Electrochemical Cell Vs Hydrogen Cell: Efficiency Under Load

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical and Hydrogen Cell Technology Background

Electrochemical and hydrogen cells represent two distinct yet complementary approaches to energy conversion and storage technologies. Electrochemical cells, dating back to Alessandro Volta's pioneering work in 1800, have evolved from simple zinc-copper configurations to today's sophisticated lithium-ion, nickel-metal hydride, and flow battery systems. These cells operate on the fundamental principle of converting chemical energy directly into electrical energy through redox reactions occurring at electrodes separated by an electrolyte.

Hydrogen cells, particularly proton exchange membrane fuel cells (PEMFCs), emerged as practical energy conversion devices in the 1960s with NASA's space program adoption. Unlike traditional electrochemical cells, hydrogen fuel cells generate electricity through an electrochemical reaction between hydrogen and oxygen, producing water as the only byproduct. This clean operation has positioned hydrogen cells as promising candidates for sustainable energy solutions.

The technological evolution of both systems has been driven by increasing demands for higher energy density, improved efficiency, and reduced environmental impact. Electrochemical cells have seen remarkable advancements in electrode materials, electrolyte compositions, and cell architectures, leading to dramatic improvements in energy density from less than 30 Wh/kg in lead-acid batteries to over 250 Wh/kg in modern lithium-ion systems.

Hydrogen cell technology has similarly progressed, with significant breakthroughs in catalyst materials reducing platinum loading from 28 mg/cm² in early designs to less than 0.2 mg/cm² today. Membrane technology has evolved from early Nafion materials to advanced composite membranes with enhanced proton conductivity and durability.

Current research trends indicate convergence in certain aspects of these technologies, with hybrid systems emerging that leverage the strengths of both approaches. Electrochemical cells offer advantages in immediate response to load changes and established infrastructure, while hydrogen cells excel in energy density, refueling speed, and zero-emission operation.

The efficiency characteristics under varying load conditions represent a critical differentiator between these technologies. Electrochemical cells typically demonstrate high efficiency at low to moderate loads but experience significant efficiency drops under high-demand scenarios due to internal resistance and thermal limitations. Hydrogen cells maintain relatively stable efficiency across broader load ranges but face challenges with hydrogen storage, distribution, and overall system complexity.

Global research efforts are increasingly focused on addressing these complementary challenges, with particular emphasis on improving the round-trip efficiency of hydrogen production-storage-utilization cycles and enhancing the high-load performance of advanced electrochemical systems.

Hydrogen cells, particularly proton exchange membrane fuel cells (PEMFCs), emerged as practical energy conversion devices in the 1960s with NASA's space program adoption. Unlike traditional electrochemical cells, hydrogen fuel cells generate electricity through an electrochemical reaction between hydrogen and oxygen, producing water as the only byproduct. This clean operation has positioned hydrogen cells as promising candidates for sustainable energy solutions.

The technological evolution of both systems has been driven by increasing demands for higher energy density, improved efficiency, and reduced environmental impact. Electrochemical cells have seen remarkable advancements in electrode materials, electrolyte compositions, and cell architectures, leading to dramatic improvements in energy density from less than 30 Wh/kg in lead-acid batteries to over 250 Wh/kg in modern lithium-ion systems.

Hydrogen cell technology has similarly progressed, with significant breakthroughs in catalyst materials reducing platinum loading from 28 mg/cm² in early designs to less than 0.2 mg/cm² today. Membrane technology has evolved from early Nafion materials to advanced composite membranes with enhanced proton conductivity and durability.

Current research trends indicate convergence in certain aspects of these technologies, with hybrid systems emerging that leverage the strengths of both approaches. Electrochemical cells offer advantages in immediate response to load changes and established infrastructure, while hydrogen cells excel in energy density, refueling speed, and zero-emission operation.

