Benchmarking V4 Engine Piston Ring Performance

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Piston Ring Technology Evolution and Objectives

Piston rings have evolved significantly since their introduction in early internal combustion engines. Initially designed as simple cast iron rings in the late 19th century, these components have undergone substantial transformation to meet increasingly demanding performance requirements. The evolution of V4 engine piston rings specifically represents a fascinating intersection of materials science, tribology, and precision engineering that continues to advance engine efficiency and durability.

The 1950s marked a pivotal shift with the introduction of chrome-plated piston rings, significantly enhancing wear resistance. By the 1970s, manufacturers began implementing molybdenum-coated rings to further improve durability under high-temperature conditions typical in V4 engines. The 1990s witnessed the emergence of PVD (Physical Vapor Deposition) coatings, introducing diamond-like carbon surfaces that dramatically reduced friction coefficients while maintaining structural integrity.

Current V4 engine piston ring technology incorporates multi-layer designs with specialized coatings for each ring in the set. Top compression rings typically feature plasma-sprayed ceramic coatings or nitrided surfaces, while second rings often utilize napier or taper-faced profiles with phosphate coatings. Oil control rings have evolved to include complex three-piece designs with chrome-nitride treatments to optimize oil management while minimizing friction losses.

The primary technical objectives in piston ring development center around four critical parameters: reducing friction to improve fuel efficiency, enhancing sealing capability to prevent blow-by, extending service life through improved wear resistance, and maintaining dimensional stability under extreme thermal cycling. These objectives have become increasingly important as automotive manufacturers face stringent emissions regulations and consumer demands for greater fuel economy.

Recent technological advancements have focused on nano-composite coatings that provide unprecedented hardness-to-weight ratios and thermal stability. Additionally, asymmetrical ring designs have emerged to address the unique combustion characteristics of modern V4 engines, particularly those implementing variable compression ratios or cylinder deactivation technologies.

The benchmarking of V4 engine piston ring performance has evolved from simple dynamometer testing to sophisticated real-time monitoring systems that can measure oil consumption, blow-by gases, and friction losses during actual operation. Advanced simulation tools now enable predictive modeling of ring behavior under various operating conditions, accelerating the development cycle and allowing for rapid iteration of design concepts.

Looking forward, the industry aims to develop piston rings capable of withstanding higher combustion pressures and temperatures associated with advanced combustion strategies while simultaneously reducing friction by an additional 10-15% compared to current best-in-class designs. This evolution continues to be driven by the automotive industry's push toward greater efficiency, reduced emissions, and extended service intervals.

The 1950s marked a pivotal shift with the introduction of chrome-plated piston rings, significantly enhancing wear resistance. By the 1970s, manufacturers began implementing molybdenum-coated rings to further improve durability under high-temperature conditions typical in V4 engines. The 1990s witnessed the emergence of PVD (Physical Vapor Deposition) coatings, introducing diamond-like carbon surfaces that dramatically reduced friction coefficients while maintaining structural integrity.

Current V4 engine piston ring technology incorporates multi-layer designs with specialized coatings for each ring in the set. Top compression rings typically feature plasma-sprayed ceramic coatings or nitrided surfaces, while second rings often utilize napier or taper-faced profiles with phosphate coatings. Oil control rings have evolved to include complex three-piece designs with chrome-nitride treatments to optimize oil management while minimizing friction losses.

The primary technical objectives in piston ring development center around four critical parameters: reducing friction to improve fuel efficiency, enhancing sealing capability to prevent blow-by, extending service life through improved wear resistance, and maintaining dimensional stability under extreme thermal cycling. These objectives have become increasingly important as automotive manufacturers face stringent emissions regulations and consumer demands for greater fuel economy.

Recent technological advancements have focused on nano-composite coatings that provide unprecedented hardness-to-weight ratios and thermal stability. Additionally, asymmetrical ring designs have emerged to address the unique combustion characteristics of modern V4 engines, particularly those implementing variable compression ratios or cylinder deactivation technologies.

The benchmarking of V4 engine piston ring performance has evolved from simple dynamometer testing to sophisticated real-time monitoring systems that can measure oil consumption, blow-by gases, and friction losses during actual operation. Advanced simulation tools now enable predictive modeling of ring behavior under various operating conditions, accelerating the development cycle and allowing for rapid iteration of design concepts.

