Comparing V4 Engine Cooling Methods: Liquid vs Air

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Cooling Evolution and Objectives

Engine cooling technology has evolved significantly since the early days of internal combustion engines. The V4 engine configuration, characterized by its compact design and balance between power and efficiency, has witnessed parallel evolution in its cooling systems. Initially, early V4 engines relied primarily on rudimentary air cooling methods, utilizing natural airflow and basic heat dissipation principles. As engine performance demands increased through the 1930s and 1940s, forced air cooling systems emerged, incorporating fans and directed airflow channels to enhance thermal management.

The 1950s marked a significant transition period with the broader adoption of liquid cooling technologies in V4 engines, particularly in automotive applications. This shift was driven by increasing power outputs and the need for more precise temperature control. The subsequent decades saw continuous refinement of both cooling methodologies, with each developing distinct technological branches optimized for different applications and performance requirements.

Modern V4 engine cooling technology aims to achieve several critical objectives simultaneously. Primary among these is maintaining optimal operating temperature across all engine components under varying load conditions. This temperature control directly impacts engine efficiency, power output, emissions performance, and component longevity. Additionally, contemporary cooling systems must balance thermal management with space constraints, weight considerations, and energy consumption requirements.

The current technological landscape presents divergent paths in V4 engine cooling. Liquid cooling systems have evolved toward more sophisticated closed-loop designs with advanced coolant formulations, precision flow management, and intelligent temperature control systems. These systems excel in maintaining consistent temperatures across the entire engine block and can handle higher heat loads. Conversely, air cooling technology has progressed toward optimized fin designs, strategic airflow routing, and materials with enhanced thermal conductivity properties, offering advantages in simplicity, weight reduction, and maintenance accessibility.

Recent technological trends indicate a growing focus on hybrid cooling solutions that combine elements of both methodologies to maximize advantages while mitigating limitations. Additionally, the integration of digital thermal management systems, utilizing real-time temperature monitoring and adaptive cooling responses, represents a significant advancement in both cooling approaches. These developments are increasingly driven by efficiency requirements, emissions regulations, and the push toward more sustainable engine designs.

The trajectory of V4 engine cooling technology continues to be shaped by emerging materials science, computational fluid dynamics advancements, and the integration of smart systems that optimize cooling performance based on operational conditions and environmental factors. These evolutionary paths reflect the ongoing technical challenge of balancing performance, efficiency, reliability, and cost in modern engine design.

The 1950s marked a significant transition period with the broader adoption of liquid cooling technologies in V4 engines, particularly in automotive applications. This shift was driven by increasing power outputs and the need for more precise temperature control. The subsequent decades saw continuous refinement of both cooling methodologies, with each developing distinct technological branches optimized for different applications and performance requirements.

Modern V4 engine cooling technology aims to achieve several critical objectives simultaneously. Primary among these is maintaining optimal operating temperature across all engine components under varying load conditions. This temperature control directly impacts engine efficiency, power output, emissions performance, and component longevity. Additionally, contemporary cooling systems must balance thermal management with space constraints, weight considerations, and energy consumption requirements.

The current technological landscape presents divergent paths in V4 engine cooling. Liquid cooling systems have evolved toward more sophisticated closed-loop designs with advanced coolant formulations, precision flow management, and intelligent temperature control systems. These systems excel in maintaining consistent temperatures across the entire engine block and can handle higher heat loads. Conversely, air cooling technology has progressed toward optimized fin designs, strategic airflow routing, and materials with enhanced thermal conductivity properties, offering advantages in simplicity, weight reduction, and maintenance accessibility.

Recent technological trends indicate a growing focus on hybrid cooling solutions that combine elements of both methodologies to maximize advantages while mitigating limitations. Additionally, the integration of digital thermal management systems, utilizing real-time temperature monitoring and adaptive cooling responses, represents a significant advancement in both cooling approaches. These developments are increasingly driven by efficiency requirements, emissions regulations, and the push toward more sustainable engine designs.

