How to Minimize Heat Generation in Electrochemical Cells

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Cell Thermal Management Background and Objectives

Electrochemical cells have evolved significantly since Alessandro Volta's pioneering work in 1800, progressing from simple galvanic cells to today's sophisticated lithium-ion batteries powering electric vehicles and renewable energy storage systems. This technological evolution has consistently faced one persistent challenge: heat generation during operation, which remains a critical limiting factor in performance, safety, and longevity.

Heat generation in electrochemical cells stems from multiple sources, including ohmic resistance, electrochemical reactions, and ion transport processes. As energy density requirements increase to meet modern applications' demands, thermal management has become increasingly crucial. Historical incidents involving thermal runaway in lithium-ion batteries have highlighted the severe safety implications of inadequate thermal management, driving significant research and development efforts in this domain.

The global shift toward electrification across transportation, energy, and consumer electronics sectors has accelerated the need for advanced thermal management solutions. Market projections indicate that by 2030, electric vehicles will constitute over 30% of new vehicle sales, while grid-scale energy storage is expected to grow tenfold, both requiring electrochemical cells with optimized thermal characteristics.

Current thermal management approaches range from passive cooling systems to active liquid cooling technologies, yet they often add significant weight, complexity, and cost to battery systems. The fundamental challenge lies in addressing heat generation at its source rather than merely managing its dissipation, representing a paradigm shift in approach that could revolutionize electrochemical cell design.

This technical research aims to comprehensively examine strategies for minimizing heat generation within electrochemical cells themselves, focusing on materials science innovations, cell architecture optimization, and electrochemical engineering approaches. We seek to identify and evaluate emerging technologies that address thermal issues at their fundamental origins rather than through external management systems.

The primary objectives include mapping the thermal behavior mechanisms in various electrochemical cell chemistries, quantifying heat generation contributions from different cell components and processes, and identifying promising research directions for intrinsic heat reduction. Additionally, we aim to establish performance metrics and benchmarks for evaluating thermal efficiency improvements and develop predictive models for heat generation under various operating conditions.

Success in this research domain could enable next-generation electrochemical cells with significantly reduced thermal signatures, allowing for higher power densities, faster charging capabilities, extended cycle life, and enhanced safety profiles across applications from portable electronics to grid-scale energy storage systems.

Heat generation in electrochemical cells stems from multiple sources, including ohmic resistance, electrochemical reactions, and ion transport processes. As energy density requirements increase to meet modern applications' demands, thermal management has become increasingly crucial. Historical incidents involving thermal runaway in lithium-ion batteries have highlighted the severe safety implications of inadequate thermal management, driving significant research and development efforts in this domain.

The global shift toward electrification across transportation, energy, and consumer electronics sectors has accelerated the need for advanced thermal management solutions. Market projections indicate that by 2030, electric vehicles will constitute over 30% of new vehicle sales, while grid-scale energy storage is expected to grow tenfold, both requiring electrochemical cells with optimized thermal characteristics.

Current thermal management approaches range from passive cooling systems to active liquid cooling technologies, yet they often add significant weight, complexity, and cost to battery systems. The fundamental challenge lies in addressing heat generation at its source rather than merely managing its dissipation, representing a paradigm shift in approach that could revolutionize electrochemical cell design.

This technical research aims to comprehensively examine strategies for minimizing heat generation within electrochemical cells themselves, focusing on materials science innovations, cell architecture optimization, and electrochemical engineering approaches. We seek to identify and evaluate emerging technologies that address thermal issues at their fundamental origins rather than through external management systems.

The primary objectives include mapping the thermal behavior mechanisms in various electrochemical cell chemistries, quantifying heat generation contributions from different cell components and processes, and identifying promising research directions for intrinsic heat reduction. Additionally, we aim to establish performance metrics and benchmarks for evaluating thermal efficiency improvements and develop predictive models for heat generation under various operating conditions.

Success in this research domain could enable next-generation electrochemical cells with significantly reduced thermal signatures, allowing for higher power densities, faster charging capabilities, extended cycle life, and enhanced safety profiles across applications from portable electronics to grid-scale energy storage systems.

Market Analysis for Low-Heat Battery Technologies

The global market for low-heat battery technologies is experiencing significant growth, driven primarily by the increasing demand for safer and more efficient energy storage solutions. The market size for advanced battery technologies reached approximately $94 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 12.3% through 2030. Within this broader market, low-heat battery technologies represent a rapidly expanding segment, particularly in applications where thermal management is critical.

Consumer electronics continues to be the largest application segment for low-heat battery technologies, accounting for roughly 38% of the market share. This dominance stems from the growing consumer preference for devices with longer battery life and enhanced safety features. The electric vehicle (EV) sector follows closely, representing about 31% of the market and exhibiting the fastest growth rate at 18.7% annually, as manufacturers seek batteries that minimize heat generation during fast charging and high-power discharge scenarios.

Regionally, Asia-Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea, where major battery manufacturers have established significant production capacities. North America and Europe account for 27% and 22% of the market respectively, with both regions showing accelerated adoption rates driven by stringent safety regulations and sustainability initiatives.

