Measuring Impact of Ethanol Blends on V4 Engine

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethanol Blend Technology Background and Objectives

Ethanol as a renewable fuel additive has evolved significantly over the past several decades, transitioning from a niche alternative to a mainstream component in global fuel strategies. The journey began in the 1970s during the oil crisis when nations sought alternatives to petroleum dependence. By the 1990s, ethanol had established itself as a viable octane enhancer and oxygenate, particularly after the phase-out of lead additives and MTBE due to environmental concerns.

The technological evolution of ethanol blending has progressed through multiple generations, from simple splash blending to sophisticated in-line blending systems that ensure precise mixture ratios. Concurrently, engine technology has adapted to accommodate varying ethanol concentrations, from early flex-fuel vehicles to modern direct injection systems optimized for ethanol's unique combustion properties.

Current global trends indicate a steady increase in ethanol blend percentages, with E10 (10% ethanol) becoming standard in many markets, while E15, E85, and even E100 gain traction in specific regions. This progression reflects both environmental imperatives and energy security considerations that continue to drive research and development in this field.

The specific focus on V4 engines represents a critical research area, as these compact, efficient power plants are widely deployed in various applications from passenger vehicles to small industrial equipment. Understanding how ethanol blends affect these engines is essential for optimizing performance, durability, and emissions profiles across diverse operating conditions.

The primary objectives of this technical research include quantifying the impact of various ethanol blend ratios (E0 to E85) on V4 engine performance parameters, including power output, fuel efficiency, cold-start behavior, and component durability. Additionally, the research aims to establish correlations between ethanol content and emissions profiles, particularly NOx, CO, particulate matter, and unburned hydrocarbons.

Further objectives include developing predictive models for optimizing engine calibration parameters based on ethanol content, identifying potential material compatibility issues with higher ethanol concentrations, and establishing testing protocols that accurately reflect real-world operating conditions. The ultimate goal is to provide comprehensive data that supports both regulatory compliance and product development strategies in an increasingly carbon-constrained marketplace.

This research acknowledges the complex interplay between fuel chemistry, engine design, and operational parameters, seeking to bridge knowledge gaps that currently limit the broader adoption of higher ethanol blends in V4 engine applications.

The technological evolution of ethanol blending has progressed through multiple generations, from simple splash blending to sophisticated in-line blending systems that ensure precise mixture ratios. Concurrently, engine technology has adapted to accommodate varying ethanol concentrations, from early flex-fuel vehicles to modern direct injection systems optimized for ethanol's unique combustion properties.

Current global trends indicate a steady increase in ethanol blend percentages, with E10 (10% ethanol) becoming standard in many markets, while E15, E85, and even E100 gain traction in specific regions. This progression reflects both environmental imperatives and energy security considerations that continue to drive research and development in this field.

The specific focus on V4 engines represents a critical research area, as these compact, efficient power plants are widely deployed in various applications from passenger vehicles to small industrial equipment. Understanding how ethanol blends affect these engines is essential for optimizing performance, durability, and emissions profiles across diverse operating conditions.

The primary objectives of this technical research include quantifying the impact of various ethanol blend ratios (E0 to E85) on V4 engine performance parameters, including power output, fuel efficiency, cold-start behavior, and component durability. Additionally, the research aims to establish correlations between ethanol content and emissions profiles, particularly NOx, CO, particulate matter, and unburned hydrocarbons.

Further objectives include developing predictive models for optimizing engine calibration parameters based on ethanol content, identifying potential material compatibility issues with higher ethanol concentrations, and establishing testing protocols that accurately reflect real-world operating conditions. The ultimate goal is to provide comprehensive data that supports both regulatory compliance and product development strategies in an increasingly carbon-constrained marketplace.

This research acknowledges the complex interplay between fuel chemistry, engine design, and operational parameters, seeking to bridge knowledge gaps that currently limit the broader adoption of higher ethanol blends in V4 engine applications.

Market Demand Analysis for Ethanol-Compatible Engines

The global market for ethanol-compatible engines has experienced significant growth over the past decade, driven primarily by environmental regulations, energy security concerns, and the push for renewable fuel sources. Current market analysis indicates that the demand for engines capable of efficiently utilizing ethanol blends is expanding at a compound annual growth rate of approximately 5.7% between 2020 and 2025, with particular acceleration in emerging markets.