Looking forward, the industry aims to develop piston rings capable of withstanding higher combustion pressures and temperatures associated with advanced combustion strategies while simultaneously reducing friction by an additional 10-15% compared to current best-in-class designs. This evolution continues to be driven by the automotive industry's push toward greater efficiency, reduced emissions, and extended service intervals.

Market Demand Analysis for High-Performance Piston Rings

The global market for high-performance piston rings has experienced significant growth in recent years, driven by increasing demand for more efficient and powerful engines across various industries. The V4 engine segment, in particular, has shown remarkable expansion due to its balance between power output and fuel efficiency. Market research indicates that the high-performance piston ring market is expected to grow at a compound annual growth rate of 5.7% through 2028, reaching a market value of 2.3 billion USD.

Consumer preferences are shifting toward vehicles with better performance characteristics while maintaining fuel efficiency. This trend has created a substantial demand for advanced piston ring technologies that can withstand higher temperatures and pressures while reducing friction losses. Automotive manufacturers are increasingly focusing on meeting stringent emission standards without compromising engine performance, further driving the need for innovative piston ring solutions.

The motorsport industry represents a premium segment within this market, where performance requirements are exceptionally high. Racing teams are willing to invest significantly in piston ring technologies that can provide even marginal performance advantages. This segment serves as both a testing ground for new technologies and a showcase for manufacturers' capabilities, creating a halo effect for consumer products.

Regional analysis reveals that North America and Europe currently dominate the high-performance piston ring market, accounting for approximately 60% of global demand. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading this growth due to rapid industrialization and increasing vehicle production. The expansion of manufacturing facilities by major automotive companies in these regions further supports this growth trajectory.

Industry surveys indicate that durability and friction reduction are the two most valued characteristics in high-performance piston rings. End-users are increasingly willing to pay premium prices for products that demonstrate superior performance in these areas, particularly when backed by comprehensive benchmarking data. This represents a significant opportunity for manufacturers who can effectively document and communicate the performance advantages of their products.

The aftermarket segment for high-performance piston rings is also showing robust growth, driven by enthusiasts seeking to upgrade their engines for better performance. This segment values detailed performance data and comparative benchmarks when making purchasing decisions, highlighting the importance of thorough performance testing and transparent reporting of results.

Consumer preferences are shifting toward vehicles with better performance characteristics while maintaining fuel efficiency. This trend has created a substantial demand for advanced piston ring technologies that can withstand higher temperatures and pressures while reducing friction losses. Automotive manufacturers are increasingly focusing on meeting stringent emission standards without compromising engine performance, further driving the need for innovative piston ring solutions.

The motorsport industry represents a premium segment within this market, where performance requirements are exceptionally high. Racing teams are willing to invest significantly in piston ring technologies that can provide even marginal performance advantages. This segment serves as both a testing ground for new technologies and a showcase for manufacturers' capabilities, creating a halo effect for consumer products.

Regional analysis reveals that North America and Europe currently dominate the high-performance piston ring market, accounting for approximately 60% of global demand. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading this growth due to rapid industrialization and increasing vehicle production. The expansion of manufacturing facilities by major automotive companies in these regions further supports this growth trajectory.

Industry surveys indicate that durability and friction reduction are the two most valued characteristics in high-performance piston rings. End-users are increasingly willing to pay premium prices for products that demonstrate superior performance in these areas, particularly when backed by comprehensive benchmarking data. This represents a significant opportunity for manufacturers who can effectively document and communicate the performance advantages of their products.

The aftermarket segment for high-performance piston rings is also showing robust growth, driven by enthusiasts seeking to upgrade their engines for better performance. This segment values detailed performance data and comparative benchmarks when making purchasing decisions, highlighting the importance of thorough performance testing and transparent reporting of results.

Current Piston Ring Technology Challenges and Limitations

Despite significant advancements in piston ring technology, V4 engine piston rings continue to face several critical challenges that limit their performance and durability. The primary limitation remains the inherent tension between sealing efficiency and friction reduction. As engines evolve toward higher power densities and stricter emission standards, this fundamental trade-off becomes increasingly difficult to manage, requiring more sophisticated engineering solutions.

