How to Analyze Electrochemical Cell Response to Load Changes

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Cell Response Analysis Background and Objectives

Electrochemical cells have evolved significantly since Alessandro Volta's pioneering work in the early 19th century. From simple galvanic cells to sophisticated lithium-ion batteries and fuel cells, these energy conversion devices have become integral to modern technology. The fundamental principle remains consistent: converting chemical energy into electrical energy through redox reactions. However, the complexity of these systems has increased dramatically to meet growing demands for higher energy density, longer lifespan, and faster response times.

The evolution of electrochemical cell technology has been driven by applications ranging from portable electronics to electric vehicles and grid-scale energy storage. This progression has necessitated increasingly sophisticated methods for analyzing cell behavior, particularly under dynamic load conditions. Traditional steady-state analysis techniques have proven insufficient for understanding the complex behaviors exhibited during rapid load transitions, which are common in real-world applications.

Recent technological advancements have enabled more precise measurement and analysis capabilities, including electrochemical impedance spectroscopy (EIS), high-speed data acquisition systems, and advanced computational modeling. These tools have revealed previously unobservable phenomena during load transitions, highlighting the need for comprehensive analytical frameworks that can capture both the electrochemical and thermal dynamics of cells under varying load conditions.

The primary objective of this technical research is to develop robust methodologies for analyzing electrochemical cell responses to dynamic load changes. This includes characterizing immediate electrical responses, intermediate electrochemical adaptations, and long-term degradation effects resulting from variable loading patterns. Understanding these responses is crucial for optimizing cell design, improving battery management systems, and extending operational lifespans.

Secondary objectives include identifying key performance indicators that effectively quantify cell response characteristics, establishing standardized testing protocols for comparative analysis across different cell chemistries and designs, and developing predictive models that can anticipate cell behavior under complex load profiles. These objectives align with industry needs for more reliable energy storage solutions capable of handling increasingly demanding applications.

The scope encompasses various electrochemical cell technologies, including but not limited to lithium-ion batteries, flow batteries, fuel cells, and supercapacitors. Each technology presents unique challenges in terms of response characteristics, requiring tailored analytical approaches while maintaining sufficient generality for cross-technology comparisons. The ultimate goal is to establish a comprehensive analytical framework that bridges the gap between theoretical electrochemistry and practical engineering applications.

This research aims to address critical knowledge gaps in understanding the dynamic behavior of electrochemical cells, providing valuable insights for both academic research and industrial applications in the rapidly evolving energy storage landscape.

The evolution of electrochemical cell technology has been driven by applications ranging from portable electronics to electric vehicles and grid-scale energy storage. This progression has necessitated increasingly sophisticated methods for analyzing cell behavior, particularly under dynamic load conditions. Traditional steady-state analysis techniques have proven insufficient for understanding the complex behaviors exhibited during rapid load transitions, which are common in real-world applications.

Recent technological advancements have enabled more precise measurement and analysis capabilities, including electrochemical impedance spectroscopy (EIS), high-speed data acquisition systems, and advanced computational modeling. These tools have revealed previously unobservable phenomena during load transitions, highlighting the need for comprehensive analytical frameworks that can capture both the electrochemical and thermal dynamics of cells under varying load conditions.

The primary objective of this technical research is to develop robust methodologies for analyzing electrochemical cell responses to dynamic load changes. This includes characterizing immediate electrical responses, intermediate electrochemical adaptations, and long-term degradation effects resulting from variable loading patterns. Understanding these responses is crucial for optimizing cell design, improving battery management systems, and extending operational lifespans.

Secondary objectives include identifying key performance indicators that effectively quantify cell response characteristics, establishing standardized testing protocols for comparative analysis across different cell chemistries and designs, and developing predictive models that can anticipate cell behavior under complex load profiles. These objectives align with industry needs for more reliable energy storage solutions capable of handling increasingly demanding applications.

The scope encompasses various electrochemical cell technologies, including but not limited to lithium-ion batteries, flow batteries, fuel cells, and supercapacitors. Each technology presents unique challenges in terms of response characteristics, requiring tailored analytical approaches while maintaining sufficient generality for cross-technology comparisons. The ultimate goal is to establish a comprehensive analytical framework that bridges the gap between theoretical electrochemistry and practical engineering applications.

