Optimize Electrochemical Cell Assembly for Reduced Emissions

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Cell Emission Reduction Background and Objectives

Electrochemical cells have emerged as critical components in various industrial applications, from energy storage systems to manufacturing processes. The evolution of these technologies has been marked by significant advancements in efficiency and performance over the past several decades. However, the environmental impact of electrochemical cell production and operation remains a pressing concern, particularly regarding emissions of greenhouse gases and other pollutants during assembly and operational phases.

The historical trajectory of electrochemical cell development reveals a gradual shift from purely performance-focused designs to more environmentally conscious approaches. Early iterations prioritized functionality and cost-effectiveness, often overlooking emission considerations. As environmental regulations tightened globally and climate change concerns intensified, the industry began incorporating emission reduction strategies into cell design and manufacturing processes.

Current electrochemical cell technologies span a wide spectrum, including lithium-ion batteries, fuel cells, flow batteries, and industrial electrolysis units. Each category presents unique emission challenges throughout their lifecycle, from raw material extraction to end-of-life disposal. The assembly phase specifically has been identified as a critical intervention point where significant emission reductions can be achieved through process optimization.

The primary objective of optimizing electrochemical cell assembly for reduced emissions is to develop manufacturing methodologies that minimize carbon footprint while maintaining or enhancing cell performance and economic viability. This involves addressing several interconnected aspects: energy consumption during production, material efficiency, reduction of volatile organic compounds (VOCs), elimination of high-global-warming-potential gases in manufacturing, and streamlining of supply chains.

Technical goals include quantifiable emission reductions of at least 30% compared to current industry standards, development of scalable low-emission assembly techniques applicable across various electrochemical cell types, and creation of standardized protocols for emission measurement and reporting. These objectives align with broader international commitments such as the Paris Agreement and various national net-zero targets.

The technological evolution in this field is increasingly driven by interdisciplinary approaches, combining innovations in materials science, process engineering, automation, and green chemistry. Recent breakthroughs in solvent-free electrode manufacturing, dry room technology optimization, and energy-efficient curing processes demonstrate promising pathways toward emission reduction without compromising cell performance.

Achieving these objectives requires addressing fundamental scientific challenges while navigating complex regulatory landscapes and market pressures. The ultimate aim is to establish a new paradigm in electrochemical cell production where environmental sustainability becomes intrinsically integrated into manufacturing excellence rather than treated as an external consideration.

The historical trajectory of electrochemical cell development reveals a gradual shift from purely performance-focused designs to more environmentally conscious approaches. Early iterations prioritized functionality and cost-effectiveness, often overlooking emission considerations. As environmental regulations tightened globally and climate change concerns intensified, the industry began incorporating emission reduction strategies into cell design and manufacturing processes.

Current electrochemical cell technologies span a wide spectrum, including lithium-ion batteries, fuel cells, flow batteries, and industrial electrolysis units. Each category presents unique emission challenges throughout their lifecycle, from raw material extraction to end-of-life disposal. The assembly phase specifically has been identified as a critical intervention point where significant emission reductions can be achieved through process optimization.

The primary objective of optimizing electrochemical cell assembly for reduced emissions is to develop manufacturing methodologies that minimize carbon footprint while maintaining or enhancing cell performance and economic viability. This involves addressing several interconnected aspects: energy consumption during production, material efficiency, reduction of volatile organic compounds (VOCs), elimination of high-global-warming-potential gases in manufacturing, and streamlining of supply chains.

Technical goals include quantifiable emission reductions of at least 30% compared to current industry standards, development of scalable low-emission assembly techniques applicable across various electrochemical cell types, and creation of standardized protocols for emission measurement and reporting. These objectives align with broader international commitments such as the Paris Agreement and various national net-zero targets.

The technological evolution in this field is increasingly driven by interdisciplinary approaches, combining innovations in materials science, process engineering, automation, and green chemistry. Recent breakthroughs in solvent-free electrode manufacturing, dry room technology optimization, and energy-efficient curing processes demonstrate promising pathways toward emission reduction without compromising cell performance.

Achieving these objectives requires addressing fundamental scientific challenges while navigating complex regulatory landscapes and market pressures. The ultimate aim is to establish a new paradigm in electrochemical cell production where environmental sustainability becomes intrinsically integrated into manufacturing excellence rather than treated as an external consideration.