From an end-user perspective, automotive manufacturers represent the largest buyer segment (36%), followed by consumer electronics producers (29%) and grid storage system developers (18%). The remaining market share is distributed among various industrial applications, medical devices, and aerospace sectors.

Market analysis indicates that price sensitivity varies significantly across application segments. While consumer electronics manufacturers prioritize cost-effectiveness, automotive and aerospace sectors demonstrate willingness to pay premium prices for batteries with superior thermal management capabilities, reflecting the critical nature of safety in these applications.

Customer requirements are evolving toward batteries that not only minimize heat generation but also offer faster charging capabilities, longer cycle life, and improved energy density. This trend is particularly evident in the EV market, where consumers increasingly expect vehicles with longer ranges and shorter charging times without compromising safety.

The competitive landscape features established battery manufacturers expanding their R&D in thermal management technologies, alongside innovative startups focusing exclusively on novel approaches to heat minimization in electrochemical cells. Strategic partnerships between battery developers and thermal management specialists are becoming increasingly common, creating new market dynamics and accelerating technological advancement.

Consumer electronics continues to be the largest application segment for low-heat battery technologies, accounting for roughly 38% of the market share. This dominance stems from the growing consumer preference for devices with longer battery life and enhanced safety features. The electric vehicle (EV) sector follows closely, representing about 31% of the market and exhibiting the fastest growth rate at 18.7% annually, as manufacturers seek batteries that minimize heat generation during fast charging and high-power discharge scenarios.

Regionally, Asia-Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea, where major battery manufacturers have established significant production capacities. North America and Europe account for 27% and 22% of the market respectively, with both regions showing accelerated adoption rates driven by stringent safety regulations and sustainability initiatives.

From an end-user perspective, automotive manufacturers represent the largest buyer segment (36%), followed by consumer electronics producers (29%) and grid storage system developers (18%). The remaining market share is distributed among various industrial applications, medical devices, and aerospace sectors.

Market analysis indicates that price sensitivity varies significantly across application segments. While consumer electronics manufacturers prioritize cost-effectiveness, automotive and aerospace sectors demonstrate willingness to pay premium prices for batteries with superior thermal management capabilities, reflecting the critical nature of safety in these applications.

Customer requirements are evolving toward batteries that not only minimize heat generation but also offer faster charging capabilities, longer cycle life, and improved energy density. This trend is particularly evident in the EV market, where consumers increasingly expect vehicles with longer ranges and shorter charging times without compromising safety.

The competitive landscape features established battery manufacturers expanding their R&D in thermal management technologies, alongside innovative startups focusing exclusively on novel approaches to heat minimization in electrochemical cells. Strategic partnerships between battery developers and thermal management specialists are becoming increasingly common, creating new market dynamics and accelerating technological advancement.

Current Challenges in Battery Thermal Management

Despite significant advancements in battery technology, thermal management remains one of the most critical challenges in electrochemical cell design and operation. Heat generation in batteries occurs through multiple mechanisms, including ohmic heating from internal resistance, electrochemical reactions, and ion transport processes. These thermal issues become increasingly problematic as battery systems scale up for applications like electric vehicles and grid storage.

Current thermal management systems face significant limitations in their ability to efficiently dissipate heat, particularly under high-rate charging and discharging conditions. Conventional cooling methods such as air cooling, liquid cooling, and phase change materials each present their own set of challenges. Air cooling systems, while simple and cost-effective, offer limited cooling capacity and efficiency, making them inadequate for high-power applications.

Liquid cooling systems provide superior thermal performance but introduce complexity, weight, and potential leakage concerns. Additionally, they require parasitic power for pumps and control systems, reducing overall energy efficiency. Phase change materials offer promising thermal buffering capabilities but struggle with thermal conductivity limitations and cycle life degradation.

Another significant challenge is the non-uniform temperature distribution within battery packs. Thermal gradients can lead to differential aging of cells, creating performance imbalances that reduce overall system efficiency and lifespan. Current battery management systems often lack sufficient thermal sensing resolution to detect these gradients effectively.

The integration of thermal management with other battery subsystems presents additional complications. Engineers must balance thermal design with electrical, mechanical, and safety requirements, often leading to compromises in overall system performance. Weight and volume constraints, particularly in mobile applications, further limit the implementation of comprehensive thermal solutions.

From a materials perspective, current electrode and electrolyte formulations still generate significant heat during operation. Research into low-resistance materials and thermally stable electrolytes has shown promise but faces challenges in scaling to commercial production while maintaining performance and safety standards.

Computational modeling of battery thermal behavior remains another challenge. While significant progress has been made in developing multi-physics models that couple electrochemical and thermal phenomena, these models often require extensive computational resources and struggle to capture the full complexity of real-world operating conditions, particularly during abuse scenarios or at system-level scales.

As battery technologies continue to evolve toward higher energy densities and faster charging capabilities, these thermal management challenges will only intensify, requiring innovative approaches that address heat generation at its source rather than merely managing its effects.