This research aims to address critical knowledge gaps in understanding the dynamic behavior of electrochemical cells, providing valuable insights for both academic research and industrial applications in the rapidly evolving energy storage landscape.

Market Demand for Dynamic Load Response Analysis

The global market for dynamic load response analysis in electrochemical cells has experienced significant growth over the past decade, driven primarily by the expanding electric vehicle (EV) industry, renewable energy storage systems, and portable electronics sectors. Current market valuations indicate that the electrochemical testing equipment market exceeds $3 billion annually, with the specific segment focused on dynamic load response analysis growing at approximately 8.5% CAGR.

Electric vehicle manufacturers represent the largest demand segment, as they require sophisticated analysis tools to optimize battery performance under variable driving conditions. The ability to accurately predict how batteries respond to acceleration, regenerative braking, and varying environmental conditions directly impacts vehicle range, performance, and safety. Major automotive OEMs are increasingly investing in advanced electrochemical testing capabilities to reduce development cycles and improve battery management systems.

Grid-scale energy storage represents another rapidly expanding market segment, with utilities and renewable energy developers seeking better tools to analyze how storage systems respond to fluctuating grid demands. As renewable penetration increases, the need for responsive energy storage that can handle rapid load changes becomes critical, driving demand for advanced analytical capabilities that can model electrochemical behavior under dynamic conditions.

Consumer electronics manufacturers constitute the third major market segment, focusing on extending device battery life while supporting increasingly power-hungry applications. The ability to analyze and optimize battery response to varying computational loads directly impacts product competitiveness and user satisfaction. This segment particularly values miniaturized testing equipment and integrated analysis solutions.

Market research indicates that customers across all segments are prioritizing several key capabilities in dynamic load response analysis tools: real-time monitoring capabilities, integration with digital twin technologies, AI-powered predictive analytics, and cloud-based collaborative platforms. The shift toward Industry 4.0 and smart manufacturing is accelerating demand for connected testing solutions that can feed data directly into product development workflows.

Geographically, North America and East Asia dominate market demand, with Europe showing the fastest growth rate due to aggressive electrification policies. China represents the single largest market, driven by its dominant position in battery manufacturing and electric vehicle production. Emerging economies are showing increased interest as they develop domestic battery production capabilities and renewable energy infrastructure.

The market demonstrates strong price sensitivity in standard testing equipment but shows willingness to pay premium prices for solutions offering advanced analytics, automation capabilities, and integration with existing systems. This bifurcation creates distinct market segments for basic compliance testing versus advanced R&D and optimization tools.

Electric vehicle manufacturers represent the largest demand segment, as they require sophisticated analysis tools to optimize battery performance under variable driving conditions. The ability to accurately predict how batteries respond to acceleration, regenerative braking, and varying environmental conditions directly impacts vehicle range, performance, and safety. Major automotive OEMs are increasingly investing in advanced electrochemical testing capabilities to reduce development cycles and improve battery management systems.

Grid-scale energy storage represents another rapidly expanding market segment, with utilities and renewable energy developers seeking better tools to analyze how storage systems respond to fluctuating grid demands. As renewable penetration increases, the need for responsive energy storage that can handle rapid load changes becomes critical, driving demand for advanced analytical capabilities that can model electrochemical behavior under dynamic conditions.

Consumer electronics manufacturers constitute the third major market segment, focusing on extending device battery life while supporting increasingly power-hungry applications. The ability to analyze and optimize battery response to varying computational loads directly impacts product competitiveness and user satisfaction. This segment particularly values miniaturized testing equipment and integrated analysis solutions.

Market research indicates that customers across all segments are prioritizing several key capabilities in dynamic load response analysis tools: real-time monitoring capabilities, integration with digital twin technologies, AI-powered predictive analytics, and cloud-based collaborative platforms. The shift toward Industry 4.0 and smart manufacturing is accelerating demand for connected testing solutions that can feed data directly into product development workflows.

Geographically, North America and East Asia dominate market demand, with Europe showing the fastest growth rate due to aggressive electrification policies. China represents the single largest market, driven by its dominant position in battery manufacturing and electric vehicle production. Emerging economies are showing increased interest as they develop domestic battery production capabilities and renewable energy infrastructure.

