V4 Engine Turbocharging: Power Boost vs Fuel Consumption

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbocharging Technology Evolution and Objectives

Turbocharging technology has evolved significantly since its inception in the early 20th century, transforming from a niche performance enhancement to a mainstream efficiency solution. Initially developed for aircraft engines during World War I, turbochargers found their way into automotive applications by the 1960s, primarily in high-performance vehicles. The 1970s oil crisis marked a pivotal shift in turbocharging objectives, as manufacturers began exploring forced induction not just for power gains but also for improved fuel efficiency.

The evolution of V4 engine turbocharging specifically represents a microcosm of broader turbocharging advancements. V4 engines, with their compact design and inherent balance characteristics, present unique opportunities and challenges for turbocharging implementation. Early V4 turbocharging systems in the 1980s and 1990s focused predominantly on increasing power output, often at the expense of fuel economy and reliability.

By the early 2000s, technological breakthroughs in materials science and computational fluid dynamics enabled more sophisticated turbocharging solutions. Variable geometry turbochargers (VGTs) emerged as a significant innovation, allowing for optimized airflow across different engine speeds and load conditions. This development marked a crucial step toward reconciling the traditionally opposing goals of power enhancement and fuel efficiency in turbocharged V4 engines.

The past decade has witnessed an acceleration in turbocharging technology development, driven by increasingly stringent emissions regulations and consumer demand for both performance and efficiency. Twin-scroll turbochargers, electric turbochargers, and hybrid turbocharging systems represent the cutting edge of this technological evolution, each offering unique approaches to the power-efficiency balance.

Current technological objectives in V4 engine turbocharging center around several key areas: minimizing turbo lag through advanced aerodynamics and reduced inertia; optimizing boost pressure control for varying driving conditions; improving thermal management to enhance reliability and efficiency; and integrating turbocharging systems with other powertrain technologies such as direct injection and variable valve timing.

Looking forward, the industry trajectory points toward fully integrated powertrain approaches where turbocharging works in concert with electrification, advanced combustion strategies, and intelligent control systems. The ultimate goal is to develop V4 turbocharging solutions that deliver substantial power increases while simultaneously reducing fuel consumption and emissions—effectively resolving the traditional compromise between performance and efficiency.

This technological evolution reflects broader industry shifts toward sustainable performance, where engineering innovations aim to satisfy both driving enthusiasm and environmental responsibility. The continued development of V4 turbocharging technology represents a critical pathway toward meeting increasingly demanding regulatory requirements while preserving the engaging driving experience that consumers expect.

The evolution of V4 engine turbocharging specifically represents a microcosm of broader turbocharging advancements. V4 engines, with their compact design and inherent balance characteristics, present unique opportunities and challenges for turbocharging implementation. Early V4 turbocharging systems in the 1980s and 1990s focused predominantly on increasing power output, often at the expense of fuel economy and reliability.

By the early 2000s, technological breakthroughs in materials science and computational fluid dynamics enabled more sophisticated turbocharging solutions. Variable geometry turbochargers (VGTs) emerged as a significant innovation, allowing for optimized airflow across different engine speeds and load conditions. This development marked a crucial step toward reconciling the traditionally opposing goals of power enhancement and fuel efficiency in turbocharged V4 engines.

The past decade has witnessed an acceleration in turbocharging technology development, driven by increasingly stringent emissions regulations and consumer demand for both performance and efficiency. Twin-scroll turbochargers, electric turbochargers, and hybrid turbocharging systems represent the cutting edge of this technological evolution, each offering unique approaches to the power-efficiency balance.

Current technological objectives in V4 engine turbocharging center around several key areas: minimizing turbo lag through advanced aerodynamics and reduced inertia; optimizing boost pressure control for varying driving conditions; improving thermal management to enhance reliability and efficiency; and integrating turbocharging systems with other powertrain technologies such as direct injection and variable valve timing.