The efficiency characteristics under varying load conditions represent a critical differentiator between these technologies. Electrochemical cells typically demonstrate high efficiency at low to moderate loads but experience significant efficiency drops under high-demand scenarios due to internal resistance and thermal limitations. Hydrogen cells maintain relatively stable efficiency across broader load ranges but face challenges with hydrogen storage, distribution, and overall system complexity.

Global research efforts are increasingly focused on addressing these complementary challenges, with particular emphasis on improving the round-trip efficiency of hydrogen production-storage-utilization cycles and enhancing the high-load performance of advanced electrochemical systems.

Market Demand Analysis for Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the need for reliable grid stabilization solutions. Current projections indicate the market will reach $300 billion by 2030, with a compound annual growth rate exceeding 20% over the next decade. This remarkable expansion creates a fertile environment for both electrochemical and hydrogen cell technologies to establish their respective market positions.

Electrochemical cells, particularly lithium-ion batteries, currently dominate the energy storage landscape with approximately 90% market share in new installations. Their widespread adoption stems from continuous cost reductions, with prices falling by 89% since 2010, making them increasingly accessible for both utility-scale and residential applications. However, market research indicates growing concerns about resource constraints, with lithium, cobalt, and nickel supply chains facing potential bottlenecks as demand continues to surge.

Hydrogen fuel cells represent an emerging segment within the energy storage market, currently accounting for only 5% of installations but demonstrating the highest growth rate at 35% annually. This acceleration is primarily driven by heavy-duty transportation, industrial applications, and long-duration energy storage requirements where electrochemical solutions face limitations. The hydrogen economy is gaining momentum with over $70 billion in announced investments globally since 2020.

Customer demand patterns reveal distinct market segments forming around these technologies. Electrochemical cells dominate in applications requiring rapid response times, high round-trip efficiency, and deployment flexibility. Meanwhile, hydrogen cells are increasingly preferred for applications demanding extended discharge durations, seasonal storage capabilities, and integration with industrial processes requiring high-temperature heat.

Regional market analysis shows Asia-Pacific leading electrochemical storage adoption with 45% market share, while Europe is emerging as the hydrogen technology frontrunner with substantial policy support through initiatives like the European Clean Hydrogen Alliance. North America demonstrates balanced growth across both technologies, with particular strength in grid-scale applications.

Industry surveys indicate that efficiency under load remains a critical decision factor for 78% of potential customers, with total cost of ownership and operational flexibility following closely. The market increasingly values solutions that can maintain high efficiency across variable load profiles, creating a competitive advantage for technologies that can demonstrate superior performance metrics in real-world operating conditions rather than just ideal laboratory settings.

Electrochemical cells, particularly lithium-ion batteries, currently dominate the energy storage landscape with approximately 90% market share in new installations. Their widespread adoption stems from continuous cost reductions, with prices falling by 89% since 2010, making them increasingly accessible for both utility-scale and residential applications. However, market research indicates growing concerns about resource constraints, with lithium, cobalt, and nickel supply chains facing potential bottlenecks as demand continues to surge.

Hydrogen fuel cells represent an emerging segment within the energy storage market, currently accounting for only 5% of installations but demonstrating the highest growth rate at 35% annually. This acceleration is primarily driven by heavy-duty transportation, industrial applications, and long-duration energy storage requirements where electrochemical solutions face limitations. The hydrogen economy is gaining momentum with over $70 billion in announced investments globally since 2020.

Customer demand patterns reveal distinct market segments forming around these technologies. Electrochemical cells dominate in applications requiring rapid response times, high round-trip efficiency, and deployment flexibility. Meanwhile, hydrogen cells are increasingly preferred for applications demanding extended discharge durations, seasonal storage capabilities, and integration with industrial processes requiring high-temperature heat.

Regional market analysis shows Asia-Pacific leading electrochemical storage adoption with 45% market share, while Europe is emerging as the hydrogen technology frontrunner with substantial policy support through initiatives like the European Clean Hydrogen Alliance. North America demonstrates balanced growth across both technologies, with particular strength in grid-scale applications.