The trajectory of V4 engine cooling technology continues to be shaped by emerging materials science, computational fluid dynamics advancements, and the integration of smart systems that optimize cooling performance based on operational conditions and environmental factors. These evolutionary paths reflect the ongoing technical challenge of balancing performance, efficiency, reliability, and cost in modern engine design.

Market Demand Analysis for Advanced Cooling Systems

The global market for advanced engine cooling systems is experiencing significant growth, driven by increasing demands for higher performance, fuel efficiency, and environmental sustainability in automotive and industrial applications. The V4 engine segment, particularly in high-performance vehicles and specialized industrial equipment, represents a substantial portion of this market with distinctive cooling requirements.

Market research indicates that the advanced cooling systems market is projected to grow at a compound annual growth rate of approximately 6% through 2028, with the automotive sector being the primary contributor. This growth is primarily fueled by stringent emission regulations worldwide, pushing manufacturers to develop more efficient engines that generate less heat while maintaining optimal performance.

Consumer preferences are increasingly shifting toward vehicles with better fuel economy and reduced environmental impact, creating a direct demand for more efficient cooling solutions. Additionally, the rising popularity of high-performance vehicles, particularly in emerging economies, has created a niche market for specialized cooling systems capable of handling extreme operating conditions.

The industrial sector also demonstrates significant demand for advanced V4 engine cooling systems, particularly in applications such as generators, construction equipment, and marine propulsion systems. These applications often require cooling solutions that can operate reliably under harsh conditions and varying loads, driving innovation in both liquid and air cooling technologies.

Regional analysis reveals varying market dynamics, with North America and Europe leading in adoption of liquid cooling systems due to their established automotive industries and stringent emission standards. Meanwhile, Asia-Pacific represents the fastest-growing market for advanced cooling solutions, driven by rapid industrialization and increasing vehicle ownership in countries like China and India.

The aftermarket segment for cooling systems is also expanding, with growing consumer awareness about the benefits of upgrading to more efficient cooling solutions. This trend is particularly evident in the performance vehicle segment, where enthusiasts are willing to invest in premium cooling systems to enhance engine performance and longevity.

Economic factors such as fluctuating raw material prices and manufacturing costs significantly influence market dynamics. The recent global supply chain disruptions have highlighted the importance of resilient supply networks for cooling system components, prompting manufacturers to diversify their supplier base and explore alternative materials.

Customer feedback analysis reveals that reliability, maintenance requirements, and installation complexity are key factors influencing purchasing decisions for cooling systems. Liquid cooling systems are generally perceived as offering superior performance but at higher costs and complexity, while air cooling systems are valued for their simplicity and lower maintenance requirements.

Market research indicates that the advanced cooling systems market is projected to grow at a compound annual growth rate of approximately 6% through 2028, with the automotive sector being the primary contributor. This growth is primarily fueled by stringent emission regulations worldwide, pushing manufacturers to develop more efficient engines that generate less heat while maintaining optimal performance.

Consumer preferences are increasingly shifting toward vehicles with better fuel economy and reduced environmental impact, creating a direct demand for more efficient cooling solutions. Additionally, the rising popularity of high-performance vehicles, particularly in emerging economies, has created a niche market for specialized cooling systems capable of handling extreme operating conditions.

The industrial sector also demonstrates significant demand for advanced V4 engine cooling systems, particularly in applications such as generators, construction equipment, and marine propulsion systems. These applications often require cooling solutions that can operate reliably under harsh conditions and varying loads, driving innovation in both liquid and air cooling technologies.

Regional analysis reveals varying market dynamics, with North America and Europe leading in adoption of liquid cooling systems due to their established automotive industries and stringent emission standards. Meanwhile, Asia-Pacific represents the fastest-growing market for advanced cooling solutions, driven by rapid industrialization and increasing vehicle ownership in countries like China and India.

The aftermarket segment for cooling systems is also expanding, with growing consumer awareness about the benefits of upgrading to more efficient cooling solutions. This trend is particularly evident in the performance vehicle segment, where enthusiasts are willing to invest in premium cooling systems to enhance engine performance and longevity.

