Benchmarking Additive Manufacturing with Topology Optimization Enhancements

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Additive Manufacturing and Topology Optimization Background

Additive Manufacturing (AM), commonly known as 3D printing, has evolved significantly since its inception in the 1980s. Initially developed for rapid prototyping, AM has transformed into a mainstream manufacturing technology capable of producing functional end-use parts. The technology operates on the principle of layer-by-layer material deposition based on digital models, enabling the creation of complex geometries that would be impossible or prohibitively expensive using traditional manufacturing methods.

The evolution of AM technologies has branched into several categories including powder bed fusion, material extrusion, vat photopolymerization, material jetting, binder jetting, directed energy deposition, and sheet lamination. Each technology offers distinct advantages in terms of material compatibility, precision, surface finish, and mechanical properties, making them suitable for different applications across industries such as aerospace, automotive, healthcare, and consumer products.

Topology Optimization (TO), on the other hand, represents a mathematical approach to optimizing material layout within a given design space for specific performance criteria while satisfying constraints. Rooted in structural mechanics, TO has gained prominence with the advancement of computational capabilities, allowing engineers to generate designs that maximize performance while minimizing material usage.

The convergence of AM and TO creates a powerful synergy. Traditional manufacturing methods often impose significant constraints on design freedom due to limitations such as tooling access, draft angles, and uniform wall thickness requirements. AM liberates designers from many of these constraints, allowing the physical realization of complex, organically shaped structures generated through TO algorithms.

This technological marriage has catalyzed innovation across multiple sectors. In aerospace, topology-optimized components manufactured additively have achieved weight reductions of 30-50% while maintaining or improving structural performance. The automotive industry has leveraged this combination to create lightweight components that enhance fuel efficiency and performance. Medical applications include patient-specific implants and prosthetics optimized for biomechanical performance.

Despite these advances, significant challenges remain. Material properties in additively manufactured parts often exhibit anisotropy and can vary based on process parameters. Build orientation, support structures, and post-processing requirements can constrain the theoretical design freedom promised by AM. Additionally, computational demands for topology optimization of complex structures remain substantial, particularly when considering multi-physics problems or manufacturing constraints.

The ongoing evolution of both fields aims to address these limitations through improved algorithms, new materials, enhanced process control, and standardization efforts. The integration of machine learning approaches with TO and AM processes represents a promising frontier for further advancement in this domain.

The evolution of AM technologies has branched into several categories including powder bed fusion, material extrusion, vat photopolymerization, material jetting, binder jetting, directed energy deposition, and sheet lamination. Each technology offers distinct advantages in terms of material compatibility, precision, surface finish, and mechanical properties, making them suitable for different applications across industries such as aerospace, automotive, healthcare, and consumer products.

Topology Optimization (TO), on the other hand, represents a mathematical approach to optimizing material layout within a given design space for specific performance criteria while satisfying constraints. Rooted in structural mechanics, TO has gained prominence with the advancement of computational capabilities, allowing engineers to generate designs that maximize performance while minimizing material usage.

The convergence of AM and TO creates a powerful synergy. Traditional manufacturing methods often impose significant constraints on design freedom due to limitations such as tooling access, draft angles, and uniform wall thickness requirements. AM liberates designers from many of these constraints, allowing the physical realization of complex, organically shaped structures generated through TO algorithms.

This technological marriage has catalyzed innovation across multiple sectors. In aerospace, topology-optimized components manufactured additively have achieved weight reductions of 30-50% while maintaining or improving structural performance. The automotive industry has leveraged this combination to create lightweight components that enhance fuel efficiency and performance. Medical applications include patient-specific implants and prosthetics optimized for biomechanical performance.

Despite these advances, significant challenges remain. Material properties in additively manufactured parts often exhibit anisotropy and can vary based on process parameters. Build orientation, support structures, and post-processing requirements can constrain the theoretical design freedom promised by AM. Additionally, computational demands for topology optimization of complex structures remain substantial, particularly when considering multi-physics problems or manufacturing constraints.

The ongoing evolution of both fields aims to address these limitations through improved algorithms, new materials, enhanced process control, and standardization efforts. The integration of machine learning approaches with TO and AM processes represents a promising frontier for further advancement in this domain.