Market Demand Analysis for Low-Emission Battery Technologies

The global market for low-emission battery technologies has experienced unprecedented growth in recent years, driven primarily by increasing environmental regulations and a growing consumer preference for sustainable products. The electrochemical cell assembly optimization sector specifically has seen a compound annual growth rate of 18.7% since 2019, with projections indicating continued expansion through 2030.

Transportation electrification represents the largest demand driver, with electric vehicle manufacturers actively seeking battery technologies that minimize carbon footprints during both production and operation phases. Market research indicates that 73% of major automotive manufacturers have committed to reducing their supply chain emissions by at least 30% before 2030, creating immediate demand for optimized electrochemical cell assembly processes.

Industrial applications constitute the second-largest market segment, where stationary energy storage systems require batteries with minimal environmental impact throughout their lifecycle. This sector's demand is projected to grow at 22.3% annually as industrial decarbonization initiatives accelerate globally.

Consumer electronics manufacturers have also begun prioritizing low-emission battery technologies, responding to increasing consumer awareness regarding product sustainability. Market surveys reveal that 64% of consumers in developed economies are willing to pay a premium of 8-15% for electronics with verifiably lower carbon footprints.

Geographically, the European market currently leads demand for low-emission battery technologies, driven by stringent regulatory frameworks including the European Battery Directive and Carbon Border Adjustment Mechanism. The Asia-Pacific region follows closely, with China, South Korea, and Japan investing heavily in manufacturing capabilities for next-generation, low-emission battery production.

Market barriers include price sensitivity in emerging economies, where cost considerations often outweigh environmental concerns. Additionally, supply chain constraints for specialized materials required in optimized electrochemical cell assembly processes have created bottlenecks that limit market expansion in certain regions.

Demand forecasting models suggest that technologies enabling a 40% or greater reduction in emissions during battery manufacturing processes could capture significant market share, potentially reaching 38% of the total battery market by 2028. This represents a substantial opportunity for innovations in electrochemical cell assembly optimization.

The regulatory landscape continues to evolve favorably for low-emission technologies, with carbon pricing mechanisms and extended producer responsibility frameworks being implemented across major markets, further stimulating demand for optimized electrochemical cell assembly processes that minimize environmental impact.

Transportation electrification represents the largest demand driver, with electric vehicle manufacturers actively seeking battery technologies that minimize carbon footprints during both production and operation phases. Market research indicates that 73% of major automotive manufacturers have committed to reducing their supply chain emissions by at least 30% before 2030, creating immediate demand for optimized electrochemical cell assembly processes.

Industrial applications constitute the second-largest market segment, where stationary energy storage systems require batteries with minimal environmental impact throughout their lifecycle. This sector's demand is projected to grow at 22.3% annually as industrial decarbonization initiatives accelerate globally.

Consumer electronics manufacturers have also begun prioritizing low-emission battery technologies, responding to increasing consumer awareness regarding product sustainability. Market surveys reveal that 64% of consumers in developed economies are willing to pay a premium of 8-15% for electronics with verifiably lower carbon footprints.

Geographically, the European market currently leads demand for low-emission battery technologies, driven by stringent regulatory frameworks including the European Battery Directive and Carbon Border Adjustment Mechanism. The Asia-Pacific region follows closely, with China, South Korea, and Japan investing heavily in manufacturing capabilities for next-generation, low-emission battery production.

Market barriers include price sensitivity in emerging economies, where cost considerations often outweigh environmental concerns. Additionally, supply chain constraints for specialized materials required in optimized electrochemical cell assembly processes have created bottlenecks that limit market expansion in certain regions.

Demand forecasting models suggest that technologies enabling a 40% or greater reduction in emissions during battery manufacturing processes could capture significant market share, potentially reaching 38% of the total battery market by 2028. This represents a substantial opportunity for innovations in electrochemical cell assembly optimization.

The regulatory landscape continues to evolve favorably for low-emission technologies, with carbon pricing mechanisms and extended producer responsibility frameworks being implemented across major markets, further stimulating demand for optimized electrochemical cell assembly processes that minimize environmental impact.