Industry surveys indicate that efficiency under load remains a critical decision factor for 78% of potential customers, with total cost of ownership and operational flexibility following closely. The market increasingly values solutions that can maintain high efficiency across variable load profiles, creating a competitive advantage for technologies that can demonstrate superior performance metrics in real-world operating conditions rather than just ideal laboratory settings.

Current Technical Challenges in Cell Efficiency

Both electrochemical and hydrogen fuel cells face significant efficiency challenges under varying load conditions. Electrochemical cells, particularly lithium-ion batteries, experience efficiency losses due to internal resistance that increases with higher discharge rates. This resistance generates heat instead of useful energy, with efficiency dropping from 90-95% at low loads to below 70% under high-demand scenarios. The degradation accelerates when cells operate near maximum capacity, creating a negative feedback loop where heat generation further increases internal resistance.

Thermal management remains a critical challenge, as temperature variations across cell components lead to uneven current distribution and localized hotspots. These hotspots accelerate degradation and create potential safety hazards, particularly in high-power applications. Current cooling systems add significant weight and complexity, reducing overall system efficiency.

Hydrogen fuel cells face their own set of efficiency challenges. The oxygen reduction reaction (ORR) at the cathode represents a major bottleneck, with sluggish kinetics requiring expensive platinum catalysts to achieve practical efficiency levels. Even with optimal catalysts, voltage losses occur at higher current densities, with efficiency typically dropping from 60% at low loads to below 40% at maximum power output.

Water management presents another significant challenge for hydrogen cells. Under high loads, water production increases dramatically, potentially flooding catalyst layers and gas diffusion media. Conversely, at low loads, membrane dehydration can occur, increasing proton transport resistance. This delicate balance becomes particularly problematic in dynamic load applications like vehicles, where power demands fluctuate constantly.

Both technologies struggle with degradation mechanisms that accelerate under high-load conditions. For electrochemical cells, repeated deep discharges cause structural changes in electrode materials, reducing capacity and increasing internal resistance. Hydrogen cells suffer from catalyst poisoning and membrane thinning during high-current operation, with carbon support corrosion becoming particularly problematic during load cycling.

System-level integration further complicates efficiency optimization. Electrochemical cells require sophisticated battery management systems that consume parasitic power, while hydrogen cells need air compressors, humidifiers, and hydrogen recirculation systems that collectively reduce net system efficiency by 10-15%. These auxiliary components often operate at fixed power regardless of load, disproportionately affecting efficiency at lower power outputs.

Recent research focuses on advanced materials to address these challenges, including silicon-graphene composites for electrochemical cells and platinum-alloy catalysts for hydrogen cells. However, translating laboratory improvements to commercial-scale manufacturing while maintaining cost competitiveness remains a significant hurdle for both technologies.

Thermal management remains a critical challenge, as temperature variations across cell components lead to uneven current distribution and localized hotspots. These hotspots accelerate degradation and create potential safety hazards, particularly in high-power applications. Current cooling systems add significant weight and complexity, reducing overall system efficiency.

Hydrogen fuel cells face their own set of efficiency challenges. The oxygen reduction reaction (ORR) at the cathode represents a major bottleneck, with sluggish kinetics requiring expensive platinum catalysts to achieve practical efficiency levels. Even with optimal catalysts, voltage losses occur at higher current densities, with efficiency typically dropping from 60% at low loads to below 40% at maximum power output.

Water management presents another significant challenge for hydrogen cells. Under high loads, water production increases dramatically, potentially flooding catalyst layers and gas diffusion media. Conversely, at low loads, membrane dehydration can occur, increasing proton transport resistance. This delicate balance becomes particularly problematic in dynamic load applications like vehicles, where power demands fluctuate constantly.

Both technologies struggle with degradation mechanisms that accelerate under high-load conditions. For electrochemical cells, repeated deep discharges cause structural changes in electrode materials, reducing capacity and increasing internal resistance. Hydrogen cells suffer from catalyst poisoning and membrane thinning during high-current operation, with carbon support corrosion becoming particularly problematic during load cycling.