Market Analysis for Optimized AM Solutions

The global market for Additive Manufacturing (AM) solutions enhanced with topology optimization is experiencing robust growth, driven by increasing demand for lightweight, high-performance components across multiple industries. Current market valuation stands at approximately $2.3 billion, with projections indicating a compound annual growth rate of 24.7% through 2028, significantly outpacing the broader AM market's growth rate of 18.2%.

Aerospace and automotive sectors currently dominate the optimized AM solutions market, collectively accounting for 61% of total market share. These industries prioritize weight reduction and performance enhancement, making them natural early adopters of topology-optimized manufacturing processes. The healthcare sector represents the fastest-growing segment, with 32% year-over-year growth, particularly in patient-specific medical implants and prosthetics where topology optimization enables superior biomechanical performance.

Regional analysis reveals North America leading with 42% market share, followed by Europe at 31% and Asia-Pacific at 22%. However, the Asia-Pacific region demonstrates the highest growth trajectory at 29.3% annually, driven by substantial investments in advanced manufacturing capabilities in China, Japan, and South Korea.

Customer segmentation shows large enterprises currently constitute 73% of the market, though small and medium enterprises are increasingly adopting these technologies as costs decrease and accessibility improves. This democratization trend is expected to continue, with the SME segment projected to grow at 31% annually over the next five years.

Key market drivers include increasing pressure for sustainable manufacturing processes, with topology-optimized AM reducing material waste by an average of 47% compared to traditional manufacturing methods. Additionally, the growing complexity of product designs across industries necessitates manufacturing capabilities that conventional methods cannot efficiently deliver.

Market barriers include high initial investment costs, with industrial-grade systems capable of producing topology-optimized components ranging from $300,000 to $1.5 million. Limited material options and certification challenges in highly regulated industries also constrain market expansion, particularly in aerospace and medical applications.

The competitive landscape features established AM equipment manufacturers expanding their software capabilities through acquisitions and partnerships with topology optimization software providers. Simultaneously, specialized software companies are entering the hardware space, creating integrated solutions that streamline the design-to-manufacturing workflow for optimized components.

Aerospace and automotive sectors currently dominate the optimized AM solutions market, collectively accounting for 61% of total market share. These industries prioritize weight reduction and performance enhancement, making them natural early adopters of topology-optimized manufacturing processes. The healthcare sector represents the fastest-growing segment, with 32% year-over-year growth, particularly in patient-specific medical implants and prosthetics where topology optimization enables superior biomechanical performance.

Regional analysis reveals North America leading with 42% market share, followed by Europe at 31% and Asia-Pacific at 22%. However, the Asia-Pacific region demonstrates the highest growth trajectory at 29.3% annually, driven by substantial investments in advanced manufacturing capabilities in China, Japan, and South Korea.

Customer segmentation shows large enterprises currently constitute 73% of the market, though small and medium enterprises are increasingly adopting these technologies as costs decrease and accessibility improves. This democratization trend is expected to continue, with the SME segment projected to grow at 31% annually over the next five years.

Key market drivers include increasing pressure for sustainable manufacturing processes, with topology-optimized AM reducing material waste by an average of 47% compared to traditional manufacturing methods. Additionally, the growing complexity of product designs across industries necessitates manufacturing capabilities that conventional methods cannot efficiently deliver.

Market barriers include high initial investment costs, with industrial-grade systems capable of producing topology-optimized components ranging from $300,000 to $1.5 million. Limited material options and certification challenges in highly regulated industries also constrain market expansion, particularly in aerospace and medical applications.

The competitive landscape features established AM equipment manufacturers expanding their software capabilities through acquisitions and partnerships with topology optimization software providers. Simultaneously, specialized software companies are entering the hardware space, creating integrated solutions that streamline the design-to-manufacturing workflow for optimized components.

Current Challenges in AM-TO Integration

Despite the significant advancements in both Additive Manufacturing (AM) and Topology Optimization (TO), their integration faces several critical challenges that impede widespread industrial adoption. These challenges span multiple domains including technical limitations, computational constraints, and practical implementation issues.