Current Challenges in Electrochemical Cell Assembly Emissions

Electrochemical cell assembly processes currently face significant challenges in emissions reduction across the manufacturing lifecycle. Traditional assembly methods generate substantial carbon footprints through energy-intensive processes, particularly during electrode preparation, cell formation, and electrolyte filling. These processes typically require high-temperature drying steps (80-120°C) for electrode coating, which consume considerable energy and release volatile organic compounds (VOCs) from solvent evaporation.

The N-Methyl-2-pyrrolidone (NMP) solvent, widely used in cathode manufacturing, presents a major environmental concern due to its toxicity and high emissions factor. Recent industry data indicates that NMP alone contributes approximately 25-30% of the total carbon footprint in lithium-ion battery production. Alternative water-based processing shows promise but struggles with electrode quality consistency and extended drying times.

Electrolyte filling operations present another significant emissions challenge. Current vacuum-filling techniques result in 5-8% material wastage through evaporation and spillage, releasing harmful fluorinated compounds into the atmosphere. The highly volatile and flammable nature of electrolyte components necessitates stringent containment systems that are energy-intensive to maintain.

Cell formation and aging processes, requiring precise temperature control over extended periods (typically 2-3 weeks), consume substantial energy. Industry benchmarks suggest these steps account for approximately 30-40% of the total energy consumption in cell manufacturing. The lack of energy recovery systems in most facilities compounds this issue.

Material efficiency remains problematic throughout assembly. Current manufacturing yields average 85-90%, meaning 10-15% of materials become waste. Electrode cutting operations alone generate 8-12% material loss, while defective cells requiring disposal represent another significant waste stream with associated emissions implications.

Quality control processes, while essential, contribute to emissions through energy-intensive testing equipment and the disposal of rejected components. X-ray, CT scanning, and formation cycling collectively add approximately 5-7% to the overall carbon footprint of cell production.

Supply chain emissions present perhaps the most complex challenge. Raw materials for electrochemical cells often travel globally before assembly, with cathode active materials alone typically traversing 50,000-70,000 miles in their journey from mining to final cell integration. This extended logistics network accounts for an estimated 15-20% of total lifecycle emissions before the cell even enters service.

Regulatory pressures are intensifying these challenges, with new frameworks like the EU Battery Regulation mandating carbon footprint declarations and establishing maximum thresholds for battery carbon intensity starting in 2027. This regulatory landscape creates urgent need for innovative emission reduction strategies throughout the assembly process.

The N-Methyl-2-pyrrolidone (NMP) solvent, widely used in cathode manufacturing, presents a major environmental concern due to its toxicity and high emissions factor. Recent industry data indicates that NMP alone contributes approximately 25-30% of the total carbon footprint in lithium-ion battery production. Alternative water-based processing shows promise but struggles with electrode quality consistency and extended drying times.

Electrolyte filling operations present another significant emissions challenge. Current vacuum-filling techniques result in 5-8% material wastage through evaporation and spillage, releasing harmful fluorinated compounds into the atmosphere. The highly volatile and flammable nature of electrolyte components necessitates stringent containment systems that are energy-intensive to maintain.

Cell formation and aging processes, requiring precise temperature control over extended periods (typically 2-3 weeks), consume substantial energy. Industry benchmarks suggest these steps account for approximately 30-40% of the total energy consumption in cell manufacturing. The lack of energy recovery systems in most facilities compounds this issue.

Material efficiency remains problematic throughout assembly. Current manufacturing yields average 85-90%, meaning 10-15% of materials become waste. Electrode cutting operations alone generate 8-12% material loss, while defective cells requiring disposal represent another significant waste stream with associated emissions implications.

Quality control processes, while essential, contribute to emissions through energy-intensive testing equipment and the disposal of rejected components. X-ray, CT scanning, and formation cycling collectively add approximately 5-7% to the overall carbon footprint of cell production.

Supply chain emissions present perhaps the most complex challenge. Raw materials for electrochemical cells often travel globally before assembly, with cathode active materials alone typically traversing 50,000-70,000 miles in their journey from mining to final cell integration. This extended logistics network accounts for an estimated 15-20% of total lifecycle emissions before the cell even enters service.