The market demonstrates strong price sensitivity in standard testing equipment but shows willingness to pay premium prices for solutions offering advanced analytics, automation capabilities, and integration with existing systems. This bifurcation creates distinct market segments for basic compliance testing versus advanced R&D and optimization tools.

Current Challenges in Electrochemical Load Response Monitoring

Despite significant advancements in electrochemical cell technology, monitoring and analyzing load response remains a complex challenge for researchers and industry professionals. Current monitoring systems struggle with real-time data acquisition during rapid load fluctuations, particularly in high-power applications where response times are critical. The sensitivity of measurement equipment often fails to capture microsecond-level changes that can significantly impact cell performance and longevity.

Signal noise presents another substantial obstacle, as electrochemical processes generate electrical interference that can mask important response patterns. Traditional filtering methods frequently compromise data integrity by inadvertently removing subtle yet crucial response signatures. This challenge is especially pronounced in industrial environments where electromagnetic interference from surrounding equipment further complicates accurate measurements.

Temperature compensation represents a persistent technical hurdle, as electrochemical reactions are highly temperature-dependent. Current monitoring systems struggle to differentiate between load-induced response changes and those resulting from thermal variations. This limitation becomes particularly problematic in applications with significant thermal gradients or in environments with fluctuating ambient conditions.

Data interpretation frameworks remain inadequate for complex electrochemical systems. Most analytical models are optimized for steady-state conditions and perform poorly when applied to dynamic load scenarios. The non-linear behavior of electrochemical cells under variable loads often defies conventional mathematical modeling approaches, creating a significant gap between theoretical predictions and observed responses.

Sensor degradation and drift introduce progressive inaccuracies in long-term monitoring applications. Contact resistance changes, electrode fouling, and reference electrode instability all contribute to measurement errors that accumulate over time. Current calibration methodologies cannot fully compensate for these evolving system characteristics.

Miniaturization of monitoring systems presents additional challenges, particularly for portable or embedded applications. The trade-off between measurement accuracy and system size often forces compromises that limit analytical capabilities. Power consumption of monitoring equipment itself can become a significant factor, potentially influencing the very system parameters being measured.

Standardization remains elusive across different electrochemical technologies, with varying protocols and metrics making cross-platform comparisons difficult. This fragmentation hinders knowledge transfer between research domains and slows the development of universal monitoring solutions that could benefit multiple industries simultaneously.

Signal noise presents another substantial obstacle, as electrochemical processes generate electrical interference that can mask important response patterns. Traditional filtering methods frequently compromise data integrity by inadvertently removing subtle yet crucial response signatures. This challenge is especially pronounced in industrial environments where electromagnetic interference from surrounding equipment further complicates accurate measurements.

Temperature compensation represents a persistent technical hurdle, as electrochemical reactions are highly temperature-dependent. Current monitoring systems struggle to differentiate between load-induced response changes and those resulting from thermal variations. This limitation becomes particularly problematic in applications with significant thermal gradients or in environments with fluctuating ambient conditions.

Data interpretation frameworks remain inadequate for complex electrochemical systems. Most analytical models are optimized for steady-state conditions and perform poorly when applied to dynamic load scenarios. The non-linear behavior of electrochemical cells under variable loads often defies conventional mathematical modeling approaches, creating a significant gap between theoretical predictions and observed responses.

Sensor degradation and drift introduce progressive inaccuracies in long-term monitoring applications. Contact resistance changes, electrode fouling, and reference electrode instability all contribute to measurement errors that accumulate over time. Current calibration methodologies cannot fully compensate for these evolving system characteristics.

Miniaturization of monitoring systems presents additional challenges, particularly for portable or embedded applications. The trade-off between measurement accuracy and system size often forces compromises that limit analytical capabilities. Power consumption of monitoring equipment itself can become a significant factor, potentially influencing the very system parameters being measured.

Standardization remains elusive across different electrochemical technologies, with varying protocols and metrics making cross-platform comparisons difficult. This fragmentation hinders knowledge transfer between research domains and slows the development of universal monitoring solutions that could benefit multiple industries simultaneously.

