Benchmarking Electrochemical Cell Charge Retention in Cold Climates

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Cold Climate Performance Background and Objectives

Electrochemical cell performance in cold climates has emerged as a critical research area due to the expanding deployment of battery technologies in regions with extreme temperature variations. The fundamental challenge stems from the electrochemical processes that power batteries being temperature-dependent, with significant performance degradation observed at temperatures below 0°C. This issue has gained prominence as electric vehicles, renewable energy storage systems, and portable electronics face increasing consumer demands for reliable operation in all environmental conditions.

The historical development of cold-climate battery research traces back to the 1970s, with initial studies focusing on lead-acid batteries for automotive applications. However, the rapid proliferation of lithium-ion technology since the 1990s has shifted research priorities toward understanding the specific mechanisms of lithium-ion performance degradation in cold environments. The technical evolution has progressed from simple thermal management approaches to sophisticated material science innovations targeting the electrochemical fundamentals of low-temperature operation.

Current industry benchmarks indicate that typical lithium-ion batteries retain only 50-80% of their room temperature capacity when operating at -20°C, with charge acceptance rates decreasing by up to 80%. This performance gap represents a significant barrier to technology adoption in cold regions and seasonal applications, driving substantial research investment across academic and industrial sectors.

The primary technical objectives for cold climate battery research center on three interconnected goals: improving charge retention at low temperatures, enhancing charge acceptance rates during cold charging scenarios, and maintaining cycle life despite thermal cycling stresses. These objectives must be achieved while maintaining safety parameters and without significantly compromising energy density or cost metrics.

Recent technological trends indicate promising directions in electrolyte engineering, electrode material modifications, and advanced thermal management systems. The integration of computational modeling with experimental validation has accelerated understanding of ion transport limitations and solid-electrolyte interphase (SEI) formation dynamics at low temperatures, providing clearer pathways for systematic improvement.

This technical investigation aims to establish comprehensive benchmarking methodologies for electrochemical cell charge retention in cold climates, standardize performance metrics across different cell chemistries and form factors, and identify the most promising technological approaches for overcoming current limitations. The ultimate goal is to develop a technical roadmap that can guide research priorities and investment decisions toward batteries capable of reliable performance across the full spectrum of environmental conditions encountered in real-world applications.

The historical development of cold-climate battery research traces back to the 1970s, with initial studies focusing on lead-acid batteries for automotive applications. However, the rapid proliferation of lithium-ion technology since the 1990s has shifted research priorities toward understanding the specific mechanisms of lithium-ion performance degradation in cold environments. The technical evolution has progressed from simple thermal management approaches to sophisticated material science innovations targeting the electrochemical fundamentals of low-temperature operation.

Current industry benchmarks indicate that typical lithium-ion batteries retain only 50-80% of their room temperature capacity when operating at -20°C, with charge acceptance rates decreasing by up to 80%. This performance gap represents a significant barrier to technology adoption in cold regions and seasonal applications, driving substantial research investment across academic and industrial sectors.

The primary technical objectives for cold climate battery research center on three interconnected goals: improving charge retention at low temperatures, enhancing charge acceptance rates during cold charging scenarios, and maintaining cycle life despite thermal cycling stresses. These objectives must be achieved while maintaining safety parameters and without significantly compromising energy density or cost metrics.

Recent technological trends indicate promising directions in electrolyte engineering, electrode material modifications, and advanced thermal management systems. The integration of computational modeling with experimental validation has accelerated understanding of ion transport limitations and solid-electrolyte interphase (SEI) formation dynamics at low temperatures, providing clearer pathways for systematic improvement.

This technical investigation aims to establish comprehensive benchmarking methodologies for electrochemical cell charge retention in cold climates, standardize performance metrics across different cell chemistries and form factors, and identify the most promising technological approaches for overcoming current limitations. The ultimate goal is to develop a technical roadmap that can guide research priorities and investment decisions toward batteries capable of reliable performance across the full spectrum of environmental conditions encountered in real-world applications.