Looking forward, the industry trajectory points toward fully integrated powertrain approaches where turbocharging works in concert with electrification, advanced combustion strategies, and intelligent control systems. The ultimate goal is to develop V4 turbocharging solutions that deliver substantial power increases while simultaneously reducing fuel consumption and emissions—effectively resolving the traditional compromise between performance and efficiency.

This technological evolution reflects broader industry shifts toward sustainable performance, where engineering innovations aim to satisfy both driving enthusiasm and environmental responsibility. The continued development of V4 turbocharging technology represents a critical pathway toward meeting increasingly demanding regulatory requirements while preserving the engaging driving experience that consumers expect.

Market Analysis for Turbocharged V4 Engines

The global market for turbocharged V4 engines has experienced significant growth over the past decade, driven primarily by stringent emission regulations and consumer demand for fuel-efficient yet powerful vehicles. The market size for turbocharged engines reached approximately $12 billion in 2022, with V4 configurations representing about 18% of this segment. Industry forecasts project a compound annual growth rate of 6.3% through 2028, indicating robust market potential.

Consumer preferences have shifted notably toward smaller displacement engines that deliver comparable power to larger naturally aspirated units. This trend is particularly evident in European and Asian markets, where fuel prices and emission taxes have historically been higher. Market research indicates that 72% of new car buyers now consider fuel economy as a "very important" factor in purchasing decisions, while 65% simultaneously rank performance as equally significant.

The automotive industry's transition toward electrification has paradoxically strengthened the market position of advanced turbocharged engines. As manufacturers develop bridge technologies between conventional internal combustion and fully electric powertrains, turbocharged V4 engines have emerged as an optimal compromise solution. This is reflected in the 23% increase in turbocharged V4 applications across hybrid vehicle platforms since 2019.

Regional market analysis reveals distinct patterns of adoption. European markets show the highest penetration rate at 42% of new passenger vehicles featuring turbocharged engines, with V4 configurations dominant in compact and mid-size segments. North American markets have seen accelerated adoption, growing from 22% in 2018 to 34% in 2022, primarily in crossover SUVs and entry-level luxury vehicles.

The commercial vehicle sector represents an expanding application area, with light commercial vehicles increasingly adopting turbocharged V4 engines to meet both payload requirements and emissions standards. This segment has grown at 8.7% annually since 2020, outpacing the broader market.

Price sensitivity analysis indicates consumers are willing to pay a 5-8% premium for vehicles equipped with turbocharged engines versus comparable naturally aspirated alternatives, provided the performance improvement is at least 15% and fuel economy gains exceed 10%. This value proposition has been key to market expansion beyond traditional performance-oriented niches.

Market forecasts suggest turbocharged V4 engines will maintain relevance through at least 2030, even as electrification accelerates. The technology is expected to evolve toward integration with mild hybrid systems, potentially extending market viability while serving as a transitional technology in the broader evolution toward zero-emission vehicles.

Consumer preferences have shifted notably toward smaller displacement engines that deliver comparable power to larger naturally aspirated units. This trend is particularly evident in European and Asian markets, where fuel prices and emission taxes have historically been higher. Market research indicates that 72% of new car buyers now consider fuel economy as a "very important" factor in purchasing decisions, while 65% simultaneously rank performance as equally significant.

The automotive industry's transition toward electrification has paradoxically strengthened the market position of advanced turbocharged engines. As manufacturers develop bridge technologies between conventional internal combustion and fully electric powertrains, turbocharged V4 engines have emerged as an optimal compromise solution. This is reflected in the 23% increase in turbocharged V4 applications across hybrid vehicle platforms since 2019.

Regional market analysis reveals distinct patterns of adoption. European markets show the highest penetration rate at 42% of new passenger vehicles featuring turbocharged engines, with V4 configurations dominant in compact and mid-size segments. North American markets have seen accelerated adoption, growing from 22% in 2018 to 34% in 2022, primarily in crossover SUVs and entry-level luxury vehicles.

