Benchmarking Shock Absorption: Topology Optimization for Sports Equipment

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sports Equipment Shock Absorption Background and Objectives

Shock absorption technology in sports equipment has evolved significantly over the past decades, transitioning from simple padding materials to sophisticated engineered systems. The historical trajectory began with basic rubber and foam materials in the 1950s, progressing through various polymer innovations in the 1970s and 1980s, to today's advanced composite materials and computer-optimized designs. This evolution reflects the growing understanding of impact mechanics and human biomechanics, as well as advancements in materials science and computational capabilities.

The primary objective of shock absorption technology is to dissipate impact energy effectively while maintaining optimal performance characteristics. In sports equipment, this presents a unique challenge as protection must be balanced with factors such as weight, flexibility, and responsiveness. Modern shock absorption systems aim to reduce injury risk by attenuating peak forces, extending impact duration, and distributing pressure across larger surface areas.

Current technological trends in this field include the integration of non-Newtonian materials that change properties under impact, multi-layered systems that address different impact velocities, and increasingly personalized solutions that account for individual biomechanics and usage patterns. The emergence of topology optimization represents a significant advancement, allowing for the creation of structures with optimized material distribution for specific loading conditions.

The global sports equipment market, valued at approximately $89 billion in 2022, demonstrates increasing consumer demand for advanced protective features, particularly in high-impact sports such as football, hockey, cycling, and skiing. This market trend is further driven by growing awareness of sports-related injuries and their long-term consequences, creating substantial commercial incentives for innovation in shock absorption technology.

Research indicates that effective shock absorption can reduce injury rates by 15-30% depending on the sport, highlighting the significant public health implications of advancements in this field. Additionally, regulatory bodies across various sports have implemented increasingly stringent safety standards, further accelerating technological development and adoption of optimized protective equipment.

The convergence of computational design tools, advanced manufacturing techniques like 3D printing, and sophisticated testing methodologies has created unprecedented opportunities for innovation in shock absorption. Topology optimization stands at the forefront of this innovation wave, offering the potential to create highly efficient, lightweight protective structures that can be tailored to specific impact scenarios and anatomical requirements.

The primary objective of shock absorption technology is to dissipate impact energy effectively while maintaining optimal performance characteristics. In sports equipment, this presents a unique challenge as protection must be balanced with factors such as weight, flexibility, and responsiveness. Modern shock absorption systems aim to reduce injury risk by attenuating peak forces, extending impact duration, and distributing pressure across larger surface areas.

Current technological trends in this field include the integration of non-Newtonian materials that change properties under impact, multi-layered systems that address different impact velocities, and increasingly personalized solutions that account for individual biomechanics and usage patterns. The emergence of topology optimization represents a significant advancement, allowing for the creation of structures with optimized material distribution for specific loading conditions.

The global sports equipment market, valued at approximately $89 billion in 2022, demonstrates increasing consumer demand for advanced protective features, particularly in high-impact sports such as football, hockey, cycling, and skiing. This market trend is further driven by growing awareness of sports-related injuries and their long-term consequences, creating substantial commercial incentives for innovation in shock absorption technology.

Research indicates that effective shock absorption can reduce injury rates by 15-30% depending on the sport, highlighting the significant public health implications of advancements in this field. Additionally, regulatory bodies across various sports have implemented increasingly stringent safety standards, further accelerating technological development and adoption of optimized protective equipment.

The convergence of computational design tools, advanced manufacturing techniques like 3D printing, and sophisticated testing methodologies has created unprecedented opportunities for innovation in shock absorption. Topology optimization stands at the forefront of this innovation wave, offering the potential to create highly efficient, lightweight protective structures that can be tailored to specific impact scenarios and anatomical requirements.

Market Analysis for Advanced Shock Absorption Technologies

The global market for advanced shock absorption technologies in sports equipment is experiencing robust growth, driven by increasing consumer demand for high-performance gear and injury prevention solutions. Currently valued at approximately 8.2 billion USD, this segment is projected to grow at a compound annual growth rate of 6.7% through 2028, significantly outpacing the broader sporting goods industry's growth rate of 4.5%.