Material constraints represent a fundamental challenge in AM-TO integration. While TO algorithms can generate geometrically optimal structures, these designs often assume isotropic material properties. However, AM processes typically produce anisotropic materials with directional mechanical properties that vary based on build orientation. This discrepancy creates a significant gap between theoretical optimization and practical manufacturing outcomes.

Computational complexity presents another major hurdle. TO algorithms require substantial computational resources, particularly when incorporating manufacturing constraints specific to AM processes. The multi-physics simulations needed to accurately predict build outcomes, including thermal effects, residual stresses, and microstructural variations, exponentially increase computational demands, making real-time design optimization prohibitively expensive for many applications.

Design-to-manufacturing translation remains problematic. Optimized topologies frequently include features that are challenging to manufacture, such as thin walls, sharp corners, or enclosed voids that trap support material. Current software solutions struggle to automatically adapt TO results to AM constraints while preserving the intended performance benefits, often requiring significant manual intervention by experienced designers.

Post-processing requirements further complicate integration efforts. Many AM parts require substantial post-processing to achieve desired surface finish, dimensional accuracy, and mechanical properties. These additional steps are rarely accounted for in TO algorithms, leading to designs that may be theoretically optimal but practically suboptimal when considering the entire manufacturing workflow.

Verification and validation methodologies are inadequately developed for AM-TO integrated processes. Traditional testing protocols may not effectively capture the unique characteristics of topologically optimized AM parts, particularly regarding long-term performance, fatigue behavior, and failure modes. This creates uncertainty in quality assurance and certification, especially for critical applications in aerospace, medical, and automotive sectors.

Standards and certification frameworks specifically addressing AM-TO integration remain underdeveloped. The lack of standardized approaches for design validation, process qualification, and quality assurance creates barriers to adoption in regulated industries where certification is mandatory. This regulatory gap significantly limits the application scope of integrated AM-TO solutions in high-value sectors.

Material constraints represent a fundamental challenge in AM-TO integration. While TO algorithms can generate geometrically optimal structures, these designs often assume isotropic material properties. However, AM processes typically produce anisotropic materials with directional mechanical properties that vary based on build orientation. This discrepancy creates a significant gap between theoretical optimization and practical manufacturing outcomes.

Computational complexity presents another major hurdle. TO algorithms require substantial computational resources, particularly when incorporating manufacturing constraints specific to AM processes. The multi-physics simulations needed to accurately predict build outcomes, including thermal effects, residual stresses, and microstructural variations, exponentially increase computational demands, making real-time design optimization prohibitively expensive for many applications.

Design-to-manufacturing translation remains problematic. Optimized topologies frequently include features that are challenging to manufacture, such as thin walls, sharp corners, or enclosed voids that trap support material. Current software solutions struggle to automatically adapt TO results to AM constraints while preserving the intended performance benefits, often requiring significant manual intervention by experienced designers.

Post-processing requirements further complicate integration efforts. Many AM parts require substantial post-processing to achieve desired surface finish, dimensional accuracy, and mechanical properties. These additional steps are rarely accounted for in TO algorithms, leading to designs that may be theoretically optimal but practically suboptimal when considering the entire manufacturing workflow.

Verification and validation methodologies are inadequately developed for AM-TO integrated processes. Traditional testing protocols may not effectively capture the unique characteristics of topologically optimized AM parts, particularly regarding long-term performance, fatigue behavior, and failure modes. This creates uncertainty in quality assurance and certification, especially for critical applications in aerospace, medical, and automotive sectors.

Standards and certification frameworks specifically addressing AM-TO integration remain underdeveloped. The lack of standardized approaches for design validation, process qualification, and quality assurance creates barriers to adoption in regulated industries where certification is mandatory. This regulatory gap significantly limits the application scope of integrated AM-TO solutions in high-value sectors.

