), and military applications (12%), with the remaining 6% distributed across various niche applications. The power generation sector's dominance is attributed to increasing focus on distributed generation systems and grid resilience.

Customer requirements are evolving toward higher efficiency, longer operational lifetimes, and reduced manufacturing costs. Current market demands indicate a preference for systems achieving at least 60% electrical efficiency, operational lifetimes exceeding 40,000 hours, and capital costs below $2,000/kW for widespread commercial adoption.

Market barriers include high initial capital costs, limited awareness of high-temperature electrochemical technologies, and competition from established conventional technologies. However, these barriers are gradually diminishing as technological advancements reduce costs and environmental regulations favor cleaner energy solutions.

The market is increasingly influenced by sustainability considerations, with customers prioritizing technologies that offer reduced carbon footprints, higher resource efficiency, and compatibility with renewable energy sources. This trend is expected to accelerate market growth for high-temperature electrochemical applications that demonstrate superior environmental performance metrics.

Solid oxide fuel cells (SOFCs) constitute the largest segment within this market, accounting for nearly 45% of the total market share. These cells operate at temperatures between 600-1000°C and find extensive applications in stationary power generation, distributed energy systems, and combined heat and power (CHP) units. The SOFC market alone is expected to grow at 12.3% annually through 2030, outpacing other electrochemical technologies.

Molten carbonate fuel cells (MCFCs) represent another significant segment, operating at temperatures around 650°C and particularly valued for their fuel flexibility and carbon capture capabilities. This segment currently holds approximately 20% of the market share and is gaining traction in industrial and utility-scale applications.

Geographically, Asia-Pacific dominates the market with 38% share, led by significant investments in Japan, South Korea, and China. North America follows at 32%, with Europe accounting for 25% of the global market. The remaining 5% is distributed across other regions, with notable growth observed in Middle Eastern countries investing in alternative energy technologies.

Key industry verticals driving demand include power generation (36%), industrial processing (28%), transportation (18%), and military applications (12%), with the remaining 6% distributed across various niche applications. The power generation sector's dominance is attributed to increasing focus on distributed generation systems and grid resilience.

Customer requirements are evolving toward higher efficiency, longer operational lifetimes, and reduced manufacturing costs. Current market demands indicate a preference for systems achieving at least 60% electrical efficiency, operational lifetimes exceeding 40,000 hours, and capital costs below $2,000/kW for widespread commercial adoption.

Market barriers include high initial capital costs, limited awareness of high-temperature electrochemical technologies, and competition from established conventional technologies. However, these barriers are gradually diminishing as technological advancements reduce costs and environmental regulations favor cleaner energy solutions.

The market is increasingly influenced by sustainability considerations, with customers prioritizing technologies that offer reduced carbon footprints, higher resource efficiency, and compatibility with renewable energy sources. This trend is expected to accelerate market growth for high-temperature electrochemical applications that demonstrate superior environmental performance metrics.

Current Challenges in High-Temperature Cell Performance

Despite significant advancements in electrochemical cell technology, high-temperature applications continue to present formidable challenges that limit overall system efficiency and commercial viability. The primary obstacle remains material degradation under extreme thermal conditions, with electrode materials suffering accelerated corrosion, delamination, and microstructural changes that dramatically reduce cell lifespan. Current state-of-the-art ceramic and metal-ceramic composite electrodes still demonstrate performance decay after 1,000-2,000 hours of operation at temperatures exceeding 800°C.

Electrolyte stability represents another critical challenge, as conventional liquid electrolytes experience rapid decomposition and increased volatility at elevated temperatures. While solid-state and ceramic electrolytes offer improved thermal stability, they typically exhibit lower ionic conductivity, creating an inherent performance trade-off. Recent research indicates that even advanced ceramic electrolytes like yttria-stabilized zirconia (YSZ) experience conductivity degradation of approximately 15-20% after extended high-temperature cycling.

Interfacial resistance emerges as a significant barrier to efficiency, particularly at the electrode-electrolyte boundaries. Thermal expansion coefficient mismatches between cell components lead to mechanical stress during thermal cycling, creating microcracks and delamination that increase internal resistance. Current interface engineering approaches have reduced but not eliminated this issue, with interfacial resistance still accounting for 30-40% of total cell resistance in many high-temperature systems.