Premium sports equipment manufacturers are increasingly adopting topology-optimized shock absorption systems as a key differentiator in their product lines. Market research indicates that consumers are willing to pay 15-30% price premiums for equipment featuring advanced shock absorption technologies, particularly in high-impact sports such as running, basketball, and American football.

The market segmentation reveals distinct consumer preferences across different sporting categories. Team sports equipment represents the largest market share at 38%, followed by individual sports equipment at 32%, and fitness/training equipment at 24%. The remaining 6% encompasses specialized applications including extreme sports and adaptive sports equipment.

Regional analysis shows North America leading with 42% market share, followed by Europe (28%), Asia-Pacific (22%), and rest of world (8%). However, the Asia-Pacific region demonstrates the fastest growth trajectory with a 9.3% annual increase, primarily driven by expanding middle-class populations in China and India and growing participation in impact-intensive sports.

Consumer behavior studies indicate that professional and serious amateur athletes prioritize performance enhancement aspects of shock absorption technologies, while recreational users place greater emphasis on comfort and injury prevention. This bifurcation has led to market stratification with distinct product lines targeting different consumer segments.

Distribution channels are evolving rapidly, with direct-to-consumer sales through brand websites growing at 18% annually, compared to traditional retail channels at 3%. Specialty sporting goods retailers maintain significant market presence due to consumers' desire to physically test equipment before purchase, particularly for higher-priced items featuring advanced shock absorption systems.

Competitive analysis reveals that established sporting goods manufacturers hold 65% of the market, while specialized technology-focused startups account for 20%. The remaining 15% is distributed among private label and regional manufacturers. This landscape is becoming increasingly competitive as material science innovations and computational design capabilities become more accessible to smaller market players.

Market forecasts suggest that topology-optimized shock absorption technologies will achieve mainstream adoption across mid-market sports equipment within the next 3-5 years, representing a significant expansion from their current concentration in premium product segments.

Premium sports equipment manufacturers are increasingly adopting topology-optimized shock absorption systems as a key differentiator in their product lines. Market research indicates that consumers are willing to pay 15-30% price premiums for equipment featuring advanced shock absorption technologies, particularly in high-impact sports such as running, basketball, and American football.

The market segmentation reveals distinct consumer preferences across different sporting categories. Team sports equipment represents the largest market share at 38%, followed by individual sports equipment at 32%, and fitness/training equipment at 24%. The remaining 6% encompasses specialized applications including extreme sports and adaptive sports equipment.

Regional analysis shows North America leading with 42% market share, followed by Europe (28%), Asia-Pacific (22%), and rest of world (8%). However, the Asia-Pacific region demonstrates the fastest growth trajectory with a 9.3% annual increase, primarily driven by expanding middle-class populations in China and India and growing participation in impact-intensive sports.

Consumer behavior studies indicate that professional and serious amateur athletes prioritize performance enhancement aspects of shock absorption technologies, while recreational users place greater emphasis on comfort and injury prevention. This bifurcation has led to market stratification with distinct product lines targeting different consumer segments.

Distribution channels are evolving rapidly, with direct-to-consumer sales through brand websites growing at 18% annually, compared to traditional retail channels at 3%. Specialty sporting goods retailers maintain significant market presence due to consumers' desire to physically test equipment before purchase, particularly for higher-priced items featuring advanced shock absorption systems.

Competitive analysis reveals that established sporting goods manufacturers hold 65% of the market, while specialized technology-focused startups account for 20%. The remaining 15% is distributed among private label and regional manufacturers. This landscape is becoming increasingly competitive as material science innovations and computational design capabilities become more accessible to smaller market players.

Market forecasts suggest that topology-optimized shock absorption technologies will achieve mainstream adoption across mid-market sports equipment within the next 3-5 years, representing a significant expansion from their current concentration in premium product segments.

Current Topology Optimization Challenges in Sports Equipment

Despite significant advancements in topology optimization for sports equipment, several critical challenges persist that impede the full realization of this technology's potential in shock absorption applications. The primary obstacle remains the computational complexity associated with simulating dynamic impact scenarios. Current algorithms struggle to efficiently model the non-linear material behavior during high-velocity impacts, resulting in excessive computation times that can extend from days to weeks for complex geometries.