Current thermal management systems face significant limitations in their ability to efficiently dissipate heat, particularly under high-rate charging and discharging conditions. Conventional cooling methods such as air cooling, liquid cooling, and phase change materials each present their own set of challenges. Air cooling systems, while simple and cost-effective, offer limited cooling capacity and efficiency, making them inadequate for high-power applications.

Liquid cooling systems provide superior thermal performance but introduce complexity, weight, and potential leakage concerns. Additionally, they require parasitic power for pumps and control systems, reducing overall energy efficiency. Phase change materials offer promising thermal buffering capabilities but struggle with thermal conductivity limitations and cycle life degradation.

Another significant challenge is the non-uniform temperature distribution within battery packs. Thermal gradients can lead to differential aging of cells, creating performance imbalances that reduce overall system efficiency and lifespan. Current battery management systems often lack sufficient thermal sensing resolution to detect these gradients effectively.

The integration of thermal management with other battery subsystems presents additional complications. Engineers must balance thermal design with electrical, mechanical, and safety requirements, often leading to compromises in overall system performance. Weight and volume constraints, particularly in mobile applications, further limit the implementation of comprehensive thermal solutions.

From a materials perspective, current electrode and electrolyte formulations still generate significant heat during operation. Research into low-resistance materials and thermally stable electrolytes has shown promise but faces challenges in scaling to commercial production while maintaining performance and safety standards.

Computational modeling of battery thermal behavior remains another challenge. While significant progress has been made in developing multi-physics models that couple electrochemical and thermal phenomena, these models often require extensive computational resources and struggle to capture the full complexity of real-world operating conditions, particularly during abuse scenarios or at system-level scales.

As battery technologies continue to evolve toward higher energy densities and faster charging capabilities, these thermal management challenges will only intensify, requiring innovative approaches that address heat generation at its source rather than merely managing its effects.

Current Heat Reduction Methods and Technologies

01 Thermal management systems for electrochemical cells

Various thermal management systems are designed to control heat generation in electrochemical cells. These systems include cooling mechanisms, heat exchangers, and thermal regulation components that help maintain optimal operating temperatures. Effective thermal management prevents overheating, extends battery life, and improves overall performance and safety of electrochemical cells, particularly in high-power applications.- Heat management systems in electrochemical cells: Various heat management systems are employed in electrochemical cells to control temperature during operation. These systems include cooling mechanisms, thermal regulation components, and heat dissipation structures that help maintain optimal operating temperatures. Effective heat management prevents thermal runaway, extends cell life, and improves overall efficiency and safety of the electrochemical cells.

- Heat generation during electrochemical reactions: Electrochemical cells generate heat during operation due to various electrochemical reactions and internal resistance. This heat generation is influenced by factors such as current density, electrode materials, and electrolyte composition. Understanding the mechanisms of heat generation is crucial for designing cells that can operate efficiently while managing thermal output, particularly in high-power applications.

- Thermal management in battery packs: Battery packs composed of multiple electrochemical cells require specialized thermal management strategies to handle collective heat generation. These strategies include active cooling systems, thermal interface materials, and strategic cell arrangement to facilitate heat dissipation. Effective thermal management in battery packs prevents temperature gradients between cells, which can lead to uneven performance and accelerated degradation.

- Heat utilization and energy recovery: Some advanced electrochemical cell designs incorporate systems to capture and utilize the heat generated during operation. These systems convert thermal energy into additional electrical output or use it for other applications, improving overall energy efficiency. Heat recovery techniques include thermoelectric converters, heat exchangers, and integrated thermal energy storage systems that can repurpose what would otherwise be wasted energy.

- Materials and designs for thermal stability: Specialized materials and cell designs are developed to enhance thermal stability in electrochemical cells. These include heat-resistant electrode materials, thermally conductive components, and structural designs that facilitate heat dissipation. Advanced electrolytes and separators with improved thermal properties help prevent thermal runaway and enhance safety during high-temperature operation or in extreme environmental conditions.

02 Heat generation monitoring and control methods

Methods for monitoring and controlling heat generation in electrochemical cells involve temperature sensors, electronic control units, and algorithms that analyze thermal behavior. These systems can detect abnormal heat patterns, adjust operating parameters in real-time, and implement protective measures when temperature thresholds are exceeded. Advanced monitoring techniques help prevent thermal runaway situations and optimize energy efficiency during cell operation.Expand Specific Solutions03 Electrode materials and designs for heat reduction

Specialized electrode materials and designs can significantly impact heat generation in electrochemical cells. By optimizing electrode composition, structure, and surface area, researchers have developed cells with reduced internal resistance and improved thermal characteristics. These advancements include novel composite materials, nanostructured electrodes, and optimized geometries that minimize unwanted heat production during charging and discharging cycles.Expand Specific Solutions04 Electrolyte formulations for thermal stability

Advanced electrolyte formulations play a crucial role in managing heat generation within electrochemical cells. These specialized formulations include additives that enhance thermal stability, reduce exothermic reactions, and improve ion transport efficiency. By optimizing electrolyte composition, researchers have developed cells that generate less heat during operation while maintaining or improving electrochemical performance and safety characteristics.Expand Specific Solutions05 Heat utilization and energy recovery systems