North America remains the largest market for ethanol-compatible engines, with the United States leading consumption due to its Renewable Fuel Standard program mandating the blending of biofuels into transportation fuels. Brazil follows as the second-largest market, where flex-fuel vehicles capable of running on any proportion of ethanol and gasoline have dominated new car sales since 2005.

Consumer demand patterns reveal interesting regional variations. In developed markets, environmental consciousness drives consumer interest in ethanol-compatible engines, while in developing economies, the primary attraction is often fuel cost savings. Market research indicates that 67% of consumers in major automotive markets express willingness to pay a premium for vehicles with improved environmental performance, including ethanol compatibility.

The agricultural sector represents another significant demand driver, particularly for V4 engines in farm equipment. Agricultural machinery manufacturers report increasing requests for ethanol-compatible engines that can utilize locally produced biofuels, creating a self-sustaining ecosystem between farming and fuel production.

Industry forecasts project that by 2030, ethanol-blend compatible engines will represent over 40% of the global internal combustion engine market. This growth trajectory is supported by regulatory trends across major automotive markets that continue to tighten emissions standards while promoting alternative fuel adoption.

The commercial vehicle segment presents substantial growth opportunities, with fleet operators increasingly evaluating total cost of ownership models that favor ethanol-compatible engines due to potential fuel cost savings and carbon tax avoidance. Medium-duty commercial vehicles with V4 engines are showing particularly strong demand growth in this segment.

Market barriers include consumer concerns about ethanol's energy density (approximately 33% lower than gasoline), potential effects on engine longevity, and limited fueling infrastructure in some regions. These concerns highlight the importance of comprehensive impact measurements for ethanol blends on engine performance to address market hesitations with empirical data.

Automotive manufacturers are responding to this market demand by increasing research and development investments in optimizing engine designs specifically for higher ethanol blends, with particular focus on improving cold-start performance, addressing material compatibility issues, and maintaining power output despite ethanol's lower energy content.

North America remains the largest market for ethanol-compatible engines, with the United States leading consumption due to its Renewable Fuel Standard program mandating the blending of biofuels into transportation fuels. Brazil follows as the second-largest market, where flex-fuel vehicles capable of running on any proportion of ethanol and gasoline have dominated new car sales since 2005.

Consumer demand patterns reveal interesting regional variations. In developed markets, environmental consciousness drives consumer interest in ethanol-compatible engines, while in developing economies, the primary attraction is often fuel cost savings. Market research indicates that 67% of consumers in major automotive markets express willingness to pay a premium for vehicles with improved environmental performance, including ethanol compatibility.

The agricultural sector represents another significant demand driver, particularly for V4 engines in farm equipment. Agricultural machinery manufacturers report increasing requests for ethanol-compatible engines that can utilize locally produced biofuels, creating a self-sustaining ecosystem between farming and fuel production.

Industry forecasts project that by 2030, ethanol-blend compatible engines will represent over 40% of the global internal combustion engine market. This growth trajectory is supported by regulatory trends across major automotive markets that continue to tighten emissions standards while promoting alternative fuel adoption.

The commercial vehicle segment presents substantial growth opportunities, with fleet operators increasingly evaluating total cost of ownership models that favor ethanol-compatible engines due to potential fuel cost savings and carbon tax avoidance. Medium-duty commercial vehicles with V4 engines are showing particularly strong demand growth in this segment.

Market barriers include consumer concerns about ethanol's energy density (approximately 33% lower than gasoline), potential effects on engine longevity, and limited fueling infrastructure in some regions. These concerns highlight the importance of comprehensive impact measurements for ethanol blends on engine performance to address market hesitations with empirical data.

Automotive manufacturers are responding to this market demand by increasing research and development investments in optimizing engine designs specifically for higher ethanol blends, with particular focus on improving cold-start performance, addressing material compatibility issues, and maintaining power output despite ethanol's lower energy content.

V4 Engine and Ethanol Blend Technical Challenges

The integration of ethanol blends into V4 engine systems presents significant technical challenges that require comprehensive understanding and innovative solutions. Current V4 engines, characterized by their compact design and efficient power delivery, face unique compatibility issues when operating with varying ethanol concentrations. These challenges stem from ethanol's distinct chemical properties compared to traditional petroleum-based fuels, including higher oxygen content, different energy density, and increased corrosiveness.