Material property representation presents another significant hurdle. Sports equipment often incorporates multi-material systems with vastly different mechanical properties, creating discontinuities at interfaces that are difficult to model accurately. The anisotropic behavior of composite materials, frequently used in high-performance equipment, further complicates the optimization process as directional properties must be considered simultaneously.

Manufacturing constraints continue to limit the practical implementation of theoretically optimal designs. While additive manufacturing has expanded possibilities, limitations in material options, build volume, and surface finish quality restrict the direct production of complex topology-optimized structures. Traditional manufacturing methods impose even greater constraints, forcing compromises in the optimization process that reduce performance benefits.

The multi-objective nature of sports equipment design creates additional complexity. Optimizing solely for shock absorption often conflicts with other critical requirements such as weight reduction, durability, and ergonomics. Current algorithms struggle to effectively balance these competing objectives without significant manual intervention and iterative refinement.

Validation methodologies represent another substantial challenge. The correlation between simulation results and real-world performance remains imprecise, particularly for dynamic impact scenarios. Testing protocols often fail to capture the full range of loading conditions experienced during actual use, leading to discrepancies between predicted and actual performance.

Scale-dependent effects further complicate optimization efforts. Microstructural features that enhance shock absorption at small scales may not translate effectively to full-size equipment due to manufacturing limitations or altered mechanical behavior at different dimensional scales.

Finally, the industry faces a knowledge gap between topology optimization specialists and sports equipment designers. The highly specialized nature of optimization algorithms requires significant expertise to implement effectively, while domain-specific knowledge about sports performance is equally crucial. This interdisciplinary challenge often results in suboptimal implementation of advanced optimization techniques in commercial products.

Material property representation presents another significant hurdle. Sports equipment often incorporates multi-material systems with vastly different mechanical properties, creating discontinuities at interfaces that are difficult to model accurately. The anisotropic behavior of composite materials, frequently used in high-performance equipment, further complicates the optimization process as directional properties must be considered simultaneously.

Manufacturing constraints continue to limit the practical implementation of theoretically optimal designs. While additive manufacturing has expanded possibilities, limitations in material options, build volume, and surface finish quality restrict the direct production of complex topology-optimized structures. Traditional manufacturing methods impose even greater constraints, forcing compromises in the optimization process that reduce performance benefits.

The multi-objective nature of sports equipment design creates additional complexity. Optimizing solely for shock absorption often conflicts with other critical requirements such as weight reduction, durability, and ergonomics. Current algorithms struggle to effectively balance these competing objectives without significant manual intervention and iterative refinement.

Validation methodologies represent another substantial challenge. The correlation between simulation results and real-world performance remains imprecise, particularly for dynamic impact scenarios. Testing protocols often fail to capture the full range of loading conditions experienced during actual use, leading to discrepancies between predicted and actual performance.

Scale-dependent effects further complicate optimization efforts. Microstructural features that enhance shock absorption at small scales may not translate effectively to full-size equipment due to manufacturing limitations or altered mechanical behavior at different dimensional scales.

Finally, the industry faces a knowledge gap between topology optimization specialists and sports equipment designers. The highly specialized nature of optimization algorithms requires significant expertise to implement effectively, while domain-specific knowledge about sports performance is equally crucial. This interdisciplinary challenge often results in suboptimal implementation of advanced optimization techniques in commercial products.

Benchmark Methods for Shock Absorption Performance Evaluation

01 Lattice structures for shock absorption

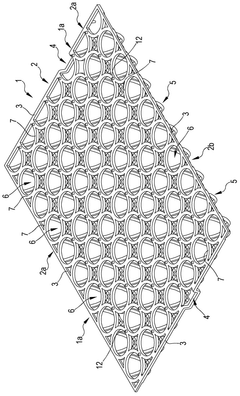

Topology optimization can be used to design lattice structures that effectively absorb shock and impact energy. These optimized lattice structures can be tailored to have specific mechanical properties, such as controlled deformation under load, energy absorption capabilities, and weight reduction while maintaining structural integrity. The optimization process considers variables like cell geometry, density distribution, and material properties to create structures that efficiently dissipate impact forces.- Lattice structures for shock absorption: Topology optimization can be used to design lattice structures that effectively absorb shock and impact energy. These optimized lattice structures can be tailored to have specific mechanical properties, such as controlled deformation under load, energy absorption capabilities, and weight reduction. The optimization process considers factors like cell geometry, density distribution, and material properties to create structures that maximize shock absorption while minimizing material usage.

