How to Enhance Electrochemical Cell Separator Strength

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Separator Technology Background and Objectives

Electrochemical separators have evolved significantly since their inception in the early 20th century, transitioning from simple porous materials to sophisticated engineered membranes. Initially designed merely to prevent physical contact between electrodes, modern separators now serve multiple critical functions in electrochemical cells, including ion transport facilitation, electrical insulation, and mechanical support. The evolution of separator technology has been closely tied to advancements in battery and fuel cell development, with significant acceleration occurring in the 1970s with the commercialization of lithium-ion batteries.

The current technological landscape demands separators with enhanced mechanical strength while maintaining optimal electrochemical performance. This dual requirement presents a fundamental engineering challenge, as improvements in mechanical properties often come at the expense of electrochemical efficiency. The primary objective of enhancing separator strength is to improve safety, extend operational lifespan, and enable next-generation high-energy-density electrochemical systems that place greater mechanical demands on separator materials.

Recent technological trends indicate a shift toward composite and hybrid separator architectures that combine multiple materials to achieve synergistic properties. Ceramic-reinforced polymeric separators, for instance, represent a promising approach to simultaneously enhance mechanical strength and maintain electrochemical performance. Additionally, nanomaterial integration, including graphene, carbon nanotubes, and nanofibers, has emerged as a frontier area for separator enhancement.

The global push toward electrification in transportation and renewable energy storage has intensified research efforts in this field. Market projections suggest that advanced separators will play a pivotal role in enabling the next generation of high-performance batteries with energy densities exceeding 400 Wh/kg, compared to current commercial systems averaging 250-300 Wh/kg. This improvement is essential for meeting the demanding requirements of electric vehicles with ranges exceeding 500 miles and grid-scale energy storage systems.

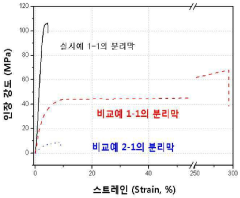

Technical objectives for enhanced separator strength include developing materials capable of withstanding mechanical stresses during cell assembly and operation, resisting dendrite penetration in lithium-metal systems, and maintaining dimensional stability under thermal and electrochemical stress. Quantitatively, industry targets include achieving tensile strengths above 200 MPa (compared to current 100-150 MPa), puncture resistance exceeding 500 gf/mil, and maintaining these properties at elevated temperatures (>150°C) and after extended cycling (>1000 cycles).

The path forward requires interdisciplinary collaboration between materials scientists, chemical engineers, and manufacturing specialists to translate laboratory innovations into commercially viable separator technologies that can be produced at scale while meeting stringent cost targets of less than $2/m² for automotive applications.

The current technological landscape demands separators with enhanced mechanical strength while maintaining optimal electrochemical performance. This dual requirement presents a fundamental engineering challenge, as improvements in mechanical properties often come at the expense of electrochemical efficiency. The primary objective of enhancing separator strength is to improve safety, extend operational lifespan, and enable next-generation high-energy-density electrochemical systems that place greater mechanical demands on separator materials.

Recent technological trends indicate a shift toward composite and hybrid separator architectures that combine multiple materials to achieve synergistic properties. Ceramic-reinforced polymeric separators, for instance, represent a promising approach to simultaneously enhance mechanical strength and maintain electrochemical performance. Additionally, nanomaterial integration, including graphene, carbon nanotubes, and nanofibers, has emerged as a frontier area for separator enhancement.

The global push toward electrification in transportation and renewable energy storage has intensified research efforts in this field. Market projections suggest that advanced separators will play a pivotal role in enabling the next generation of high-performance batteries with energy densities exceeding 400 Wh/kg, compared to current commercial systems averaging 250-300 Wh/kg. This improvement is essential for meeting the demanding requirements of electric vehicles with ranges exceeding 500 miles and grid-scale energy storage systems.

Technical objectives for enhanced separator strength include developing materials capable of withstanding mechanical stresses during cell assembly and operation, resisting dendrite penetration in lithium-metal systems, and maintaining dimensional stability under thermal and electrochemical stress. Quantitatively, industry targets include achieving tensile strengths above 200 MPa (compared to current 100-150 MPa), puncture resistance exceeding 500 gf/mil, and maintaining these properties at elevated temperatures (>150°C) and after extended cycling (>1000 cycles).