State-of-the-Art Load Response Measurement Techniques

01 Dynamic load response mechanisms in fuel cells

Fuel cells can be designed with specific mechanisms to respond to dynamic load changes. These mechanisms include adjusting reactant flow rates, controlling membrane hydration, and implementing rapid response control systems. By optimizing these parameters, fuel cells can maintain stable voltage and current output during varying load conditions, which is crucial for applications with fluctuating power demands such as automotive or portable power systems.- Dynamic load response mechanisms in fuel cells: Electrochemical cells, particularly fuel cells, can be designed with specific mechanisms to respond to load changes. These mechanisms include adjusting reactant flow rates, modifying electrode activity, and implementing control systems that can rapidly adapt to varying power demands. Such designs help maintain stable voltage output and efficiency during transient load conditions, which is crucial for applications with fluctuating power requirements.

- Battery management systems for load variation: Advanced battery management systems can optimize electrochemical cell performance during load changes. These systems monitor cell parameters in real-time and implement algorithms that adjust charging/discharging rates, thermal management, and power distribution. By predicting load requirements and preemptively adjusting cell operation, these management systems can extend battery life while maintaining performance under variable load conditions.

- Electrode composition and structure for improved load response: The composition and structure of electrodes significantly impact how electrochemical cells respond to load changes. Specialized electrode materials with high conductivity, optimized porosity, and catalytic properties can facilitate faster ion transport and reaction kinetics during sudden load variations. Multi-layered electrode designs and novel material combinations can reduce polarization losses and improve the cell's ability to handle rapid load transitions.

- Hybrid energy storage systems for load balancing: Hybrid systems combining different types of electrochemical cells can effectively manage varying load demands. By integrating high-power devices (like supercapacitors) with high-energy devices (like lithium-ion batteries), these systems can respond to both rapid load fluctuations and sustained power requirements. The complementary characteristics of different storage technologies allow for optimized performance across diverse operating conditions while extending overall system lifespan.

- Diagnostic and predictive methods for load response optimization: Advanced diagnostic techniques and predictive algorithms can be employed to optimize electrochemical cell response to load changes. These methods include electrochemical impedance spectroscopy, machine learning algorithms for load prediction, and real-time monitoring systems that can detect early signs of performance degradation. By anticipating load variations and cell behavior, these approaches enable proactive adjustments to operating parameters, ensuring optimal performance and preventing damage from extreme load conditions.

02 Battery management systems for load variation

Battery management systems can be implemented to optimize electrochemical cell response to load changes. These systems monitor cell parameters such as temperature, voltage, and state of charge, and adjust operating conditions accordingly. Advanced algorithms can predict load changes and preemptively adjust cell parameters to maintain optimal performance. This approach extends battery life and improves efficiency during variable load conditions.Expand Specific Solutions03 Electrode design for improved load response

Specialized electrode designs can significantly improve an electrochemical cell's response to load changes. These designs focus on increasing active surface area, optimizing catalyst distribution, and enhancing ion transport pathways. By reducing internal resistance and improving reaction kinetics, these electrode configurations allow for faster response times and more stable operation during rapid load fluctuations.Expand Specific Solutions04 Thermal management during load transitions

Effective thermal management systems are crucial for maintaining electrochemical cell performance during load changes. These systems can include active cooling, phase change materials, or thermal insulators strategically placed within the cell structure. By controlling temperature gradients and preventing hotspots during load transitions, these approaches help maintain cell efficiency and prevent degradation mechanisms that can be triggered by thermal stress.Expand Specific Solutions05 Advanced monitoring and predictive control systems

Sophisticated monitoring and control systems can be implemented to optimize electrochemical cell response to load changes. These systems utilize sensors to continuously monitor cell parameters and employ predictive algorithms to anticipate load variations. Machine learning approaches can adapt control strategies based on historical performance data. By implementing real-time adjustments to operating parameters, these systems maintain optimal cell performance across varying load profiles.Expand Specific Solutions

Leading Research Groups and Industrial Players

The electrochemical cell response to load changes market is currently in a growth phase, with increasing demand driven by renewable energy integration and electric vehicle expansion. The global market size is projected to reach significant scale as energy storage solutions become critical infrastructure components. Technologically, the field shows varying maturity levels across applications. Leading players include CATL and Samsung SDI focusing on battery technology advancement, while Robert Bosch and Volkswagen are developing automotive applications. Research institutions like CNRS, Caltech, and Fraunhofer-Gesellschaft are pushing fundamental innovations. Medtronic represents specialized applications in medical devices. The competitive landscape features both established industrial giants and specialized technology providers collaborating to address challenges in real-time load response monitoring and control systems.