The commercial vehicle sector represents an expanding application area, with light commercial vehicles increasingly adopting turbocharged V4 engines to meet both payload requirements and emissions standards. This segment has grown at 8.7% annually since 2020, outpacing the broader market.

Price sensitivity analysis indicates consumers are willing to pay a 5-8% premium for vehicles equipped with turbocharged engines versus comparable naturally aspirated alternatives, provided the performance improvement is at least 15% and fuel economy gains exceed 10%. This value proposition has been key to market expansion beyond traditional performance-oriented niches.

Market forecasts suggest turbocharged V4 engines will maintain relevance through at least 2030, even as electrification accelerates. The technology is expected to evolve toward integration with mild hybrid systems, potentially extending market viability while serving as a transitional technology in the broader evolution toward zero-emission vehicles.

Technical Challenges in V4 Turbocharging Systems

Turbocharging V4 engines presents a complex set of technical challenges that engineers must overcome to achieve the optimal balance between power enhancement and fuel efficiency. The compact design of V4 engines creates significant spatial constraints for turbocharger integration, requiring innovative packaging solutions that don't compromise accessibility for maintenance or heat management. These spatial limitations often necessitate custom-designed turbocharger units with specialized dimensions and configurations.

Heat management represents one of the most critical challenges in V4 turbocharging systems. The concentrated heat generation in the compact engine bay can lead to thermal stress on components and potential performance degradation. Engineers must implement advanced cooling strategies, including precision-designed heat shields, optimized coolant routing, and high-temperature-resistant materials to maintain system integrity and performance consistency.

Turbo lag—the delay between throttle input and power delivery—is particularly pronounced in turbocharged V4 engines due to their smaller displacement and lower exhaust gas volume. This challenge necessitates sophisticated approaches such as variable geometry turbochargers (VGT), twin-scroll designs, or electric turbocharger assistance to improve transient response characteristics without sacrificing top-end power.

The integration of modern emissions control systems with turbocharging technology creates additional complexities. Turbochargers affect exhaust gas temperature and flow characteristics, which can impact the efficiency of catalytic converters and particulate filters. Engineers must carefully calibrate the entire system to ensure compliance with increasingly stringent emissions regulations while maintaining performance targets.

Durability concerns are heightened in turbocharged V4 engines due to increased thermal and mechanical stresses. Components must withstand higher operating temperatures, greater pressure differentials, and more rapid thermal cycling. This necessitates advanced materials science solutions and robust design methodologies to ensure acceptable service life under these demanding conditions.

Control system complexity represents another significant challenge. Modern turbocharged engines require sophisticated electronic control units capable of processing inputs from numerous sensors and precisely managing boost pressure, fuel delivery, and ignition timing across varying operating conditions. The calibration process for these systems is extraordinarily complex, requiring thousands of hours of development and testing to optimize performance, efficiency, and reliability.

Oil management presents unique challenges in V4 turbocharging applications. The turbocharger's high-speed rotating assembly requires precise lubrication under extreme conditions, while preventing oil leakage into the exhaust stream. Engineers must design specialized oil delivery and return systems that function effectively regardless of engine orientation or operating conditions.

Heat management represents one of the most critical challenges in V4 turbocharging systems. The concentrated heat generation in the compact engine bay can lead to thermal stress on components and potential performance degradation. Engineers must implement advanced cooling strategies, including precision-designed heat shields, optimized coolant routing, and high-temperature-resistant materials to maintain system integrity and performance consistency.

Turbo lag—the delay between throttle input and power delivery—is particularly pronounced in turbocharged V4 engines due to their smaller displacement and lower exhaust gas volume. This challenge necessitates sophisticated approaches such as variable geometry turbochargers (VGT), twin-scroll designs, or electric turbocharger assistance to improve transient response characteristics without sacrificing top-end power.

The integration of modern emissions control systems with turbocharging technology creates additional complexities. Turbochargers affect exhaust gas temperature and flow characteristics, which can impact the efficiency of catalytic converters and particulate filters. Engineers must carefully calibrate the entire system to ensure compliance with increasingly stringent emissions regulations while maintaining performance targets.

