Benchmarking V4 Engine Heat Shields for Thermal Protection

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Heat Shield Evolution and Objectives

Heat shield technology for V4 engines has evolved significantly over the past decades, transitioning from basic metal barriers to sophisticated multi-layer thermal management systems. The earliest heat shields in the 1950s and 1960s were simple stamped metal plates designed primarily to prevent direct heat transfer to sensitive components. By the 1970s, manufacturers began incorporating asbestos materials for improved insulation, though these were later phased out due to health concerns.

The 1980s marked a turning point with the introduction of aluminized steel and multi-layer designs that significantly enhanced thermal protection capabilities. This evolution continued through the 1990s with the development of ceramic-based materials and composite structures that offered superior heat resistance while reducing overall weight. The 2000s saw the integration of advanced computational fluid dynamics (CFD) modeling into heat shield design, enabling more precise thermal management solutions.

Current V4 engine heat shield technology incorporates nano-materials, aerogels, and specialized coatings that can withstand temperatures exceeding 1000°C while maintaining structural integrity. These modern solutions address multiple objectives beyond simple thermal protection, including noise reduction, emissions control, and overall engine efficiency improvement.

The primary technical objectives for contemporary V4 engine heat shields focus on several key performance parameters. Thermal efficiency remains paramount, with goals to reduce underhood temperatures by 15-20% compared to previous generation designs. Weight reduction represents another critical objective, with targets to decrease heat shield mass by 30% while maintaining or improving thermal performance, directly contributing to vehicle fuel efficiency and emissions reduction.

Durability under extreme conditions constitutes a significant challenge, with benchmarks requiring sustained performance through 150,000+ miles of operation under varying thermal cycles. Cost-effectiveness in manufacturing processes is equally important, with objectives to reduce production expenses by 25% through innovative materials and simplified assembly techniques.

Environmental sustainability has emerged as a crucial consideration, driving development of recyclable materials and manufacturing processes with reduced carbon footprints. Additionally, modern heat shields must accommodate increasingly compact engine compartments, requiring more efficient space utilization while maintaining adequate airflow for cooling.

The technological trajectory points toward integrated thermal management systems that combine passive and active cooling strategies, with heat shields evolving from standalone components to elements of comprehensive thermal control networks within the powertrain ecosystem.

The 1980s marked a turning point with the introduction of aluminized steel and multi-layer designs that significantly enhanced thermal protection capabilities. This evolution continued through the 1990s with the development of ceramic-based materials and composite structures that offered superior heat resistance while reducing overall weight. The 2000s saw the integration of advanced computational fluid dynamics (CFD) modeling into heat shield design, enabling more precise thermal management solutions.

Current V4 engine heat shield technology incorporates nano-materials, aerogels, and specialized coatings that can withstand temperatures exceeding 1000°C while maintaining structural integrity. These modern solutions address multiple objectives beyond simple thermal protection, including noise reduction, emissions control, and overall engine efficiency improvement.

The primary technical objectives for contemporary V4 engine heat shields focus on several key performance parameters. Thermal efficiency remains paramount, with goals to reduce underhood temperatures by 15-20% compared to previous generation designs. Weight reduction represents another critical objective, with targets to decrease heat shield mass by 30% while maintaining or improving thermal performance, directly contributing to vehicle fuel efficiency and emissions reduction.

Durability under extreme conditions constitutes a significant challenge, with benchmarks requiring sustained performance through 150,000+ miles of operation under varying thermal cycles. Cost-effectiveness in manufacturing processes is equally important, with objectives to reduce production expenses by 25% through innovative materials and simplified assembly techniques.

Environmental sustainability has emerged as a crucial consideration, driving development of recyclable materials and manufacturing processes with reduced carbon footprints. Additionally, modern heat shields must accommodate increasingly compact engine compartments, requiring more efficient space utilization while maintaining adequate airflow for cooling.

The technological trajectory points toward integrated thermal management systems that combine passive and active cooling strategies, with heat shields evolving from standalone components to elements of comprehensive thermal control networks within the powertrain ecosystem.

Market Requirements for Advanced Thermal Protection Systems

The automotive industry is witnessing a significant shift towards more efficient and environmentally friendly engines, creating substantial demand for advanced thermal protection systems. Current market analysis indicates that V4 engine manufacturers are particularly focused on heat shield solutions that can withstand higher operating temperatures while reducing overall weight and cost. This demand is driven by increasingly stringent emissions regulations worldwide, which require engines to operate at higher temperatures for optimal combustion efficiency.