Contemporary Amperex Technology Co., Ltd.

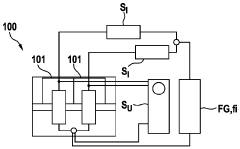

Technical Solution: CATL has developed an advanced Battery Management System (BMS) that utilizes electrochemical impedance spectroscopy (EIS) to analyze cell response to load changes in real-time. Their approach incorporates multi-frequency excitation signals to characterize the dynamic behavior of lithium-ion cells under varying load conditions. The system employs a combination of time-domain and frequency-domain analysis techniques to extract key parameters such as charge transfer resistance, diffusion coefficients, and double-layer capacitance. CATL's proprietary algorithms can detect subtle changes in electrochemical behavior that precede capacity degradation or safety issues, allowing for predictive maintenance and adaptive control strategies. Their system includes temperature compensation mechanisms that adjust measurement parameters based on thermal conditions, ensuring accurate analysis across operating environments[1][3]. The technology has been implemented in their latest generation of energy storage systems and electric vehicle battery packs, enabling dynamic power allocation based on real-time cell condition assessment.

Strengths: Superior real-time monitoring capabilities that enable dynamic power allocation and predictive maintenance; comprehensive temperature compensation for accurate analysis across various operating conditions. Weaknesses: System complexity requires significant computational resources; implementation costs may be prohibitive for lower-cost applications; requires specialized expertise for data interpretation.

GM Global Technology Operations LLC

Technical Solution: GM has developed an integrated electrochemical diagnostic system specifically designed for automotive applications that analyzes cell response to the variable loads characteristic of electric vehicle operation. Their approach combines traditional electrochemical techniques with automotive-specific load profile analysis to create a comprehensive cell health monitoring system. The technology employs a hybrid model that incorporates both physics-based and data-driven components to predict cell behavior under various driving conditions. GM's system features distributed sensing nodes that monitor cell clusters throughout the battery pack, enabling spatial resolution of performance variations. Their proprietary algorithms can differentiate between load-induced transient responses and permanent capacity changes, reducing false alarms during dynamic driving conditions[4]. The system incorporates drive cycle recognition capabilities that contextualize measurements based on vehicle operation patterns, allowing for more accurate state-of-health estimations. This technology has been deployed in GM's Ultium battery platform, enabling adaptive power management strategies that balance performance requirements with battery longevity considerations[7]. The system supports over-the-air updates to refine analysis algorithms based on fleet-wide data collection.

Strengths: Automotive-specific design optimized for variable driving loads; distributed sensing architecture provides spatial resolution of performance variations; contextual analysis based on driving patterns improves accuracy. Weaknesses: Heavily optimized for automotive use cases with limited applicability to stationary storage; requires vehicle integration for full functionality; significant development investment needed for each new battery chemistry.

Key Innovations in Electrochemical Impedance Spectroscopy

Method for examining an electrochemical cell by electrochemical impedance spectroscopy

PatentPendingDE102022202521A1

Innovation

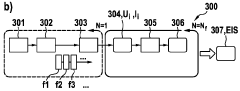

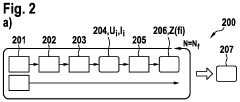

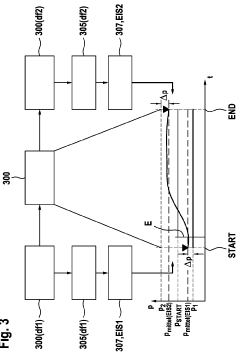

- A method using Rapid and Local Electrochemical Impedance Spectroscopy (RaLo EIS) that measures impedance spectra with both temporal and spatial resolution by impressing all frequencies within a specific range before evaluation, allowing for quick and reliable determination of parameters like membrane resistance during transient conditions.