Economic factors such as fluctuating raw material prices and manufacturing costs significantly influence market dynamics. The recent global supply chain disruptions have highlighted the importance of resilient supply networks for cooling system components, prompting manufacturers to diversify their supplier base and explore alternative materials.

Customer feedback analysis reveals that reliability, maintenance requirements, and installation complexity are key factors influencing purchasing decisions for cooling systems. Liquid cooling systems are generally perceived as offering superior performance but at higher costs and complexity, while air cooling systems are valued for their simplicity and lower maintenance requirements.

Current Cooling Technologies and Challenges

Engine cooling systems have evolved significantly over the decades, with two primary methods dominating the market: liquid cooling and air cooling. In contemporary V4 engine applications, both technologies continue to coexist, each with distinct advantages and limitations that influence their implementation across various sectors including automotive, power generation, and industrial machinery.

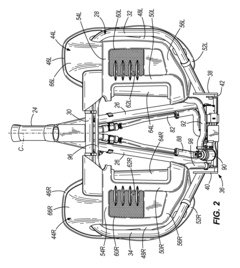

Liquid cooling systems represent the most widely adopted solution for modern V4 engines, particularly in automotive applications where power density and thermal efficiency are paramount. These systems typically employ a water-glycol mixture circulated through engine jackets and a radiator to dissipate heat. Advanced liquid cooling implementations incorporate precision-controlled electric pumps, thermostatic valves, and multi-zone cooling strategies that optimize temperature management across different engine components. The primary advantage lies in superior heat transfer capacity, allowing engines to maintain optimal operating temperatures even under high-load conditions.

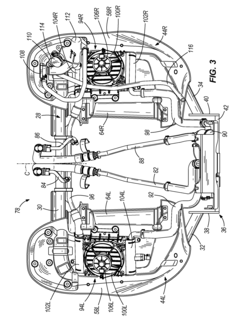

Air cooling technology, while less common in contemporary V4 applications, maintains relevance in specific niches such as motorcycle engines, small aircraft, and certain industrial equipment. These systems rely on fins cast into the engine block and cylinder heads to increase surface area, with airflow generated either passively or through forced induction via fans. Recent innovations include computational fluid dynamics-optimized fin designs and advanced materials with enhanced thermal conductivity properties that significantly improve heat dissipation efficiency compared to traditional implementations.

The fundamental challenge facing both cooling methodologies centers on balancing thermal efficiency with system complexity, weight, and cost considerations. Liquid cooling systems, while thermally superior, introduce additional failure points through pumps, hoses, radiators, and thermostats. They also add considerable weight and complexity to the overall engine package. Conversely, air cooling systems struggle to maintain consistent temperatures across all engine components, particularly under varying load conditions, potentially leading to thermal gradients that affect performance and longevity.

Emerging hybrid cooling approaches attempt to leverage the strengths of both methodologies. These include oil-air cooling systems that utilize engine lubricant as a heat transfer medium and targeted liquid cooling for critical components while maintaining air cooling for less thermally sensitive areas. Additionally, advanced thermal management systems incorporating electronic control units that actively regulate coolant flow rates and cooling fan operation based on real-time temperature monitoring represent the cutting edge of current technology.

Environmental considerations also present significant challenges, with regulations increasingly restricting the types of coolants permissible in various applications due to their potential environmental impact. This has accelerated research into alternative coolants with reduced global warming potential and improved biodegradability characteristics, particularly for liquid-cooled systems.

Liquid cooling systems represent the most widely adopted solution for modern V4 engines, particularly in automotive applications where power density and thermal efficiency are paramount. These systems typically employ a water-glycol mixture circulated through engine jackets and a radiator to dissipate heat. Advanced liquid cooling implementations incorporate precision-controlled electric pumps, thermostatic valves, and multi-zone cooling strategies that optimize temperature management across different engine components. The primary advantage lies in superior heat transfer capacity, allowing engines to maintain optimal operating temperatures even under high-load conditions.