System-level integration further complicates efficiency optimization. Electrochemical cells require sophisticated battery management systems that consume parasitic power, while hydrogen cells need air compressors, humidifiers, and hydrogen recirculation systems that collectively reduce net system efficiency by 10-15%. These auxiliary components often operate at fixed power regardless of load, disproportionately affecting efficiency at lower power outputs.

Recent research focuses on advanced materials to address these challenges, including silicon-graphene composites for electrochemical cells and platinum-alloy catalysts for hydrogen cells. However, translating laboratory improvements to commercial-scale manufacturing while maintaining cost competitiveness remains a significant hurdle for both technologies.

Comparative Analysis of Current Cell Solutions

01 Catalyst materials for improved hydrogen cell efficiency

Advanced catalyst materials play a crucial role in enhancing the efficiency of hydrogen cells. These catalysts facilitate the electrochemical reactions at the electrodes, reducing activation energy and improving overall cell performance. Novel catalyst compositions, including platinum-based alloys, non-precious metal catalysts, and nanostructured materials, can significantly increase reaction rates while reducing the amount of expensive noble metals required. These innovations lead to higher power density, better durability, and more cost-effective hydrogen cell systems.- Electrode materials and catalysts for improved efficiency: Advanced electrode materials and catalysts play a crucial role in enhancing the efficiency of electrochemical and hydrogen cells. Novel catalysts can reduce activation energy barriers, increase reaction rates, and improve overall cell performance. Materials such as platinum alloys, non-precious metal catalysts, and nanostructured electrodes have been developed to maximize surface area and catalytic activity while minimizing material costs. These innovations help overcome efficiency limitations in both hydrogen production and fuel cell operation.

- Membrane and electrolyte technologies: Specialized membranes and electrolytes are essential components that significantly impact cell efficiency. Advanced proton exchange membranes with improved conductivity, durability, and reduced crossover effects enhance performance in both electrochemical and hydrogen cells. Solid electrolytes and ionic liquids offer advantages in terms of stability and operating temperature ranges. Optimized membrane-electrode assemblies ensure efficient ion transport while maintaining separation between reaction chambers, directly contributing to higher energy conversion efficiencies.

- System design and operating conditions optimization: The overall design of electrochemical and hydrogen cell systems significantly impacts their efficiency. Factors such as cell geometry, flow field patterns, temperature management, pressure regulation, and water balance all contribute to performance optimization. Advanced system architectures incorporate heat recovery mechanisms, pressure management systems, and optimized reactant delivery to maximize efficiency. Innovative stack designs and balance-of-plant components help reduce parasitic losses and improve overall system performance under various operating conditions.

- Hydrogen production and storage technologies: Efficient hydrogen production methods and storage solutions are critical for the overall efficiency of hydrogen-based energy systems. Advanced electrolysis techniques, including high-temperature electrolysis and photoelectrochemical approaches, offer improved energy conversion efficiency. Novel hydrogen storage materials and methods address challenges related to hydrogen density, safety, and release kinetics. Integration of renewable energy sources with hydrogen production systems enables more sustainable and efficient operation of electrochemical and hydrogen cells.

- Monitoring and control systems for efficiency optimization: Advanced monitoring and control systems enable real-time optimization of electrochemical and hydrogen cell performance. Sensors and diagnostic tools provide data on critical parameters such as temperature, pressure, humidity, and reactant concentrations. Intelligent control algorithms adjust operating conditions to maintain peak efficiency across varying loads and environmental conditions. Predictive maintenance capabilities help prevent degradation and extend cell lifetime, while advanced modeling techniques support system design optimization for maximum efficiency under specific application requirements.