Material compatibility represents a primary concern, as ethanol's corrosive nature can accelerate degradation of certain metals, elastomers, and plastics commonly used in fuel systems. Components such as fuel pumps, injectors, seals, and gaskets may experience premature wear or failure when exposed to higher ethanol concentrations over extended periods. This necessitates careful material selection and potential redesign of critical fuel system components.

Combustion characteristics present another significant challenge. Ethanol's higher octane rating and oxygen content alter the combustion process, potentially affecting ignition timing, flame propagation, and overall combustion stability. V4 engines must be calibrated specifically for different ethanol blends to maintain optimal performance and emissions compliance, requiring sophisticated engine control strategies and sensor technologies.

Cold-start performance deteriorates with increasing ethanol content due to ethanol's higher heat of vaporization and lower vapor pressure. This is particularly problematic in V4 engines designed for small vehicles or equipment where robust starting capabilities are essential. Engineering solutions may include enhanced fuel heating systems, modified injection strategies, or specialized cold-start fuel management algorithms.

Fuel economy impacts present both technical and consumer acceptance challenges. Ethanol's lower energy content (approximately 33% less than gasoline) translates to reduced driving range per tank, requiring either larger fuel tanks or consumer education regarding more frequent refueling. For V4 engines with already limited space constraints, accommodating larger fuel storage presents significant packaging challenges.

Emissions control systems face recalibration requirements when operating with ethanol blends. While ethanol generally reduces carbon monoxide and hydrocarbon emissions, it may increase aldehyde emissions and potentially nitrogen oxides under certain conditions. Catalytic converter designs and exhaust aftertreatment systems must be optimized for the specific emission profiles of ethanol-blended fuels in V4 applications.

Water absorption and phase separation represent ongoing challenges, as ethanol's hygroscopic nature can lead to water accumulation in fuel systems, potentially causing corrosion, microbial growth, and fuel system malfunctions. This necessitates improved fuel system designs that minimize water exposure and provide effective water separation capabilities.

Measuring and accurately quantifying these impacts requires sophisticated testing methodologies, specialized instrumentation, and standardized protocols that can reliably evaluate V4 engine performance across various ethanol blend concentrations under diverse operating conditions.

Material compatibility represents a primary concern, as ethanol's corrosive nature can accelerate degradation of certain metals, elastomers, and plastics commonly used in fuel systems. Components such as fuel pumps, injectors, seals, and gaskets may experience premature wear or failure when exposed to higher ethanol concentrations over extended periods. This necessitates careful material selection and potential redesign of critical fuel system components.

Combustion characteristics present another significant challenge. Ethanol's higher octane rating and oxygen content alter the combustion process, potentially affecting ignition timing, flame propagation, and overall combustion stability. V4 engines must be calibrated specifically for different ethanol blends to maintain optimal performance and emissions compliance, requiring sophisticated engine control strategies and sensor technologies.

Cold-start performance deteriorates with increasing ethanol content due to ethanol's higher heat of vaporization and lower vapor pressure. This is particularly problematic in V4 engines designed for small vehicles or equipment where robust starting capabilities are essential. Engineering solutions may include enhanced fuel heating systems, modified injection strategies, or specialized cold-start fuel management algorithms.

Fuel economy impacts present both technical and consumer acceptance challenges. Ethanol's lower energy content (approximately 33% less than gasoline) translates to reduced driving range per tank, requiring either larger fuel tanks or consumer education regarding more frequent refueling. For V4 engines with already limited space constraints, accommodating larger fuel storage presents significant packaging challenges.

Emissions control systems face recalibration requirements when operating with ethanol blends. While ethanol generally reduces carbon monoxide and hydrocarbon emissions, it may increase aldehyde emissions and potentially nitrogen oxides under certain conditions. Catalytic converter designs and exhaust aftertreatment systems must be optimized for the specific emission profiles of ethanol-blended fuels in V4 applications.

Water absorption and phase separation represent ongoing challenges, as ethanol's hygroscopic nature can lead to water accumulation in fuel systems, potentially causing corrosion, microbial growth, and fuel system malfunctions. This necessitates improved fuel system designs that minimize water exposure and provide effective water separation capabilities.