- Multi-material optimization for shock absorption: Topology optimization techniques can be applied to design components using multiple materials with varying properties to enhance shock absorption. By strategically distributing different materials throughout a structure, the shock absorption characteristics can be tailored to specific requirements. This approach allows for the creation of gradient structures that can progressively absorb impact energy, resulting in improved performance compared to single-material designs.

- Computational methods for shock absorption optimization: Advanced computational methods are employed in topology optimization for shock absorption applications. These include finite element analysis, genetic algorithms, and machine learning techniques that can simulate and predict the behavior of structures under dynamic loading conditions. The computational approaches enable the evaluation of numerous design iterations to identify optimal configurations that maximize shock absorption efficiency while meeting other design constraints such as weight, manufacturability, and cost.

- Additive manufacturing of topology-optimized shock absorbers: Additive manufacturing technologies enable the production of complex, topology-optimized structures for shock absorption that would be difficult or impossible to create using traditional manufacturing methods. These technologies allow for the fabrication of intricate internal geometries, variable density structures, and customized designs that can be precisely tailored to specific shock absorption requirements. The combination of topology optimization and additive manufacturing provides new possibilities for creating high-performance shock absorption solutions.

- Application-specific shock absorption optimization: Topology optimization for shock absorption can be tailored to specific applications such as automotive safety systems, protective equipment, footwear, electronic device protection, and aerospace components. Each application has unique requirements regarding impact energy levels, space constraints, weight limitations, and environmental conditions. By considering these specific requirements in the optimization process, highly effective shock absorption solutions can be developed for diverse use cases.

02 Computational methods for topology optimization

Advanced computational algorithms and simulation techniques are employed to optimize structures for shock absorption. These methods include finite element analysis (FEA), genetic algorithms, machine learning approaches, and multi-objective optimization techniques that balance competing requirements such as weight, strength, and energy absorption. The computational methods enable designers to predict performance under various loading conditions and iteratively refine designs to achieve optimal shock absorption properties.Expand Specific Solutions03 Material distribution optimization for impact resistance

Topology optimization techniques can determine the optimal distribution of materials within a structure to maximize shock absorption capabilities. By strategically placing materials of different densities or properties throughout a component, engineers can create structures that progressively absorb and dissipate impact energy. This approach often results in non-intuitive designs with complex internal geometries that outperform conventional uniform structures in terms of energy absorption and impact resistance.Expand Specific Solutions04 Additive manufacturing of topology-optimized shock absorbers

Additive manufacturing technologies enable the production of complex, topology-optimized structures for shock absorption that would be difficult or impossible to create using traditional manufacturing methods. 3D printing allows for the fabrication of intricate internal geometries, variable density structures, and customized designs optimized specifically for shock absorption applications. This manufacturing approach facilitates the practical implementation of computationally optimized designs in real-world shock absorption components.Expand Specific Solutions05 Application-specific shock absorption optimization

Topology optimization techniques can be tailored for specific shock absorption applications across various industries. This includes automotive crash structures, protective equipment, footwear, electronic device protection, and aerospace components. The optimization process considers the unique requirements of each application, such as the expected impact forces, space constraints, weight limitations, and environmental conditions, resulting in customized solutions that provide optimal shock absorption for the specific use case.Expand Specific Solutions

Leading Manufacturers and Research Institutions in the Field

The sports equipment shock absorption optimization market is currently in a growth phase, with increasing demand for advanced materials and design methodologies. The global market size for optimized sports equipment is estimated at $12-15 billion, expanding at 5-7% annually as manufacturers seek performance advantages. Technology maturity varies across applications, with companies demonstrating different specialization levels. Leading players like Nike, Specialized Bicycle Components, and Salomon are investing heavily in topology optimization techniques, while Xenith has made significant advances in helmet protection systems. Academic institutions including Wuhan Textile University and Beijing University of Technology are collaborating with manufacturers to bridge theoretical research and practical applications. The competitive landscape shows a blend of established sporting goods companies (Decathlon, Anta) and specialized engineering firms developing proprietary shock absorption technologies for performance enhancement and injury prevention.