Innovative systems have been developed to capture and utilize the heat generated by electrochemical cells. These technologies convert thermal energy into useful power through thermoelectric generators or use it for heating applications. Some designs incorporate phase change materials to absorb excess heat during high-load operations and release it when needed. These approaches improve overall system efficiency by recovering energy that would otherwise be wasted as heat.Expand Specific Solutions

Leading Companies and Research Institutions in Battery Thermal Solutions

The heat minimization in electrochemical cells market is currently in a growth phase, with increasing demand driven by electric vehicle and energy storage applications. The global market size is expanding rapidly, expected to reach significant volumes as battery technologies advance. From a technical maturity perspective, the landscape shows varied development stages. Industry leaders like Siemens AG and Robert Bosch GmbH are implementing advanced thermal management systems, while specialized players such as 24M Technologies and Ampcera are developing innovative solutions with novel electrolyte materials. Research institutions including Caltech and CNRS are contributing fundamental breakthroughs, while companies like NGK Insulators and VARTA Microbattery focus on commercial applications. The competitive dynamics involve both established manufacturers and emerging startups developing next-generation technologies to address this critical challenge.

Siemens AG

Technical Solution: Siemens has pioneered an innovative approach to electrochemical cell heat management through their Thermal-Electric Coupled Design (TECD) technology. This system utilizes computational fluid dynamics modeling to optimize cell geometry and material selection specifically for heat dissipation. Their cells incorporate specialized current collectors with enhanced thermal conductivity properties that efficiently channel heat away from reaction sites. Siemens has also developed a unique cooling architecture that integrates micro-channels directly into cell components, allowing for active cooling without compromising energy density. Their technology employs machine learning algorithms to continuously monitor thermal signatures and adjust operational parameters in real-time, preventing thermal runaway conditions before they develop.

Strengths: Superior integration with industrial automation systems; advanced predictive thermal modeling capabilities; excellent scalability for large installations. Weaknesses: Higher initial implementation costs; requires sophisticated control systems; optimization primarily focused on industrial-scale applications rather than consumer electronics.

24M Technologies, Inc.

Technical Solution: 24M Technologies has pioneered a semi-solid electrode technology that significantly reduces heat generation in electrochemical cells. Their patented SemiSolid manufacturing platform creates thicker electrodes with optimized ion transport pathways, reducing internal resistance by up to 40% compared to conventional designs. The company's approach eliminates numerous energy-intensive manufacturing steps, resulting in cells that generate less heat during both production and operation. 24M's technology incorporates specialized electrolyte formulations that maintain high ionic conductivity while improving thermal stability. Their cell architecture features reduced inactive material content and optimized current collector designs that minimize resistive heating. Additionally, 24M has developed advanced thermal modeling capabilities that enable precise prediction and management of heat generation patterns during various operational conditions.

Strengths: Simplified manufacturing process reduces cost barriers to implementation; significant reduction in internal cell resistance; compatible with multiple cell chemistries and form factors. Weaknesses: Requires adaptation of existing manufacturing infrastructure; optimal performance benefits may require complete cell redesign; technology still scaling to mass production levels.

Key Innovations in Electrochemical Cell Cooling Systems

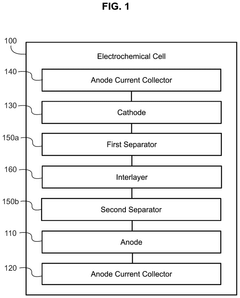

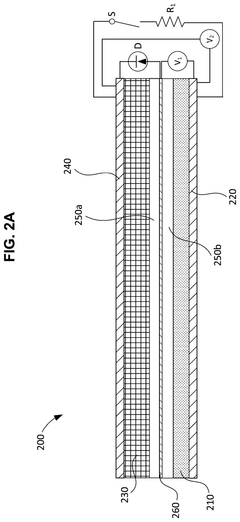

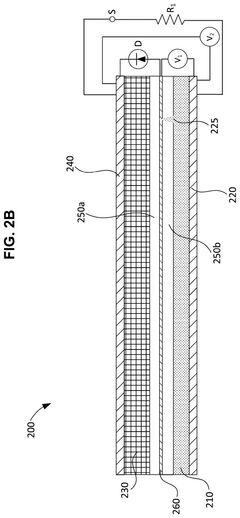

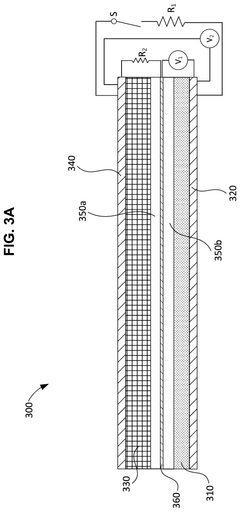

Systems and methods for minimizing and preventing dendrite formation in electrochemical cells

PatentActiveUS12119458B2

Innovation

- Incorporating an interlayer with electroactive material between the anode and cathode, connected to a power source that maintains a voltage difference below a threshold value, and utilizing a battery management system (BMS) to detect and prevent dendrite growth by safely discharging energy or dissolving dendrites using voltage manipulation.