Sealing and containment technologies present persistent engineering challenges, as traditional glass-ceramic seals deteriorate under thermal cycling conditions. Hermetic sealing failures not only compromise system integrity but also accelerate degradation through unwanted reactions with environmental contaminants. The latest compressive sealing systems show improved performance but still limit operational flexibility and increase system complexity.

Heat management inefficiencies further compound these challenges, with thermal gradients across cell components causing localized hotspots that accelerate degradation. Current thermal management systems add significant weight, volume, and parasitic energy losses to the overall system. Computational models suggest that up to 25% of energy input may be lost to inefficient thermal management in some high-temperature electrochemical systems.

Manufacturing scalability remains problematic, with precise control of material properties and component geometries becoming increasingly difficult at commercial production scales. The complex interdependence of material properties, processing parameters, and performance metrics creates significant barriers to consistent mass production, with rejection rates for high-performance cells often exceeding 30% in production environments.

Electrolyte stability represents another critical challenge, as conventional liquid electrolytes experience rapid decomposition and increased volatility at elevated temperatures. While solid-state and ceramic electrolytes offer improved thermal stability, they typically exhibit lower ionic conductivity, creating an inherent performance trade-off. Recent research indicates that even advanced ceramic electrolytes like yttria-stabilized zirconia (YSZ) experience conductivity degradation of approximately 15-20% after extended high-temperature cycling.

Interfacial resistance emerges as a significant barrier to efficiency, particularly at the electrode-electrolyte boundaries. Thermal expansion coefficient mismatches between cell components lead to mechanical stress during thermal cycling, creating microcracks and delamination that increase internal resistance. Current interface engineering approaches have reduced but not eliminated this issue, with interfacial resistance still accounting for 30-40% of total cell resistance in many high-temperature systems.

Sealing and containment technologies present persistent engineering challenges, as traditional glass-ceramic seals deteriorate under thermal cycling conditions. Hermetic sealing failures not only compromise system integrity but also accelerate degradation through unwanted reactions with environmental contaminants. The latest compressive sealing systems show improved performance but still limit operational flexibility and increase system complexity.

Heat management inefficiencies further compound these challenges, with thermal gradients across cell components causing localized hotspots that accelerate degradation. Current thermal management systems add significant weight, volume, and parasitic energy losses to the overall system. Computational models suggest that up to 25% of energy input may be lost to inefficient thermal management in some high-temperature electrochemical systems.

Manufacturing scalability remains problematic, with precise control of material properties and component geometries becoming increasingly difficult at commercial production scales. The complex interdependence of material properties, processing parameters, and performance metrics creates significant barriers to consistent mass production, with rejection rates for high-performance cells often exceeding 30% in production environments.

Existing Approaches to Thermal Stability Enhancement

01 Electrode materials and catalysts for improved efficiency

The choice of electrode materials and catalysts significantly impacts electrochemical cell efficiency. Advanced materials like platinum alloys, carbon-supported catalysts, and novel metal oxides can reduce activation energy, increase reaction rates, and improve overall cell performance. These materials enhance electron transfer processes and minimize energy losses during electrochemical reactions, leading to higher conversion efficiencies and extended operational lifetimes.- Electrode materials and catalysts for improved efficiency: Advanced electrode materials and catalysts can significantly enhance the efficiency of electrochemical cells. These materials can reduce activation energy, increase reaction rates, and improve electron transfer at the electrode-electrolyte interface. Novel catalysts, including nanostructured materials and metal alloys, can lower overpotential and increase current density, leading to higher overall cell efficiency and performance.

- Electrolyte composition and optimization: The composition and properties of the electrolyte play a crucial role in electrochemical cell efficiency. Optimized electrolytes can enhance ionic conductivity, reduce internal resistance, and improve mass transport within the cell. Additives and specialized formulations can prevent side reactions, minimize electrode degradation, and extend cell lifespan, contributing to sustained high efficiency over multiple charge-discharge cycles.