Market research reveals that OEMs are specifically seeking heat shield materials that can maintain structural integrity at temperatures exceeding 800°C, a requirement that has increased by approximately 150°C over the past decade due to advancements in engine design and performance expectations. Additionally, there is growing demand for heat shields that offer a minimum 30% weight reduction compared to traditional metallic solutions, without compromising thermal protection capabilities.

Durability requirements have also evolved significantly, with manufacturers now expecting heat shield systems to maintain performance throughout the vehicle's entire lifecycle (typically 150,000+ miles) without degradation. This represents a substantial increase from previous expectations of replacement or maintenance at mid-life service intervals.

Cost considerations remain paramount in the competitive automotive market. While premium manufacturers demonstrate willingness to invest in advanced thermal protection systems, mainstream vehicle manufacturers require solutions that add no more than 5-7% to current heat management system costs. This cost sensitivity is creating market opportunities for innovative materials and manufacturing processes that can deliver enhanced performance at competitive price points.

Regional market variations are notable, with European manufacturers prioritizing weight reduction and emissions compliance, North American manufacturers focusing on durability and cost-effectiveness, and Asian manufacturers emphasizing manufacturing scalability and integration with existing production processes. These regional differences are shaping the development of specialized heat shield solutions tailored to specific market requirements.

Emerging market trends indicate growing interest in multi-functional heat shields that provide not only thermal protection but also contribute to noise reduction, vibration dampening, and even energy recovery. This trend is particularly evident in the premium vehicle segment, where manufacturers are willing to pay premium prices for integrated solutions that address multiple engineering challenges simultaneously.

The aftermarket segment presents additional requirements, with a focus on ease of installation, universal fitment capabilities, and enhanced durability under extreme conditions. This segment values heat shield solutions that offer visible performance benefits that can be marketed directly to consumers, such as reduced underhood temperatures and improved component longevity.

Market research reveals that OEMs are specifically seeking heat shield materials that can maintain structural integrity at temperatures exceeding 800°C, a requirement that has increased by approximately 150°C over the past decade due to advancements in engine design and performance expectations. Additionally, there is growing demand for heat shields that offer a minimum 30% weight reduction compared to traditional metallic solutions, without compromising thermal protection capabilities.

Durability requirements have also evolved significantly, with manufacturers now expecting heat shield systems to maintain performance throughout the vehicle's entire lifecycle (typically 150,000+ miles) without degradation. This represents a substantial increase from previous expectations of replacement or maintenance at mid-life service intervals.

Cost considerations remain paramount in the competitive automotive market. While premium manufacturers demonstrate willingness to invest in advanced thermal protection systems, mainstream vehicle manufacturers require solutions that add no more than 5-7% to current heat management system costs. This cost sensitivity is creating market opportunities for innovative materials and manufacturing processes that can deliver enhanced performance at competitive price points.

Regional market variations are notable, with European manufacturers prioritizing weight reduction and emissions compliance, North American manufacturers focusing on durability and cost-effectiveness, and Asian manufacturers emphasizing manufacturing scalability and integration with existing production processes. These regional differences are shaping the development of specialized heat shield solutions tailored to specific market requirements.

Emerging market trends indicate growing interest in multi-functional heat shields that provide not only thermal protection but also contribute to noise reduction, vibration dampening, and even energy recovery. This trend is particularly evident in the premium vehicle segment, where manufacturers are willing to pay premium prices for integrated solutions that address multiple engineering challenges simultaneously.

The aftermarket segment presents additional requirements, with a focus on ease of installation, universal fitment capabilities, and enhanced durability under extreme conditions. This segment values heat shield solutions that offer visible performance benefits that can be marketed directly to consumers, such as reduced underhood temperatures and improved component longevity.

Current Heat Shield Technologies and Barriers

The current landscape of heat shield technologies for V4 engines presents a diverse array of solutions, each with specific advantages and limitations. Traditional metallic heat shields, predominantly made from aluminum, stainless steel, or titanium alloys, remain widely utilized due to their durability and relatively low manufacturing costs. These materials typically offer thermal resistance up to 1200°C for titanium-based shields, though aluminum variants are limited to approximately 600°C before experiencing significant degradation in protective properties.