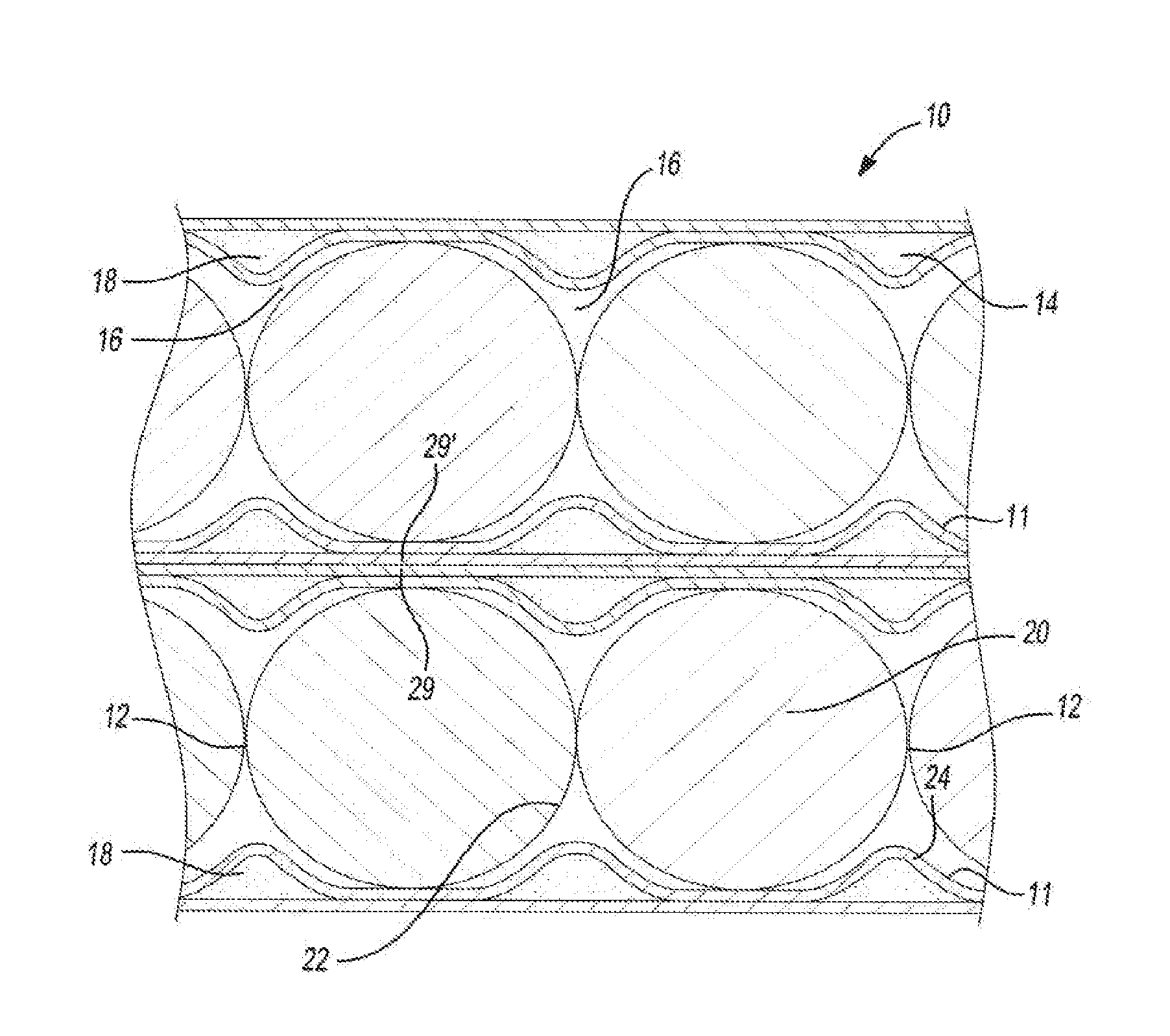

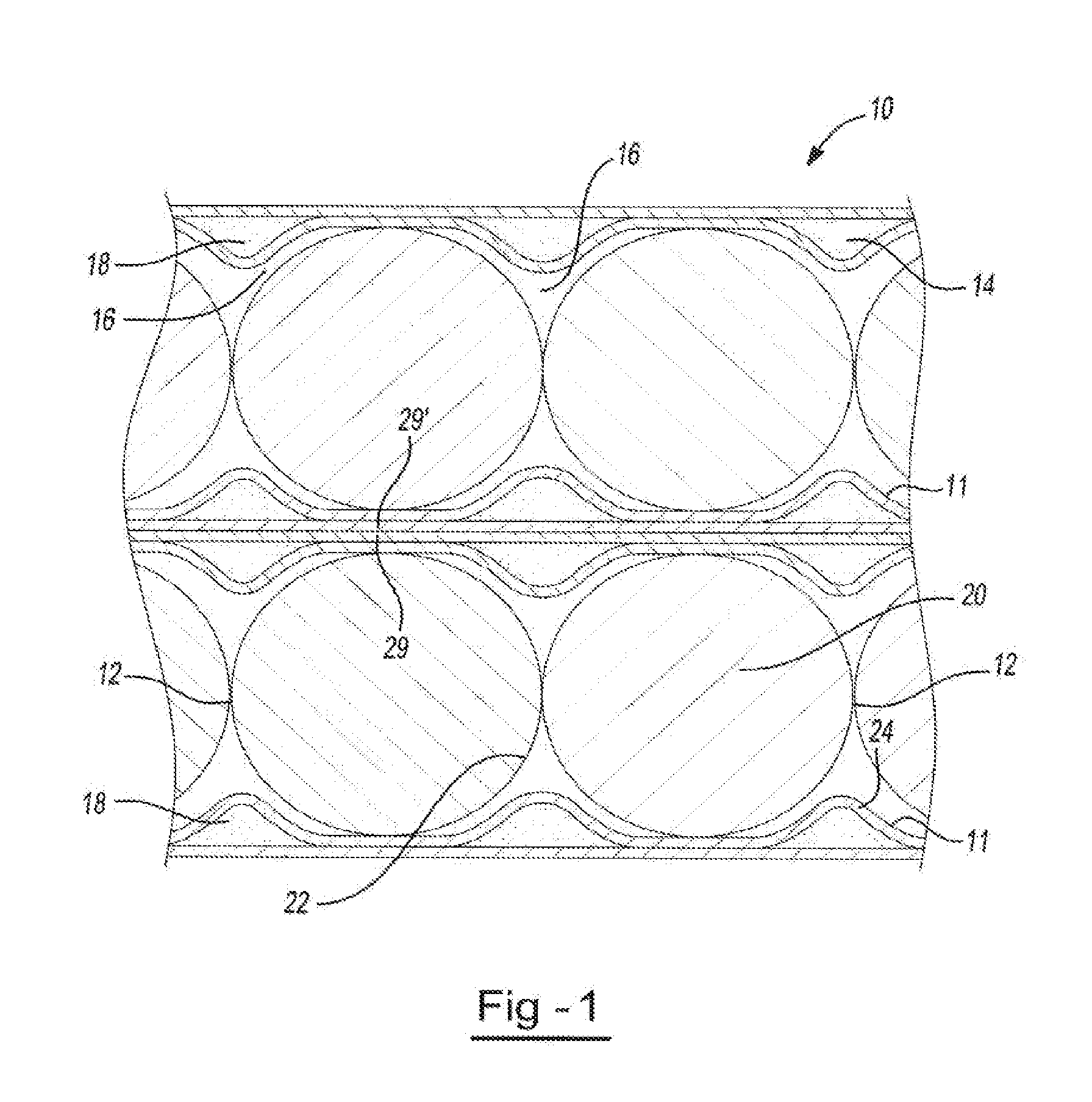

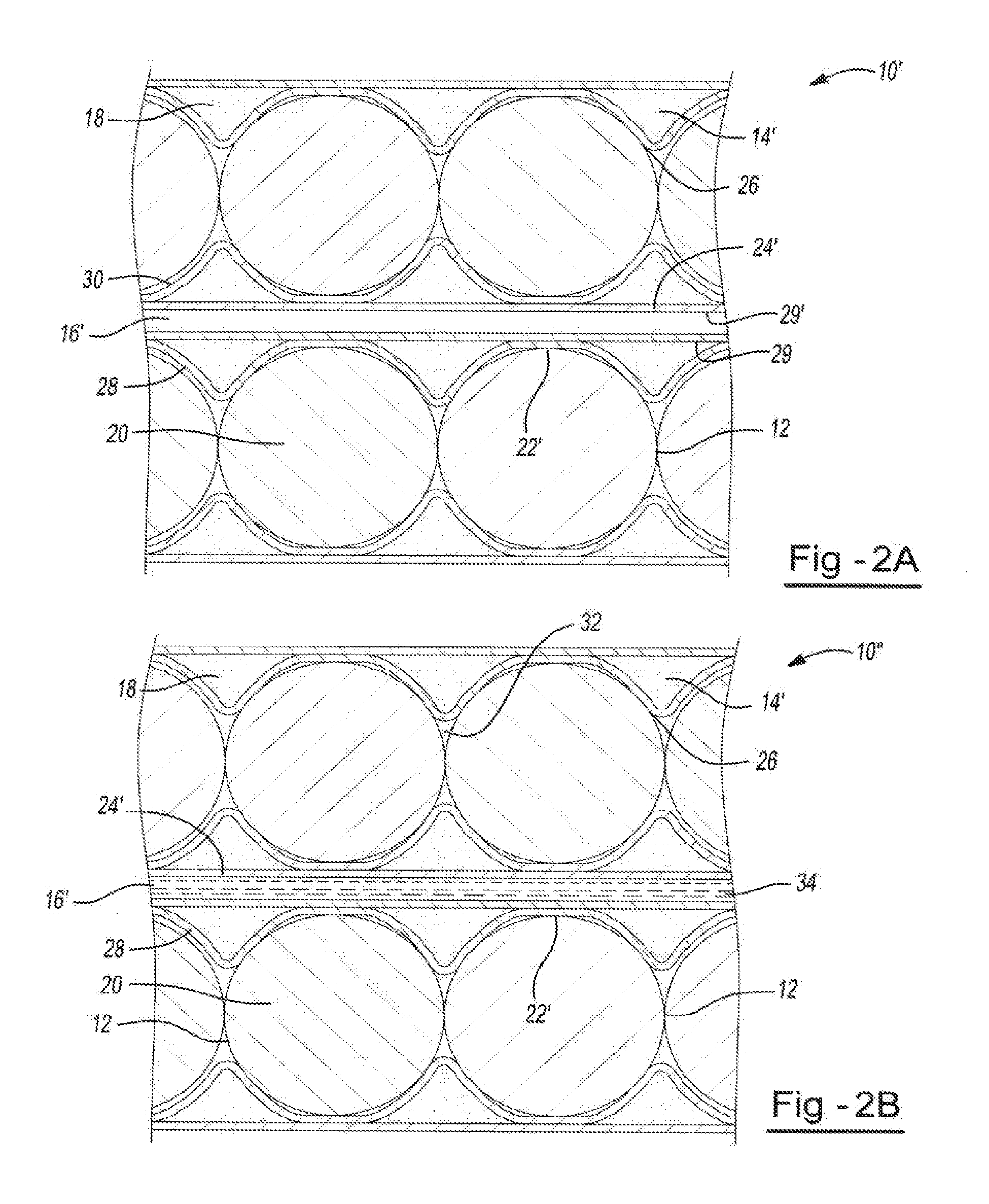

Thermal management of an electrochemical cell by a combination of heat transfer fluid and phase change material

PatentInactiveUS20120263980A1

Innovation

- A device comprising electrochemical cell compartments, thermal energy storage material compartments, and heat transfer fluid compartments, where the heat transfer fluid is in direct thermal communication with both the electrochemical cells and the thermal energy storage materials, allowing for rapid heat transfer and efficient temperature regulation within a target range.

Safety Standards and Regulatory Requirements for Battery Thermal Management

The regulatory landscape for battery thermal management has evolved significantly in response to safety incidents involving lithium-ion batteries. International standards such as IEC 62133, UL 1642, and UN 38.3 establish comprehensive requirements for battery safety, including thermal management specifications. These standards mandate specific temperature thresholds during normal operation and abuse conditions, requiring cells to maintain temperatures below critical limits to prevent thermal runaway.

The European Union's Battery Directive (2006/66/EC) and its recent update (2023/1657) incorporate specific thermal safety requirements, emphasizing the importance of effective heat management in electrochemical cells. Similarly, the UN Transportation Regulations (UN 38.3) outline rigorous testing protocols for batteries in transit, including thermal cycling and external short circuit tests that directly assess a battery's thermal management capabilities.