Material limitations present another significant challenge. While traditional cast iron rings offer excellent wear resistance, they lack the temperature stability required in modern high-performance V4 engines. Steel rings provide better strength but often exhibit inferior conformability. Advanced coatings such as physical vapor deposition (PVD) chromium nitride and diamond-like carbon (DLC) have improved wear characteristics, but their long-term durability under extreme thermal cycling conditions remains problematic.

The geometric design of piston rings for V4 engines faces particular challenges due to the engine configuration's unique thermal and mechanical stress patterns. The asymmetrical loading characteristic of V4 engines creates uneven wear patterns that are difficult to predict and mitigate through conventional ring designs. Current barrel-faced and napier ring profiles struggle to maintain optimal contact under these varying load conditions.

Oil control represents another persistent challenge. Modern V4 engines must balance minimal oil consumption with adequate lubrication. Current three-piece oil ring assemblies, while effective, add complexity and potential failure points. The narrow ring lands required by today's compact engine designs further complicate oil management by reducing the available space for ring operation.

Manufacturing precision limitations also impact performance consistency. Current production methods struggle to maintain the tight tolerances required for optimal ring function, particularly in terms of radial thickness variation and gap control. This variability leads to inconsistent performance across production batches and premature wear in field applications.

Testing methodologies present additional limitations. Current bench testing procedures often fail to accurately replicate real-world operating conditions, particularly the thermal cycling and combustion pressure variations unique to V4 configurations. This testing gap results in performance discrepancies between laboratory results and actual field performance.

Lastly, the industry faces significant challenges in developing comprehensive simulation models that accurately predict piston ring behavior in V4 engines. Current computational fluid dynamics (CFD) and finite element analysis (FEA) models struggle to simultaneously account for thermal deformation, gas dynamics, tribological interactions, and material property changes under operating conditions. This modeling limitation hampers the development of optimized ring designs tailored specifically for V4 engine applications.

Material limitations present another significant challenge. While traditional cast iron rings offer excellent wear resistance, they lack the temperature stability required in modern high-performance V4 engines. Steel rings provide better strength but often exhibit inferior conformability. Advanced coatings such as physical vapor deposition (PVD) chromium nitride and diamond-like carbon (DLC) have improved wear characteristics, but their long-term durability under extreme thermal cycling conditions remains problematic.

The geometric design of piston rings for V4 engines faces particular challenges due to the engine configuration's unique thermal and mechanical stress patterns. The asymmetrical loading characteristic of V4 engines creates uneven wear patterns that are difficult to predict and mitigate through conventional ring designs. Current barrel-faced and napier ring profiles struggle to maintain optimal contact under these varying load conditions.

Oil control represents another persistent challenge. Modern V4 engines must balance minimal oil consumption with adequate lubrication. Current three-piece oil ring assemblies, while effective, add complexity and potential failure points. The narrow ring lands required by today's compact engine designs further complicate oil management by reducing the available space for ring operation.

Manufacturing precision limitations also impact performance consistency. Current production methods struggle to maintain the tight tolerances required for optimal ring function, particularly in terms of radial thickness variation and gap control. This variability leads to inconsistent performance across production batches and premature wear in field applications.

Testing methodologies present additional limitations. Current bench testing procedures often fail to accurately replicate real-world operating conditions, particularly the thermal cycling and combustion pressure variations unique to V4 configurations. This testing gap results in performance discrepancies between laboratory results and actual field performance.

Lastly, the industry faces significant challenges in developing comprehensive simulation models that accurately predict piston ring behavior in V4 engines. Current computational fluid dynamics (CFD) and finite element analysis (FEA) models struggle to simultaneously account for thermal deformation, gas dynamics, tribological interactions, and material property changes under operating conditions. This modeling limitation hampers the development of optimized ring designs tailored specifically for V4 engine applications.