Durability concerns are heightened in turbocharged V4 engines due to increased thermal and mechanical stresses. Components must withstand higher operating temperatures, greater pressure differentials, and more rapid thermal cycling. This necessitates advanced materials science solutions and robust design methodologies to ensure acceptable service life under these demanding conditions.

Control system complexity represents another significant challenge. Modern turbocharged engines require sophisticated electronic control units capable of processing inputs from numerous sensors and precisely managing boost pressure, fuel delivery, and ignition timing across varying operating conditions. The calibration process for these systems is extraordinarily complex, requiring thousands of hours of development and testing to optimize performance, efficiency, and reliability.

Oil management presents unique challenges in V4 turbocharging applications. The turbocharger's high-speed rotating assembly requires precise lubrication under extreme conditions, while preventing oil leakage into the exhaust stream. Engineers must design specialized oil delivery and return systems that function effectively regardless of engine orientation or operating conditions.

Current V4 Turbocharging Solutions Analysis

01 Turbocharger design for V4 engines

Specialized turbocharger designs for V4 engines can significantly boost power output while maintaining fuel efficiency. These designs include optimized turbine geometry, advanced wastegate control systems, and proper sizing of the compressor relative to engine displacement. The integration of variable geometry turbochargers allows for better response across the entire RPM range, reducing turbo lag and improving overall engine performance.- Turbocharger design for V4 engines: Specialized turbocharger designs for V4 engines can significantly boost power output while maintaining fuel efficiency. These designs include optimized turbine geometry, advanced wastegate control systems, and proper sizing of the compressor relative to engine displacement. The integration of variable geometry turbochargers allows for better response across the engine's RPM range, reducing turbo lag and improving overall performance.

- Electronic control systems for turbocharging: Advanced electronic control systems play a crucial role in optimizing turbocharger performance in V4 engines. These systems monitor various parameters such as intake air temperature, boost pressure, and engine load to adjust turbocharger operation in real-time. By precisely controlling boost pressure and fuel delivery, these systems can maximize power output while minimizing fuel consumption, especially during transient operating conditions.

- Multi-stage turbocharging systems: Multi-stage turbocharging systems utilize two or more turbochargers working in sequence or parallel to enhance V4 engine performance across a wider operating range. These systems can include combinations of differently sized turbochargers or sequential turbocharging arrangements that optimize both low-end torque and high-end power. The staged approach helps eliminate turbo lag while providing significant power boosts with improved fuel economy compared to single turbocharger setups.

- Intercooling and charge air management: Effective intercooling and charge air management systems are essential for maximizing the efficiency of turbocharged V4 engines. These systems cool the compressed air from the turbocharger before it enters the engine, increasing air density and allowing for more efficient combustion. Advanced intercooler designs, optimized air flow paths, and water-injection systems can further enhance power output while reducing fuel consumption and emissions.

- Hybrid turbocharging technologies: Hybrid turbocharging technologies combine conventional turbochargers with electric assistance to improve response times and overall efficiency in V4 engines. These systems use electric motors to spin up the turbocharger quickly at low engine speeds, eliminating lag and providing immediate boost. Additionally, they can recover waste energy during deceleration, which can be stored and used later to assist the turbocharger or power vehicle electrical systems, further improving fuel economy.