Ceramic-based heat shields have gained significant market share in premium engine applications, offering superior thermal insulation with temperature resistance exceeding 1600°C. These advanced materials provide weight reduction of up to 40% compared to metallic alternatives while maintaining structural integrity under extreme thermal cycling conditions. However, their widespread adoption faces barriers related to manufacturing complexity and substantially higher production costs—often 3-5 times that of conventional metallic shields.

Composite heat shields incorporating carbon fiber, ceramic matrices, or multi-layer designs represent the cutting edge of thermal protection systems. These technologies deliver exceptional performance with thermal resistance reaching 2000°C in specialized applications while reducing weight by up to 60% compared to traditional solutions. Despite their impressive specifications, market penetration remains limited due to prohibitive costs and complex integration requirements with existing engine architectures.

A significant technical barrier across all heat shield technologies involves the management of thermal expansion differentials between the shield and engine components. This challenge frequently leads to mounting complications, seal failures, and premature material fatigue. Current solutions typically employ floating mount designs or flexible attachment systems, though these introduce additional complexity and potential failure points.

Manufacturing scalability presents another substantial barrier, particularly for advanced ceramic and composite solutions. Production processes often require specialized equipment, tightly controlled environments, and extensive quality control measures that limit mass production capabilities and contribute to elevated costs. The industry has yet to develop standardized manufacturing protocols that balance performance requirements with economic feasibility.

Durability under real-world operating conditions remains problematic, with many advanced heat shield technologies demonstrating excellent performance in laboratory settings but failing to maintain integrity when subjected to vibration, thermal cycling, and chemical exposure simultaneously. This performance gap necessitates extensive validation testing, further increasing development timelines and costs for new thermal protection solutions.

Ceramic-based heat shields have gained significant market share in premium engine applications, offering superior thermal insulation with temperature resistance exceeding 1600°C. These advanced materials provide weight reduction of up to 40% compared to metallic alternatives while maintaining structural integrity under extreme thermal cycling conditions. However, their widespread adoption faces barriers related to manufacturing complexity and substantially higher production costs—often 3-5 times that of conventional metallic shields.

Composite heat shields incorporating carbon fiber, ceramic matrices, or multi-layer designs represent the cutting edge of thermal protection systems. These technologies deliver exceptional performance with thermal resistance reaching 2000°C in specialized applications while reducing weight by up to 60% compared to traditional solutions. Despite their impressive specifications, market penetration remains limited due to prohibitive costs and complex integration requirements with existing engine architectures.

A significant technical barrier across all heat shield technologies involves the management of thermal expansion differentials between the shield and engine components. This challenge frequently leads to mounting complications, seal failures, and premature material fatigue. Current solutions typically employ floating mount designs or flexible attachment systems, though these introduce additional complexity and potential failure points.

Manufacturing scalability presents another substantial barrier, particularly for advanced ceramic and composite solutions. Production processes often require specialized equipment, tightly controlled environments, and extensive quality control measures that limit mass production capabilities and contribute to elevated costs. The industry has yet to develop standardized manufacturing protocols that balance performance requirements with economic feasibility.

Durability under real-world operating conditions remains problematic, with many advanced heat shield technologies demonstrating excellent performance in laboratory settings but failing to maintain integrity when subjected to vibration, thermal cycling, and chemical exposure simultaneously. This performance gap necessitates extensive validation testing, further increasing development timelines and costs for new thermal protection solutions.

Benchmark Analysis of Existing Heat Shield Solutions

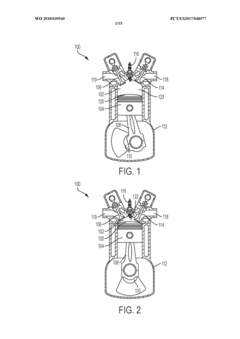

01 Multilayer thermal protection systems for V4 engines

Multilayer thermal protection systems are designed to provide effective heat shielding for V4 engines. These systems typically consist of multiple layers of different materials, each serving a specific function in heat management. The outer layer often features a reflective material to deflect radiant heat, while inner layers provide insulation and structural support. This multilayer approach creates an effective barrier against heat transfer, protecting sensitive engine components and surrounding vehicle parts from excessive temperatures generated during engine operation.- Multilayer thermal insulation materials for heat shields: Heat shields for V4 engines can be constructed using multilayer thermal insulation materials to effectively manage heat transfer. These shields typically consist of multiple layers including reflective metallic foils, insulating core materials, and protective outer layers. The multilayer design creates air gaps that provide additional insulation properties, reducing heat radiation to surrounding engine components and vehicle structures. This approach offers superior thermal protection while maintaining a compact design suitable for the limited space around V4 engines.