- Cell design and structural improvements: Innovative cell designs and structural modifications can optimize electrochemical efficiency. This includes improvements in cell geometry, electrode spacing, and flow field designs that enhance mass transport and reduce concentration polarization. Advanced manufacturing techniques allow for precise control of component dimensions and interfaces, minimizing contact resistance and improving overall energy conversion efficiency.

- Temperature management and control systems: Effective temperature management is essential for maintaining optimal electrochemical cell efficiency. Systems that regulate operating temperature can prevent efficiency losses due to increased internal resistance at extreme temperatures. Thermal management solutions include active cooling systems, phase change materials, and insulation designs that maintain cells within their ideal operating temperature range, ensuring consistent performance and prolonged cell life.

- Monitoring and control algorithms for efficiency optimization: Advanced monitoring systems and control algorithms can dynamically optimize electrochemical cell efficiency during operation. These systems use real-time data from sensors to adjust operating parameters such as current density, flow rates, and temperature. Machine learning algorithms can predict performance degradation and implement preventive measures, while sophisticated battery management systems can balance cell performance in multi-cell configurations to maximize overall system efficiency.

02 Electrolyte composition and optimization

The composition and properties of electrolytes play a crucial role in electrochemical cell efficiency. Optimized electrolyte formulations can enhance ionic conductivity, reduce internal resistance, and improve mass transport within the cell. Additives and specialized compounds can stabilize the electrolyte-electrode interface, prevent unwanted side reactions, and extend the operational temperature range of the cell, resulting in more efficient and stable electrochemical performance.Expand Specific Solutions03 Cell design and structural innovations

Innovative cell designs and structural modifications can significantly enhance electrochemical efficiency. This includes optimizing cell geometry, electrode spacing, flow patterns, and membrane configurations to reduce internal resistance and improve mass transport. Advanced manufacturing techniques enable the creation of more precise and effective cell structures, while modular designs allow for better heat management and more efficient operation under varying load conditions.Expand Specific Solutions04 Temperature and pressure control systems

Effective management of temperature and pressure conditions is essential for maximizing electrochemical cell efficiency. Advanced control systems can maintain optimal operating conditions, prevent degradation of cell components, and ensure consistent performance. Thermal management solutions help dissipate heat generated during operation, while pressure regulation systems optimize reaction kinetics and prevent mechanical stress on cell components, leading to improved efficiency and extended service life.Expand Specific Solutions05 Monitoring and control algorithms

Sophisticated monitoring systems and control algorithms enable real-time optimization of electrochemical cell performance. These systems track key parameters such as voltage, current, temperature, and reactant concentrations to identify inefficiencies and adjust operating conditions accordingly. Machine learning and predictive analytics can anticipate performance degradation and implement preventive measures, while advanced control strategies balance efficiency with durability to maximize overall system performance and energy conversion efficiency.Expand Specific Solutions

Industry Leaders in High-Temperature Electrochemical Solutions

The electrochemical cell efficiency market for high-temperature applications is currently in a growth phase, with increasing demand driven by renewable energy storage needs and industrial applications. The global market size is estimated to reach $15-20 billion by 2025, with a CAGR of approximately 8-10%. Leading players demonstrate varying levels of technological maturity: established manufacturers like BYD, Ningde Amperex Technology, and Saft Groupe have commercialized solutions, while research institutions such as MIT, Caltech, and Northwestern University are developing next-generation technologies. Emerging companies like JTEC Energy and 24M Technologies are introducing innovative approaches to high-temperature electrochemical systems, focusing on improved efficiency and durability. Research collaborations between industry leaders and academic institutions are accelerating technological advancement in this competitive landscape.

Ningde Amperex Technology Ltd.

Technical Solution: CATL (Ningde Amperex Technology) has developed advanced high-temperature electrochemical cell technology utilizing nickel-rich cathode materials combined with silicon-carbon composite anodes. Their solution incorporates specialized electrolyte formulations with flame-retardant additives and high thermal stability solvents that maintain performance at elevated temperatures (up to 60°C continuous operation). The cells feature a multi-layer ceramic-polymer composite separator with thermal shutdown properties and a proprietary thermal management system using phase change materials integrated directly into cell packaging. This comprehensive approach allows their cells to maintain over 80% capacity retention after 1000 cycles at high temperatures, significantly outperforming conventional lithium-ion batteries in extreme thermal environments.