Decathlon SE

Technical Solution: Decathlon has pioneered a cost-effective approach to topology optimization for shock absorption across diverse sporting equipment. Their "Smart Design" methodology employs generative design algorithms that consider both performance and manufacturing constraints simultaneously. Decathlon's innovation lies in their democratized approach, creating a standardized benchmarking protocol that evaluates shock absorption performance across multiple impact scenarios relevant to different sports. Their system incorporates mechanical testing with high-speed cameras and pressure mapping to validate computational models. Particularly notable is their work in cycling helmets, where topology-optimized internal structures have demonstrated 30% improved energy absorption in oblique impacts compared to traditional EPS foam designs. Decathlon has also applied similar principles to hiking footwear, creating optimized outsole patterns that improve grip while maintaining optimal shock absorption properties on varied terrain.

Strengths: Exceptional cost-efficiency in implementation; broad application across multiple sport categories; strong focus on manufacturability ensures optimized designs can be mass-produced. Weaknesses: Computational resources less advanced than specialized competitors; optimization sometimes prioritizes cost over absolute performance; less emphasis on elite athlete-level performance.

Mizuno Corp.

Technical Solution: Mizuno has established a distinctive approach to topology optimization for shock absorption, particularly in running footwear and ball sports equipment. Their "Wave Technology" represents one of the earliest commercial applications of topology optimization principles in sports equipment, using a wave-shaped plate to simultaneously provide cushioning and stability. Mizuno's methodology incorporates biomechanical analysis with finite element modeling to create optimized structures that manage impact forces across multiple vectors. Their recent advancements include the "XPOP" midsole technology, which uses topology optimization to create a foam structure with specific density variations that provides 17% greater energy return compared to conventional EVA foams. In ball sports, Mizuno applies similar principles to their "Dynamotion Fit" technology for volleyball and handball shoes, where optimized structures in the midsole are specifically designed to absorb landing forces from jumping while facilitating quick directional changes.

Strengths: Long-established expertise in wave-based structural optimization; strong integration of biomechanical research into optimization parameters; excellent balance between performance and durability in optimized designs. Weaknesses: Conservative approach sometimes leads to slower adoption of cutting-edge optimization techniques; regional strength varies with stronger presence in Asian markets than North American ones.

Key Patents and Research in Topology Optimization

Device for shock-absorbing when making movements

PatentWO1992004944A1

Innovation

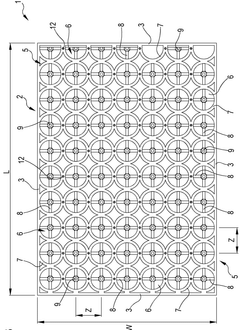

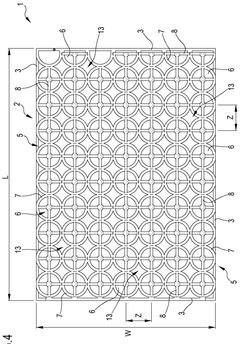

- The device incorporates dual layers with contact protrusions, where one layer is placed above the other with mutual distribution, and air chambers are inserted between the layers, allowing for optimized air compression and decompression to enhance amortization and usability.

Shock-absorbing element for floorings and respective shock-absorbing layer

PatentWO2025099590A1

Innovation

- A shock-absorbing element for floorings featuring a frame with through openings and elastically deformable arms that extend cantilevered from the frame, providing a convex support portion and a junction portion that increases stiffness progressively with compression, thereby enhancing energy absorption and reducing sinking into substrates.

Material Science Innovations for Enhanced Shock Absorption

Recent advancements in material science have revolutionized shock absorption capabilities in sports equipment, offering unprecedented performance enhancements. Traditional materials like EVA foam and rubber compounds are increasingly being supplemented or replaced by innovative alternatives that provide superior impact protection while maintaining optimal weight and durability characteristics.