- Ceramic and composite materials for high-temperature protection: Advanced ceramic and composite materials are utilized in V4 engine heat shields to withstand extreme temperatures. These materials combine high thermal resistance with relatively low weight, making them ideal for automotive applications. Ceramic-based shields can withstand temperatures exceeding 1000°C while maintaining structural integrity. Some designs incorporate ceramic fibers embedded in metallic matrices to create shields that offer both heat resistance and mechanical durability. These materials provide effective thermal barriers between hot engine components and temperature-sensitive parts.

- Active cooling systems integrated with heat shields: Modern V4 engine heat shield designs incorporate active cooling systems to enhance thermal protection. These systems may include liquid cooling channels, forced air circulation, or thermoelectric cooling elements integrated directly into the shield structure. Active cooling significantly improves the heat dissipation capacity of the shields, allowing for more efficient temperature management in high-performance engines. Some designs feature smart cooling systems that activate only when specific temperature thresholds are reached, optimizing energy efficiency while maintaining effective thermal protection.

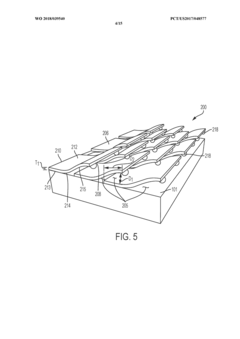

- Modular and adjustable heat shield designs: Modular heat shield systems for V4 engines allow for customized thermal protection based on specific engine configurations and operating conditions. These designs feature interchangeable components that can be adjusted or replaced to accommodate different heat profiles or maintenance requirements. Adjustable mounting systems enable precise positioning of the shields relative to heat sources, optimizing their protective function. Some modular designs incorporate different materials in various sections of the shield to address specific thermal challenges around different parts of the engine.

- Aerodynamic heat shield designs for improved cooling: Aerodynamically optimized heat shields for V4 engines incorporate features that manage airflow to enhance cooling efficiency. These designs include strategically placed vents, channels, and surface textures that direct air to hot spots while maintaining overall thermal protection. By leveraging principles of fluid dynamics, these shields can create pressure differentials that promote natural air circulation around the engine. Some advanced designs adjust their aerodynamic properties based on vehicle speed or engine temperature, providing adaptive thermal management under varying operating conditions.

02 Advanced materials for heat shield construction

Various advanced materials are utilized in the construction of heat shields for V4 engines to enhance thermal protection. These materials include ceramic composites, metallic alloys with high heat resistance, and specialized polymers. Some heat shields incorporate aerogel or similar high-performance insulating materials that provide exceptional thermal resistance despite being lightweight. The selection of materials is critical to achieving optimal heat management while maintaining durability under the extreme conditions experienced in engine compartments, including vibration, temperature cycling, and exposure to various fluids.Expand Specific Solutions03 Strategic placement and design of heat shields

The strategic placement and design of heat shields around V4 engines significantly impacts their thermal protection effectiveness. Heat shields are specifically engineered to cover critical areas where heat concentration is highest, such as exhaust manifolds, turbochargers, and catalytic converters. The design often incorporates air gaps between the heat source and the shield to create an insulating barrier. Additionally, the shape and contour of heat shields are optimized to manage airflow around hot components, facilitating heat dissipation while protecting surrounding components from thermal damage.Expand Specific Solutions04 Active cooling systems integrated with heat shields

Active cooling systems are increasingly being integrated with heat shields to enhance thermal protection for V4 engines. These systems may include liquid cooling channels, forced air circulation, or thermoelectric cooling elements embedded within or working in conjunction with traditional heat shields. Some advanced designs incorporate phase-change materials that absorb heat during high-temperature operation and release it during cooler periods. This active approach to thermal management allows for more precise temperature control and can significantly improve the overall efficiency and longevity of engine components.Expand Specific Solutions05 Modular and adaptable heat shield systems