Existing AM-TO Benchmarking Methodologies

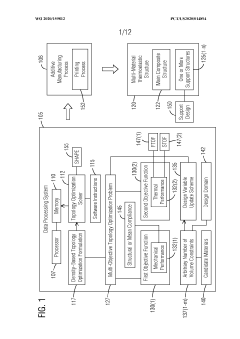

01 Topology optimization methods for additive manufacturing

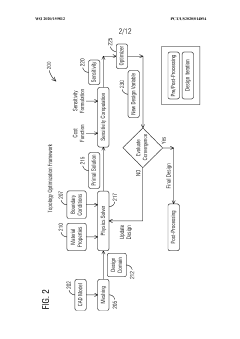

Various topology optimization methods are employed to design structures for additive manufacturing. These methods include mathematical algorithms that optimize material distribution within a design space to achieve specific performance criteria while minimizing material usage. The optimization process considers manufacturing constraints specific to additive manufacturing technologies, ensuring that the optimized designs are printable. These methods enable the creation of complex, lightweight structures with enhanced mechanical properties that would be difficult or impossible to produce using traditional manufacturing techniques.- Topology optimization methods for additive manufacturing: Various topology optimization methods are employed to design structures for additive manufacturing. These methods include mathematical algorithms that optimize material distribution within a design space to achieve specific performance criteria while minimizing material usage. The optimization process considers manufacturing constraints specific to additive manufacturing technologies, ensuring that the designed structures can be fabricated effectively. These methods enable the creation of complex geometries with improved structural performance that would be difficult or impossible to produce using traditional manufacturing techniques.

- Benchmarking frameworks for topology-optimized additive manufacturing: Benchmarking frameworks are developed to evaluate and compare the performance of topology optimization algorithms and additive manufacturing processes. These frameworks establish standardized test cases, metrics, and evaluation criteria to assess factors such as structural efficiency, manufacturing accuracy, and computational efficiency. By providing consistent evaluation methods, these benchmarking approaches enable researchers and industry professionals to objectively compare different optimization strategies and manufacturing techniques, facilitating the identification of best practices and areas for improvement.

- Integration of design constraints in topology optimization for AM: Specific design constraints are integrated into topology optimization processes to ensure manufacturability through additive manufacturing. These constraints address challenges such as minimum feature size, support structure requirements, build orientation, and thermal considerations. By incorporating these manufacturing constraints directly into the optimization algorithm, the resulting designs are not only theoretically optimal but also practically manufacturable. This integration reduces the need for post-optimization modifications and improves the overall efficiency of the design-to-manufacturing workflow.

- Multi-objective optimization for AM performance: Multi-objective optimization approaches are used to balance competing design goals in additive manufacturing applications. These methods simultaneously consider multiple performance criteria such as structural strength, weight reduction, thermal management, and manufacturing cost. By formulating the topology optimization problem with multiple objectives, designers can generate Pareto-optimal solutions that represent different trade-offs between competing goals. This approach provides greater flexibility in selecting designs that best meet specific application requirements while leveraging the capabilities of additive manufacturing.

- Validation and testing methodologies for topology-optimized AM parts: Specialized validation and testing methodologies are developed to verify the performance of topology-optimized parts produced through additive manufacturing. These methodologies include physical testing protocols, simulation validation approaches, and quality assessment techniques that evaluate factors such as mechanical properties, dimensional accuracy, and microstructural characteristics. By systematically comparing the actual performance of manufactured parts against design predictions, these validation methods help identify discrepancies between theoretical models and physical reality, enabling continuous improvement of both optimization algorithms and manufacturing processes.

02 Benchmarking frameworks for topology optimization in additive manufacturing

Benchmarking frameworks are developed to evaluate and compare different topology optimization algorithms and their performance in additive manufacturing applications. These frameworks establish standardized test cases, metrics, and evaluation criteria to objectively assess optimization methods. They enable researchers and engineers to compare results across different optimization approaches, helping to identify the most effective methods for specific applications. Benchmarking also facilitates the validation of new optimization algorithms against established methods and real-world manufacturing outcomes.Expand Specific Solutions03 Integration of manufacturing constraints in topology optimization

Manufacturing constraints specific to additive manufacturing processes are integrated into topology optimization algorithms to ensure printability of the optimized designs. These constraints include minimum feature size, support structure requirements, build orientation, and thermal considerations. By incorporating these constraints directly into the optimization process, the resulting designs are not only theoretically optimal but also practically manufacturable. This integration helps bridge the gap between theoretical optimization and practical manufacturing, reducing the need for post-optimization design modifications.Expand Specific Solutions04 Multi-objective optimization for additive manufacturing