02 Electronic control systems for turbocharging

Advanced electronic control systems play a crucial role in optimizing turbocharger performance in V4 engines. These systems monitor various parameters such as intake air temperature, boost pressure, engine load, and throttle position to adjust turbocharger operation in real-time. By precisely controlling boost pressure and fuel delivery, these systems can maximize power output while minimizing fuel consumption, especially during transient operating conditions.Expand Specific Solutions03 Multi-stage turbocharging systems

Multi-stage turbocharging systems for V4 engines utilize sequential or parallel turbochargers to optimize performance across different engine speeds. These systems typically employ a smaller turbocharger for low-end torque and responsiveness, combined with a larger unit for maximum power at higher RPMs. This arrangement helps eliminate turbo lag while providing significant power boost and maintaining fuel efficiency through the entire operating range.Expand Specific Solutions04 Intercooling and charge air management

Effective intercooling and charge air management systems are essential for maximizing the performance of turbocharged V4 engines. By cooling the compressed air before it enters the combustion chamber, intercoolers increase air density, allowing for more efficient combustion. Advanced charge air management systems, including variable flow paths and optimized intake manifold designs, further enhance power output while reducing fuel consumption through improved volumetric efficiency.Expand Specific Solutions05 Hybrid turbocharging technologies

Hybrid turbocharging technologies combine conventional turbochargers with electric assistance to improve response and efficiency in V4 engines. These systems use electric motors to spin up the turbocharger at low engine speeds, eliminating lag and providing immediate boost. Additionally, they can recover waste energy during deceleration, which can be stored and reused to assist the turbocharger or power vehicle electrical systems, resulting in both power enhancement and fuel consumption reduction.Expand Specific Solutions

Leading Manufacturers and Competition Landscape

The V4 engine turbocharging market is currently in a growth phase, with increasing demand for enhanced power while maintaining fuel efficiency. The global market size is estimated to exceed $25 billion, driven by stringent emission regulations and consumer preference for performance vehicles. Leading players include BorgWarner and Robert Bosch GmbH, who have established mature turbocharging technologies, while Ford Global Technologies and Toyota Motor Corp. are advancing innovative solutions balancing power and consumption. Emerging competitors like Weichai Power and Geely are rapidly gaining market share through cost-effective solutions. Academic institutions such as MIT and Beijing Institute of Technology are contributing breakthrough research in thermal efficiency and electronic control systems, pushing the technology toward greater maturity with advanced materials and intelligent control algorithms.

BorgWarner, Inc.

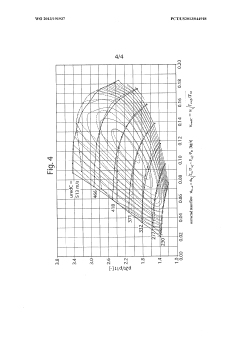

Technical Solution: BorgWarner has developed their eTurbo™ technology specifically optimized for V4 engine applications, integrating an electric motor directly into the turbocharger shaft. This innovation allows for immediate torque delivery by electrically spooling the turbocharger before exhaust gases reach sufficient velocity, effectively eliminating turbo lag. Their system can recover waste energy during deceleration by operating as a generator, contributing to the vehicle's electrical system and improving overall efficiency. BorgWarner's advanced aerodynamic compressor wheel designs feature specialized blade geometry that optimizes airflow while minimizing turbulence and noise. Their proprietary dual-volute turbine housing design effectively separates exhaust pulses from different cylinders, maximizing energy extraction efficiency. The company's variable turbine geometry (VTG) technology continuously adjusts the effective aspect ratio of the turbine, providing optimal boost across all engine operating conditions. Internal testing has demonstrated power increases of up to 25% while simultaneously reducing fuel consumption by 8-15% compared to naturally aspirated V4 engines.

Strengths: The electrified turbocharger technology provides unmatched responsiveness and effectively eliminates traditional turbo lag issues. Their energy recovery capabilities contribute to overall vehicle efficiency beyond just engine performance. Weaknesses: The added complexity of the electrical components increases system cost and requires integration with the vehicle's electrical architecture, potentially limiting adoption in cost-sensitive applications.

Toyota Motor Corp.