Market Analysis for Cold-Weather Energy Storage Solutions

The cold-weather energy storage market is experiencing significant growth driven by increasing demand for reliable energy solutions in regions with extreme temperature variations. North America dominates this market segment, particularly in Canada and the northern United States, where temperatures frequently drop below freezing for extended periods. The European market follows closely, with Scandinavian countries, Russia, and parts of Eastern Europe showing substantial demand for cold-resistant energy storage technologies.

Market research indicates that the global cold-weather energy storage market was valued at approximately $4.2 billion in 2022 and is projected to reach $7.8 billion by 2028, representing a compound annual growth rate of 10.9%. This growth is primarily fueled by expanding electric vehicle adoption in cold regions, increasing renewable energy integration requiring robust storage solutions, and growing industrial applications in remote cold environments.

Consumer segments demonstrate distinct needs across various applications. The automotive sector represents the largest market share (38%), where battery performance in sub-zero temperatures directly impacts vehicle reliability and consumer satisfaction. Grid-scale energy storage follows at 27%, driven by utilities seeking to maintain consistent power supply during winter peaks. Telecommunications and remote infrastructure applications account for 18%, with these sectors requiring dependable backup power in isolated cold regions.

Market trends reveal increasing customer sophistication regarding performance expectations in extreme conditions. End-users now specifically request cold-weather performance metrics when evaluating energy storage solutions, with charge retention at -20°C emerging as a standard benchmark. This represents a significant shift from previous years when cold-weather performance was considered a secondary specification.

Pricing analysis shows consumers are willing to pay a 15-25% premium for energy storage solutions with verified cold-weather performance. This premium is highest in regions experiencing the most extreme temperature variations, particularly in industrial and critical infrastructure applications where reliability outweighs initial cost considerations.

Distribution channels are evolving to accommodate specialized cold-weather products, with technical support capabilities becoming a key differentiator among suppliers. Regional certification standards are emerging, with several countries developing specific testing protocols for cold-weather energy storage performance, creating both market entry barriers and opportunities for technically advanced solutions.

The competitive landscape remains fragmented, with specialized manufacturers focusing exclusively on cold-weather applications competing against major energy storage providers who are expanding their product lines to include cold-resistant offerings. This market segmentation creates opportunities for strategic partnerships between technology developers and established distribution networks.

Market research indicates that the global cold-weather energy storage market was valued at approximately $4.2 billion in 2022 and is projected to reach $7.8 billion by 2028, representing a compound annual growth rate of 10.9%. This growth is primarily fueled by expanding electric vehicle adoption in cold regions, increasing renewable energy integration requiring robust storage solutions, and growing industrial applications in remote cold environments.

Consumer segments demonstrate distinct needs across various applications. The automotive sector represents the largest market share (38%), where battery performance in sub-zero temperatures directly impacts vehicle reliability and consumer satisfaction. Grid-scale energy storage follows at 27%, driven by utilities seeking to maintain consistent power supply during winter peaks. Telecommunications and remote infrastructure applications account for 18%, with these sectors requiring dependable backup power in isolated cold regions.

Market trends reveal increasing customer sophistication regarding performance expectations in extreme conditions. End-users now specifically request cold-weather performance metrics when evaluating energy storage solutions, with charge retention at -20°C emerging as a standard benchmark. This represents a significant shift from previous years when cold-weather performance was considered a secondary specification.

Pricing analysis shows consumers are willing to pay a 15-25% premium for energy storage solutions with verified cold-weather performance. This premium is highest in regions experiencing the most extreme temperature variations, particularly in industrial and critical infrastructure applications where reliability outweighs initial cost considerations.

Distribution channels are evolving to accommodate specialized cold-weather products, with technical support capabilities becoming a key differentiator among suppliers. Regional certification standards are emerging, with several countries developing specific testing protocols for cold-weather energy storage performance, creating both market entry barriers and opportunities for technically advanced solutions.

The competitive landscape remains fragmented, with specialized manufacturers focusing exclusively on cold-weather applications competing against major energy storage providers who are expanding their product lines to include cold-resistant offerings. This market segmentation creates opportunities for strategic partnerships between technology developers and established distribution networks.