Viscoelastic polymers represent a significant breakthrough, exhibiting both viscous and elastic properties that effectively dissipate impact energy across a wide range of loading rates. These materials demonstrate time-dependent deformation responses, allowing them to adapt to different impact intensities encountered in various sporting activities. Their non-linear behavior provides progressive resistance that increases proportionally with impact force.

Auxetic materials have emerged as particularly promising for shock absorption applications. Unlike conventional materials that thin when stretched, auxetic structures expand laterally when extended, resulting in a negative Poisson's ratio. This counter-intuitive property enables enhanced energy absorption and improved indentation resistance, making them ideal for protective sports equipment. Research indicates auxetic foams can absorb up to 30% more energy than their conventional counterparts.

Composite sandwich structures combining multiple material layers have demonstrated exceptional shock-dampening capabilities. These engineered systems typically feature a low-density core material sandwiched between high-strength face sheets, creating a structure that maximizes impact energy dissipation while maintaining structural integrity. Advanced fiber-reinforced composites utilizing carbon, aramid, or natural fibers further enhance performance characteristics.

Metamaterials—artificially engineered structures with properties not found in nature—represent the cutting edge of shock absorption technology. These materials derive their properties from their geometric arrangement rather than chemical composition, allowing precise tuning of mechanical responses. Lattice-based metamaterials with carefully designed unit cells can selectively filter mechanical waves, effectively redirecting impact energy away from critical areas.

Phase-change materials (PCMs) offer another innovative approach, absorbing energy through reversible phase transitions. During impact, these materials temporarily transform from solid to liquid state, absorbing significant energy in the process before returning to their original form. This mechanism provides exceptional energy dissipation capabilities while maintaining consistent performance across multiple impacts.

Nanomaterial-enhanced polymers incorporate carbon nanotubes, graphene, or nanocellulose to dramatically improve mechanical properties. These nanoscale additives create hierarchical structures within the base material, enhancing energy absorption through multiple deformation mechanisms operating at different length scales. Research demonstrates improvements in impact resistance of up to 40% with nanomaterial concentrations as low as 2% by weight.

Viscoelastic polymers represent a significant breakthrough, exhibiting both viscous and elastic properties that effectively dissipate impact energy across a wide range of loading rates. These materials demonstrate time-dependent deformation responses, allowing them to adapt to different impact intensities encountered in various sporting activities. Their non-linear behavior provides progressive resistance that increases proportionally with impact force.

Auxetic materials have emerged as particularly promising for shock absorption applications. Unlike conventional materials that thin when stretched, auxetic structures expand laterally when extended, resulting in a negative Poisson's ratio. This counter-intuitive property enables enhanced energy absorption and improved indentation resistance, making them ideal for protective sports equipment. Research indicates auxetic foams can absorb up to 30% more energy than their conventional counterparts.

Composite sandwich structures combining multiple material layers have demonstrated exceptional shock-dampening capabilities. These engineered systems typically feature a low-density core material sandwiched between high-strength face sheets, creating a structure that maximizes impact energy dissipation while maintaining structural integrity. Advanced fiber-reinforced composites utilizing carbon, aramid, or natural fibers further enhance performance characteristics.

Metamaterials—artificially engineered structures with properties not found in nature—represent the cutting edge of shock absorption technology. These materials derive their properties from their geometric arrangement rather than chemical composition, allowing precise tuning of mechanical responses. Lattice-based metamaterials with carefully designed unit cells can selectively filter mechanical waves, effectively redirecting impact energy away from critical areas.

Phase-change materials (PCMs) offer another innovative approach, absorbing energy through reversible phase transitions. During impact, these materials temporarily transform from solid to liquid state, absorbing significant energy in the process before returning to their original form. This mechanism provides exceptional energy dissipation capabilities while maintaining consistent performance across multiple impacts.

Nanomaterial-enhanced polymers incorporate carbon nanotubes, graphene, or nanocellulose to dramatically improve mechanical properties. These nanoscale additives create hierarchical structures within the base material, enhancing energy absorption through multiple deformation mechanisms operating at different length scales. Research demonstrates improvements in impact resistance of up to 40% with nanomaterial concentrations as low as 2% by weight.