The path forward requires interdisciplinary collaboration between materials scientists, chemical engineers, and manufacturing specialists to translate laboratory innovations into commercially viable separator technologies that can be produced at scale while meeting stringent cost targets of less than $2/m² for automotive applications.

Market Analysis for Enhanced Separator Materials

The global market for enhanced separator materials in electrochemical cells is experiencing robust growth, driven primarily by the expanding electric vehicle (EV) sector and increasing demand for high-performance energy storage solutions. Current market valuations indicate that the separator materials market reached approximately 3.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 12-15% through 2030.

The demand for enhanced separator strength stems from several market imperatives. Safety concerns remain paramount, particularly following high-profile battery failure incidents that have resulted in recalls and significant brand damage for manufacturers. Stronger separators directly address thermal runaway risks by maintaining structural integrity under extreme conditions, a feature increasingly mandated by regulatory frameworks worldwide.

Performance requirements are simultaneously evolving as consumers and industries demand faster charging capabilities, longer cycle life, and higher energy densities. Enhanced separator strength enables thinner separator designs without compromising safety, directly contributing to improved energy density metrics that manufacturers can leverage as competitive advantages.

Regional market analysis reveals interesting patterns in demand distribution. Asia-Pacific dominates production capacity, with China, South Korea, and Japan collectively accounting for over 70% of global separator manufacturing. However, recent geopolitical tensions and supply chain vulnerabilities have accelerated localization efforts in North America and Europe, creating new market opportunities for innovative separator technologies with enhanced mechanical properties.

End-user segmentation shows automotive applications leading demand growth at 18% annually, followed by consumer electronics at 11% and grid storage applications at 14%. This segmentation reflects the different performance requirements across applications, with automotive demanding the highest safety standards and mechanical resilience.

Price sensitivity analysis indicates that while enhanced separator materials command premium pricing (typically 30-40% above standard offerings), manufacturers demonstrate willingness to absorb these costs due to the downstream benefits in product performance, warranty claim reduction, and brand protection. This price elasticity creates favorable conditions for innovation investment in stronger separator technologies.

Market consolidation trends show increasing vertical integration, with cell manufacturers acquiring or developing proprietary separator technologies to secure competitive advantages. This trend suggests that separator strength enhancement technologies with demonstrable performance improvements represent high-value acquisition targets in the current market landscape.

The demand for enhanced separator strength stems from several market imperatives. Safety concerns remain paramount, particularly following high-profile battery failure incidents that have resulted in recalls and significant brand damage for manufacturers. Stronger separators directly address thermal runaway risks by maintaining structural integrity under extreme conditions, a feature increasingly mandated by regulatory frameworks worldwide.

Performance requirements are simultaneously evolving as consumers and industries demand faster charging capabilities, longer cycle life, and higher energy densities. Enhanced separator strength enables thinner separator designs without compromising safety, directly contributing to improved energy density metrics that manufacturers can leverage as competitive advantages.

Regional market analysis reveals interesting patterns in demand distribution. Asia-Pacific dominates production capacity, with China, South Korea, and Japan collectively accounting for over 70% of global separator manufacturing. However, recent geopolitical tensions and supply chain vulnerabilities have accelerated localization efforts in North America and Europe, creating new market opportunities for innovative separator technologies with enhanced mechanical properties.

End-user segmentation shows automotive applications leading demand growth at 18% annually, followed by consumer electronics at 11% and grid storage applications at 14%. This segmentation reflects the different performance requirements across applications, with automotive demanding the highest safety standards and mechanical resilience.

Price sensitivity analysis indicates that while enhanced separator materials command premium pricing (typically 30-40% above standard offerings), manufacturers demonstrate willingness to absorb these costs due to the downstream benefits in product performance, warranty claim reduction, and brand protection. This price elasticity creates favorable conditions for innovation investment in stronger separator technologies.

Market consolidation trends show increasing vertical integration, with cell manufacturers acquiring or developing proprietary separator technologies to secure competitive advantages. This trend suggests that separator strength enhancement technologies with demonstrable performance improvements represent high-value acquisition targets in the current market landscape.