In the United States, the Consumer Product Safety Commission (CPSC) has established guidelines specifically addressing thermal risks in consumer electronics. The National Fire Protection Association (NFPA) has developed standard NFPA 855, which provides requirements for the installation of energy storage systems, including specific provisions for thermal management and fire prevention in battery installations.

Industry-specific standards have also emerged, such as SAE J2464 for electric vehicle batteries, which includes detailed thermal propagation requirements. These standards require manufacturers to demonstrate that thermal events in one cell will not propagate to adjacent cells, necessitating sophisticated thermal management solutions.

Compliance with these regulations requires manufacturers to implement comprehensive thermal monitoring systems. Temperature sensors must be strategically placed throughout battery packs, with automated shutdown mechanisms that activate when temperatures approach dangerous thresholds. Documentation requirements are equally stringent, with manufacturers needing to maintain detailed records of thermal testing and validation procedures.

Recent regulatory trends indicate a move toward more stringent thermal management requirements, particularly for high-energy density applications. The International Electrotechnical Commission (IEC) is developing new standards specifically focused on thermal propagation prevention, while transportation authorities are implementing more rigorous thermal abuse testing protocols. These evolving standards are driving innovation in thermal management technologies, pushing manufacturers to develop more effective solutions for minimizing heat generation in electrochemical cells.

The European Union's Battery Directive (2006/66/EC) and its recent update (2023/1657) incorporate specific thermal safety requirements, emphasizing the importance of effective heat management in electrochemical cells. Similarly, the UN Transportation Regulations (UN 38.3) outline rigorous testing protocols for batteries in transit, including thermal cycling and external short circuit tests that directly assess a battery's thermal management capabilities.

In the United States, the Consumer Product Safety Commission (CPSC) has established guidelines specifically addressing thermal risks in consumer electronics. The National Fire Protection Association (NFPA) has developed standard NFPA 855, which provides requirements for the installation of energy storage systems, including specific provisions for thermal management and fire prevention in battery installations.

Industry-specific standards have also emerged, such as SAE J2464 for electric vehicle batteries, which includes detailed thermal propagation requirements. These standards require manufacturers to demonstrate that thermal events in one cell will not propagate to adjacent cells, necessitating sophisticated thermal management solutions.