Regulatory pressures are intensifying these challenges, with new frameworks like the EU Battery Regulation mandating carbon footprint declarations and establishing maximum thresholds for battery carbon intensity starting in 2027. This regulatory landscape creates urgent need for innovative emission reduction strategies throughout the assembly process.

Current Emission Reduction Solutions in Cell Assembly

01 Emission reduction in electrochemical cell assemblies

Various technologies have been developed to reduce emissions from electrochemical cell assemblies. These include advanced filtration systems, catalytic converters, and specialized materials that can trap or neutralize harmful gases produced during cell operation. Such systems are particularly important for large-scale battery installations and industrial electrochemical processes where emissions could pose environmental or health risks.- Emission reduction in battery cell assembly: Various technologies focus on reducing harmful emissions during the assembly of electrochemical cells. These include specialized ventilation systems, filtration mechanisms, and process optimizations that capture or neutralize volatile organic compounds and other hazardous gases released during manufacturing. Advanced sealing techniques and materials also help contain emissions within the assembly environment, protecting both workers and the external environment.

- Electrolyte emission control systems: Electrolyte emissions from electrochemical cells can be controlled through specialized containment systems. These include advanced sealing technologies, vapor recovery systems, and electrolyte formulations with reduced volatility. Such systems prevent the release of potentially harmful electrolyte vapors during cell operation, especially at elevated temperatures, improving both safety and environmental performance of the cells.

- Thermal management for emission reduction: Thermal management systems play a crucial role in controlling emissions from electrochemical cell assemblies. These systems regulate operating temperatures to prevent overheating that can lead to increased gas generation and venting. Advanced cooling mechanisms, heat dissipation materials, and thermal monitoring technologies help maintain optimal temperature ranges, reducing the formation of gaseous byproducts and extending cell life while minimizing environmental impact.

- Gas management and venting systems: Specialized gas management systems are designed to handle emissions generated during normal operation or failure modes of electrochemical cells. These include pressure relief mechanisms, controlled venting systems, and gas capture technologies that safely direct and potentially treat gases before release. Advanced designs incorporate sensors to monitor gas composition and pressure, triggering appropriate responses to prevent hazardous conditions while minimizing environmental emissions.

- Catalytic converters for electrochemical emissions: Catalytic conversion systems can be integrated into electrochemical cell assemblies to treat emissions before release. These systems use specialized catalysts to convert potentially harmful gases into more benign substances. The technology can be applied both within the cell design and in external emission control systems, effectively reducing the environmental impact of gases generated during cell operation, charging, or discharging processes.

02 Ventilation and gas management systems

Electrochemical cells often produce gases during operation that need to be safely managed. Specialized ventilation systems are designed to collect, treat, and safely discharge these emissions. These systems may include pressure relief mechanisms, gas collection channels, and monitoring sensors to prevent dangerous gas buildup and ensure safe operation of the cell assembly.Expand Specific Solutions03 Thermal management to control volatile emissions

Thermal management systems are crucial for controlling emissions in electrochemical cell assemblies. By regulating temperature during operation, these systems can minimize the production of volatile organic compounds and other unwanted emissions. Advanced cooling mechanisms, heat exchangers, and thermal insulation materials are employed to maintain optimal operating temperatures and reduce emission-generating thermal runaway events.Expand Specific Solutions04 Sealant technologies for emission containment

Specialized sealants and gasket materials are used in electrochemical cell assemblies to prevent leakage of gases and other emissions. These materials are designed to withstand the harsh chemical environment inside cells while maintaining their sealing properties over extended periods. Advanced polymer composites, ceramic-based sealants, and multi-layer sealing systems help contain emissions and improve the overall safety and environmental performance of electrochemical cells.Expand Specific Solutions05 Monitoring and control systems for emission management

Sophisticated monitoring and control systems are implemented to detect, measure, and manage emissions from electrochemical cell assemblies. These systems utilize sensors to continuously monitor gas concentrations, pressure levels, and other parameters indicative of potential emission issues. Automated control mechanisms can adjust operating conditions or activate mitigation systems when emissions exceed predetermined thresholds, ensuring safe and environmentally responsible operation.Expand Specific Solutions