Accurate Assessment of the State of Charge of Electrochemical Cells

PatentActiveUS20160146895A1

Innovation

- The development of systems and methods that simultaneously collect and measure a suite of interconnected electrochemical and thermodynamic parameters, allowing for the accurate characterization of electrode reaction states, including state functions like Gibbs free energy, enthalpy, and entropy, to predict performance attributes like energy, power density, and cycle life.

Safety Standards and Testing Protocols

Safety standards and testing protocols for electrochemical cell response analysis have evolved significantly to address the inherent risks associated with these energy storage systems. The International Electrotechnical Commission (IEC) has established comprehensive standards, particularly IEC 62660 for lithium-ion cells in electric vehicles and IEC 61960 for consumer applications. These standards outline specific testing methodologies for evaluating cell performance under various load conditions while maintaining safety parameters.

Testing protocols typically include controlled environment requirements where temperature, humidity, and pressure must be maintained within specified ranges during load response analysis. ASTM International's standards complement these with detailed procedures for thermal stability testing (ASTM E1354) and electrical safety evaluations (ASTM F2575) that are critical when subjecting cells to dynamic load changes.

For laboratory testing of electrochemical cell response, safety measures include mandatory use of protective equipment such as thermal gloves, face shields, and fire-resistant clothing. Testing facilities must be equipped with appropriate ventilation systems, fire suppression mechanisms, and emergency power-off capabilities. The IEEE 1625 and 1725 standards provide additional guidelines for safe testing environments when analyzing portable cell technologies under variable loads.

Data acquisition during load response testing presents unique safety challenges. Protocols require isolation of measurement equipment from high-voltage systems, with proper grounding and shielding to prevent electrical hazards. The National Fire Protection Association (NFPA) standards, particularly NFPA 70E, outline electrical safety requirements applicable to electrochemical testing environments.

Failure mode analysis constitutes a critical component of safety protocols. Standards require documentation of potential failure scenarios during load changes, including thermal runaway, electrolyte leakage, and short-circuit events. The UN Manual of Tests and Criteria, specifically UN 38.3, provides standardized testing procedures for transport safety that incorporate load response characteristics.

Recent developments in safety standards emphasize real-time monitoring systems during testing. These include continuous temperature tracking, gas detection for early identification of cell degradation, and automated shutdown procedures when parameters exceed safety thresholds. The UL 1642 standard for lithium batteries has been updated to include specific requirements for monitoring systems during dynamic load testing.

Compliance documentation represents the final critical element of safety protocols. Testing facilities must maintain detailed records of safety measures implemented, calibration of safety equipment, and personnel training certifications. This documentation serves both regulatory compliance purposes and provides valuable data for improving future safety standards in electrochemical cell response analysis.

Testing protocols typically include controlled environment requirements where temperature, humidity, and pressure must be maintained within specified ranges during load response analysis. ASTM International's standards complement these with detailed procedures for thermal stability testing (ASTM E1354) and electrical safety evaluations (ASTM F2575) that are critical when subjecting cells to dynamic load changes.

For laboratory testing of electrochemical cell response, safety measures include mandatory use of protective equipment such as thermal gloves, face shields, and fire-resistant clothing. Testing facilities must be equipped with appropriate ventilation systems, fire suppression mechanisms, and emergency power-off capabilities. The IEEE 1625 and 1725 standards provide additional guidelines for safe testing environments when analyzing portable cell technologies under variable loads.

Data acquisition during load response testing presents unique safety challenges. Protocols require isolation of measurement equipment from high-voltage systems, with proper grounding and shielding to prevent electrical hazards. The National Fire Protection Association (NFPA) standards, particularly NFPA 70E, outline electrical safety requirements applicable to electrochemical testing environments.

Failure mode analysis constitutes a critical component of safety protocols. Standards require documentation of potential failure scenarios during load changes, including thermal runaway, electrolyte leakage, and short-circuit events. The UN Manual of Tests and Criteria, specifically UN 38.3, provides standardized testing procedures for transport safety that incorporate load response characteristics.

Recent developments in safety standards emphasize real-time monitoring systems during testing. These include continuous temperature tracking, gas detection for early identification of cell degradation, and automated shutdown procedures when parameters exceed safety thresholds. The UL 1642 standard for lithium batteries has been updated to include specific requirements for monitoring systems during dynamic load testing.