Air cooling technology, while less common in contemporary V4 applications, maintains relevance in specific niches such as motorcycle engines, small aircraft, and certain industrial equipment. These systems rely on fins cast into the engine block and cylinder heads to increase surface area, with airflow generated either passively or through forced induction via fans. Recent innovations include computational fluid dynamics-optimized fin designs and advanced materials with enhanced thermal conductivity properties that significantly improve heat dissipation efficiency compared to traditional implementations.

The fundamental challenge facing both cooling methodologies centers on balancing thermal efficiency with system complexity, weight, and cost considerations. Liquid cooling systems, while thermally superior, introduce additional failure points through pumps, hoses, radiators, and thermostats. They also add considerable weight and complexity to the overall engine package. Conversely, air cooling systems struggle to maintain consistent temperatures across all engine components, particularly under varying load conditions, potentially leading to thermal gradients that affect performance and longevity.

Emerging hybrid cooling approaches attempt to leverage the strengths of both methodologies. These include oil-air cooling systems that utilize engine lubricant as a heat transfer medium and targeted liquid cooling for critical components while maintaining air cooling for less thermally sensitive areas. Additionally, advanced thermal management systems incorporating electronic control units that actively regulate coolant flow rates and cooling fan operation based on real-time temperature monitoring represent the cutting edge of current technology.

Environmental considerations also present significant challenges, with regulations increasingly restricting the types of coolants permissible in various applications due to their potential environmental impact. This has accelerated research into alternative coolants with reduced global warming potential and improved biodegradability characteristics, particularly for liquid-cooled systems.

Comparative Analysis of Liquid vs Air Cooling Solutions

01 Liquid cooling systems for V4 engines

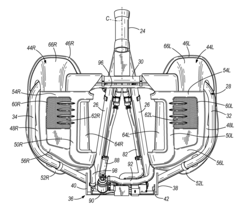

Liquid cooling systems are commonly used in V4 engines to improve cooling efficiency. These systems typically include a water pump, radiator, and coolant passages throughout the engine block and cylinder heads. The liquid coolant absorbs heat from the engine components and transfers it to the radiator where it is dissipated into the air. This method provides more uniform cooling compared to air cooling systems and helps maintain optimal operating temperatures even under high load conditions.- Liquid cooling systems for V4 engines: Liquid cooling systems are commonly used in V4 engines to improve cooling efficiency. These systems typically involve a coolant that circulates through the engine block and cylinder heads, absorbing heat and then releasing it through a radiator. Advanced liquid cooling systems may include optimized coolant flow paths, improved water jackets, and specialized coolant formulations to enhance heat transfer and overall cooling efficiency.

- Air cooling enhancements for V4 engines: Air cooling methods for V4 engines focus on maximizing airflow around critical engine components. These methods include strategically placed cooling fins, optimized air ducts, and enhanced fan designs to direct air to high-temperature areas. Some systems incorporate thermostatically controlled fans that adjust airflow based on engine temperature, improving cooling efficiency while minimizing power consumption.

- Integrated cooling management systems: Integrated cooling management systems combine electronic controls with mechanical cooling components to optimize V4 engine cooling efficiency. These systems use temperature sensors, electronic control units, and variable-speed pumps or fans to adjust cooling intensity based on real-time engine conditions. By providing cooling precisely when and where needed, these systems improve efficiency while reducing energy consumption and emissions.

- Oil cooling techniques for V4 engines: Oil cooling techniques utilize the engine's lubricating oil as a secondary cooling medium. These methods include oil jets that spray the underside of pistons, oil coolers that exchange heat with air or coolant, and optimized oil circulation paths through high-heat areas. Oil cooling is particularly effective for reducing temperatures in bearing surfaces and other internal components where liquid coolant cannot reach, complementing primary cooling systems.