Strengths: Superior thermal stability with minimal capacity degradation at high temperatures; excellent safety profile with multiple redundant protection mechanisms; high energy density maintained across wide temperature range. Weaknesses: Higher production costs compared to standard cells; slightly lower initial energy density due to thermal management components; requires specialized manufacturing processes.

JTEC Energy, Inc.

Technical Solution: JTEC Energy has pioneered a revolutionary approach to high-temperature electrochemical cells through their Johnson Thermo-Electrochemical Converter (JTEC) technology. This system operates as a solid-state heat engine that converts thermal energy directly into electricity without combustion. The JTEC utilizes specialized proton-conducting membrane electrochemical cells arranged in a thermally regenerative configuration that can operate efficiently at temperatures between 200-600°C. The technology employs proprietary ceramic-metallic (cermet) electrodes with nanostructured catalysts that remain stable at high temperatures while facilitating rapid proton transport. Their system achieves theoretical efficiencies approaching 40% of Carnot efficiency, significantly higher than conventional thermoelectric generators. JTEC's cells incorporate temperature-resistant sealing materials and interconnects that maintain integrity during thermal cycling, addressing one of the key challenges in high-temperature electrochemical applications.

Strengths: Exceptional thermal-to-electrical conversion efficiency; solid-state operation with no moving parts increases reliability; can utilize waste heat from various industrial processes. Weaknesses: Complex manufacturing requirements for specialized membrane materials; higher initial capital costs compared to some competing technologies; requires careful thermal management to maintain optimal temperature gradients.

Critical Patents in Heat-Resistant Electrode Materials

High-temperature electrochemical cell and battery

PatentInactiveUS20070054188A1

Innovation

- Development of rechargeable lithium-sulfur electrochemical cells with a sulfur-containing cathode, a lithium anode, and a non-aqueous electrolyte comprising lithium salts and higher glymes, along with a flexible metal oxide separator, capable of operating above 80°C, which enhances sulfur utilization and cycle life without mechanical cooling.