Modular and adaptable heat shield systems provide flexible thermal protection solutions for various V4 engine configurations. These systems feature interchangeable components that can be customized to specific engine layouts and thermal requirements. The modular approach allows for easier installation, maintenance, and replacement of individual shield components without requiring complete system overhauls. Some adaptable systems also incorporate adjustable mounting mechanisms that can accommodate thermal expansion and contraction while maintaining optimal positioning relative to heat sources. This flexibility is particularly valuable for performance applications where engine modifications may alter thermal characteristics.Expand Specific Solutions

Leading Manufacturers in Automotive Heat Shield Industry

The V4 engine heat shield thermal protection market is currently in a growth phase, with increasing demand driven by automotive and aerospace applications. The market size is expanding due to rising vehicle production and stricter thermal management requirements. Technologically, the field shows varying maturity levels across players. Industry leaders like ElringKlinger AG and Federal-Mogul (Tenneco) demonstrate advanced capabilities in high-performance shielding solutions, while BorgWarner and Dana Automotive Systems offer innovative composite materials. Asian manufacturers including BYD, Chery, and SAIC GM Wuling are rapidly advancing their technologies to meet domestic market demands. European companies such as Renault, Peugeot, and Nissan maintain strong positions through established R&D networks, while specialized players like Pratt & Whitney Canada and Rolls-Royce lead in aerospace thermal protection applications.

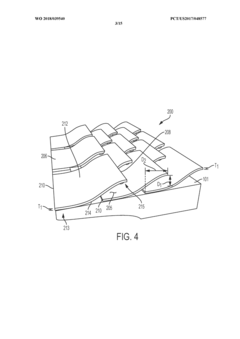

Reinz-Dichtungs GmbH

Technical Solution: Reinz-Dichtungs has developed innovative V4 engine heat shield solutions utilizing their proprietary "Thermal-Lock" technology that combines multiple layers of precision-formed metal with specialized high-temperature insulation materials. Their heat shields feature computer-optimized embossing patterns that create effective air gaps while maintaining structural integrity under extreme temperature conditions. The company implements specialized surface treatments that enhance thermal reflectivity by up to 35% compared to conventional materials. Reinz's V4 engine heat shields incorporate advanced edge-sealing techniques that prevent hot gas infiltration between layers, maintaining thermal efficiency throughout the product lifecycle. Their manufacturing process includes automated dimensional verification systems that ensure consistent thermal performance across production runs. The company has developed specialized attachment systems designed to accommodate thermal expansion while minimizing heat transfer through mounting points, addressing a common weakness in conventional heat shield designs.

Strengths: Superior thermal protection with temperature reductions of up to 75°C at critical points; excellent vibration resistance with specialized damping features; good longevity with minimal performance degradation over time. Weaknesses: Higher manufacturing complexity requiring specialized equipment; more expensive than basic heat shield designs; requires precise installation procedures to achieve optimal performance.

ElringKlinger AG

Technical Solution: ElringKlinger has developed advanced multi-layer metal heat shields for V4 engines that combine different materials and surface structures to optimize thermal protection. Their proprietary design incorporates up to five layers of embossed metal sheets with air gaps that create effective thermal barriers. The company utilizes specialized aluminum alloys with high-temperature resistance coatings and implements precision-engineered micro-perforation patterns that enhance heat dissipation while maintaining structural integrity. ElringKlinger's heat shields feature integrated attachment systems that reduce thermal bridging and accommodate engine movement during thermal expansion cycles. Their manufacturing process includes automated quality control systems that ensure consistent thermal performance across production batches.

Strengths: Superior thermal insulation efficiency with up to 95% heat reflection capability; excellent durability with proven 150,000+ mile lifespan; reduced weight compared to traditional solutions. Weaknesses: Higher production costs than single-layer alternatives; requires specialized manufacturing equipment; more complex installation procedures.

Critical Patents and Innovations in Heat Shield Materials

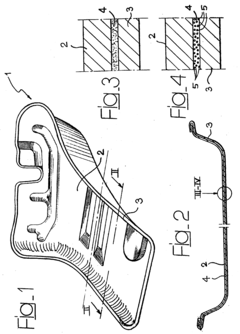

Thermal barriers for engines and methods of making the same

PatentWO2018039540A1

Innovation

- A thermal barrier comprising an array of metallic shields with overlapping edges and a body with a mounting and overlapping portion, designed to be directly or indirectly joined to engine surfaces, utilizing convective cooling through void volumes and potentially filled with insulation material to enhance thermal resistance and durability.