- Advanced materials and design for thermal efficiency: The use of advanced materials and innovative design approaches can significantly improve V4 engine cooling efficiency. These include high thermal conductivity materials for engine blocks and heads, ceramic coatings that provide thermal barriers, and optimized component geometries that enhance heat dissipation. Some designs incorporate targeted cooling for specific high-temperature components and reduced thermal mass in critical areas to improve overall cooling performance.

02 Advanced thermal management systems

Advanced thermal management systems for V4 engines incorporate electronic control units that regulate coolant flow and temperature based on engine operating conditions. These systems may include variable-speed water pumps, electronically controlled thermostats, and multiple cooling circuits to optimize cooling efficiency. By precisely controlling the cooling system based on real-time data, these advanced systems can improve engine performance, reduce fuel consumption, and decrease emissions while maintaining ideal operating temperatures.Expand Specific Solutions03 Air cooling and hybrid cooling methods

Some V4 engines utilize air cooling or hybrid cooling methods to enhance cooling efficiency. Air-cooled systems use fins on the cylinder and heads to increase surface area for heat dissipation, while hybrid systems combine both air and liquid cooling techniques. These methods may incorporate directed airflow channels, auxiliary cooling fans, and strategic placement of cooling fins to maximize heat transfer. For certain applications, these approaches can offer advantages in terms of weight reduction, simplicity, and reliability.Expand Specific Solutions04 Oil cooling systems and lubrication integration

Oil cooling systems play a significant role in V4 engine thermal management by utilizing engine oil as both a lubricant and coolant. These systems may include oil jets that spray the underside of pistons, oil coolers that exchange heat with external air or the engine coolant system, and specialized oil passages in critical components. By integrating cooling functions with the lubrication system, these methods provide targeted cooling to high-temperature areas while reducing the overall complexity of the engine design.Expand Specific Solutions05 Innovative cooling efficiency enhancements

Various innovative approaches are employed to enhance V4 engine cooling efficiency, including optimized coolant flow patterns, improved radiator designs, and the use of advanced materials with superior thermal conductivity. Some systems incorporate precision-engineered water jackets, specialized coolant additives, and computational fluid dynamics to identify and eliminate hot spots. Additional innovations include heat pipes, phase-change cooling technologies, and nanofluids that significantly improve heat transfer rates compared to conventional cooling methods.Expand Specific Solutions

Leading Manufacturers in Engine Cooling Industry

The V4 engine cooling market is in a growth phase, with increasing demand for efficient cooling solutions across automotive and industrial sectors. The competition between liquid and air cooling methods is intensifying as manufacturers seek optimal thermal management solutions. Major automotive players like Ford, BMW, and Harley-Davidson are investing heavily in advanced cooling technologies, while specialized companies such as Iceotope Group focus on precision liquid cooling innovations. Traditional manufacturers (Daimler-Benz, Scania) continue refining air cooling systems, but liquid cooling is gaining momentum due to higher efficiency and power density requirements. Research institutions like Beijing Institute of Technology are contributing significant advancements, particularly in hybrid cooling approaches that combine benefits of both methods for next-generation engine applications.

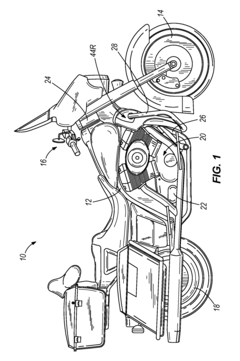

Ford Global Technologies LLC

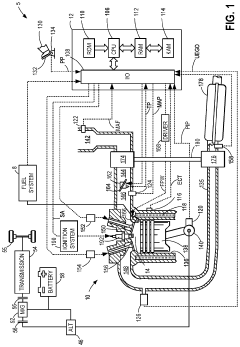

Technical Solution: Ford has developed an advanced split cooling system for V4 engines that utilizes dual cooling circuits - a high-temperature circuit for the cylinder head and exhaust components, and a low-temperature circuit for the engine block and intake components. This approach allows for optimized temperature management across different engine components. Their system incorporates precision coolant flow control valves that adjust flow rates based on real-time engine load and temperature data. Ford's cooling technology also features integrated heat recovery systems that capture waste heat for cabin heating and faster warm-up cycles, improving overall efficiency. The company has implemented advanced computational fluid dynamics (CFD) modeling to optimize coolant passage design, eliminating hot spots while maintaining uniform temperature distribution across critical engine components.