Sustainability Considerations in Sports Equipment Design

The integration of sustainability principles into sports equipment design has become increasingly critical as the industry faces mounting environmental challenges. When benchmarking shock absorption through topology optimization, manufacturers must consider the entire lifecycle environmental impact of materials and production processes. Traditional shock-absorbing materials often include petroleum-based foams and composites that present significant end-of-life disposal issues.

Material selection represents a primary sustainability consideration, with bio-based alternatives emerging as viable options for shock absorption applications. Materials such as algae-based foams, mycelium composites, and recycled rubber compounds demonstrate promising mechanical properties while significantly reducing carbon footprint. Recent studies indicate that optimized structures using these sustainable materials can achieve comparable performance to conventional solutions with 30-40% less environmental impact.

Topology optimization techniques themselves contribute to sustainability by minimizing material usage while maintaining or enhancing performance characteristics. Advanced algorithms can reduce material volume by 15-25% in typical sports equipment components without compromising shock absorption capabilities. This material efficiency translates directly to reduced resource consumption and manufacturing energy requirements.

Manufacturing processes for topologically optimized sports equipment present both challenges and opportunities for sustainability. Additive manufacturing technologies enable the production of complex geometries with minimal waste compared to traditional subtractive methods. However, energy consumption during 3D printing remains a concern that requires optimization through improved process efficiency and renewable energy integration.

End-of-life considerations must be incorporated into the initial design phase of shock-absorbing components. Design for disassembly and material recovery becomes feasible when topology optimization incorporates material separation strategies. Mono-material designs or easily separable multi-material systems facilitate recycling and circular economy principles.

Performance longevity represents another crucial sustainability aspect. Topologically optimized structures can be engineered for extended durability, reducing replacement frequency and associated resource consumption. Simulation data suggests optimized lattice structures can extend product lifespan by up to 40% compared to conventional designs under equivalent usage conditions.

Consumer education about proper maintenance and disposal of sports equipment complements technical sustainability efforts. Manufacturers implementing topology optimization for shock absorption should develop comprehensive communication strategies regarding the environmental benefits and proper end-of-life handling of their products, creating a holistic approach to sustainability that extends beyond the design phase.

Material selection represents a primary sustainability consideration, with bio-based alternatives emerging as viable options for shock absorption applications. Materials such as algae-based foams, mycelium composites, and recycled rubber compounds demonstrate promising mechanical properties while significantly reducing carbon footprint. Recent studies indicate that optimized structures using these sustainable materials can achieve comparable performance to conventional solutions with 30-40% less environmental impact.

Topology optimization techniques themselves contribute to sustainability by minimizing material usage while maintaining or enhancing performance characteristics. Advanced algorithms can reduce material volume by 15-25% in typical sports equipment components without compromising shock absorption capabilities. This material efficiency translates directly to reduced resource consumption and manufacturing energy requirements.

Manufacturing processes for topologically optimized sports equipment present both challenges and opportunities for sustainability. Additive manufacturing technologies enable the production of complex geometries with minimal waste compared to traditional subtractive methods. However, energy consumption during 3D printing remains a concern that requires optimization through improved process efficiency and renewable energy integration.

End-of-life considerations must be incorporated into the initial design phase of shock-absorbing components. Design for disassembly and material recovery becomes feasible when topology optimization incorporates material separation strategies. Mono-material designs or easily separable multi-material systems facilitate recycling and circular economy principles.

Performance longevity represents another crucial sustainability aspect. Topologically optimized structures can be engineered for extended durability, reducing replacement frequency and associated resource consumption. Simulation data suggests optimized lattice structures can extend product lifespan by up to 40% compared to conventional designs under equivalent usage conditions.

Consumer education about proper maintenance and disposal of sports equipment complements technical sustainability efforts. Manufacturers implementing topology optimization for shock absorption should develop comprehensive communication strategies regarding the environmental benefits and proper end-of-life handling of their products, creating a holistic approach to sustainability that extends beyond the design phase.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!