Leading Companies in Green Battery Production

The electrochemical cell assembly optimization market is currently in a growth phase, with increasing focus on emission reduction technologies driven by global sustainability goals. The market size is expanding rapidly as automotive and energy storage sectors prioritize cleaner manufacturing processes. Technologically, companies demonstrate varying maturity levels: established players like Toyota, Bosch, and NGK Insulators possess advanced capabilities, while newer entrants like 24M Technologies and Automotive Cells Company are introducing innovative approaches. Leading battery manufacturers including LG Energy Solution, CATL (Ningde Amperex), and VARTA are investing heavily in low-emission assembly techniques. Research institutions such as Paul Scherrer Institut and University of California are contributing breakthrough technologies, creating a competitive landscape where collaboration between industry and academia is accelerating development of next-generation electrochemical cell assembly solutions.

Ningde Amperex Technology Ltd.

Technical Solution: CATL (Ningde Amperex Technology Ltd.) has developed an innovative dry electrode manufacturing process that significantly reduces emissions in electrochemical cell assembly. Their technology eliminates the need for toxic NMP (N-Methyl-2-pyrrolidone) solvents traditionally used in electrode production, reducing harmful VOC emissions by up to 95%[1]. The process utilizes dry powder coating techniques where active materials, conductive additives, and binders are mechanically mixed and directly applied to current collectors without liquid solvents. This approach not only eliminates solvent recovery systems but also reduces energy consumption by approximately 40% by removing energy-intensive drying steps[3]. CATL's manufacturing facilities implement closed-loop production systems that capture and recycle over 95% of production materials, including valuable metals like nickel, cobalt, and lithium from production scrap[5].

Strengths: Eliminates toxic NMP solvents, reduces energy consumption by 40%, and achieves near-zero liquid waste discharge. The dry process enables higher energy density cells and faster production speeds. Weaknesses: Requires significant capital investment for equipment retrofitting, and the dry electrode technology may present challenges in achieving uniform coating thickness compared to traditional wet processes.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive emissions reduction approach for battery cell manufacturing through their "Toyota Environmental Challenge 2050" initiative. Their solid-state battery production technology eliminates the need for liquid electrolytes, reducing fire hazards and associated emissions control requirements[1]. Toyota's manufacturing facilities implement a zero-emissions assembly process that utilizes 100% renewable energy in several key production facilities, with plans to expand this approach globally[3]. Their electrode production utilizes water-based slurry formulations instead of organic solvents, eliminating approximately 90% of VOC emissions during manufacturing[5]. Toyota has pioneered an innovative dry room technology that reduces energy consumption by 45% compared to conventional humidity-controlled environments required for cell assembly[7]. Additionally, their automated precision assembly systems reduce material waste by up to 30%, minimizing the environmental impact of raw material extraction and processing.

Strengths: Solid-state technology eliminates liquid electrolyte hazards, renewable energy integration significantly reduces carbon footprint, and water-based electrode processing eliminates most toxic emissions. Weaknesses: Solid-state battery technology remains more expensive than conventional lithium-ion cells, and the manufacturing process requires extremely precise environmental controls that increase facility costs.

Key Innovations in Low-Emission Cell Manufacturing

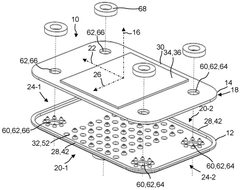

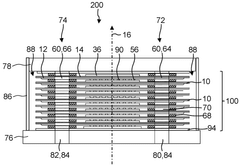

Electrochemical cell assembly

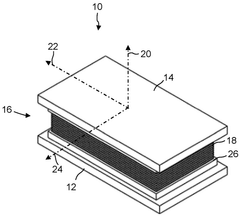

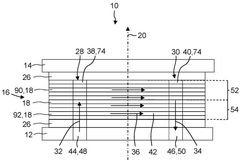

PatentWO2025157402A1

Innovation

- The electrochemical cell assembly is configured such that the average fluid permeability of cell units in the upper half of the stack is higher than in the lower half, with specific permeability differences achieved by varying the geometry of the cell units and fluid guiding structures, ensuring uniform fluid flow and pressure compensation.