02 Membrane and electrode assembly optimization

The efficiency of electrochemical and hydrogen cells heavily depends on the design and optimization of membrane electrode assemblies (MEAs). Advanced membrane materials with improved ion conductivity, reduced crossover, and enhanced mechanical stability contribute to higher cell efficiency. Electrode structures with optimized porosity, hydrophobicity, and catalyst distribution ensure effective mass transport and reaction kinetics. Innovations in MEA fabrication techniques, such as novel coating methods and composite structures, further enhance performance and durability under various operating conditions.Expand Specific Solutions03 System integration and thermal management

Effective system integration and thermal management are essential for maximizing electrochemical and hydrogen cell efficiency. Advanced heat exchange systems help maintain optimal operating temperatures, preventing performance degradation and extending cell lifetime. Integrated balance-of-plant components, such as humidifiers, pressure regulators, and power conditioning systems, ensure harmonized operation across the entire system. Innovative cell stack designs with improved flow field configurations enhance reactant distribution and product removal, leading to more uniform current density and higher overall efficiency.Expand Specific Solutions04 Electrolyte composition and water management

The composition of electrolytes and effective water management strategies significantly impact the efficiency of electrochemical and hydrogen cells. Advanced electrolyte formulations with optimized ionic conductivity and stability under various operating conditions improve cell performance. Water management techniques, including innovative humidification systems and water recovery methods, help maintain proper membrane hydration while preventing flooding or drying of electrodes. These advancements ensure consistent performance across a wide range of operating conditions and contribute to higher overall system efficiency.Expand Specific Solutions05 Novel cell architectures and operating strategies

Innovative cell architectures and operating strategies offer pathways to significantly enhance electrochemical and hydrogen cell efficiency. These include advanced cell geometries that optimize reactant flow and minimize pressure drops, reversible cell designs that can operate in both electrolysis and fuel cell modes, and hybrid systems that integrate multiple electrochemical technologies. Smart control strategies that dynamically adjust operating parameters based on load demands and ambient conditions further improve efficiency. These novel approaches enable higher power density, better resource utilization, and improved overall system performance.Expand Specific Solutions

Key Industry Players in Cell Technology Development

The electrochemical cell versus hydrogen cell efficiency landscape is currently in a growth phase, with the market expanding rapidly as clean energy solutions gain traction. The global market size for these technologies is projected to reach significant scale as automotive and stationary power applications increase. Technologically, electrochemical cells (particularly lithium-ion) have reached higher maturity levels, with companies like Toyota, Sony, and Hyundai leading commercial deployment. Meanwhile, hydrogen fuel cell technology is advancing through significant investments from Bosch, Toshiba, and Toyota, though still facing efficiency and infrastructure challenges. NGK Insulators and DuPont are making notable progress in materials innovation, while newer entrants like Electric Hydrogen and Power To Hydrogen are driving cost reductions. The competitive dynamics suggest a complementary future where both technologies serve different market segments based on specific power and duration requirements.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced electrochemical and hydrogen cell technologies with a focus on automotive applications. Their electrochemical cell solutions include high-performance lithium-ion batteries with energy densities reaching 350-400 Wh/kg, featuring silicon-carbon composite anodes and high-nickel cathodes. For hydrogen fuel cells, Bosch has created a modular stack design with power outputs ranging from 70-200 kW, utilizing metallic bipolar plates with specialized coatings that reduce platinum catalyst loading by up to 60% compared to conventional designs. Their systems demonstrate 60% efficiency under variable load conditions, with proprietary membrane electrode assemblies (MEAs) that maintain performance stability even during rapid power demand fluctuations. Bosch's technology incorporates advanced thermal management systems that optimize efficiency across a wide temperature range (-30°C to 45°C) and humidity conditions.