Measuring and accurately quantifying these impacts requires sophisticated testing methodologies, specialized instrumentation, and standardized protocols that can reliably evaluate V4 engine performance across various ethanol blend concentrations under diverse operating conditions.

Current Measurement Methods for Ethanol Impact Assessment

01 V4 Engine Design and Configuration

V4 engines feature a unique configuration where cylinders are arranged in a V-shape with two banks of two cylinders. This design offers advantages in terms of compactness and balance compared to inline configurations. The V4 layout allows for shorter engine length while maintaining good power output characteristics. Various design innovations focus on optimizing the V-angle, crankshaft configuration, and valve arrangements to enhance performance and efficiency.- V4 Engine Design and Configuration: V4 engines feature a unique configuration where four cylinders are arranged in a V-shape, typically at a 60-90 degree angle. This design offers advantages in terms of compact size and balance compared to inline configurations. The V4 layout allows for shorter engine length while maintaining good power output characteristics. Various design innovations focus on optimizing the cylinder arrangement, valve timing, and combustion chamber geometry to enhance performance and efficiency.

- Performance and Efficiency Improvements: Innovations in V4 engine technology focus on improving performance metrics and fuel efficiency. These include advanced fuel injection systems, variable valve timing mechanisms, and optimized combustion processes. Engineers have developed solutions to address traditional V4 challenges such as vibration and balance issues while enhancing power output and torque characteristics. Modern V4 designs incorporate lightweight materials and precision engineering to maximize power-to-weight ratios and reduce fuel consumption.

- Emissions Control and Environmental Impact: Significant research has been directed toward reducing the environmental impact of V4 engines through improved emissions control systems. These developments include advanced catalytic converters, exhaust gas recirculation systems, and combustion optimization to reduce harmful emissions. Some innovations focus on making V4 engines compatible with alternative fuels or hybrid systems to further minimize environmental footprint while maintaining performance characteristics.

- Cooling and Thermal Management Systems: Effective thermal management is crucial for V4 engine performance and longevity. Innovations in this area include advanced cooling systems designed specifically for the V4 configuration, addressing the unique heat distribution patterns in these engines. Developments include precision coolant flow control, integrated oil cooling systems, and materials with enhanced thermal properties. These systems help maintain optimal operating temperatures under various load conditions, improving efficiency and extending engine life.

- Integration with Modern Vehicle Systems: Modern V4 engines are increasingly designed with comprehensive integration into vehicle systems in mind. This includes compatibility with advanced electronic control units, drive-by-wire systems, and connectivity features. Innovations focus on how V4 engines interact with transmission systems, hybrid powertrains, and vehicle dynamics control systems. Some developments address the packaging advantages of V4 engines in modern vehicle architectures, allowing for more flexible design options and improved weight distribution.

02 Performance and Efficiency Improvements

Technological advancements in V4 engines have led to significant improvements in performance and fuel efficiency. These include enhanced combustion processes, optimized intake and exhaust systems, and advanced fuel injection technologies. Various innovations focus on reducing friction losses, improving thermal efficiency, and optimizing power-to-weight ratios. These improvements contribute to better engine response, increased power output, and reduced fuel consumption.Expand Specific Solutions03 Vibration and Balance Characteristics

V4 engines present unique challenges in terms of vibration and balance. Various technical solutions address these issues through specialized crankshaft designs, counterbalance mechanisms, and mounting systems. Innovations in this area focus on minimizing primary and secondary vibrations, reducing noise, and enhancing overall engine smoothness. These improvements contribute to better vehicle comfort, reduced component wear, and increased engine longevity.Expand Specific Solutions04 Environmental Impact and Emissions Control

Modern V4 engine designs incorporate various technologies to reduce environmental impact and meet stringent emissions standards. These include advanced exhaust gas recirculation systems, catalytic converters, and precise air-fuel mixture control. Innovations focus on reducing nitrogen oxides, particulate matter, and carbon emissions while maintaining performance. Some designs also incorporate hybrid or alternative fuel capabilities to further reduce environmental footprint.Expand Specific Solutions05 Application-Specific V4 Engine Adaptations