Current Limitations of Electrochemical Cells in Low Temperatures

Electrochemical cells, particularly lithium-ion batteries, face significant performance degradation when operating in cold climates. The fundamental challenge stems from the reduced kinetics of electrochemical reactions at low temperatures, which dramatically impacts charge transfer processes across electrode-electrolyte interfaces. As temperatures drop below 0°C, the ionic conductivity of standard electrolytes decreases exponentially, resulting in increased internal resistance and diminished power output.

Laboratory testing reveals that at -20°C, typical lithium-ion cells may deliver only 50-60% of their rated capacity compared to operation at room temperature. This capacity loss becomes even more pronounced during high-rate discharge scenarios, where available energy can plummet to merely 20-30% of nominal values. The reduced performance is primarily attributed to the increased viscosity of electrolytes and the slower diffusion of lithium ions through the solid electrolyte interphase (SEI) layer.

Another critical limitation is the phenomenon of lithium plating, which occurs when lithium ions cannot intercalate quickly enough into graphite anodes at low temperatures. This results in metallic lithium deposition on electrode surfaces, leading to permanent capacity loss, internal short circuits, and potential safety hazards. Current commercial cells utilizing conventional carbonate-based electrolytes exhibit significant lithium plating when charged at temperatures below -10°C.

Cold temperature operation also accelerates aging mechanisms in electrochemical cells. Repeated cycling in cold environments can cause accelerated SEI growth, electrode particle cracking, and electrolyte decomposition. Studies indicate that cells cycled exclusively at -10°C may lose up to 20% of their initial capacity after just 200 cycles, compared to 5-7% loss for cells operated at optimal temperatures.

Energy density trade-offs present another significant challenge. Modifications that improve cold-weather performance, such as electrolyte additives or alternative electrode materials, often come at the expense of energy density or cycle life at normal temperatures. This creates a difficult engineering compromise for applications requiring operation across wide temperature ranges.

Current battery management systems (BMS) also struggle to accurately estimate state-of-charge (SOC) and state-of-health (SOH) in cold conditions. The highly non-linear behavior of cells at low temperatures confounds conventional estimation algorithms, leading to unreliable range predictions in electric vehicles and unexpected shutdowns in portable electronics.

From a manufacturing perspective, specialized cold-weather cells require more expensive materials and more complex production processes, increasing costs by approximately 15-30% compared to standard cells. This economic barrier has limited widespread adoption of cold-optimized energy storage solutions in price-sensitive markets.

Laboratory testing reveals that at -20°C, typical lithium-ion cells may deliver only 50-60% of their rated capacity compared to operation at room temperature. This capacity loss becomes even more pronounced during high-rate discharge scenarios, where available energy can plummet to merely 20-30% of nominal values. The reduced performance is primarily attributed to the increased viscosity of electrolytes and the slower diffusion of lithium ions through the solid electrolyte interphase (SEI) layer.

Another critical limitation is the phenomenon of lithium plating, which occurs when lithium ions cannot intercalate quickly enough into graphite anodes at low temperatures. This results in metallic lithium deposition on electrode surfaces, leading to permanent capacity loss, internal short circuits, and potential safety hazards. Current commercial cells utilizing conventional carbonate-based electrolytes exhibit significant lithium plating when charged at temperatures below -10°C.

Cold temperature operation also accelerates aging mechanisms in electrochemical cells. Repeated cycling in cold environments can cause accelerated SEI growth, electrode particle cracking, and electrolyte decomposition. Studies indicate that cells cycled exclusively at -10°C may lose up to 20% of their initial capacity after just 200 cycles, compared to 5-7% loss for cells operated at optimal temperatures.

Energy density trade-offs present another significant challenge. Modifications that improve cold-weather performance, such as electrolyte additives or alternative electrode materials, often come at the expense of energy density or cycle life at normal temperatures. This creates a difficult engineering compromise for applications requiring operation across wide temperature ranges.

Current battery management systems (BMS) also struggle to accurately estimate state-of-charge (SOC) and state-of-health (SOH) in cold conditions. The highly non-linear behavior of cells at low temperatures confounds conventional estimation algorithms, leading to unreliable range predictions in electric vehicles and unexpected shutdowns in portable electronics.