Strengths: Precision temperature control improves engine efficiency and reduces emissions; dual-circuit design allows for optimized cooling of different components; integrated heat recovery improves overall vehicle efficiency. Weaknesses: More complex system with additional components increases manufacturing costs; requires sophisticated electronic controls; potential for increased maintenance requirements compared to simpler cooling systems.

Wärtsilä Finland Oy

Technical Solution: Wärtsilä has developed a hybrid cooling system for V4 engines that combines both liquid and air cooling technologies. Their system utilizes liquid cooling for high-heat components like cylinder heads and exhaust manifolds, while implementing targeted air cooling for peripheral components. The company's approach incorporates advanced heat exchanger technology with optimized fin designs that maximize heat transfer efficiency while minimizing pressure drop. Wärtsilä's cooling system features intelligent thermal management that adjusts coolant flow and fan speeds based on real-time operating conditions and environmental factors. Their technology also includes specialized corrosion-resistant materials and treatments for cooling passages that extend system longevity in harsh operating environments. Additionally, Wärtsilä has implemented waste heat recovery systems that capture thermal energy from the cooling system for use in other vehicle or vessel systems.

Strengths: Hybrid approach optimizes cooling efficiency for different engine components; intelligent thermal management reduces energy consumption; waste heat recovery improves overall system efficiency. Weaknesses: More complex integration of multiple cooling technologies increases engineering challenges; higher initial cost compared to single-method cooling systems; requires more sophisticated control systems to manage both liquid and air cooling components.

Key Patents and Innovations in V4 Engine Cooling

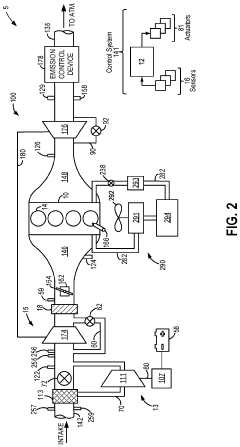

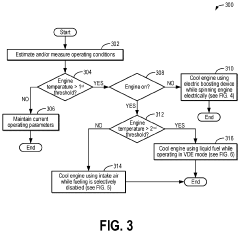

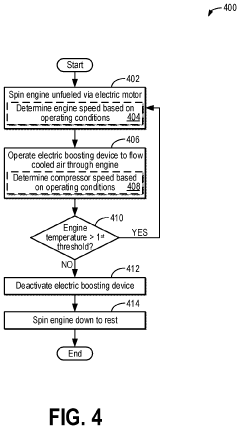

Systems and methods for reducing engine overheating using liquid fuel

PatentActiveUS11473491B2

Innovation

- The method involves deactivating a subset of engine cylinders and directly injecting liquid fuel into these sealed cylinders, where the fuel coats the cylinder surfaces, absorbs heat, and vaporizes to enhance cooling, combined with air cooling methods selected based on operating conditions.

Cylinder head cooling system

PatentInactiveUS20110114044A1

Innovation

- A liquid cooling system for motorcycle engines featuring a cylinder head design with a single-loop cooling passage that follows the curvature of the exhaust passage for at least 270 degrees, providing focused cooling for the cylinder heads while maintaining air flow efficiency through strategically positioned radiators and air ducts.

Environmental Impact of Different Cooling Methods

The environmental impact of cooling systems extends far beyond their immediate performance in V4 engines. Liquid cooling systems, while more efficient at heat transfer, introduce significant environmental considerations throughout their lifecycle. The production of coolants, particularly traditional ethylene glycol-based fluids, involves petrochemical processes that generate substantial carbon emissions. Additionally, these coolants require proper disposal as they contain toxic compounds that can contaminate soil and water systems if improperly handled. Recent industry data indicates that approximately 150 million gallons of coolant are improperly disposed of annually, creating potential environmental hazards.