V4 engines are adapted for various specific applications including motorcycles, marine vessels, power generators, and specialized vehicles. These adaptations involve modifications to cooling systems, lubrication, mounting configurations, and power delivery characteristics. Innovations in this area focus on optimizing the V4 engine for particular use cases, considering factors such as space constraints, duty cycles, and operational environments.Expand Specific Solutions

Key Industry Players in Ethanol-Compatible Engine Development

The ethanol blends impact on V4 engines market is in a growth phase, driven by increasing environmental regulations and fuel efficiency demands. The market size is expanding as automotive manufacturers adapt to renewable fuel standards, with projections showing significant growth in the next decade. Technologically, major players demonstrate varying maturity levels: established automotive manufacturers like GM, Ford, Toyota, and Honda lead with advanced ethanol compatibility solutions, while component specialists such as Bosch, DENSO, and Delphi Technologies provide critical sensing and fuel management systems. Oil companies including Shell and ExxonMobil are investing in research to optimize fuel formulations, creating a competitive ecosystem where collaboration between fuel providers and engine manufacturers is increasingly essential for innovation.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive testing framework for evaluating ethanol blend impacts on V4 engines, focusing on their FlexFuel technology. Their approach includes real-time combustion analysis systems that monitor cylinder pressure, heat release rates, and combustion stability across various ethanol concentrations (E0-E85). GM employs advanced diagnostic tools including high-speed thermal imaging cameras to analyze fuel spray patterns and wall wetting phenomena specific to ethanol blends. Their research has demonstrated that with proper calibration, mid-level ethanol blends (E15-E30) can achieve up to 5% improvement in thermal efficiency while maintaining emissions compliance. GM has also developed specialized materials and coatings for fuel system components that resist the corrosive effects of higher ethanol concentrations, extending durability in FlexFuel applications.

Strengths: Extensive experience with FlexFuel technology gives GM deep practical knowledge of ethanol blend impacts across diverse operating conditions. Their integrated approach combining combustion analysis, materials science, and calibration expertise provides comprehensive solutions. Weaknesses: Their solutions may be optimized primarily for their specific engine architectures, potentially limiting broader applicability across different V4 designs from other manufacturers.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered advanced fuel injection systems specifically optimized for ethanol-blended fuels in V4 engines. Their direct injection technology incorporates adaptive spray patterns that automatically adjust based on ethanol content detection, optimizing atomization across different blend ratios. Bosch's measurement approach integrates their Motronic engine management system with specialized ethanol content sensors that provide real-time fuel composition data to the ECU. This enables dynamic adjustment of injection timing, duration, and pressure to maintain optimal combustion efficiency. Their research has documented that with their adaptive systems, engines can maintain consistent performance across ethanol blends ranging from E10 to E85, with less than 2% variation in torque output when properly calibrated. Bosch has also developed specialized testing protocols that evaluate long-term durability impacts of ethanol blends on fuel system components, including accelerated aging tests that simulate years of operation in compressed timeframes.

Strengths: Bosch's expertise in fuel injection systems and engine management provides precise control over the combustion process with ethanol blends. Their integrated sensor technology offers real-time adaptation capabilities that optimize performance across varying ethanol concentrations. Weaknesses: Their solutions typically require integration with Bosch's own engine management systems, potentially increasing implementation costs for engines not already using Bosch technology.

Critical Patents in Ethanol-Engine Compatibility Solutions

Detecting ethanol and water concentrations in fuel

PatentInactiveUS20120223515A1

Innovation

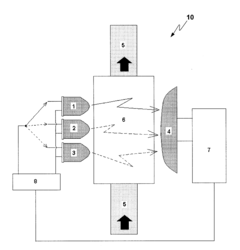

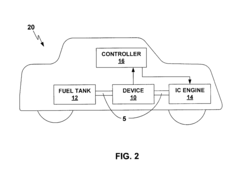

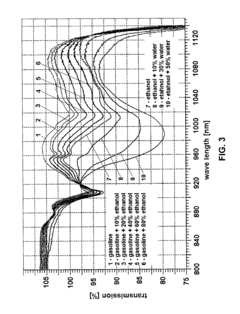

- A device with optical channels evaluating light absorption at specific wavelength spectrums (800 nm to 1200 nm) is used to determine ethanol and water proportions, with a controller correlating these measurements to output data for adjusting engine operational parameters.