Current Challenges in Separator Strength Development

Despite significant advancements in electrochemical cell technology, separator strength remains a critical bottleneck in achieving optimal performance and safety. Current separators face multiple challenges that limit their mechanical integrity under operational conditions. The primary issue is the inherent trade-off between porosity and mechanical strength - higher porosity facilitates better ion transport but compromises structural integrity, while increased thickness for strength reduces energy density and rate capability.

Temperature sensitivity presents another significant challenge, as many separator materials experience dramatic mechanical degradation at elevated temperatures typical in high-power applications. Polyolefin-based separators, widely used for their chemical stability, begin to lose dimensional stability at temperatures above 100°C, potentially leading to catastrophic cell failure through internal short circuits.

Chemical degradation mechanisms pose persistent challenges, particularly in advanced battery chemistries with aggressive electrolytes. Long-term exposure to these environments causes gradual weakening of separator materials through mechanisms including solvent-induced swelling, plasticization effects, and direct chemical attack on polymer chains. These processes accelerate under the combined stresses of temperature fluctuations and mechanical deformation during cycling.

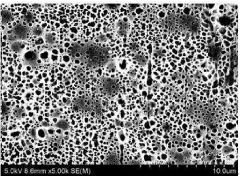

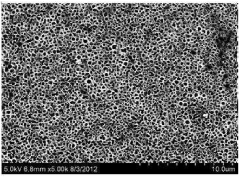

Manufacturing inconsistencies further complicate separator strength development. Current production techniques struggle to achieve uniform thickness, porosity distribution, and crystallinity across large-area separators. These inconsistencies create weak points that become failure initiation sites under mechanical stress, significantly reducing the effective strength of the separator system.

The scaling challenge remains particularly problematic for emerging separator technologies. Novel approaches demonstrating excellent strength characteristics in laboratory settings often encounter significant barriers during scale-up, including process variability, increased defect rates, and cost constraints that force compromises in material quality or processing parameters.

Mechanical stress during cell assembly and operation represents another unresolved challenge. Modern high-energy-density cell designs subject separators to complex multi-directional stresses during winding or stacking processes. These stresses are further exacerbated during cycling by electrode expansion/contraction, particularly in silicon-based or conversion-type electrodes that experience substantial volume changes.

Finally, there exists a significant measurement and standardization gap in the field. Current testing protocols inadequately capture the complex mechanical environment within operating cells, leading to discrepancies between laboratory performance metrics and real-world reliability. The lack of standardized testing methodologies also hampers meaningful comparison between different separator technologies and slows industry-wide progress toward robust solutions.

Temperature sensitivity presents another significant challenge, as many separator materials experience dramatic mechanical degradation at elevated temperatures typical in high-power applications. Polyolefin-based separators, widely used for their chemical stability, begin to lose dimensional stability at temperatures above 100°C, potentially leading to catastrophic cell failure through internal short circuits.

Chemical degradation mechanisms pose persistent challenges, particularly in advanced battery chemistries with aggressive electrolytes. Long-term exposure to these environments causes gradual weakening of separator materials through mechanisms including solvent-induced swelling, plasticization effects, and direct chemical attack on polymer chains. These processes accelerate under the combined stresses of temperature fluctuations and mechanical deformation during cycling.

Manufacturing inconsistencies further complicate separator strength development. Current production techniques struggle to achieve uniform thickness, porosity distribution, and crystallinity across large-area separators. These inconsistencies create weak points that become failure initiation sites under mechanical stress, significantly reducing the effective strength of the separator system.

The scaling challenge remains particularly problematic for emerging separator technologies. Novel approaches demonstrating excellent strength characteristics in laboratory settings often encounter significant barriers during scale-up, including process variability, increased defect rates, and cost constraints that force compromises in material quality or processing parameters.

Mechanical stress during cell assembly and operation represents another unresolved challenge. Modern high-energy-density cell designs subject separators to complex multi-directional stresses during winding or stacking processes. These stresses are further exacerbated during cycling by electrode expansion/contraction, particularly in silicon-based or conversion-type electrodes that experience substantial volume changes.