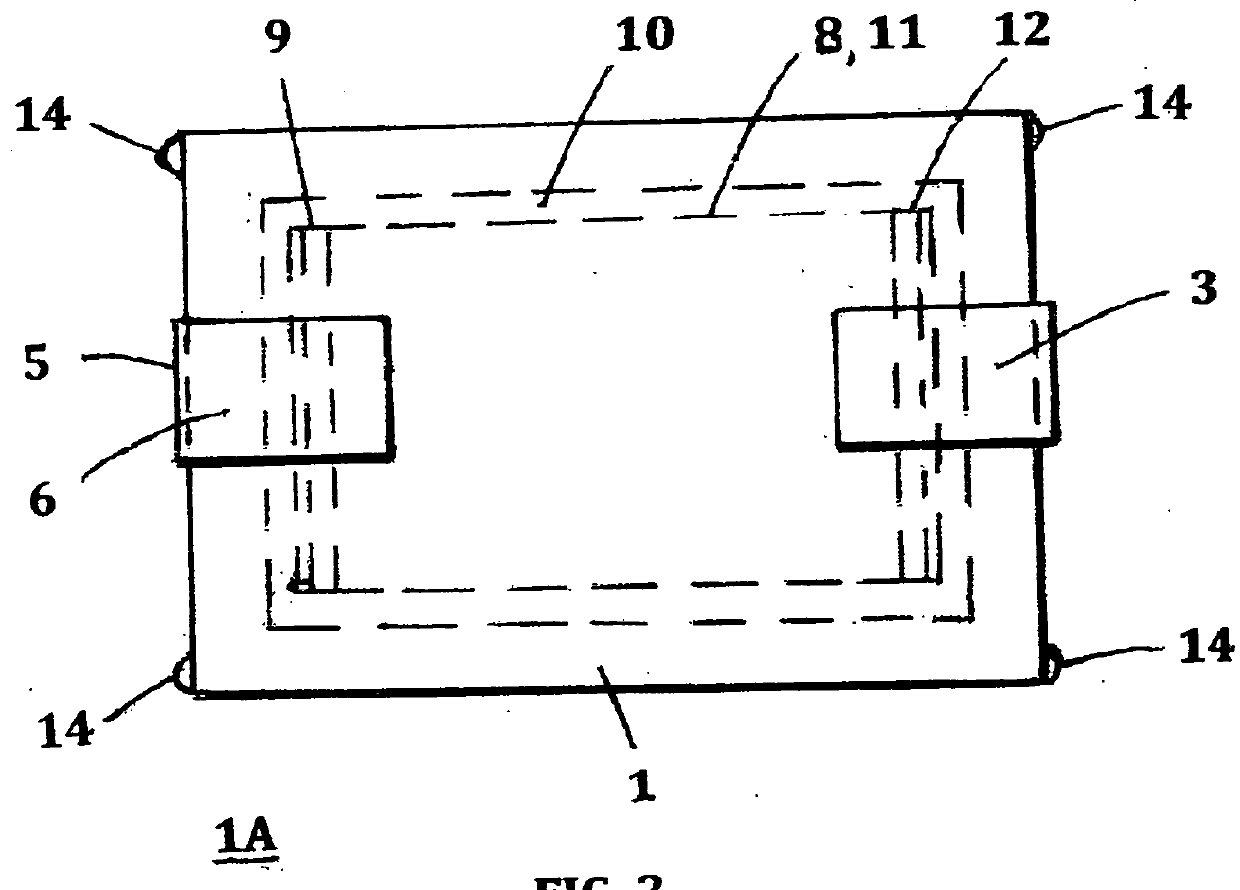

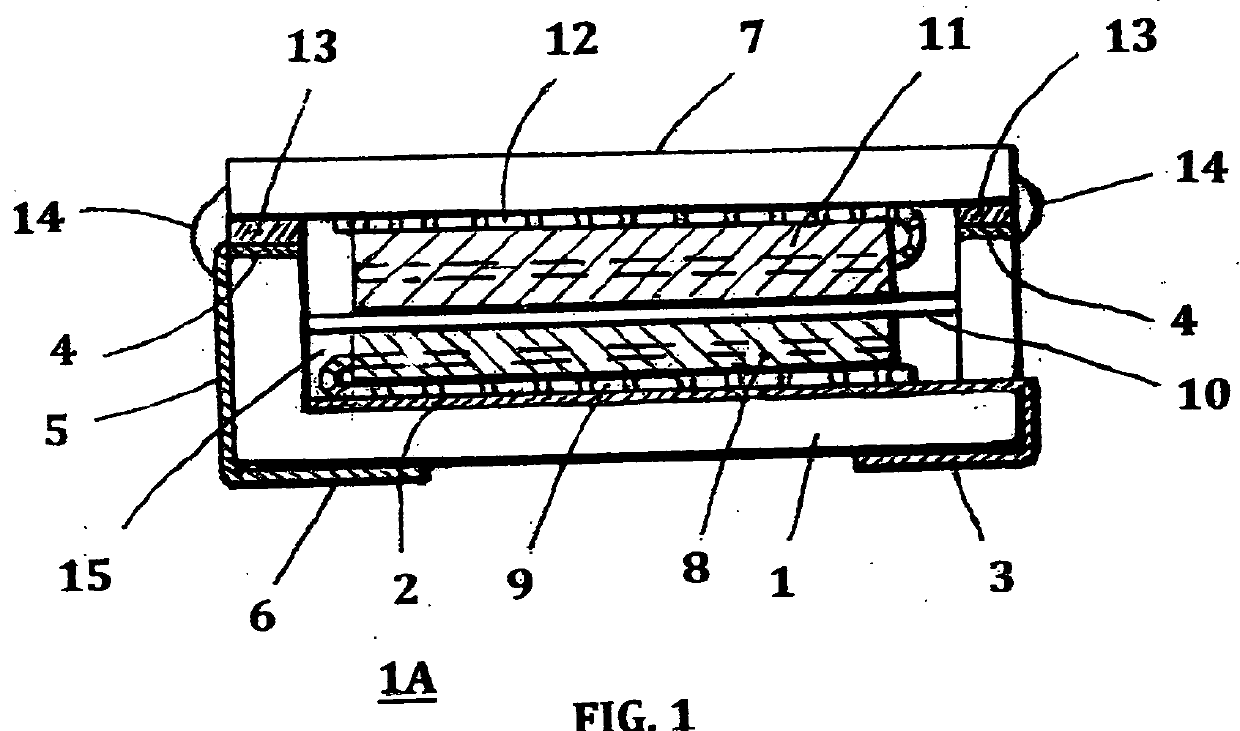

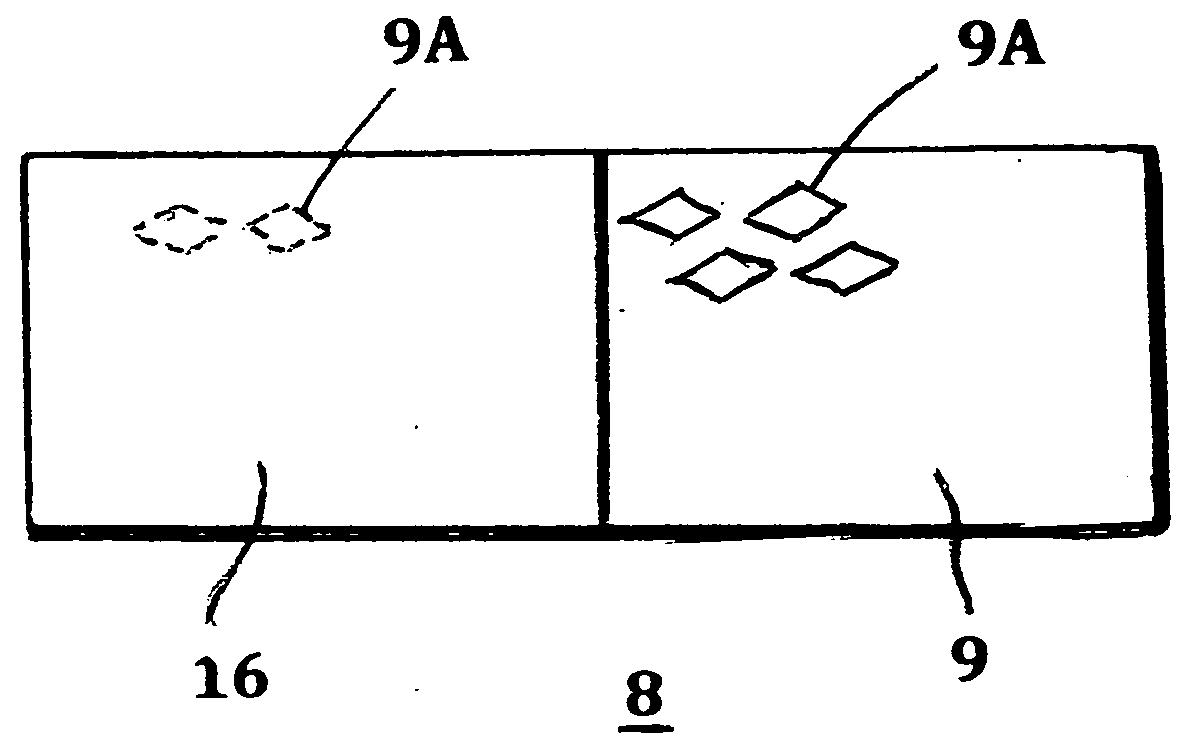

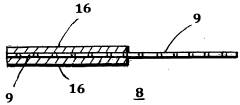

Method of Assembly of Electrochemical Cells for High Temperature Applications

PatentInactiveUS20180108496A1

Innovation

- The electrodes are coated with a water-based binder on pretreated aluminum or copper micro-grids without electrolyte, allowing assembly in air with long terminal tabs welded to the housing, using vacuum drying and high-temperature epoxy sealing to create a conductive and impermeable cell structure.