Compliance documentation represents the final critical element of safety protocols. Testing facilities must maintain detailed records of safety measures implemented, calibration of safety equipment, and personnel training certifications. This documentation serves both regulatory compliance purposes and provides valuable data for improving future safety standards in electrochemical cell response analysis.

Energy Storage Applications and Performance Metrics

Electrochemical energy storage systems represent a critical component in modern energy infrastructure, serving diverse applications from grid-scale storage to electric vehicles and portable electronics. The performance of these systems under varying load conditions directly impacts their practical utility and economic viability. Battery technologies, including lithium-ion, lead-acid, and emerging chemistries like sodium-ion and solid-state, each demonstrate distinct response characteristics to dynamic load changes that must be thoroughly understood for optimal implementation.

For grid applications, energy storage systems must demonstrate reliable performance metrics including high round-trip efficiency (typically 80-95% for advanced systems), rapid response times (milliseconds to seconds), and cycle stability under fluctuating demand patterns. The ability to analyze and predict electrochemical cell response becomes particularly crucial for frequency regulation services, where batteries must respond to sub-second grid signals while maintaining thermal stability and minimizing degradation.

In electric vehicle applications, performance metrics focus on power density (W/kg), energy density (Wh/kg), and transient response characteristics during acceleration and regenerative braking events. The electrochemical cell's ability to handle high C-rates without excessive temperature rise or capacity fade determines vehicle range, acceleration capabilities, and overall battery lifespan. Modern EVs require batteries capable of delivering 3-10C discharge rates while maintaining efficiency above 90%.

Consumer electronics present unique challenges with highly variable load profiles, from standby operation to processor-intensive tasks that create sudden current spikes. Performance metrics in this domain emphasize volumetric energy density, self-discharge rates (typically <5% monthly), and consistent voltage delivery across state-of-charge ranges. The electrochemical response analysis must account for these rapid transitions between low and high power states.

Industrial applications, including uninterruptible power supplies and material handling equipment, prioritize metrics such as peak power capability, operational temperature range, and cycle life under deep discharge conditions. These systems often face harsh operating environments where electrochemical performance must remain predictable despite temperature fluctuations, vibration, and irregular usage patterns.

Standardized testing protocols have emerged to quantify these performance metrics, including pulse power characterization, hybrid pulse power characterization (HPPC), and dynamic stress tests (DST). These methodologies provide frameworks for analyzing load-response behavior across different timescales, from milliseconds to hours, enabling meaningful comparisons between different electrochemical storage technologies and their suitability for specific applications.

For grid applications, energy storage systems must demonstrate reliable performance metrics including high round-trip efficiency (typically 80-95% for advanced systems), rapid response times (milliseconds to seconds), and cycle stability under fluctuating demand patterns. The ability to analyze and predict electrochemical cell response becomes particularly crucial for frequency regulation services, where batteries must respond to sub-second grid signals while maintaining thermal stability and minimizing degradation.

In electric vehicle applications, performance metrics focus on power density (W/kg), energy density (Wh/kg), and transient response characteristics during acceleration and regenerative braking events. The electrochemical cell's ability to handle high C-rates without excessive temperature rise or capacity fade determines vehicle range, acceleration capabilities, and overall battery lifespan. Modern EVs require batteries capable of delivering 3-10C discharge rates while maintaining efficiency above 90%.

Consumer electronics present unique challenges with highly variable load profiles, from standby operation to processor-intensive tasks that create sudden current spikes. Performance metrics in this domain emphasize volumetric energy density, self-discharge rates (typically <5% monthly), and consistent voltage delivery across state-of-charge ranges. The electrochemical response analysis must account for these rapid transitions between low and high power states.

Industrial applications, including uninterruptible power supplies and material handling equipment, prioritize metrics such as peak power capability, operational temperature range, and cycle life under deep discharge conditions. These systems often face harsh operating environments where electrochemical performance must remain predictable despite temperature fluctuations, vibration, and irregular usage patterns.

Standardized testing protocols have emerged to quantify these performance metrics, including pulse power characterization, hybrid pulse power characterization (HPPC), and dynamic stress tests (DST). These methodologies provide frameworks for analyzing load-response behavior across different timescales, from milliseconds to hours, enabling meaningful comparisons between different electrochemical storage technologies and their suitability for specific applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!