Compliance with these regulations requires manufacturers to implement comprehensive thermal monitoring systems. Temperature sensors must be strategically placed throughout battery packs, with automated shutdown mechanisms that activate when temperatures approach dangerous thresholds. Documentation requirements are equally stringent, with manufacturers needing to maintain detailed records of thermal testing and validation procedures.

Recent regulatory trends indicate a move toward more stringent thermal management requirements, particularly for high-energy density applications. The International Electrotechnical Commission (IEC) is developing new standards specifically focused on thermal propagation prevention, while transportation authorities are implementing more rigorous thermal abuse testing protocols. These evolving standards are driving innovation in thermal management technologies, pushing manufacturers to develop more effective solutions for minimizing heat generation in electrochemical cells.

Environmental Impact of Advanced Cooling Technologies

The environmental implications of advanced cooling technologies for electrochemical cells extend far beyond their immediate operational benefits. As these technologies evolve to address heat generation challenges, their ecological footprint becomes increasingly significant in sustainability assessments.

Advanced liquid cooling systems, while effective at temperature management, often utilize specialized coolants containing glycols or other chemical compounds that pose environmental risks if leaked or improperly disposed of. The manufacturing of these coolants requires energy-intensive processes and raw materials extraction, contributing to upstream carbon emissions and resource depletion.

Passive cooling technologies generally offer more environmentally favorable profiles. Phase change materials (PCMs), for instance, can be designed using bio-based compounds with lower environmental impact than traditional petroleum-derived alternatives. However, the longevity and end-of-life management of these materials remain concerns, as some PCMs may degrade into potentially harmful substances over time.

The energy efficiency gains from advanced cooling technologies must be evaluated through comprehensive life cycle assessments. While improved thermal management reduces operational energy consumption in electrochemical cells, the embodied energy in manufacturing sophisticated cooling systems may offset these benefits in short-term applications. Studies indicate that advanced cooling systems typically need to operate for 2-3 years before their energy savings surpass their production footprint.

Water consumption represents another critical environmental consideration. Direct water cooling systems can place significant pressure on local water resources, particularly in water-stressed regions. Closed-loop systems mitigate this concern but require additional energy for water recirculation and treatment.

Material selection for cooling components increasingly incorporates recyclability and biodegradability considerations. Aluminum heat sinks, commonly used in passive cooling designs, offer excellent recyclability, while newer biopolymer-based heat dissipation materials present promising end-of-life advantages despite currently lower thermal performance.

Refrigerant-based cooling technologies face particular scrutiny due to their global warming potential. While modern refrigerants have significantly reduced ozone depletion impacts compared to historical compounds, their contribution to climate change remains substantial if released. Regulatory frameworks worldwide continue to evolve, pushing manufacturers toward natural refrigerants with minimal environmental impact.

The environmental calculus of cooling technologies ultimately depends on application context, deployment scale, and regional factors including energy mix and waste management infrastructure. As electrochemical cell applications expand across industries, holistic environmental assessment frameworks become essential for guiding cooling technology selection and development.

Advanced liquid cooling systems, while effective at temperature management, often utilize specialized coolants containing glycols or other chemical compounds that pose environmental risks if leaked or improperly disposed of. The manufacturing of these coolants requires energy-intensive processes and raw materials extraction, contributing to upstream carbon emissions and resource depletion.

Passive cooling technologies generally offer more environmentally favorable profiles. Phase change materials (PCMs), for instance, can be designed using bio-based compounds with lower environmental impact than traditional petroleum-derived alternatives. However, the longevity and end-of-life management of these materials remain concerns, as some PCMs may degrade into potentially harmful substances over time.

The energy efficiency gains from advanced cooling technologies must be evaluated through comprehensive life cycle assessments. While improved thermal management reduces operational energy consumption in electrochemical cells, the embodied energy in manufacturing sophisticated cooling systems may offset these benefits in short-term applications. Studies indicate that advanced cooling systems typically need to operate for 2-3 years before their energy savings surpass their production footprint.

Water consumption represents another critical environmental consideration. Direct water cooling systems can place significant pressure on local water resources, particularly in water-stressed regions. Closed-loop systems mitigate this concern but require additional energy for water recirculation and treatment.

Material selection for cooling components increasingly incorporates recyclability and biodegradability considerations. Aluminum heat sinks, commonly used in passive cooling designs, offer excellent recyclability, while newer biopolymer-based heat dissipation materials present promising end-of-life advantages despite currently lower thermal performance.

Refrigerant-based cooling technologies face particular scrutiny due to their global warming potential. While modern refrigerants have significantly reduced ozone depletion impacts compared to historical compounds, their contribution to climate change remains substantial if released. Regulatory frameworks worldwide continue to evolve, pushing manufacturers toward natural refrigerants with minimal environmental impact.

The environmental calculus of cooling technologies ultimately depends on application context, deployment scale, and regional factors including energy mix and waste management infrastructure. As electrochemical cell applications expand across industries, holistic environmental assessment frameworks become essential for guiding cooling technology selection and development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!