Material Science Advancements for Extreme Temperature Operation

Recent advancements in material science have revolutionized the performance capabilities of electrochemical cells in extreme temperature environments. Traditional materials used in electrochemical cells often experience significant degradation when exposed to temperatures exceeding 200°C, resulting in reduced efficiency, shortened lifespan, and potential safety hazards. The development of novel materials capable of withstanding these harsh conditions represents a critical frontier in energy storage and conversion technologies.

Ceramic-based electrolytes have emerged as promising candidates for high-temperature applications, with materials such as yttria-stabilized zirconia (YSZ) and gadolinium-doped ceria (GDC) demonstrating remarkable ionic conductivity at temperatures above 500°C. These materials maintain structural integrity and electrochemical performance where conventional polymer electrolytes would fail catastrophically, enabling the operation of solid oxide fuel cells (SOFCs) and high-temperature batteries.

Electrode materials have similarly undergone significant evolution, with researchers developing composite structures incorporating nanoparticles of platinum group metals supported on temperature-resistant ceramics. These composites maximize catalytic activity while minimizing degradation mechanisms such as sintering and agglomeration that typically occur at elevated temperatures. Recent breakthroughs in perovskite-structured materials have yielded electrodes with exceptional stability at temperatures up to 800°C while maintaining high electronic conductivity.

Interfacial engineering represents another crucial advancement, addressing the challenges of thermal expansion mismatch between different cell components. Gradient functional materials (GFMs) that feature compositional variations across their thickness have demonstrated superior resistance to delamination and cracking during thermal cycling. These materials effectively distribute stress and maintain critical electrochemical interfaces even under extreme thermal conditions.

Nanostructured protective coatings have been developed to shield sensitive components from oxidation and corrosion in high-temperature environments. Atomic layer deposition techniques now enable the creation of conformal barrier layers just nanometers thick, which can dramatically extend component lifetimes without significantly impacting electrochemical performance. Silicon carbide and aluminum oxide-based coatings have shown particular promise in protecting current collectors and interconnects.

Computational materials science has accelerated these advancements through high-throughput screening methodologies and molecular dynamics simulations that predict material behavior under extreme conditions. Machine learning algorithms have identified previously overlooked material combinations with exceptional thermal stability and electrochemical properties, guiding experimental efforts toward the most promising candidates and significantly reducing development timelines.

Ceramic-based electrolytes have emerged as promising candidates for high-temperature applications, with materials such as yttria-stabilized zirconia (YSZ) and gadolinium-doped ceria (GDC) demonstrating remarkable ionic conductivity at temperatures above 500°C. These materials maintain structural integrity and electrochemical performance where conventional polymer electrolytes would fail catastrophically, enabling the operation of solid oxide fuel cells (SOFCs) and high-temperature batteries.

Electrode materials have similarly undergone significant evolution, with researchers developing composite structures incorporating nanoparticles of platinum group metals supported on temperature-resistant ceramics. These composites maximize catalytic activity while minimizing degradation mechanisms such as sintering and agglomeration that typically occur at elevated temperatures. Recent breakthroughs in perovskite-structured materials have yielded electrodes with exceptional stability at temperatures up to 800°C while maintaining high electronic conductivity.

Interfacial engineering represents another crucial advancement, addressing the challenges of thermal expansion mismatch between different cell components. Gradient functional materials (GFMs) that feature compositional variations across their thickness have demonstrated superior resistance to delamination and cracking during thermal cycling. These materials effectively distribute stress and maintain critical electrochemical interfaces even under extreme thermal conditions.

Nanostructured protective coatings have been developed to shield sensitive components from oxidation and corrosion in high-temperature environments. Atomic layer deposition techniques now enable the creation of conformal barrier layers just nanometers thick, which can dramatically extend component lifetimes without significantly impacting electrochemical performance. Silicon carbide and aluminum oxide-based coatings have shown particular promise in protecting current collectors and interconnects.

Computational materials science has accelerated these advancements through high-throughput screening methodologies and molecular dynamics simulations that predict material behavior under extreme conditions. Machine learning algorithms have identified previously overlooked material combinations with exceptional thermal stability and electrochemical properties, guiding experimental efforts toward the most promising candidates and significantly reducing development timelines.