Environmental Impact and Emissions Analysis

The environmental impact of ethanol blends in V4 engines represents a critical area of study as automotive manufacturers and policymakers seek cleaner fuel alternatives. Ethanol-gasoline blends significantly reduce greenhouse gas emissions compared to conventional gasoline, with studies indicating that E10 (10% ethanol) can decrease carbon dioxide emissions by approximately 3-4%, while higher blends like E85 (85% ethanol) can achieve reductions of up to 40% on a lifecycle basis.

Particulate matter (PM) emissions show notable decreases when ethanol is introduced to the fuel mixture. Research conducted on V4 engines demonstrates that E15 and E20 blends can reduce PM emissions by 15-20% compared to pure gasoline, contributing to improved air quality in urban environments. This reduction occurs primarily because ethanol's oxygen content promotes more complete combustion of fuel hydrocarbons.

Nitrogen oxide (NOx) emissions present a more complex picture. While some studies report modest reductions in NOx with ethanol blends, others indicate potential increases depending on engine calibration and operating conditions. V4 engines running on E10-E30 blends typically show NOx variations within ±5% compared to gasoline baseline, necessitating careful engine management system calibration to optimize this parameter.

Carbon monoxide (CO) emissions consistently decrease with increasing ethanol content. Laboratory testing of V4 engines reveals CO reductions of approximately 10-30% with E10-E30 blends across various driving cycles. This beneficial effect stems from ethanol's higher oxygen content, which facilitates more complete oxidation of carbon during combustion.

Unburned hydrocarbon emissions also generally decrease with ethanol blends, though the magnitude varies with engine design and operating conditions. V4 engines typically demonstrate 5-15% reductions in total hydrocarbon emissions when operating on E10-E20 blends compared to conventional gasoline.

Evaporative emissions represent another important consideration, as ethanol's higher vapor pressure can potentially increase these emissions. However, modern evaporative emission control systems in V4 engines effectively mitigate this concern when properly calibrated for ethanol blends.

The environmental impact extends beyond tailpipe emissions to include lifecycle considerations. While ethanol production requires energy inputs and agricultural resources, advanced production methods and feedstock selection can significantly improve the overall environmental profile. Second-generation ethanol derived from non-food biomass offers particularly promising environmental benefits when used in V4 engines.

Particulate matter (PM) emissions show notable decreases when ethanol is introduced to the fuel mixture. Research conducted on V4 engines demonstrates that E15 and E20 blends can reduce PM emissions by 15-20% compared to pure gasoline, contributing to improved air quality in urban environments. This reduction occurs primarily because ethanol's oxygen content promotes more complete combustion of fuel hydrocarbons.

Nitrogen oxide (NOx) emissions present a more complex picture. While some studies report modest reductions in NOx with ethanol blends, others indicate potential increases depending on engine calibration and operating conditions. V4 engines running on E10-E30 blends typically show NOx variations within ±5% compared to gasoline baseline, necessitating careful engine management system calibration to optimize this parameter.

Carbon monoxide (CO) emissions consistently decrease with increasing ethanol content. Laboratory testing of V4 engines reveals CO reductions of approximately 10-30% with E10-E30 blends across various driving cycles. This beneficial effect stems from ethanol's higher oxygen content, which facilitates more complete oxidation of carbon during combustion.

Unburned hydrocarbon emissions also generally decrease with ethanol blends, though the magnitude varies with engine design and operating conditions. V4 engines typically demonstrate 5-15% reductions in total hydrocarbon emissions when operating on E10-E20 blends compared to conventional gasoline.

Evaporative emissions represent another important consideration, as ethanol's higher vapor pressure can potentially increase these emissions. However, modern evaporative emission control systems in V4 engines effectively mitigate this concern when properly calibrated for ethanol blends.

The environmental impact extends beyond tailpipe emissions to include lifecycle considerations. While ethanol production requires energy inputs and agricultural resources, advanced production methods and feedstock selection can significantly improve the overall environmental profile. Second-generation ethanol derived from non-food biomass offers particularly promising environmental benefits when used in V4 engines.