From a manufacturing perspective, specialized cold-weather cells require more expensive materials and more complex production processes, increasing costs by approximately 15-30% compared to standard cells. This economic barrier has limited widespread adoption of cold-optimized energy storage solutions in price-sensitive markets.

Existing Cold Climate Battery Performance Enhancement Methods

01 Electrolyte composition for improved charge retention

Specialized electrolyte formulations can significantly enhance charge retention in electrochemical cells. These formulations may include additives that reduce self-discharge rates, improve ion conductivity, and stabilize the electrode-electrolyte interface. Advanced electrolytes can also minimize side reactions that typically lead to capacity loss during storage, thereby extending the effective shelf life and operational reliability of the cell.- Electrolyte composition for improved charge retention: Specific electrolyte compositions can significantly enhance charge retention in electrochemical cells. These compositions may include additives that reduce self-discharge rates, improve ion conductivity, or form protective layers on electrode surfaces. Advanced electrolyte formulations can stabilize the electrode-electrolyte interface, preventing unwanted side reactions that lead to capacity loss during storage or cycling.

- Electrode material modifications for enhanced charge storage: Modifications to electrode materials can improve charge retention capabilities of electrochemical cells. These modifications may include doping of active materials, surface treatments, or novel composite structures that enhance stability during charge-discharge cycles. Engineered electrode materials can reduce self-discharge by minimizing unwanted reactions and improving the structural integrity of the electrodes during long-term storage.

- Cell design and construction techniques: The physical design and construction of electrochemical cells significantly impact charge retention. Innovations in cell architecture, sealing methods, and internal component arrangement can minimize leakage currents and prevent contamination that leads to self-discharge. Advanced manufacturing techniques ensure better contact between components and reduce internal resistance, contributing to improved charge retention over the cell's lifetime.

- Monitoring and diagnostic systems for charge retention: Sophisticated monitoring and diagnostic systems can help maintain optimal charge retention in electrochemical cells. These systems may include sensors that detect early signs of capacity fade, algorithms that predict remaining useful life, or adaptive charging protocols that minimize stress on the cell. Real-time monitoring enables preventive maintenance and operational adjustments that extend the effective charge retention period of the cell.

- Temperature management for optimized charge retention: Temperature control systems play a crucial role in maintaining charge retention in electrochemical cells. Effective thermal management can prevent accelerated self-discharge rates at high temperatures and reduced performance at low temperatures. Advanced cooling and heating strategies, insulation techniques, and temperature-responsive materials help maintain cells within optimal operating temperature ranges, significantly improving their ability to retain charge during both storage and operation.

02 Electrode material modifications for enhanced charge storage

Modifications to electrode materials can substantially improve charge retention capabilities. These include surface treatments, doping with specific elements, and structural engineering at the nanoscale. Such modifications can create more stable interfaces with the electrolyte, reduce unwanted reactions, and provide additional sites for charge storage. Advanced electrode materials may also feature self-healing properties that mitigate degradation mechanisms affecting long-term charge retention.Expand Specific Solutions03 Battery management systems for optimizing charge retention

Sophisticated battery management systems can be implemented to monitor and control factors affecting charge retention. These systems may include algorithms for optimal charging protocols, temperature management, and state-of-charge control. By maintaining cells within ideal operating parameters, these systems can prevent conditions that accelerate self-discharge and degradation mechanisms, thereby preserving charge for longer periods during both active use and storage.Expand Specific Solutions04 Separator and membrane technologies

Advanced separator and membrane technologies play a crucial role in improving charge retention. These components can be engineered to prevent internal short circuits, reduce ion crossover that leads to self-discharge, and maintain physical integrity over extended periods. Specialized coatings and composite structures can enhance the stability of these components, ensuring consistent performance and improved charge retention throughout the cell's lifecycle.Expand Specific Solutions05 Diagnostic methods for charge retention assessment