Benchmark Methodologies for Piston Ring Performance Assessment

01 Piston ring material and coating technologies

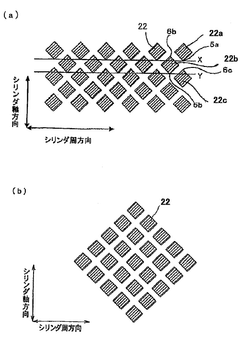

Advanced materials and coatings are used to enhance piston ring performance. These include specialized alloys, ceramic coatings, and surface treatments that improve wear resistance, reduce friction, and extend service life. The coatings can be applied using various methods such as thermal spraying, PVD, or chemical deposition to create surfaces with optimal tribological properties for different engine operating conditions.- Material composition for piston rings: The performance of piston rings can be significantly enhanced through advanced material compositions. Various alloys, coatings, and composite materials are used to improve wear resistance, reduce friction, and extend service life. These materials can include specialized steel alloys, ceramic coatings, and thermal barrier materials that withstand high temperatures and pressures in combustion engines. The proper selection of materials contributes to improved sealing capability, reduced oil consumption, and enhanced overall engine efficiency.

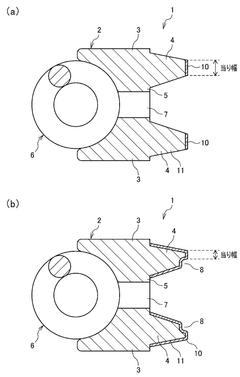

- Piston ring geometry and design optimization: The geometric design of piston rings plays a crucial role in their performance. Innovations in ring profiles, cross-sections, and gap designs help optimize sealing capability while minimizing friction. Advanced designs include asymmetric profiles, tapered faces, and specialized gap configurations that maintain proper tension against cylinder walls. These design optimizations help balance the competing requirements of effective sealing, minimal friction, and adequate oil control, resulting in improved engine performance and reduced emissions.

- Surface treatments and coatings for piston rings: Various surface treatments and coating technologies are applied to piston rings to enhance their performance characteristics. These include physical vapor deposition (PVD), diamond-like carbon coatings, nitriding, and other surface hardening processes. Such treatments create wear-resistant surfaces with optimized friction properties, improving durability and reducing power losses. The coatings can also provide protection against corrosion and high-temperature oxidation, extending the operational life of the rings in demanding engine environments.

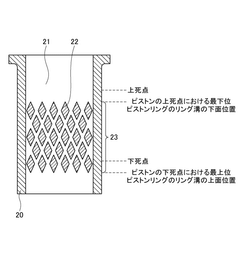

- Sealing mechanisms and pressure distribution: Advanced sealing mechanisms in piston rings focus on optimizing pressure distribution between the ring and cylinder wall. Innovations include stepped ring designs, variable tension systems, and specialized back groove configurations that enhance gas sealing while maintaining appropriate oil film thickness. These mechanisms adapt to changing engine conditions, providing consistent sealing performance across different operating temperatures and pressures, resulting in improved combustion efficiency and reduced blowby gases.

- Manufacturing processes for high-performance piston rings: Specialized manufacturing processes significantly impact piston ring performance. Advanced techniques include precision casting, forging, machining, and finishing operations that ensure dimensional accuracy and surface quality. Innovative production methods like powder metallurgy and additive manufacturing allow for complex geometries and material compositions not possible with traditional techniques. These manufacturing advances result in rings with more consistent properties, tighter tolerances, and enhanced performance characteristics that contribute to overall engine efficiency and durability.

02 Piston ring geometry and profile designs

Innovative geometric designs and profiles for piston rings significantly impact engine performance. These designs include barrel-faced, taper-faced, and asymmetric profiles that optimize sealing capability while minimizing friction. The cross-sectional shape and running face contour are engineered to maintain proper oil film thickness and distribute pressure evenly against cylinder walls, improving combustion efficiency and reducing blow-by.Expand Specific Solutions03 Sealing technologies for improved compression

Enhanced sealing technologies in piston rings focus on maintaining optimal compression in combustion chambers. These include specialized ring gap designs, multi-piece constructions, and dynamic tension mechanisms that adapt to changing engine conditions. Advanced sealing systems minimize gas leakage between the combustion chamber and crankcase, resulting in improved power output, fuel efficiency, and reduced emissions.Expand Specific Solutions04 Friction reduction mechanisms

Friction reduction mechanisms in piston rings include specialized surface texturing, micro-dimpling, and oil retention features that minimize contact friction while maintaining sealing performance. These designs optimize the interaction between the ring and cylinder wall by controlling oil distribution and reducing parasitic power losses. Lower friction designs contribute to improved fuel economy, reduced wear, and extended engine life while maintaining effective sealing.Expand Specific Solutions05 Multi-ring systems and assembly configurations