Finally, there exists a significant measurement and standardization gap in the field. Current testing protocols inadequately capture the complex mechanical environment within operating cells, leading to discrepancies between laboratory performance metrics and real-world reliability. The lack of standardized testing methodologies also hampers meaningful comparison between different separator technologies and slows industry-wide progress toward robust solutions.

Current Approaches to Separator Strength Enhancement

01 Mechanical strength enhancement techniques for separators

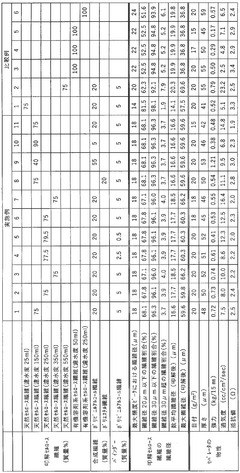

Various techniques can be employed to enhance the mechanical strength of electrochemical cell separators. These include the use of reinforcement materials, specialized coating processes, and structural modifications. Improved mechanical strength helps prevent separator failure during cell operation, enhances safety, and extends the overall lifespan of the electrochemical cell. These techniques often involve composite structures that maintain ion permeability while providing superior tensile and puncture resistance.- Mechanical strength enhancement techniques for separators: Various techniques can be employed to enhance the mechanical strength of electrochemical cell separators. These include the use of reinforcing materials, specialized coating processes, and structural modifications. Improved mechanical strength helps prevent separator failure during cell operation, enhances safety, and extends the overall lifespan of the electrochemical cell. These techniques often involve composite structures that maintain ion permeability while providing superior tensile and puncture resistance.

- Ceramic-reinforced separator materials: Incorporating ceramic particles or coatings into separator materials significantly improves their mechanical and thermal stability. These ceramic components provide structural reinforcement while maintaining necessary porosity for ion transport. The ceramic materials can include alumina, silica, or other metal oxides that enhance the separator's ability to withstand physical stress and high temperatures. This approach results in separators with improved puncture resistance and dimensional stability under various operating conditions.

- Polymer-based separator strength optimization: Polymer-based separators can be optimized for strength through molecular weight control, cross-linking techniques, and polymer blending. These approaches create separator materials with enhanced mechanical properties while maintaining flexibility and ion permeability. Advanced polymer engineering techniques allow for the development of separators that resist deformation under pressure and temperature fluctuations. The optimization process often involves balancing mechanical strength with other critical properties such as porosity and wettability.

- Testing and measurement methods for separator strength: Standardized testing protocols have been developed to evaluate the mechanical strength of electrochemical cell separators. These include tensile strength tests, puncture resistance measurements, and thermal stability assessments. Advanced characterization techniques provide quantitative data on separator performance under various stress conditions, enabling manufacturers to optimize separator designs. These testing methods help ensure that separators meet the required specifications for specific electrochemical cell applications.

- Multi-layer separator designs for enhanced strength: Multi-layer separator designs incorporate different materials in a layered structure to achieve superior mechanical properties. These composite structures can combine the benefits of different materials, such as the flexibility of polymers with the strength of ceramics or the thermal stability of specialized coatings. The layered approach allows for the optimization of different properties in each layer, resulting in separators with excellent overall performance characteristics including enhanced mechanical strength and improved safety features.

02 Ceramic-reinforced separator materials

Incorporating ceramic particles or coatings into separator materials significantly improves their mechanical strength and thermal stability. These ceramic components can include alumina, silica, or other metal oxides that create a more robust structure while maintaining necessary porosity for ion transport. Ceramic-reinforced separators offer enhanced puncture resistance and dimensional stability under high-temperature conditions, making them particularly valuable for high-energy density applications where safety is paramount.Expand Specific Solutions03 Polymer-based separator strength optimization

Polymer-based separators can be optimized for strength through various formulation and processing techniques. These include controlled crystallinity, cross-linking methods, and polymer blending approaches that enhance mechanical properties while maintaining ion conductivity. Advanced polymer engineering allows for the development of separators with tailored strength characteristics suited to specific electrochemical cell requirements, including flexibility, puncture resistance, and dimensional stability under varying operating conditions.Expand Specific Solutions04 Testing and measurement methods for separator strength