Strengths: Bosch's systems excel in durability and reliability under automotive duty cycles, with fuel cells maintaining over 90% of initial performance after 5,000 hours of operation. Their integrated control systems optimize power delivery based on real-time load demands. Weaknesses: Their electrochemical solutions still face challenges with fast-charging capabilities and low-temperature performance, while hydrogen systems require complex balance-of-plant components that increase system complexity and cost.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered hydrogen fuel cell technology through its Mirai vehicle platform, now in its second generation. Their latest hydrogen fuel cell system achieves 43% tank-to-wheel efficiency under real-world driving conditions, representing a 10% improvement over the first generation. Toyota's proprietary catalyst technology reduces platinum usage by approximately 30% while maintaining performance metrics. Their fuel cell stacks operate at 70-95°C with power densities of 3.1 kW/L, allowing for compact integration into vehicle platforms. For load management, Toyota employs a hybrid approach combining hydrogen fuel cells with buffer batteries to handle peak power demands, optimizing system efficiency across varying load profiles. Their electrochemical battery research focuses on solid-state technology, with prototype cells demonstrating energy densities of 400 Wh/L and the ability to maintain 80% capacity after 800 charge cycles. Toyota's comparative testing shows their hydrogen systems maintain consistent efficiency (40-43%) across a wider range of load conditions compared to pure battery systems that experience efficiency drops of 15-20% under high-load operations.

Strengths: Toyota's hydrogen technology excels in rapid refueling (3-5 minutes) and consistent performance across temperature extremes. Their integrated systems demonstrate exceptional cold-start capabilities down to -30°C. Weaknesses: Current hydrogen infrastructure limitations restrict widespread adoption, and production costs remain significantly higher than conventional battery electric solutions, with stack manufacturing requiring specialized processes that limit economies of scale.

Technical Innovations in Efficiency Optimization

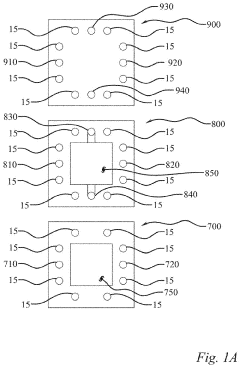

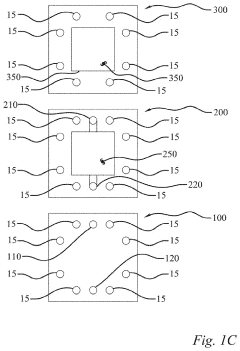

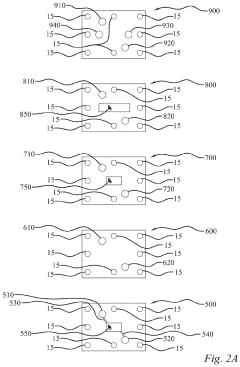

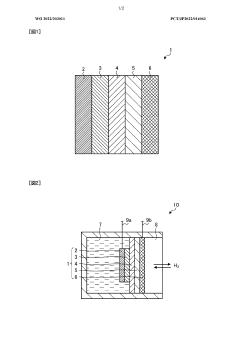

Electrochemical cell and method of using same

PatentActiveUS20210036352A1

Innovation

- A cell design combining a gas-impermeable Anion Exchange Membrane (AEM) with a liquid electrolyte, where at least one electrode is not flooded by liquid, allowing for high-rate gas flow and using a porous matrix or nickel metal foam to separate the electrodes, enabling efficient hydrogen production and storage while minimizing corrosion and degradation.

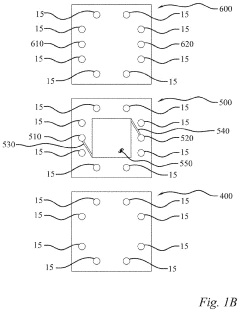

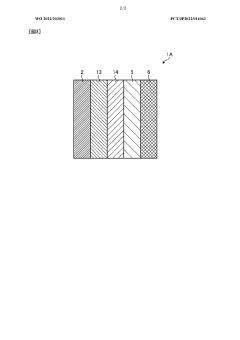

Electrochemical cell

PatentWO2022203011A1

Innovation

- An electrochemical cell design featuring an electrolyte layer with ionic conductivity, a first electrode layer containing metal hydroxide and an electron conductor, and a second electrode layer with water repellency, allowing reversible operation between hydrogen generation and power generation with improved performance by using alkaline or acidic electrolytes, reducing corrosion and optimizing reaction voltages.