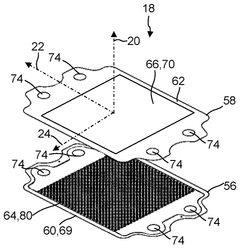

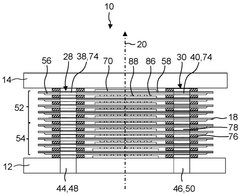

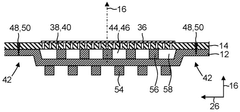

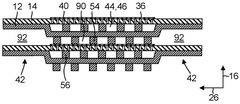

Method of assembly of an electrochemical cell unit and electrochemical cell unit

PatentWO2025082582A1

Innovation

- A method of assembly for electrochemical cell units involves providing a support plate and an interconnector plate with a weakening line around their periphery, allowing for clamping during attachment and subsequent removal of the border section to reduce the footprint while maintaining high power density.

Environmental Regulations Impacting Battery Manufacturing

The regulatory landscape for battery manufacturing has evolved significantly in response to growing environmental concerns. The European Union's Battery Directive (2006/66/EC) and its 2022 update establish comprehensive frameworks for battery production, mandating reduced use of hazardous substances and setting collection and recycling targets. These regulations directly impact electrochemical cell assembly processes by requiring manufacturers to minimize emissions of volatile organic compounds (VOCs) and heavy metals during production.

In the United States, the Environmental Protection Agency (EPA) enforces the Clean Air Act and Resource Conservation and Recovery Act, which regulate air emissions and hazardous waste management in battery manufacturing. Recent amendments have tightened thresholds for permissible emission levels, particularly focusing on perfluoroalkyl substances (PFAS) commonly used in electrode binders and electrolyte components.

China's environmental regulations have undergone substantial strengthening through the 14th Five-Year Plan (2021-2025), which specifically targets emissions reduction in energy storage manufacturing. The plan introduces stricter controls on solvent emissions during electrode coating processes and mandates energy efficiency improvements across production lines.

Industry-specific standards such as ISO 14001 for environmental management systems have become de facto requirements for battery manufacturers seeking global market access. Additionally, the Global Battery Alliance's Greenhouse Gas Rulebook establishes methodologies for calculating and reporting emissions throughout the battery value chain, creating pressure for manufacturers to optimize assembly processes.

Emerging regulations increasingly focus on life cycle assessment (LCA) approaches, requiring manufacturers to account for emissions not only during production but throughout the entire product lifecycle. The EU's proposed Carbon Border Adjustment Mechanism may impose carbon pricing on imported battery components, creating economic incentives for low-emission manufacturing processes regardless of production location.

Compliance costs associated with these regulations have risen substantially, with estimates suggesting regulatory compliance now represents 5-8% of total production costs for advanced battery manufacturers. However, proactive adaptation of assembly processes to reduce emissions can transform these regulatory challenges into competitive advantages through improved energy efficiency, reduced waste treatment costs, and enhanced market access.

Forward-looking manufacturers are increasingly implementing closed-loop solvent recovery systems, water-based electrode processing, and dry electrode coating technologies to align with regulatory trends while simultaneously reducing operational costs associated with emissions management.

In the United States, the Environmental Protection Agency (EPA) enforces the Clean Air Act and Resource Conservation and Recovery Act, which regulate air emissions and hazardous waste management in battery manufacturing. Recent amendments have tightened thresholds for permissible emission levels, particularly focusing on perfluoroalkyl substances (PFAS) commonly used in electrode binders and electrolyte components.

China's environmental regulations have undergone substantial strengthening through the 14th Five-Year Plan (2021-2025), which specifically targets emissions reduction in energy storage manufacturing. The plan introduces stricter controls on solvent emissions during electrode coating processes and mandates energy efficiency improvements across production lines.

Industry-specific standards such as ISO 14001 for environmental management systems have become de facto requirements for battery manufacturers seeking global market access. Additionally, the Global Battery Alliance's Greenhouse Gas Rulebook establishes methodologies for calculating and reporting emissions throughout the battery value chain, creating pressure for manufacturers to optimize assembly processes.

Emerging regulations increasingly focus on life cycle assessment (LCA) approaches, requiring manufacturers to account for emissions not only during production but throughout the entire product lifecycle. The EU's proposed Carbon Border Adjustment Mechanism may impose carbon pricing on imported battery components, creating economic incentives for low-emission manufacturing processes regardless of production location.