Innovative diagnostic techniques have been developed to accurately assess and predict charge retention capabilities. These methods include impedance spectroscopy, voltage relaxation analysis, and accelerated aging tests specifically designed to evaluate self-discharge mechanisms. Such diagnostic approaches enable more precise quality control during manufacturing and allow for early detection of cells with potential charge retention issues before deployment in critical applications.Expand Specific Solutions

Leading Battery Manufacturers and Research Institutions

The electrochemical cell charge retention in cold climates market is in a growth phase, with increasing demand driven by electric vehicle adoption in regions with harsh winters. The market size is expanding rapidly, projected to reach significant value as automotive manufacturers prioritize cold-weather performance. Technologically, the field shows varying maturity levels, with established players like Robert Bosch, Mercedes-Benz, and Volkswagen leading commercial applications, while research institutions such as California Institute of Technology and University of Washington drive fundamental innovations. Battery specialists including Samsung SDI, CATL, and Saft Groupe are advancing specialized cold-climate solutions, creating a competitive landscape balanced between automotive OEMs, dedicated battery manufacturers, and research organizations collaborating to overcome temperature-related performance challenges.

Robert Bosch GmbH

Technical Solution: Bosch has established a comprehensive battery benchmarking system specifically designed for automotive applications in cold climates. Their methodology integrates vehicle-level testing with cell-level characterization to provide holistic performance metrics. Bosch's testing protocol includes standardized cold-cranking tests that measure power availability after various cold-soak periods (4, 12, 24, and 72 hours) at temperatures ranging from -30°C to 0°C. Their approach incorporates electrochemical impedance spectroscopy (EIS) measurements at multiple frequencies to characterize the various resistance components that limit performance at low temperatures. Bosch has developed advanced thermal preconditioning strategies that can improve cold-start capacity by up to 40% through intelligent battery management. Their benchmarking system also evaluates the effectiveness of various heating strategies, including internal heating elements, external thermal jackets, and waste heat recovery systems, providing comparative data on energy efficiency and warm-up times.

Strengths: Holistic approach that considers the entire vehicle electrical system rather than just the battery; extensive automotive industry expertise and integration capabilities. Weakness: Solutions often require significant vehicle integration and may be less applicable to stationary storage or non-automotive applications.

Saft Groupe SA

Technical Solution: Saft has developed a specialized cold climate battery benchmarking methodology focused on industrial and defense applications. Their approach incorporates military-standard testing protocols (MIL-STD-810G) for extreme environment performance evaluation. Saft's testing infrastructure includes thermal shock chambers that can rapidly transition between temperature extremes (-65°C to +85°C) to evaluate cell structural integrity and performance recovery. Their proprietary lithium thionyl chloride (Li-SOCl₂) primary cell technology demonstrates exceptional charge retention at temperatures as low as -60°C, maintaining operational capability where conventional lithium-ion systems fail completely. For rechargeable applications, Saft's nickel-based technology with modified electrolyte compositions shows 3x better cycle life at -20°C compared to standard lithium-ion formulations. Their benchmarking includes pulse power testing at various states of charge to characterize performance under high-demand scenarios in cold environments.

Strengths: Unparalleled expertise in extreme cold environment battery performance; specialized solutions for mission-critical applications where failure is not an option. Weakness: Technologies often prioritize reliability and performance over cost-efficiency, making solutions less suitable for consumer applications.

Key Patents in Low-Temperature Electrochemical Cell Technology

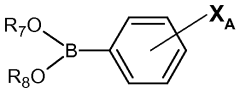

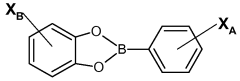

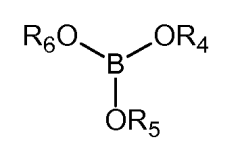

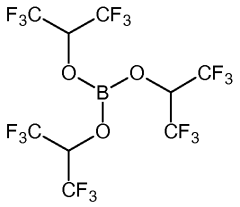

Low temperature electrochemical cell

PatentInactiveEP1992028A2

Innovation

- Development of lithium batteries with subfluorinated carbonaceous positive electrodes and high-performance nonaqueous electrolytes, featuring nanostructured subfluorinated carbonaceous materials and anion receptor additives, which enhance ionic conductivity and charge transfer kinetics, allowing for higher discharge rates and improved low-temperature operation.