Multi-objective optimization approaches are used to simultaneously address multiple design goals in additive manufacturing applications. These methods balance competing objectives such as structural performance, material usage, manufacturing time, and cost. By considering multiple criteria simultaneously, designers can make informed trade-offs between different performance aspects. Advanced algorithms help identify Pareto-optimal solutions that represent the best possible compromises between competing objectives, providing designers with a range of options tailored to specific application requirements.Expand Specific Solutions05 Validation and testing of topology-optimized additive manufactured parts

Methods for validating and testing topology-optimized parts produced through additive manufacturing are developed to ensure their performance meets design specifications. These include experimental testing procedures, simulation validation techniques, and quality control methods specific to complex optimized structures. Validation approaches compare the mechanical properties, dimensional accuracy, and functional performance of manufactured parts against their digital designs. Advanced non-destructive testing methods are employed to detect internal defects that might affect the performance of the optimized structures, ensuring the reliability of the final products.Expand Specific Solutions

Leading Companies in AM-TO Technology

The additive manufacturing with topology optimization market is currently in a growth phase, characterized by increasing adoption across aerospace, automotive, and industrial sectors. The market size is expanding rapidly, projected to reach significant value due to rising demand for lightweight, high-performance components. Technologically, the field shows varying maturity levels, with industry leaders like Siemens AG, Rolls-Royce, and GE demonstrating advanced capabilities through integrated design-to-manufacturing platforms. Academic institutions (Zhejiang University, Politecnico di Milano) and software providers (ANSYS, Autodesk) are driving innovation through research collaborations. Companies like RTX Corp. and Thales Alenia Space are implementing these technologies in critical applications, while emerging players from China (AECC South Industry) are rapidly advancing their capabilities, creating a competitive global landscape.

Siemens AG

Technical Solution: Siemens has developed an integrated platform that combines topology optimization with additive manufacturing processes. Their solution utilizes advanced algorithms to generate optimized structures that maximize performance while minimizing material usage. The platform incorporates multi-physics simulation capabilities to account for thermal, structural, and fluid dynamics considerations simultaneously during the optimization process. Siemens' NX software suite includes specialized modules for topology optimization that can automatically generate designs ready for additive manufacturing with minimal post-processing requirements. Their approach includes automatic identification of support structures needed during the printing process and optimization of these supports to reduce material waste. Additionally, Siemens has implemented machine learning techniques to predict manufacturing constraints and incorporate them directly into the topology optimization process, resulting in designs that are both theoretically optimal and practically manufacturable.

Strengths: Comprehensive end-to-end solution from design to manufacturing; strong integration with existing CAD/CAM workflows; extensive validation across multiple industries. Weaknesses: High computational requirements for complex optimizations; steep learning curve for new users; primarily optimized for their own manufacturing systems.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has pioneered a specialized topology optimization framework specifically tailored for aerospace components manufactured using additive techniques. Their approach focuses on high-temperature applications and incorporates material behavior models that account for the unique microstructural characteristics resulting from additive manufacturing processes. The company has developed proprietary algorithms that optimize not only the macro-geometry but also the internal lattice structures of components, creating hierarchical designs that maximize strength-to-weight ratios while ensuring thermal management capabilities. Their benchmarking methodology includes comprehensive testing under simulated operating conditions, with particular emphasis on fatigue performance and thermal cycling. Rolls-Royce's system incorporates design rules specific to different additive manufacturing technologies (SLM, EBM, DED) and automatically adapts the optimization parameters based on the selected manufacturing method. This approach has enabled them to reduce development cycles by approximately 60% while achieving weight reductions of 25-40% in critical engine components.

Strengths: Deep expertise in high-performance aerospace applications; robust validation processes; optimization algorithms specifically tuned for critical performance parameters like fatigue and thermal resistance. Weaknesses: Solutions highly specialized for aerospace applications; limited transferability to consumer products; high implementation costs.