Environmental Impact of High-Temperature Cell Technologies

The environmental implications of high-temperature electrochemical cell technologies extend far beyond their operational efficiency. These systems, while offering significant advantages in energy conversion and storage, present complex environmental trade-offs that warrant careful consideration in their development and deployment.

High-temperature electrochemical cells typically operate at temperatures exceeding 500°C, requiring substantial energy input for heating and maintenance. This thermal requirement contributes significantly to their overall carbon footprint, particularly when powered by fossil fuel sources. Studies indicate that the initial warming phase can account for 15-20% of the total lifetime emissions of these systems, highlighting the importance of renewable energy integration for temperature maintenance.

Material degradation presents another environmental concern. The extreme operating conditions accelerate component deterioration, necessitating more frequent replacements and generating additional waste streams. Particularly problematic are ceramic components containing rare earth elements and specialized alloys, which pose recycling challenges due to their complex composition and contamination during operation.

Emissions profiles vary significantly across different high-temperature cell technologies. Solid oxide systems may release trace amounts of chromium compounds and other metal oxides during long-term operation, while molten carbonate cells can produce carbon dioxide as a byproduct of their electrochemical reactions. These emissions, though relatively minor compared to conventional energy technologies, require appropriate mitigation strategies to minimize environmental impact.

Water consumption represents an often-overlooked environmental factor. Cooling systems for temperature regulation in industrial-scale implementations can consume substantial water resources, creating potential conflicts in water-stressed regions. Advanced air-cooling technologies and heat recovery systems offer promising alternatives but often at the cost of reduced overall efficiency.

Life cycle assessments reveal that despite these challenges, high-temperature electrochemical cells generally demonstrate favorable environmental performance compared to conventional energy technologies when evaluated across their entire lifespan. Their superior efficiency in certain applications can offset the environmental costs associated with manufacturing and operation, particularly in long-duration energy storage and industrial process heat applications.

Emerging research in bio-derived electrolytes and catalysts shows potential for reducing the environmental footprint of these technologies. Sustainable sourcing of critical materials and design for recyclability are increasingly becoming priorities in research and development efforts, pointing toward more environmentally benign implementations in the future.

High-temperature electrochemical cells typically operate at temperatures exceeding 500°C, requiring substantial energy input for heating and maintenance. This thermal requirement contributes significantly to their overall carbon footprint, particularly when powered by fossil fuel sources. Studies indicate that the initial warming phase can account for 15-20% of the total lifetime emissions of these systems, highlighting the importance of renewable energy integration for temperature maintenance.

Material degradation presents another environmental concern. The extreme operating conditions accelerate component deterioration, necessitating more frequent replacements and generating additional waste streams. Particularly problematic are ceramic components containing rare earth elements and specialized alloys, which pose recycling challenges due to their complex composition and contamination during operation.

Emissions profiles vary significantly across different high-temperature cell technologies. Solid oxide systems may release trace amounts of chromium compounds and other metal oxides during long-term operation, while molten carbonate cells can produce carbon dioxide as a byproduct of their electrochemical reactions. These emissions, though relatively minor compared to conventional energy technologies, require appropriate mitigation strategies to minimize environmental impact.

Water consumption represents an often-overlooked environmental factor. Cooling systems for temperature regulation in industrial-scale implementations can consume substantial water resources, creating potential conflicts in water-stressed regions. Advanced air-cooling technologies and heat recovery systems offer promising alternatives but often at the cost of reduced overall efficiency.

Life cycle assessments reveal that despite these challenges, high-temperature electrochemical cells generally demonstrate favorable environmental performance compared to conventional energy technologies when evaluated across their entire lifespan. Their superior efficiency in certain applications can offset the environmental costs associated with manufacturing and operation, particularly in long-duration energy storage and industrial process heat applications.

Emerging research in bio-derived electrolytes and catalysts shows potential for reducing the environmental footprint of these technologies. Sustainable sourcing of critical materials and design for recyclability are increasingly becoming priorities in research and development efforts, pointing toward more environmentally benign implementations in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!