Low temperature electrochemical cell

PatentWO2007098369A2

Innovation

- The development of lithium batteries with subfluorinated carbonaceous positive electrodes and high-performance nonaqueous electrolytes, which include anion receptors and specific solvent compositions, enhances low temperature performance by improving ionic conductivity and charge transfer properties.

Standardized Testing Protocols for Cold Climate Battery Performance

Standardized testing protocols are essential for accurately evaluating battery performance in cold climates. Current protocols vary significantly across industries and research institutions, creating challenges for meaningful comparisons between different electrochemical cell technologies. The development of unified testing methodologies would enable more reliable benchmarking of charge retention capabilities under low-temperature conditions.

The most comprehensive protocols currently implemented include the USABC (United States Advanced Battery Consortium) procedures, which specify testing at multiple temperature points ranging from -30°C to 25°C. These protocols typically measure capacity retention, internal resistance changes, and self-discharge rates at various temperature intervals. However, they often lack standardization in pre-conditioning procedures, which can significantly impact cold-weather performance results.

Temperature cycling represents another critical aspect of standardized testing. Batteries should undergo controlled temperature transitions that simulate real-world conditions, including gradual cooling rates and temperature hold periods. The IEC 62660 standard provides guidance on temperature profiles, but industry-specific adaptations are necessary for applications ranging from consumer electronics to electric vehicles and grid storage systems.

Charge/discharge rate standardization presents particular challenges in cold climate testing. Current protocols often fail to account for the relationship between C-rates and temperature effects. A comprehensive protocol should include multiple discharge rates at each temperature point to generate performance matrices that better represent real-world usage patterns. The EUCAR (European Council for Automotive Research) has proposed testing at 0.2C, 0.5C, and 1C rates across the temperature spectrum.

Data reporting formats also require standardization to facilitate cross-industry comparisons. Key metrics should include capacity retention percentages, power capability at various states of charge, voltage profiles during discharge, and recovery characteristics upon returning to standard temperatures. The development of standardized visualization tools would further enhance the utility of these protocols.

Implementation challenges include the significant time requirements for comprehensive cold-weather testing and the need for specialized environmental chambers capable of precise temperature control. Cost considerations have limited widespread adoption of the most rigorous protocols, particularly among smaller manufacturers and research institutions. A tiered approach to standardization might address these barriers, offering basic and advanced testing options depending on resource availability.

The most comprehensive protocols currently implemented include the USABC (United States Advanced Battery Consortium) procedures, which specify testing at multiple temperature points ranging from -30°C to 25°C. These protocols typically measure capacity retention, internal resistance changes, and self-discharge rates at various temperature intervals. However, they often lack standardization in pre-conditioning procedures, which can significantly impact cold-weather performance results.

Temperature cycling represents another critical aspect of standardized testing. Batteries should undergo controlled temperature transitions that simulate real-world conditions, including gradual cooling rates and temperature hold periods. The IEC 62660 standard provides guidance on temperature profiles, but industry-specific adaptations are necessary for applications ranging from consumer electronics to electric vehicles and grid storage systems.

Charge/discharge rate standardization presents particular challenges in cold climate testing. Current protocols often fail to account for the relationship between C-rates and temperature effects. A comprehensive protocol should include multiple discharge rates at each temperature point to generate performance matrices that better represent real-world usage patterns. The EUCAR (European Council for Automotive Research) has proposed testing at 0.2C, 0.5C, and 1C rates across the temperature spectrum.

Data reporting formats also require standardization to facilitate cross-industry comparisons. Key metrics should include capacity retention percentages, power capability at various states of charge, voltage profiles during discharge, and recovery characteristics upon returning to standard temperatures. The development of standardized visualization tools would further enhance the utility of these protocols.

Implementation challenges include the significant time requirements for comprehensive cold-weather testing and the need for specialized environmental chambers capable of precise temperature control. Cost considerations have limited widespread adoption of the most rigorous protocols, particularly among smaller manufacturers and research institutions. A tiered approach to standardization might address these barriers, offering basic and advanced testing options depending on resource availability.