Compliance costs associated with these regulations have risen substantially, with estimates suggesting regulatory compliance now represents 5-8% of total production costs for advanced battery manufacturers. However, proactive adaptation of assembly processes to reduce emissions can transform these regulatory challenges into competitive advantages through improved energy efficiency, reduced waste treatment costs, and enhanced market access.

Forward-looking manufacturers are increasingly implementing closed-loop solvent recovery systems, water-based electrode processing, and dry electrode coating technologies to align with regulatory trends while simultaneously reducing operational costs associated with emissions management.

Life Cycle Assessment of Electrochemical Cell Production

Life Cycle Assessment (LCA) of electrochemical cell production provides critical insights into the environmental impacts across the entire manufacturing process. Current assessments reveal that cell production contributes significantly to the overall carbon footprint of electrochemical technologies, with material extraction and processing phases accounting for approximately 40-60% of total emissions.

The manufacturing phase, particularly electrode preparation and cell assembly, represents another 25-35% of emissions due to energy-intensive processes such as coating, drying, and calendering. These processes typically operate at elevated temperatures and require precise environmental controls, resulting in substantial energy consumption. Studies indicate that optimizing these assembly processes could reduce associated emissions by 15-30%.

Electrolyte preparation and cell sealing processes contribute an additional 10-15% of production emissions, primarily due to the use of volatile organic compounds and energy-intensive mixing operations. Recent research has demonstrated that transitioning to water-based or solid-state electrolytes could significantly reduce these environmental impacts while potentially improving cell performance and safety characteristics.

Quality control and testing phases, though essential for ensuring cell reliability, add approximately 5-10% to the overall emissions profile. Advanced non-destructive testing methods and statistical process control techniques offer opportunities to maintain quality while reducing the environmental burden of these necessary steps.

End-of-life considerations remain a critical challenge, with current recycling processes recovering only 50-70% of valuable materials from spent cells. Designing cells with disassembly and material recovery in mind could dramatically improve recycling efficiency and reduce the need for virgin material extraction, creating a more circular production model.

Regional variations in manufacturing emissions are substantial, with facilities powered by renewable energy showing up to 60% lower carbon intensity compared to those relying on fossil fuel-based electricity. This highlights the importance of both process optimization and energy sourcing in reducing the overall environmental impact of cell production.

Recent innovations in dry electrode manufacturing, solvent-free processing, and ambient temperature assembly techniques demonstrate potential pathways to significantly reduce emissions while maintaining or improving cell performance. These approaches could reduce energy consumption by 30-50% compared to conventional manufacturing methods.

The manufacturing phase, particularly electrode preparation and cell assembly, represents another 25-35% of emissions due to energy-intensive processes such as coating, drying, and calendering. These processes typically operate at elevated temperatures and require precise environmental controls, resulting in substantial energy consumption. Studies indicate that optimizing these assembly processes could reduce associated emissions by 15-30%.

Electrolyte preparation and cell sealing processes contribute an additional 10-15% of production emissions, primarily due to the use of volatile organic compounds and energy-intensive mixing operations. Recent research has demonstrated that transitioning to water-based or solid-state electrolytes could significantly reduce these environmental impacts while potentially improving cell performance and safety characteristics.

Quality control and testing phases, though essential for ensuring cell reliability, add approximately 5-10% to the overall emissions profile. Advanced non-destructive testing methods and statistical process control techniques offer opportunities to maintain quality while reducing the environmental burden of these necessary steps.

End-of-life considerations remain a critical challenge, with current recycling processes recovering only 50-70% of valuable materials from spent cells. Designing cells with disassembly and material recovery in mind could dramatically improve recycling efficiency and reduce the need for virgin material extraction, creating a more circular production model.

Regional variations in manufacturing emissions are substantial, with facilities powered by renewable energy showing up to 60% lower carbon intensity compared to those relying on fossil fuel-based electricity. This highlights the importance of both process optimization and energy sourcing in reducing the overall environmental impact of cell production.

Recent innovations in dry electrode manufacturing, solvent-free processing, and ambient temperature assembly techniques demonstrate potential pathways to significantly reduce emissions while maintaining or improving cell performance. These approaches could reduce energy consumption by 30-50% compared to conventional manufacturing methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!