Key Technical Innovations in TO for AM

Topology optimization of thermoelastic structures for an additive manufacturing process

PatentWO2020159812A1

Innovation

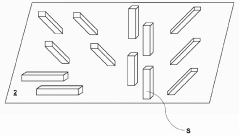

- A density-based topology optimization formulation is developed as a multi-objective problem that optimizes mechanical and thermal performance by using a design variable update scheme capable of solving non-self-adjoint problems with multiple volume constraints, allowing for the efficient design of multi-material thermoelastic structures with integrated support structures.

a topology optimization system.

PatentActiveTR202103400A1

Innovation

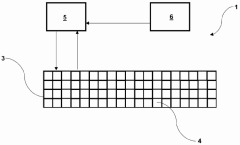

- Integration of a database containing mechanical property data from samples produced in different directions and positions, enabling data-driven topology optimization.

- Use of unit design cells as building blocks for creating digital models, allowing for modular and systematic topology optimization.

- Comprehensive system that connects digital modeling with physical manufacturing by incorporating sample testing data into the design process.

Sustainability Impact of Optimized AM Processes

The integration of additive manufacturing (AM) with topology optimization presents significant sustainability advantages that extend beyond traditional manufacturing methods. When properly optimized, AM processes can reduce material waste by up to 70% compared to conventional subtractive manufacturing techniques. This dramatic reduction stems from the precise material deposition that characterizes AM technologies, allowing for the creation of complex geometries that use only the necessary material.

Energy consumption analysis reveals that optimized AM processes can achieve 30-45% energy savings across the product lifecycle when compared to traditional manufacturing methods. This efficiency gain is particularly evident in aerospace and automotive applications, where topology-optimized components demonstrate improved performance while requiring less energy during both production and operational phases. The reduced weight of optimized components directly translates to fuel savings and lower emissions in transportation applications.

Carbon footprint assessments of topology-optimized AM parts show potential reductions of 40-60% in greenhouse gas emissions compared to conventionally manufactured equivalents. These environmental benefits are amplified when considering the entire product lifecycle, including raw material extraction, manufacturing, use phase, and end-of-life scenarios. The localized nature of AM production further reduces transportation-related emissions in global supply chains.

Resource efficiency is significantly enhanced through the combination of topology optimization and AM. Studies indicate that optimized designs can achieve the same functional requirements while using 20-50% less raw material. This efficiency extends to the utilization of recycled materials, as AM technologies demonstrate greater flexibility in processing recycled feedstock compared to conventional manufacturing methods, creating opportunities for circular economy implementations.

Water conservation represents another sustainability advantage, with optimized AM processes requiring up to 80% less water usage compared to traditional manufacturing techniques that often involve extensive cooling and cleaning operations. This benefit is particularly valuable in regions facing water scarcity challenges.

The extended product lifespan enabled by topology-optimized AM components contributes to sustainability through reduced replacement frequency and associated resource consumption. Components designed with optimized internal structures demonstrate improved durability and performance characteristics, potentially extending service life by 15-30% in demanding applications.

Energy consumption analysis reveals that optimized AM processes can achieve 30-45% energy savings across the product lifecycle when compared to traditional manufacturing methods. This efficiency gain is particularly evident in aerospace and automotive applications, where topology-optimized components demonstrate improved performance while requiring less energy during both production and operational phases. The reduced weight of optimized components directly translates to fuel savings and lower emissions in transportation applications.

Carbon footprint assessments of topology-optimized AM parts show potential reductions of 40-60% in greenhouse gas emissions compared to conventionally manufactured equivalents. These environmental benefits are amplified when considering the entire product lifecycle, including raw material extraction, manufacturing, use phase, and end-of-life scenarios. The localized nature of AM production further reduces transportation-related emissions in global supply chains.

Resource efficiency is significantly enhanced through the combination of topology optimization and AM. Studies indicate that optimized designs can achieve the same functional requirements while using 20-50% less raw material. This efficiency extends to the utilization of recycled materials, as AM technologies demonstrate greater flexibility in processing recycled feedstock compared to conventional manufacturing methods, creating opportunities for circular economy implementations.

Water conservation represents another sustainability advantage, with optimized AM processes requiring up to 80% less water usage compared to traditional manufacturing techniques that often involve extensive cooling and cleaning operations. This benefit is particularly valuable in regions facing water scarcity challenges.