Standardized testing protocols and measurement methods are essential for evaluating and comparing the mechanical strength of electrochemical cell separators. These include tensile testing, puncture resistance measurements, and accelerated aging tests that simulate real-world operating conditions. Advanced characterization techniques such as microscopy and spectroscopy help correlate structural features with mechanical performance, enabling more precise design and quality control of separator materials for different electrochemical applications.Expand Specific Solutions05 Relationship between separator strength and cell performance

The mechanical strength of separators directly impacts overall electrochemical cell performance and safety. Stronger separators can withstand higher operating pressures, prevent internal short circuits, and maintain consistent ion transport pathways throughout the cell lifetime. Research demonstrates correlations between separator mechanical properties and cell cycle life, rate capability, and safety under extreme conditions. Optimizing separator strength must balance mechanical robustness with other critical properties like porosity, thickness, and ionic conductivity.Expand Specific Solutions

Leading Companies in Separator Manufacturing

The electrochemical cell separator strength enhancement market is currently in a growth phase, with increasing demand driven by the expanding electric vehicle and energy storage sectors. The global market size is projected to reach significant volumes as battery technology advances. Leading players like SEMCORP, LG Energy Solution, and Contemporary Amperex Technology are investing heavily in R&D to develop stronger, thinner separators that maintain safety while improving energy density. Technical maturity varies, with established companies like Toray Industries and Kuraray offering proven solutions, while innovative approaches emerge from newer entrants like 24M Technologies and EnPower with their multi-layer architectures. Research institutions such as Karlsruher Institut für Technologie and California Institute of Technology are advancing fundamental separator science, creating opportunities for commercial partnerships.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a proprietary Safety Reinforced Separator (SRS) technology that significantly enhances mechanical strength through a ceramic coating process. Their approach involves applying a uniform layer of inorganic particles (primarily alumina) bonded with heat-resistant polymers onto a polyethylene base. The company has further advanced this technology with their SRS+ system, which implements a dual-sided coating technique that increases puncture strength by approximately 50% compared to conventional separators. LG's latest innovation incorporates nano-scale ceramic particles with optimized morphology and distribution, creating a more uniform coating that enhances both mechanical strength and ion transport properties. Their manufacturing process employs precision coating technology that ensures consistent thickness and adhesion between the ceramic layer and the base film, which is critical for maintaining separator integrity under mechanical stress. Additionally, LG has developed specialized binder systems that maintain flexibility while improving the cohesion between ceramic particles, preventing particle shedding during cell assembly and operation.

Strengths: Excellent thermal stability combined with mechanical strength; proven safety record in commercial applications; proprietary coating technology that maintains ion conductivity. Weaknesses: Higher production costs than uncoated separators; potential for ceramic particle shedding in some applications; slightly increased thickness affecting energy density in some cell designs.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a multi-layer composite separator technology that combines ceramic coatings with polymer substrates to enhance mechanical strength. Their CTP (Cell-to-Pack) technology requires separators with superior mechanical properties to withstand higher pressure in the integrated battery structure. CATL's approach involves applying nano-ceramic particles (including alumina and silica) to polyolefin base films, creating a gradient structure that distributes mechanical stress more effectively. The company has also pioneered thermal-resistant binders that maintain separator integrity at elevated temperatures, preventing thermal shrinkage and mechanical failure. Their latest generation separators incorporate aramid nanofibers into the ceramic coating, which significantly improves puncture resistance and tensile strength while maintaining ion permeability. This technology has enabled CATL to achieve separator tensile strength improvements of over 40% compared to conventional polyolefin separators.

Strengths: Superior thermal stability and mechanical strength due to ceramic-polymer composite structure; excellent integration with their cell-to-pack technology; high puncture resistance. Weaknesses: Higher manufacturing costs compared to traditional separators; potential for increased thickness affecting energy density; complex manufacturing process requiring specialized equipment.

Key Innovations in Separator Material Science

Separator for electrochemical cell with improved mechanical properties and method for preparing the same

PatentActiveKR1020140028326A

Innovation

- A method involving casting a polymer solution of engineering plastic and a pore-forming agent on a support, drying, forming pores by dipping in water, and peeling off the film to create a separator with enhanced mechanical strength, using polyamideimide, polyetherimide, or polyethersulfone compounds, and pore-forming agents like PVP, PVA, or PEG, with optional inorganic particles for improved mechanical properties.