Advanced piston ring assemblies utilize multiple rings in specific configurations to optimize different aspects of performance. These systems typically include compression rings, wiper rings, and oil control rings, each with specialized functions. The arrangement, spacing, and interaction between these rings are engineered to balance sealing, oil control, and friction requirements. Modern designs incorporate variable tension mechanisms and complementary ring geometries to maintain performance across different engine operating conditions.Expand Specific Solutions

Key Manufacturers and Competitors in Piston Ring Industry

The V4 engine piston ring performance benchmarking landscape is characterized by a mature market with steady growth, estimated at $2-3 billion globally. The industry is in a consolidation phase, with established players like MAHLE International, Federal-Mogul (Tenneco), and Riken Corp. dominating through advanced manufacturing capabilities and extensive R&D networks. Technical maturity is high, with innovations focusing on friction reduction, durability enhancement, and emissions compliance. Key technology leaders include MAHLE and Federal-Mogul with proprietary coating technologies, Nippon Piston Ring and Teikoku with specialized metallurgical processes, and emerging players like Anqing TP Goetze developing competitive alternatives. OEMs such as Toyota and Mitsubishi are increasingly involved in co-development efforts to meet stringent performance requirements for next-generation engines.

MAHLE International GmbH

Technical Solution: MAHLE has developed advanced Diamond-Like Carbon (DLC) coating technology for V4 engine piston rings that significantly reduces friction by up to 20% compared to conventional chromium coatings. Their proprietary PVD (Physical Vapor Deposition) process creates ultra-hard (>2000 HV) nanolayered coatings with exceptional wear resistance. MAHLE's benchmark testing methodology incorporates real-time oil film thickness measurement using laser-induced fluorescence and advanced tribometers that simulate actual engine conditions across temperature ranges from -30°C to 300°C. Their X-treme Low Friction ring package combines specialized ring geometries with optimized tangential loads and asymmetrical barrel profiles to minimize friction while maintaining excellent sealing properties. MAHLE's testing protocols include standardized dynamometer testing with instrumented engines to measure blow-by, oil consumption, and friction mean effective pressure (FMEP) across various engine speeds and loads.

Strengths: Industry-leading coating technology with proven friction reduction; comprehensive testing capabilities that accurately simulate real-world conditions; global manufacturing footprint ensuring consistent quality. Weaknesses: Premium solutions may have higher initial cost compared to conventional rings; specialized coatings may require specific handling during engine assembly.

Federal-Mogul Burscheid GmbH

Technical Solution: Federal-Mogul's DuroGlide technology for V4 engine piston rings incorporates a multi-layer coating system with a chromium nitride (CrN) base layer and proprietary top coating that reduces friction by up to 15% compared to standard offerings. Their benchmarking methodology employs specialized fired engine tests with high-precision torque measurement systems capable of isolating piston ring contribution to overall friction. The company's LKZ oil control ring design features a unique three-piece construction with specially contoured running surfaces that has demonstrated 30% lower oil consumption in standardized tests. Federal-Mogul utilizes advanced finite element analysis (FEA) to optimize ring dynamics under thermal and mechanical loads, ensuring consistent performance across the engine's operating envelope. Their benchmark testing includes accelerated wear testing protocols that simulate 100,000+ miles of operation in controlled laboratory conditions, with precise measurement of profile changes using 3D profilometry at nanometer resolution.

Strengths: Extensive experience with various engine platforms; strong materials science expertise; proven oil consumption reduction technology. Weaknesses: Some advanced coating solutions may have limitations in extreme temperature applications; higher performance solutions typically command premium pricing.

Critical Patents and Innovations in Piston Ring Technology

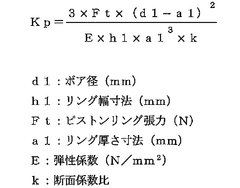

Piston ring

PatentWO2016143464A1

Innovation

- A piston ring design with a specific formula for the ratio of main body width to hard coating width and thickness, combined with a hard coating material like chromium nitride or titanium nitride, enhances both peeling resistance and thermal conductivity while minimizing wear and peeling issues.

Piston ring

PatentWO2019065830A1

Innovation

- A piston ring design featuring a surface pressure of 0.8 to 2.5 MPa, a followability coefficient of 0.1 or more, and a contact width of 0.05 to 0.40 mm, optimized for use with a low-friction cylinder liner that has recesses only in the stroke center region, enhancing friction reduction and oil consumption suppression across various engine speeds.