Environmental Impact Assessment

The environmental impact of energy conversion technologies represents a critical dimension in evaluating their sustainability and long-term viability. When comparing electrochemical cells and hydrogen cells under load conditions, several environmental factors must be considered throughout their lifecycle.

Electrochemical cells, particularly lithium-ion batteries, present significant environmental challenges during raw material extraction. Mining operations for lithium, cobalt, and nickel cause habitat destruction, water pollution, and contribute to carbon emissions. The manufacturing process is energy-intensive, with estimates suggesting that producing 1 kWh of lithium-ion battery capacity generates 150-200 kg of CO2 equivalent emissions.

Hydrogen cells demonstrate different environmental profiles depending on hydrogen production methods. Grey hydrogen derived from natural gas reforming generates substantial carbon emissions (9-12 kg CO2/kg H2), while green hydrogen produced via electrolysis using renewable energy offers near-zero operational emissions. However, the energy efficiency losses in hydrogen production, compression, and storage create an environmental burden that must be factored into lifecycle assessments.

Under load conditions, electrochemical cells maintain relatively stable environmental performance, with minimal direct emissions during operation. Their environmental impact primarily stems from electricity generation sources used for recharging. In contrast, hydrogen fuel cells emit only water vapor during operation, representing a significant advantage in urban environments where air quality is a concern.

End-of-life considerations reveal further distinctions. Lithium-ion batteries require specialized recycling processes, with current global recycling rates below 5%. Improper disposal risks toxic material leaching into ecosystems. Hydrogen fuel cells contain valuable platinum group metals that incentivize higher recycling rates, though membrane degradation presents recycling challenges.

Water consumption patterns differ markedly between technologies. Hydrogen production via electrolysis requires approximately 9 kg of water per kg of hydrogen, while lithium-ion battery manufacturing consumes 50-65 liters per kWh of capacity. Under load conditions, hydrogen cells produce water as a byproduct, potentially offering water recovery opportunities in certain applications.

Land use impacts also vary significantly. Battery production facilities require substantial industrial footprints, while hydrogen infrastructure necessitates extensive storage and distribution networks. The efficiency differences under load conditions directly influence these spatial requirements, with higher efficiency technologies generally requiring less extensive supporting infrastructure.

Electrochemical cells, particularly lithium-ion batteries, present significant environmental challenges during raw material extraction. Mining operations for lithium, cobalt, and nickel cause habitat destruction, water pollution, and contribute to carbon emissions. The manufacturing process is energy-intensive, with estimates suggesting that producing 1 kWh of lithium-ion battery capacity generates 150-200 kg of CO2 equivalent emissions.

Hydrogen cells demonstrate different environmental profiles depending on hydrogen production methods. Grey hydrogen derived from natural gas reforming generates substantial carbon emissions (9-12 kg CO2/kg H2), while green hydrogen produced via electrolysis using renewable energy offers near-zero operational emissions. However, the energy efficiency losses in hydrogen production, compression, and storage create an environmental burden that must be factored into lifecycle assessments.

Under load conditions, electrochemical cells maintain relatively stable environmental performance, with minimal direct emissions during operation. Their environmental impact primarily stems from electricity generation sources used for recharging. In contrast, hydrogen fuel cells emit only water vapor during operation, representing a significant advantage in urban environments where air quality is a concern.

End-of-life considerations reveal further distinctions. Lithium-ion batteries require specialized recycling processes, with current global recycling rates below 5%. Improper disposal risks toxic material leaching into ecosystems. Hydrogen fuel cells contain valuable platinum group metals that incentivize higher recycling rates, though membrane degradation presents recycling challenges.

Water consumption patterns differ markedly between technologies. Hydrogen production via electrolysis requires approximately 9 kg of water per kg of hydrogen, while lithium-ion battery manufacturing consumes 50-65 liters per kWh of capacity. Under load conditions, hydrogen cells produce water as a byproduct, potentially offering water recovery opportunities in certain applications.