Separator for electrochemical elements

PatentWO2021131396A1

Innovation

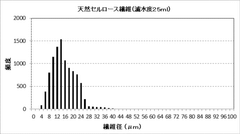

- A separator composed of synthetic fibers and beaten cellulose fibers with specific freeness and fiber diameter distribution, combined with a binder, to maintain strength while achieving a thinner thickness.

Safety Standards and Testing Protocols

The development of robust safety standards and testing protocols for electrochemical cell separators represents a critical component in ensuring battery reliability and consumer safety. Current international standards, including IEC 62133, UL 1642, and UN 38.3, establish comprehensive requirements for separator integrity under various stress conditions. These standards mandate specific mechanical strength tests, including puncture resistance, tensile strength, and elongation measurements, with minimum thresholds that vary based on battery chemistry and application.

Thermal stability testing has become increasingly stringent, requiring separators to maintain dimensional stability and mechanical properties at temperatures ranging from -40°C to 150°C, with particular emphasis on performance during thermal runaway scenarios. The hot needle penetration test, which simulates internal short circuits, has emerged as a standard evaluation method for separator resilience under extreme conditions.

Chemical compatibility testing protocols have evolved to assess separator degradation when exposed to electrolytes over extended periods. Standard procedures now include immersion tests lasting 500-1000 hours, with requirements for less than 5% reduction in mechanical properties. These protocols have been instrumental in identifying incompatibilities between novel electrolyte formulations and separator materials before commercial deployment.

Accelerated aging tests have been standardized to predict long-term separator performance, typically involving exposure to elevated temperatures (45-85°C) for periods of 3-12 months. These tests must demonstrate that separators retain at least 80% of their initial mechanical strength throughout the projected battery lifetime, which may extend to 8-10 years for automotive applications.

Industry-specific standards have emerged to address unique requirements in different sectors. For instance, aerospace applications follow DO-311A guidelines, which mandate separator strength retention under rapid decompression scenarios. Medical device batteries adhere to ISO 13485, requiring biocompatibility testing and enhanced mechanical integrity standards.

The development of in-situ testing methodologies represents a significant advancement in separator evaluation. These techniques enable real-time monitoring of separator properties during battery operation, providing insights into degradation mechanisms that traditional post-mortem analyses cannot capture. Acoustic emission testing and electrochemical impedance spectroscopy have been standardized as non-destructive methods for monitoring separator integrity throughout battery life.

Harmonization efforts between different regional standards bodies have accelerated in recent years, with the Global Battery Alliance working to establish unified testing protocols that facilitate international trade while maintaining rigorous safety requirements. These collaborative initiatives aim to address emerging challenges posed by next-generation battery technologies while ensuring consistent safety evaluation across global markets.

Thermal stability testing has become increasingly stringent, requiring separators to maintain dimensional stability and mechanical properties at temperatures ranging from -40°C to 150°C, with particular emphasis on performance during thermal runaway scenarios. The hot needle penetration test, which simulates internal short circuits, has emerged as a standard evaluation method for separator resilience under extreme conditions.

Chemical compatibility testing protocols have evolved to assess separator degradation when exposed to electrolytes over extended periods. Standard procedures now include immersion tests lasting 500-1000 hours, with requirements for less than 5% reduction in mechanical properties. These protocols have been instrumental in identifying incompatibilities between novel electrolyte formulations and separator materials before commercial deployment.

Accelerated aging tests have been standardized to predict long-term separator performance, typically involving exposure to elevated temperatures (45-85°C) for periods of 3-12 months. These tests must demonstrate that separators retain at least 80% of their initial mechanical strength throughout the projected battery lifetime, which may extend to 8-10 years for automotive applications.

Industry-specific standards have emerged to address unique requirements in different sectors. For instance, aerospace applications follow DO-311A guidelines, which mandate separator strength retention under rapid decompression scenarios. Medical device batteries adhere to ISO 13485, requiring biocompatibility testing and enhanced mechanical integrity standards.