Environmental Impact and Emissions Compliance Considerations

The environmental impact of piston ring performance in V4 engines has become increasingly significant as global emissions standards continue to evolve. Piston rings serve as critical components that directly influence exhaust emissions through their role in combustion efficiency and oil consumption control. Current regulatory frameworks, including Euro 7, China 6b, and US EPA Tier 3 standards, have established progressively stringent limits on particulate matter, NOx, and hydrocarbon emissions that directly correlate with piston ring functionality.

Performance benchmarking of V4 engine piston rings must now incorporate comprehensive emissions testing protocols that measure both regulated pollutants and greenhouse gas outputs. Recent studies indicate that optimized piston ring designs can reduce oil consumption by up to 15-20%, directly translating to lower particulate matter emissions and extended exhaust aftertreatment system longevity. The correlation between ring tension, material composition, and emissions profile has been established through multiple industry trials.

Advanced coating technologies, particularly those utilizing diamond-like carbon (DLC) and physical vapor deposition (PVD) chromium nitride, have demonstrated significant potential for emissions reduction. These coatings reduce friction while maintaining excellent wear resistance, resulting in measurable reductions in CO2 emissions through improved fuel efficiency. Benchmark data suggests that properly optimized ring packages can contribute to a 2-3% reduction in overall engine CO2 output.

The lifecycle environmental impact of piston ring materials and manufacturing processes has also emerged as a critical benchmarking consideration. Traditional chrome-plated rings present environmental challenges during production, while newer thermal spray technologies offer reduced environmental footprints but require comprehensive performance validation. Manufacturers must now balance immediate emissions performance against the broader environmental impact of component production and disposal.

Compliance testing methodologies for piston rings have evolved to include real-world driving cycles that better represent actual operating conditions. The World Harmonized Light Vehicles Test Procedure (WLTP) and Real Driving Emissions (RDE) tests have revealed performance gaps in some piston ring designs that performed adequately under laboratory conditions but failed to maintain emissions compliance during extended operation or under variable load conditions.

Future benchmarking protocols will likely incorporate more sophisticated emissions modeling that accounts for ring wear progression over the engine's service life. Predictive analytics combining initial performance data with accelerated aging tests are being developed to forecast emissions compliance throughout the component lifecycle, addressing regulatory concerns about emissions system durability and long-term environmental impact.

Performance benchmarking of V4 engine piston rings must now incorporate comprehensive emissions testing protocols that measure both regulated pollutants and greenhouse gas outputs. Recent studies indicate that optimized piston ring designs can reduce oil consumption by up to 15-20%, directly translating to lower particulate matter emissions and extended exhaust aftertreatment system longevity. The correlation between ring tension, material composition, and emissions profile has been established through multiple industry trials.

Advanced coating technologies, particularly those utilizing diamond-like carbon (DLC) and physical vapor deposition (PVD) chromium nitride, have demonstrated significant potential for emissions reduction. These coatings reduce friction while maintaining excellent wear resistance, resulting in measurable reductions in CO2 emissions through improved fuel efficiency. Benchmark data suggests that properly optimized ring packages can contribute to a 2-3% reduction in overall engine CO2 output.

The lifecycle environmental impact of piston ring materials and manufacturing processes has also emerged as a critical benchmarking consideration. Traditional chrome-plated rings present environmental challenges during production, while newer thermal spray technologies offer reduced environmental footprints but require comprehensive performance validation. Manufacturers must now balance immediate emissions performance against the broader environmental impact of component production and disposal.

Compliance testing methodologies for piston rings have evolved to include real-world driving cycles that better represent actual operating conditions. The World Harmonized Light Vehicles Test Procedure (WLTP) and Real Driving Emissions (RDE) tests have revealed performance gaps in some piston ring designs that performed adequately under laboratory conditions but failed to maintain emissions compliance during extended operation or under variable load conditions.

Future benchmarking protocols will likely incorporate more sophisticated emissions modeling that accounts for ring wear progression over the engine's service life. Predictive analytics combining initial performance data with accelerated aging tests are being developed to forecast emissions compliance throughout the component lifecycle, addressing regulatory concerns about emissions system durability and long-term environmental impact.