Technical Solution: Toyota has developed a Dynamic Force Turbo system specifically for their V4 engine lineup, focusing on balancing power delivery with exceptional fuel efficiency. Their approach incorporates a single-scroll turbocharger with variable nozzle technology that continuously adjusts the turbine geometry based on engine load and speed. Toyota's system features their proprietary D-4S dual injection technology that combines direct and port fuel injection, optimizing fuel delivery based on engine conditions to maximize both power and efficiency. Their turbocharger design incorporates lightweight ceramic turbine wheels that reduce rotational inertia by approximately 40% compared to conventional metal components, significantly improving throttle response. Toyota's Exhaust Gas Recirculation (EGR) system works in conjunction with the turbocharger to reduce combustion temperatures, minimizing NOx emissions while improving fuel economy. Their advanced electronic control unit continuously monitors and adjusts multiple parameters including boost pressure, ignition timing, and fuel delivery to maintain optimal air-fuel ratios across all operating conditions. Testing has demonstrated power increases of 15-20% while achieving fuel economy improvements of 10-15% compared to their naturally aspirated counterparts.

Strengths: Exceptional reliability and durability consistent with Toyota's engineering philosophy. Their integrated approach to engine and turbocharger design results in seamless operation and excellent real-world efficiency. Weaknesses: More conservative boost levels compared to some competitors limit maximum power potential, prioritizing longevity and efficiency over peak performance figures.

Key Patents and Innovations in Turbocharging

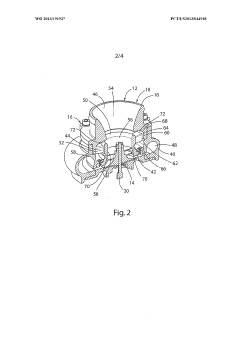

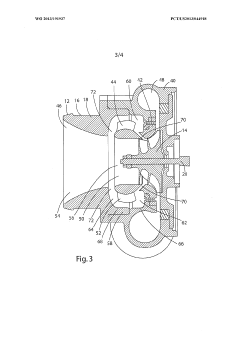

Compressor cover for turbochargers

PatentWO2013191937A1

Innovation

- The compressor cover incorporates a recirculation geometry with a converging nozzle inlet, angled recirculation slot, and inlet re-entry slot, allowing airflow to bleed off the compressor impeller and recirculate into the inlet section, enhancing surge control and aerodynamics, and reducing noise through improved airflow stabilization.

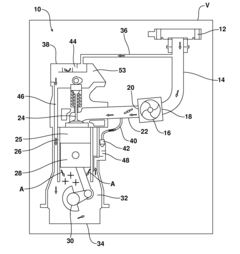

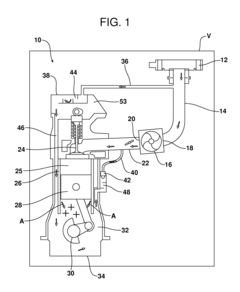

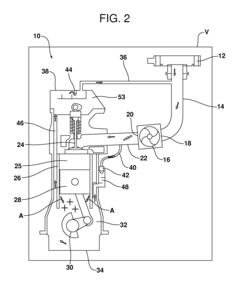

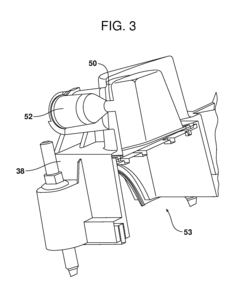

Vehicle with integrated turbocharger oil control restriction

PatentActiveUS20160146076A1

Innovation

- A ventilation system for a turbocharged internal combustion engine that includes a first vent line connecting the cam cover and air intake duct, a second vent line connecting the crankcase and intake manifold, a one-way valve allowing airflow toward the intake manifold, and a restriction integrated into the spigots or quick connects of the vent lines to manage airflow and prevent pressure buildup.

Emissions Regulations Impact on Turbocharging Development

Emissions regulations have become a primary driver in the evolution of turbocharging technology for V4 engines, creating a complex relationship between performance enhancement and environmental compliance. Since the early 2000s, increasingly stringent standards such as Euro 6, EPA Tier 3, and China 6 have fundamentally reshaped how manufacturers approach turbocharger design and implementation.