Heat shield for motor-vehicles

PatentInactiveEP1006023A2

Innovation

- A heat shield with a high-temperature-resistant silicone adhesive layer incorporating ceramic micro-spheres, providing elastic connection between two aluminium foils for enhanced thermal, acoustical, and vibrational insulation.

Environmental Impact and Sustainability Considerations

The environmental impact of heat shield technologies in V4 engines represents a critical consideration in modern automotive engineering. Traditional heat shield materials often incorporate environmentally problematic components such as asbestos (historically), certain metal alloys containing hexavalent chromium, and manufacturing processes that generate significant carbon emissions. Recent benchmarking studies indicate that the production of conventional metallic heat shields generates approximately 2.5-3.2 kg CO2 equivalent per unit, highlighting the need for more sustainable alternatives.

Advanced ceramic-based heat shields demonstrate promising environmental credentials, with lifecycle assessments revealing 30-40% lower carbon footprints compared to traditional metallic counterparts. These materials typically require less energy-intensive manufacturing processes and offer extended service life, reducing replacement frequency and associated resource consumption. Furthermore, innovative composite heat shields incorporating recycled materials have emerged as viable options, utilizing up to 25% post-industrial recycled content without compromising thermal protection performance.

Water consumption represents another significant environmental factor in heat shield production. Conventional manufacturing processes consume approximately 40-60 liters of water per unit, primarily for cooling and cleaning operations. Newer dry manufacturing techniques have demonstrated potential water usage reductions of up to 70%, addressing growing concerns regarding industrial water consumption in water-stressed regions.

End-of-life considerations have gained prominence in recent benchmarking studies. Traditional heat shields often end up in landfills due to difficulties in separating bonded materials. Innovative designs now incorporate disassembly features that facilitate material recovery, with some manufacturers achieving material recovery rates exceeding 85%. Additionally, several leading suppliers have implemented take-back programs for heat shield components, creating closed-loop material cycles.

Regulatory compliance increasingly shapes heat shield development, with global standards like Euro 7 and China 6b imposing stricter requirements on automotive components' environmental impact. These regulations address not only emissions during vehicle operation but also manufacturing processes and material selection. Forward-thinking manufacturers have begun implementing Environmental Product Declarations (EPDs) for heat shield components, providing transparent lifecycle impact data to customers and regulatory bodies.

The transition toward electric vehicles presents both challenges and opportunities for heat shield sustainability. While traditional combustion engine heat shields may become obsolete, new thermal management requirements emerge for battery systems and power electronics, necessitating innovative, environmentally conscious thermal protection solutions that align with the broader sustainability goals of electrified transportation.

Advanced ceramic-based heat shields demonstrate promising environmental credentials, with lifecycle assessments revealing 30-40% lower carbon footprints compared to traditional metallic counterparts. These materials typically require less energy-intensive manufacturing processes and offer extended service life, reducing replacement frequency and associated resource consumption. Furthermore, innovative composite heat shields incorporating recycled materials have emerged as viable options, utilizing up to 25% post-industrial recycled content without compromising thermal protection performance.

Water consumption represents another significant environmental factor in heat shield production. Conventional manufacturing processes consume approximately 40-60 liters of water per unit, primarily for cooling and cleaning operations. Newer dry manufacturing techniques have demonstrated potential water usage reductions of up to 70%, addressing growing concerns regarding industrial water consumption in water-stressed regions.

End-of-life considerations have gained prominence in recent benchmarking studies. Traditional heat shields often end up in landfills due to difficulties in separating bonded materials. Innovative designs now incorporate disassembly features that facilitate material recovery, with some manufacturers achieving material recovery rates exceeding 85%. Additionally, several leading suppliers have implemented take-back programs for heat shield components, creating closed-loop material cycles.

Regulatory compliance increasingly shapes heat shield development, with global standards like Euro 7 and China 6b imposing stricter requirements on automotive components' environmental impact. These regulations address not only emissions during vehicle operation but also manufacturing processes and material selection. Forward-thinking manufacturers have begun implementing Environmental Product Declarations (EPDs) for heat shield components, providing transparent lifecycle impact data to customers and regulatory bodies.

The transition toward electric vehicles presents both challenges and opportunities for heat shield sustainability. While traditional combustion engine heat shields may become obsolete, new thermal management requirements emerge for battery systems and power electronics, necessitating innovative, environmentally conscious thermal protection solutions that align with the broader sustainability goals of electrified transportation.