Air cooling systems present a different environmental profile. They eliminate the need for liquid coolants entirely, reducing the risk of toxic fluid leakage and subsequent environmental contamination. However, air-cooled engines typically operate at higher temperatures, which can lead to increased nitrogen oxide (NOx) emissions—a significant contributor to air pollution and smog formation. Studies have shown that air-cooled V4 engines may produce up to 15% more NOx emissions compared to their liquid-cooled counterparts under similar operating conditions.

From a resource perspective, liquid cooling systems require additional components such as radiators, pumps, and hoses, increasing the material footprint of the engine. These components often incorporate aluminum and copper, metals whose extraction and processing are energy-intensive. Conversely, air cooling systems generally utilize fewer materials but may require specialized alloys capable of withstanding higher operating temperatures, which can involve rare or difficult-to-source elements.

Energy efficiency considerations also factor into the environmental assessment. Liquid-cooled engines typically maintain more consistent operating temperatures, potentially improving fuel efficiency by 3-7% compared to air-cooled equivalents. This translates to reduced lifetime carbon emissions from the vehicle, partially offsetting the environmental impact of the cooling system itself.

Maintenance requirements further differentiate the environmental impact of these cooling methods. Liquid systems require periodic coolant replacement, generating waste fluids that must be properly recycled. Air cooling systems generally demand less maintenance but may necessitate more frequent engine rebuilds due to higher thermal stress, resulting in additional resource consumption over the engine's lifetime.

Recent innovations are addressing these environmental concerns. Biodegradable coolants derived from propylene glycol offer reduced toxicity, while advanced air cooling designs incorporating phase-change materials are improving thermal efficiency without liquid coolants. These developments suggest a future where the environmental gap between cooling methods may narrow significantly.

Air cooling systems present a different environmental profile. They eliminate the need for liquid coolants entirely, reducing the risk of toxic fluid leakage and subsequent environmental contamination. However, air-cooled engines typically operate at higher temperatures, which can lead to increased nitrogen oxide (NOx) emissions—a significant contributor to air pollution and smog formation. Studies have shown that air-cooled V4 engines may produce up to 15% more NOx emissions compared to their liquid-cooled counterparts under similar operating conditions.

From a resource perspective, liquid cooling systems require additional components such as radiators, pumps, and hoses, increasing the material footprint of the engine. These components often incorporate aluminum and copper, metals whose extraction and processing are energy-intensive. Conversely, air cooling systems generally utilize fewer materials but may require specialized alloys capable of withstanding higher operating temperatures, which can involve rare or difficult-to-source elements.

Energy efficiency considerations also factor into the environmental assessment. Liquid-cooled engines typically maintain more consistent operating temperatures, potentially improving fuel efficiency by 3-7% compared to air-cooled equivalents. This translates to reduced lifetime carbon emissions from the vehicle, partially offsetting the environmental impact of the cooling system itself.

Maintenance requirements further differentiate the environmental impact of these cooling methods. Liquid systems require periodic coolant replacement, generating waste fluids that must be properly recycled. Air cooling systems generally demand less maintenance but may necessitate more frequent engine rebuilds due to higher thermal stress, resulting in additional resource consumption over the engine's lifetime.

Recent innovations are addressing these environmental concerns. Biodegradable coolants derived from propylene glycol offer reduced toxicity, while advanced air cooling designs incorporating phase-change materials are improving thermal efficiency without liquid coolants. These developments suggest a future where the environmental gap between cooling methods may narrow significantly.

Cost-Benefit Analysis of Cooling System Implementation

The implementation of cooling systems for V4 engines represents a significant investment decision for manufacturers, requiring careful analysis of both initial costs and long-term economic implications. Liquid cooling systems typically demand higher upfront expenditures, with components such as water pumps, radiators, thermostats, and complex piping networks contributing to approximately 20-30% higher initial costs compared to air cooling solutions. Additionally, the installation process for liquid cooling systems requires more specialized labor and precision, further increasing implementation expenses.