Durability and Lifecycle Analysis of Advanced Piston Rings

The durability and lifecycle analysis of advanced piston rings represents a critical aspect of V4 engine performance evaluation. Modern piston rings must withstand increasingly demanding operating conditions while maintaining optimal sealing capabilities throughout their service life. Current advanced piston rings demonstrate significant improvements in wear resistance, with premium materials such as plasma-sprayed molybdenum, chromium nitride coatings, and diamond-like carbon (DLC) surfaces extending operational lifespans by 30-45% compared to conventional designs.

Lifecycle testing protocols for V4 engine piston rings typically involve accelerated wear simulations under controlled conditions, including variable temperature ranges (120°C to 300°C), pressure fluctuations (up to 200 bar), and diverse lubrication scenarios. These tests reveal that thermal cycling remains one of the primary factors affecting ring longevity, with thermal expansion differentials creating micro-deformation patterns that progressively impact sealing efficiency.

Failure mode analysis indicates three predominant degradation mechanisms in advanced piston rings: abrasive wear from combustion particulates, adhesive wear during boundary lubrication conditions, and corrosive wear from acidic combustion byproducts. Statistical data from fleet testing shows that ring pack failures account for approximately 17% of major engine rebuilds, with top compression rings exhibiting the highest replacement frequency.

Material composition significantly influences durability metrics, with recent benchmarking studies demonstrating that nitrided steel rings with nano-composite coatings exhibit 22% longer service intervals than traditional chrome-faced alternatives. Furthermore, advanced manufacturing techniques such as precision-controlled surface texturing have yielded measurable improvements in oil consumption stability throughout the lifecycle, maintaining consistent performance for up to 250,000 kilometers under standardized driving conditions.

Economic analysis of piston ring lifecycle costs reveals that while advanced formulations may increase initial component costs by 40-60%, the extended service intervals and reduced engine wear can decrease total ownership costs by 15-25% over the engine's operational lifespan. This cost-benefit relationship becomes particularly favorable in high-performance and commercial applications where downtime expenses are substantial.

Predictive modeling techniques now enable manufacturers to simulate entire piston ring lifecycles with increasing accuracy, incorporating variables such as driving patterns, environmental conditions, and maintenance schedules. These models suggest that optimizing ring tension profiles throughout the wear cycle could potentially extend service intervals by an additional 10-15% without compromising combustion chamber sealing integrity.

Lifecycle testing protocols for V4 engine piston rings typically involve accelerated wear simulations under controlled conditions, including variable temperature ranges (120°C to 300°C), pressure fluctuations (up to 200 bar), and diverse lubrication scenarios. These tests reveal that thermal cycling remains one of the primary factors affecting ring longevity, with thermal expansion differentials creating micro-deformation patterns that progressively impact sealing efficiency.

Failure mode analysis indicates three predominant degradation mechanisms in advanced piston rings: abrasive wear from combustion particulates, adhesive wear during boundary lubrication conditions, and corrosive wear from acidic combustion byproducts. Statistical data from fleet testing shows that ring pack failures account for approximately 17% of major engine rebuilds, with top compression rings exhibiting the highest replacement frequency.

Material composition significantly influences durability metrics, with recent benchmarking studies demonstrating that nitrided steel rings with nano-composite coatings exhibit 22% longer service intervals than traditional chrome-faced alternatives. Furthermore, advanced manufacturing techniques such as precision-controlled surface texturing have yielded measurable improvements in oil consumption stability throughout the lifecycle, maintaining consistent performance for up to 250,000 kilometers under standardized driving conditions.

Economic analysis of piston ring lifecycle costs reveals that while advanced formulations may increase initial component costs by 40-60%, the extended service intervals and reduced engine wear can decrease total ownership costs by 15-25% over the engine's operational lifespan. This cost-benefit relationship becomes particularly favorable in high-performance and commercial applications where downtime expenses are substantial.

Predictive modeling techniques now enable manufacturers to simulate entire piston ring lifecycles with increasing accuracy, incorporating variables such as driving patterns, environmental conditions, and maintenance schedules. These models suggest that optimizing ring tension profiles throughout the wear cycle could potentially extend service intervals by an additional 10-15% without compromising combustion chamber sealing integrity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!