The extended product lifespan enabled by topology-optimized AM components contributes to sustainability through reduced replacement frequency and associated resource consumption. Components designed with optimized internal structures demonstrate improved durability and performance characteristics, potentially extending service life by 15-30% in demanding applications.

Standardization Efforts for AM-TO Benchmarking

The standardization of benchmarking methodologies for Additive Manufacturing with Topology Optimization (AM-TO) has gained significant momentum in recent years. Several international organizations, including ISO (International Organization for Standardization), ASTM International, and AMSC (Additive Manufacturing Standardization Collaborative), have initiated dedicated working groups to establish consistent frameworks for evaluating AM-TO processes and outcomes.

These standardization efforts primarily focus on three critical areas: performance metrics, testing protocols, and reporting methodologies. The development of standardized performance metrics aims to quantify key parameters such as weight reduction, structural integrity, material efficiency, and manufacturing time across different AM-TO implementations. This enables objective comparisons between various optimization algorithms and manufacturing techniques.

Testing protocols represent another crucial aspect of standardization, with organizations developing reference geometries and test cases specifically designed to evaluate the capabilities of AM-TO systems. These reference models include features with varying complexity levels to assess how different systems handle geometric constraints, multi-objective optimization scenarios, and manufacturing limitations.

The ASTM F42 committee has been particularly active in this domain, developing the F3413 standard that provides guidelines for reporting topology optimization results in additive manufacturing contexts. This standard ensures that research findings and industrial applications can be communicated in a consistent manner, facilitating knowledge transfer and comparative analysis.

Industry consortia have also contributed significantly to standardization efforts. The Additive Manufacturing Consortium (AMC) has established a benchmarking database that collects performance data from various AM-TO implementations across different industries. This collaborative approach allows for the identification of best practices and the continuous refinement of benchmarking methodologies.

Academic institutions have partnered with industry to develop open-source benchmarking frameworks, such as the TO-Bench initiative, which provides standardized test cases and evaluation metrics for topology optimization algorithms. These frameworks enable researchers and practitioners to validate new approaches against established baselines using consistent evaluation criteria.

Despite these advances, challenges remain in standardizing benchmarking across the diverse landscape of AM technologies and topology optimization methods. Current efforts are increasingly focused on developing technology-specific benchmarks that account for the unique characteristics of different AM processes while maintaining cross-platform comparability where possible.

These standardization efforts primarily focus on three critical areas: performance metrics, testing protocols, and reporting methodologies. The development of standardized performance metrics aims to quantify key parameters such as weight reduction, structural integrity, material efficiency, and manufacturing time across different AM-TO implementations. This enables objective comparisons between various optimization algorithms and manufacturing techniques.

Testing protocols represent another crucial aspect of standardization, with organizations developing reference geometries and test cases specifically designed to evaluate the capabilities of AM-TO systems. These reference models include features with varying complexity levels to assess how different systems handle geometric constraints, multi-objective optimization scenarios, and manufacturing limitations.

The ASTM F42 committee has been particularly active in this domain, developing the F3413 standard that provides guidelines for reporting topology optimization results in additive manufacturing contexts. This standard ensures that research findings and industrial applications can be communicated in a consistent manner, facilitating knowledge transfer and comparative analysis.

Industry consortia have also contributed significantly to standardization efforts. The Additive Manufacturing Consortium (AMC) has established a benchmarking database that collects performance data from various AM-TO implementations across different industries. This collaborative approach allows for the identification of best practices and the continuous refinement of benchmarking methodologies.

Academic institutions have partnered with industry to develop open-source benchmarking frameworks, such as the TO-Bench initiative, which provides standardized test cases and evaluation metrics for topology optimization algorithms. These frameworks enable researchers and practitioners to validate new approaches against established baselines using consistent evaluation criteria.

Despite these advances, challenges remain in standardizing benchmarking across the diverse landscape of AM technologies and topology optimization methods. Current efforts are increasingly focused on developing technology-specific benchmarks that account for the unique characteristics of different AM processes while maintaining cross-platform comparability where possible.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!