Performance Testing Methodologies and Standards

Effective benchmarking of V4 engine heat shields requires standardized testing methodologies that accurately simulate real-world thermal conditions while providing reproducible results. The automotive industry has developed several key testing protocols that have become standard practice for evaluating heat shield performance.

The Society of Automotive Engineers (SAE) has established comprehensive standards for thermal protection testing, including SAE J2302 for heat shield materials and SAE J1349 for engine thermal performance. These standards specify precise testing conditions, measurement points, and data collection procedures to ensure consistency across different testing facilities.

Temperature mapping represents a fundamental testing methodology, utilizing thermal imaging cameras and strategically placed thermocouples to create detailed heat distribution profiles across the shield surface. Modern systems can capture data at millisecond intervals, providing insights into how heat dissipates during various engine operating conditions. This approach typically requires a minimum of 16 measurement points for V4 engines to ensure comprehensive coverage.

Cyclic thermal shock testing evaluates heat shield durability by subjecting materials to rapid temperature fluctuations between extreme hot and cold conditions. Industry standards typically require 500-1000 cycles between -40°C and 650°C for automotive heat shields, with visual inspections and performance measurements conducted at predetermined intervals.

Vibration coupled thermal testing combines thermal exposure with mechanical stress to simulate real-world driving conditions. Test rigs apply specific vibration profiles (typically 10-500 Hz frequency range) while the shield is subjected to operational temperatures. This methodology has proven particularly valuable for identifying failure points at material interfaces and mounting brackets.

Computational Fluid Dynamics (CFD) simulation has emerged as a complementary testing methodology, allowing engineers to model thermal performance before physical prototypes are produced. These simulations must be validated against physical test data, with industry standards requiring correlation coefficients of at least 0.85 between simulated and measured results.

Standardized reporting formats have been developed to facilitate comparison between different heat shield designs. The Thermal Protection Factor (TPF) has become an industry benchmark, combining temperature reduction efficiency, weight, durability, and cost factors into a single comparative metric. Leading manufacturers typically target a TPF of 8.5 or higher for premium automotive applications.

Accelerated aging protocols simulate extended use conditions, exposing heat shields to thermal cycling, chemical exposure, and humidity in compressed timeframes. The standard 1000-hour test is designed to approximate 100,000 miles of typical driving conditions, providing insights into long-term performance degradation.

The Society of Automotive Engineers (SAE) has established comprehensive standards for thermal protection testing, including SAE J2302 for heat shield materials and SAE J1349 for engine thermal performance. These standards specify precise testing conditions, measurement points, and data collection procedures to ensure consistency across different testing facilities.

Temperature mapping represents a fundamental testing methodology, utilizing thermal imaging cameras and strategically placed thermocouples to create detailed heat distribution profiles across the shield surface. Modern systems can capture data at millisecond intervals, providing insights into how heat dissipates during various engine operating conditions. This approach typically requires a minimum of 16 measurement points for V4 engines to ensure comprehensive coverage.

Cyclic thermal shock testing evaluates heat shield durability by subjecting materials to rapid temperature fluctuations between extreme hot and cold conditions. Industry standards typically require 500-1000 cycles between -40°C and 650°C for automotive heat shields, with visual inspections and performance measurements conducted at predetermined intervals.

Vibration coupled thermal testing combines thermal exposure with mechanical stress to simulate real-world driving conditions. Test rigs apply specific vibration profiles (typically 10-500 Hz frequency range) while the shield is subjected to operational temperatures. This methodology has proven particularly valuable for identifying failure points at material interfaces and mounting brackets.

Computational Fluid Dynamics (CFD) simulation has emerged as a complementary testing methodology, allowing engineers to model thermal performance before physical prototypes are produced. These simulations must be validated against physical test data, with industry standards requiring correlation coefficients of at least 0.85 between simulated and measured results.

Standardized reporting formats have been developed to facilitate comparison between different heat shield designs. The Thermal Protection Factor (TPF) has become an industry benchmark, combining temperature reduction efficiency, weight, durability, and cost factors into a single comparative metric. Leading manufacturers typically target a TPF of 8.5 or higher for premium automotive applications.

Accelerated aging protocols simulate extended use conditions, exposing heat shields to thermal cycling, chemical exposure, and humidity in compressed timeframes. The standard 1000-hour test is designed to approximate 100,000 miles of typical driving conditions, providing insights into long-term performance degradation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!