The development of in-situ testing methodologies represents a significant advancement in separator evaluation. These techniques enable real-time monitoring of separator properties during battery operation, providing insights into degradation mechanisms that traditional post-mortem analyses cannot capture. Acoustic emission testing and electrochemical impedance spectroscopy have been standardized as non-destructive methods for monitoring separator integrity throughout battery life.

Harmonization efforts between different regional standards bodies have accelerated in recent years, with the Global Battery Alliance working to establish unified testing protocols that facilitate international trade while maintaining rigorous safety requirements. These collaborative initiatives aim to address emerging challenges posed by next-generation battery technologies while ensuring consistent safety evaluation across global markets.

Environmental Impact of Advanced Separator Materials

The advancement of separator materials for electrochemical cells brings significant environmental considerations that must be evaluated alongside performance improvements. Traditional separator materials often rely on petroleum-based polymers and energy-intensive manufacturing processes, contributing to carbon emissions and resource depletion. Advanced separator materials designed for enhanced strength typically incorporate synthetic compounds, ceramic coatings, or composite structures that may present new environmental challenges.

When examining the lifecycle impact of these advanced materials, production processes for high-strength separators often require specialized chemical treatments and precision manufacturing techniques that consume more energy than conventional methods. However, this initial environmental cost must be balanced against the extended lifespan and improved safety these materials provide to electrochemical cells, potentially reducing overall waste generation through fewer replacement cycles.

The disposal and recyclability of advanced separator materials present complex environmental trade-offs. While stronger separators contribute to longer-lasting batteries and reduced electronic waste, their complex compositions may complicate end-of-life processing. Multi-layer composite separators, for instance, can be difficult to separate into constituent materials for recycling, potentially increasing the volume of non-recyclable waste compared to simpler designs.

Water usage and chemical emissions during manufacturing represent another significant environmental consideration. Ceramic-coated separators and nanofiber-reinforced materials often require substantial water resources for processing and may generate wastewater containing specialized chemical compounds that require advanced treatment before release into the environment.

Biodegradability remains a challenge for most high-strength separator materials. While research into bio-based alternatives shows promise, these materials currently struggle to match the performance characteristics of synthetic options. The environmental persistence of advanced separator materials, particularly those incorporating nanomaterials or fluorinated compounds, raises concerns about long-term ecosystem impacts if improperly disposed of.

The environmental benefits of stronger separators include enhanced safety through reduced risk of thermal runaway events and chemical leakage, which can prevent contamination incidents. Additionally, by enabling more efficient electrochemical performance, advanced separators can contribute to overall system efficiency, potentially reducing the environmental footprint of the devices they power through lower energy consumption and extended operational lifespans.

When examining the lifecycle impact of these advanced materials, production processes for high-strength separators often require specialized chemical treatments and precision manufacturing techniques that consume more energy than conventional methods. However, this initial environmental cost must be balanced against the extended lifespan and improved safety these materials provide to electrochemical cells, potentially reducing overall waste generation through fewer replacement cycles.

The disposal and recyclability of advanced separator materials present complex environmental trade-offs. While stronger separators contribute to longer-lasting batteries and reduced electronic waste, their complex compositions may complicate end-of-life processing. Multi-layer composite separators, for instance, can be difficult to separate into constituent materials for recycling, potentially increasing the volume of non-recyclable waste compared to simpler designs.

Water usage and chemical emissions during manufacturing represent another significant environmental consideration. Ceramic-coated separators and nanofiber-reinforced materials often require substantial water resources for processing and may generate wastewater containing specialized chemical compounds that require advanced treatment before release into the environment.

Biodegradability remains a challenge for most high-strength separator materials. While research into bio-based alternatives shows promise, these materials currently struggle to match the performance characteristics of synthetic options. The environmental persistence of advanced separator materials, particularly those incorporating nanomaterials or fluorinated compounds, raises concerns about long-term ecosystem impacts if improperly disposed of.

The environmental benefits of stronger separators include enhanced safety through reduced risk of thermal runaway events and chemical leakage, which can prevent contamination incidents. Additionally, by enabling more efficient electrochemical performance, advanced separators can contribute to overall system efficiency, potentially reducing the environmental footprint of the devices they power through lower energy consumption and extended operational lifespans.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!