Environmental Impact of Cold Climate Battery Solutions

The environmental implications of battery solutions designed for cold climates extend far beyond their immediate operational benefits. As electrochemical cells are increasingly deployed in harsh winter environments, their ecological footprint becomes a critical consideration for sustainable technology development.

Cold climate battery solutions often require additional materials and components to maintain performance in low temperatures, including insulation materials, heating elements, and specialized electrolytes. The extraction and processing of these materials contribute significantly to environmental degradation through increased mining activities, energy-intensive manufacturing processes, and potential habitat destruction. Particularly concerning are the rare earth elements often utilized in advanced battery technologies, which present substantial environmental challenges during extraction.

Energy consumption patterns associated with cold climate batteries present another environmental consideration. The additional energy required to maintain optimal battery temperature in cold environments—often through integrated heating systems—creates a secondary environmental burden. This increased energy demand can offset some of the environmental benefits typically associated with battery-powered systems, especially when the heating energy is derived from fossil fuel sources.

Waste management challenges are amplified for cold climate battery solutions. The specialized components and materials used to enhance cold weather performance may complicate recycling processes, potentially reducing recovery rates of valuable materials. Additionally, the accelerated degradation that can occur in batteries repeatedly exposed to temperature extremes may shorten their operational lifespan, increasing the frequency of replacement and subsequent waste generation.

Water resource impacts must also be considered, as battery manufacturing processes are often water-intensive. The production of specialized cold-resistant batteries may require additional processing steps that increase water consumption and potential contamination risks. This is particularly problematic in regions where water resources are already under stress due to climate change.

Carbon footprint calculations for cold climate battery solutions must account for the entire lifecycle, including the additional emissions associated with specialized manufacturing processes, increased energy consumption during operation, and potentially more complex end-of-life management. These factors can significantly alter the comparative environmental advantage of battery technologies in cold regions.

Regulatory frameworks are increasingly acknowledging these environmental considerations, with emerging standards specifically addressing the ecological impact of batteries designed for extreme environments. Forward-thinking manufacturers are responding by developing more environmentally conscious cold climate battery solutions, incorporating biodegradable components and designing for easier disassembly and material recovery.

Cold climate battery solutions often require additional materials and components to maintain performance in low temperatures, including insulation materials, heating elements, and specialized electrolytes. The extraction and processing of these materials contribute significantly to environmental degradation through increased mining activities, energy-intensive manufacturing processes, and potential habitat destruction. Particularly concerning are the rare earth elements often utilized in advanced battery technologies, which present substantial environmental challenges during extraction.

Energy consumption patterns associated with cold climate batteries present another environmental consideration. The additional energy required to maintain optimal battery temperature in cold environments—often through integrated heating systems—creates a secondary environmental burden. This increased energy demand can offset some of the environmental benefits typically associated with battery-powered systems, especially when the heating energy is derived from fossil fuel sources.

Waste management challenges are amplified for cold climate battery solutions. The specialized components and materials used to enhance cold weather performance may complicate recycling processes, potentially reducing recovery rates of valuable materials. Additionally, the accelerated degradation that can occur in batteries repeatedly exposed to temperature extremes may shorten their operational lifespan, increasing the frequency of replacement and subsequent waste generation.

Water resource impacts must also be considered, as battery manufacturing processes are often water-intensive. The production of specialized cold-resistant batteries may require additional processing steps that increase water consumption and potential contamination risks. This is particularly problematic in regions where water resources are already under stress due to climate change.

Carbon footprint calculations for cold climate battery solutions must account for the entire lifecycle, including the additional emissions associated with specialized manufacturing processes, increased energy consumption during operation, and potentially more complex end-of-life management. These factors can significantly alter the comparative environmental advantage of battery technologies in cold regions.

Regulatory frameworks are increasingly acknowledging these environmental considerations, with emerging standards specifically addressing the ecological impact of batteries designed for extreme environments. Forward-thinking manufacturers are responding by developing more environmentally conscious cold climate battery solutions, incorporating biodegradable components and designing for easier disassembly and material recovery.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!