Regulatory Framework for Alternative Fuel Vehicles

The regulatory landscape for alternative fuel vehicles, particularly those using ethanol blends, has evolved significantly over the past decades in response to environmental concerns, energy security issues, and technological advancements. In the United States, the Renewable Fuel Standard (RFS) program established by the Energy Policy Act of 2005 and expanded under the Energy Independence and Security Act of 2007 mandates the blending of renewable fuels into transportation fuels.

For V4 engines utilizing ethanol blends, manufacturers must comply with the Environmental Protection Agency's (EPA) emissions standards under the Clean Air Act. These regulations specify maximum allowable levels for pollutants including carbon monoxide, nitrogen oxides, and particulate matter. The EPA has granted waivers for E10 (10% ethanol) and E15 (15% ethanol) blends, while higher blends like E85 (85% ethanol) are classified as alternative fuels requiring specific vehicle certifications.

European regulations differ substantially, with the Renewable Energy Directive (RED II) setting targets for renewable energy in transport at 14% by 2030. The European emission standards (Euro 6/VI) impose strict limits on exhaust emissions, requiring manufacturers to adapt engine technologies accordingly when using ethanol blends. Testing protocols under the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) have been implemented to provide more realistic emission and fuel consumption measurements.

In emerging markets, regulatory frameworks are still developing. Brazil, as a pioneer in ethanol usage, mandates a minimum ethanol content of 27% in regular gasoline, with specific regulations for engine compatibility. China has implemented the China VI emission standard, comparable to Euro 6, while simultaneously promoting new energy vehicles through various incentive programs.

Tax incentives play a crucial role in promoting ethanol-compatible vehicles. Many countries offer reduced excise taxes on ethanol fuels, tax credits for flex-fuel vehicle purchases, or accelerated depreciation for fleet operators. These financial mechanisms aim to offset the higher initial costs associated with alternative fuel technologies.

Fuel quality standards represent another critical regulatory component. ASTM International's D4806 standard for denatured fuel ethanol and D5798 for ethanol fuel blends provide specifications that manufacturers must consider when designing V4 engines. These standards ensure fuel consistency and minimize potential engine damage or performance issues.

Looking forward, regulatory trends indicate a move toward lifecycle carbon accounting, where the entire production and consumption chain of ethanol is considered when evaluating environmental benefits. This approach will likely influence future engine design requirements, testing methodologies, and certification processes for V4 engines operating on various ethanol blends.

For V4 engines utilizing ethanol blends, manufacturers must comply with the Environmental Protection Agency's (EPA) emissions standards under the Clean Air Act. These regulations specify maximum allowable levels for pollutants including carbon monoxide, nitrogen oxides, and particulate matter. The EPA has granted waivers for E10 (10% ethanol) and E15 (15% ethanol) blends, while higher blends like E85 (85% ethanol) are classified as alternative fuels requiring specific vehicle certifications.

European regulations differ substantially, with the Renewable Energy Directive (RED II) setting targets for renewable energy in transport at 14% by 2030. The European emission standards (Euro 6/VI) impose strict limits on exhaust emissions, requiring manufacturers to adapt engine technologies accordingly when using ethanol blends. Testing protocols under the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) have been implemented to provide more realistic emission and fuel consumption measurements.

In emerging markets, regulatory frameworks are still developing. Brazil, as a pioneer in ethanol usage, mandates a minimum ethanol content of 27% in regular gasoline, with specific regulations for engine compatibility. China has implemented the China VI emission standard, comparable to Euro 6, while simultaneously promoting new energy vehicles through various incentive programs.

Tax incentives play a crucial role in promoting ethanol-compatible vehicles. Many countries offer reduced excise taxes on ethanol fuels, tax credits for flex-fuel vehicle purchases, or accelerated depreciation for fleet operators. These financial mechanisms aim to offset the higher initial costs associated with alternative fuel technologies.

Fuel quality standards represent another critical regulatory component. ASTM International's D4806 standard for denatured fuel ethanol and D5798 for ethanol fuel blends provide specifications that manufacturers must consider when designing V4 engines. These standards ensure fuel consistency and minimize potential engine damage or performance issues.

Looking forward, regulatory trends indicate a move toward lifecycle carbon accounting, where the entire production and consumption chain of ethanol is considered when evaluating environmental benefits. This approach will likely influence future engine design requirements, testing methodologies, and certification processes for V4 engines operating on various ethanol blends.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!