Air cooling systems, while more economical in terms of initial investment, present different cost considerations. The simpler design utilizing fins and air flow reduces material costs and assembly complexity. However, the need for larger surface areas to achieve adequate cooling efficiency often necessitates more space within the engine compartment, potentially affecting overall vehicle design and manufacturing processes.

When evaluating long-term operational economics, liquid cooling systems demonstrate superior efficiency in maintaining optimal engine temperatures, resulting in reduced fuel consumption by approximately 3-7% compared to air-cooled counterparts. This translates to significant cost savings over the engine's lifetime, particularly in commercial applications where vehicles operate continuously.

Maintenance requirements present another critical cost factor. Liquid cooling systems require periodic fluid replacement, potential pump repairs, and attention to leakage issues, averaging maintenance costs of $200-400 annually for commercial vehicles. Conversely, air cooling systems exhibit lower maintenance demands but may require more frequent engine overhauls due to higher operating temperatures, potentially offsetting initial savings.

Environmental conditions significantly impact the cost-benefit equation. In extreme temperature environments, liquid cooling systems maintain more consistent performance, reducing stress-related failures and extending engine lifespan by an estimated 15-25%. This reliability factor translates to fewer replacement parts and reduced downtime, particularly valuable in industrial and commercial applications.

Manufacturing scalability also influences implementation costs. Air cooling systems generally offer more straightforward production processes with fewer components, allowing for more efficient mass production. Liquid cooling systems, while more complex, benefit from established manufacturing ecosystems and supply chains in the automotive industry, partially mitigating their higher complexity costs.

The return on investment timeline differs significantly between these cooling methodologies. While air cooling systems provide immediate cost benefits through lower implementation expenses, liquid cooling systems typically demonstrate superior ROI over extended periods, with break-even points occurring at approximately 3-5 years of operation for commercial vehicles, primarily through improved fuel efficiency and reduced maintenance interventions.

Air cooling systems, while more economical in terms of initial investment, present different cost considerations. The simpler design utilizing fins and air flow reduces material costs and assembly complexity. However, the need for larger surface areas to achieve adequate cooling efficiency often necessitates more space within the engine compartment, potentially affecting overall vehicle design and manufacturing processes.

When evaluating long-term operational economics, liquid cooling systems demonstrate superior efficiency in maintaining optimal engine temperatures, resulting in reduced fuel consumption by approximately 3-7% compared to air-cooled counterparts. This translates to significant cost savings over the engine's lifetime, particularly in commercial applications where vehicles operate continuously.

Maintenance requirements present another critical cost factor. Liquid cooling systems require periodic fluid replacement, potential pump repairs, and attention to leakage issues, averaging maintenance costs of $200-400 annually for commercial vehicles. Conversely, air cooling systems exhibit lower maintenance demands but may require more frequent engine overhauls due to higher operating temperatures, potentially offsetting initial savings.

Environmental conditions significantly impact the cost-benefit equation. In extreme temperature environments, liquid cooling systems maintain more consistent performance, reducing stress-related failures and extending engine lifespan by an estimated 15-25%. This reliability factor translates to fewer replacement parts and reduced downtime, particularly valuable in industrial and commercial applications.

Manufacturing scalability also influences implementation costs. Air cooling systems generally offer more straightforward production processes with fewer components, allowing for more efficient mass production. Liquid cooling systems, while more complex, benefit from established manufacturing ecosystems and supply chains in the automotive industry, partially mitigating their higher complexity costs.

The return on investment timeline differs significantly between these cooling methodologies. While air cooling systems provide immediate cost benefits through lower implementation expenses, liquid cooling systems typically demonstrate superior ROI over extended periods, with break-even points occurring at approximately 3-5 years of operation for commercial vehicles, primarily through improved fuel efficiency and reduced maintenance interventions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!