Land use impacts also vary significantly. Battery production facilities require substantial industrial footprints, while hydrogen infrastructure necessitates extensive storage and distribution networks. The efficiency differences under load conditions directly influence these spatial requirements, with higher efficiency technologies generally requiring less extensive supporting infrastructure.

Cost-Benefit Analysis of Cell Technologies

When evaluating electrochemical cells versus hydrogen cells under load conditions, cost-benefit analysis reveals significant economic considerations that influence technology adoption. Initial capital expenditure for electrochemical systems typically ranges from $300-800/kWh for lithium-ion batteries, while hydrogen fuel cell systems require approximately $1,500-3,000/kW for the fuel cell stack plus additional infrastructure costs for hydrogen storage and distribution.

Operational expenses present a contrasting picture. Electrochemical cells benefit from higher round-trip efficiency (85-95% for lithium-ion) compared to hydrogen systems (30-45% overall when considering production, compression, and conversion). This efficiency differential translates to lower energy input costs for electrochemical systems, with operational savings of approximately 40-60% per kWh delivered.

Maintenance requirements further differentiate these technologies. Hydrogen cells demand regular maintenance due to catalyst degradation and membrane issues, with maintenance costs averaging 3-5% of capital expenditure annually. Electrochemical systems typically require less intervention, with annual maintenance costs of 1-2% of capital expenditure, though battery replacement represents a significant periodic expense.

Lifecycle economics reveal that electrochemical cells generally offer superior short-term returns for applications requiring frequent cycling at moderate depths of discharge. Financial modeling indicates break-even periods of 3-5 years for grid-connected lithium-ion systems versus 7-10 years for comparable hydrogen installations under current market conditions.

Environmental cost considerations must include manufacturing impacts, operational emissions, and end-of-life management. While hydrogen systems potentially offer zero-emission operation when using renewable energy for hydrogen production, the comprehensive lifecycle assessment shows electrochemical systems currently maintain a 15-30% advantage in carbon footprint per kWh delivered, primarily due to efficiency advantages.

Scaling economics demonstrate that hydrogen systems may achieve cost parity with electrochemical alternatives in large-scale, long-duration applications exceeding 24 hours of storage. Market projections suggest hydrogen system costs could decrease by 65-70% by 2030 through manufacturing scale and technological improvements, potentially shifting the economic balance for specific use cases requiring extended duration storage or rapid refueling capabilities.

Operational expenses present a contrasting picture. Electrochemical cells benefit from higher round-trip efficiency (85-95% for lithium-ion) compared to hydrogen systems (30-45% overall when considering production, compression, and conversion). This efficiency differential translates to lower energy input costs for electrochemical systems, with operational savings of approximately 40-60% per kWh delivered.

Maintenance requirements further differentiate these technologies. Hydrogen cells demand regular maintenance due to catalyst degradation and membrane issues, with maintenance costs averaging 3-5% of capital expenditure annually. Electrochemical systems typically require less intervention, with annual maintenance costs of 1-2% of capital expenditure, though battery replacement represents a significant periodic expense.

Lifecycle economics reveal that electrochemical cells generally offer superior short-term returns for applications requiring frequent cycling at moderate depths of discharge. Financial modeling indicates break-even periods of 3-5 years for grid-connected lithium-ion systems versus 7-10 years for comparable hydrogen installations under current market conditions.

Environmental cost considerations must include manufacturing impacts, operational emissions, and end-of-life management. While hydrogen systems potentially offer zero-emission operation when using renewable energy for hydrogen production, the comprehensive lifecycle assessment shows electrochemical systems currently maintain a 15-30% advantage in carbon footprint per kWh delivered, primarily due to efficiency advantages.

Scaling economics demonstrate that hydrogen systems may achieve cost parity with electrochemical alternatives in large-scale, long-duration applications exceeding 24 hours of storage. Market projections suggest hydrogen system costs could decrease by 65-70% by 2030 through manufacturing scale and technological improvements, potentially shifting the economic balance for specific use cases requiring extended duration storage or rapid refueling capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!