The regulatory landscape has pushed manufacturers toward a dual optimization challenge: simultaneously reducing emissions while maintaining or improving power output. This has accelerated the development of advanced turbocharging solutions that can precisely balance air-fuel ratios across varying engine loads, minimizing both NOx and particulate emissions without sacrificing the power boost that consumers expect.

Variable geometry turbochargers (VGTs) have gained significant traction as a direct response to these regulations. By dynamically adjusting the turbine geometry based on engine operating conditions, VGTs enable V4 engines to maintain optimal combustion efficiency across a broader operating range, thereby reducing emissions while preserving performance characteristics. This technology has become particularly valuable for meeting transient emission requirements during certification testing cycles.

The introduction of Real Driving Emissions (RDE) testing in Europe has further complicated turbocharger development, as systems must now perform efficiently not just in laboratory conditions but across diverse real-world driving scenarios. This has led to more sophisticated electronic control systems that continuously adjust turbocharger operation based on multiple parameters including ambient conditions, driving behavior, and instantaneous emissions readings.

Waste heat recovery systems integrated with turbocharging technology have emerged as another regulatory-driven innovation. These systems capture thermal energy that would otherwise be lost through the exhaust, improving overall engine efficiency and helping manufacturers meet fleet-wide CO2 emission targets while maintaining the power advantages of turbocharged V4 configurations.

The regulatory push toward electrification has also influenced turbocharger development, with electric-assist turbochargers (e-turbos) gaining prominence. These hybrid systems use small electric motors to eliminate turbo lag and provide precise boost control, offering a pathway to meet both emission standards and performance expectations as the industry transitions toward partial or full electrification.

Looking forward, upcoming regulations like Euro 7 and equivalent standards in other markets will likely drive further integration between turbocharging systems and other powertrain technologies, potentially including advanced thermal management, intelligent boost control algorithms, and greater coordination with hybrid electric systems in V4 engine applications.

The regulatory landscape has pushed manufacturers toward a dual optimization challenge: simultaneously reducing emissions while maintaining or improving power output. This has accelerated the development of advanced turbocharging solutions that can precisely balance air-fuel ratios across varying engine loads, minimizing both NOx and particulate emissions without sacrificing the power boost that consumers expect.

Variable geometry turbochargers (VGTs) have gained significant traction as a direct response to these regulations. By dynamically adjusting the turbine geometry based on engine operating conditions, VGTs enable V4 engines to maintain optimal combustion efficiency across a broader operating range, thereby reducing emissions while preserving performance characteristics. This technology has become particularly valuable for meeting transient emission requirements during certification testing cycles.

The introduction of Real Driving Emissions (RDE) testing in Europe has further complicated turbocharger development, as systems must now perform efficiently not just in laboratory conditions but across diverse real-world driving scenarios. This has led to more sophisticated electronic control systems that continuously adjust turbocharger operation based on multiple parameters including ambient conditions, driving behavior, and instantaneous emissions readings.

Waste heat recovery systems integrated with turbocharging technology have emerged as another regulatory-driven innovation. These systems capture thermal energy that would otherwise be lost through the exhaust, improving overall engine efficiency and helping manufacturers meet fleet-wide CO2 emission targets while maintaining the power advantages of turbocharged V4 configurations.

The regulatory push toward electrification has also influenced turbocharger development, with electric-assist turbochargers (e-turbos) gaining prominence. These hybrid systems use small electric motors to eliminate turbo lag and provide precise boost control, offering a pathway to meet both emission standards and performance expectations as the industry transitions toward partial or full electrification.

Looking forward, upcoming regulations like Euro 7 and equivalent standards in other markets will likely drive further integration between turbocharging systems and other powertrain technologies, potentially including advanced thermal management, intelligent boost control algorithms, and greater coordination with hybrid electric systems in V4 engine applications.

Thermal Management Strategies for Turbocharged V4 Engines

Effective thermal management is critical for optimizing the performance and efficiency of turbocharged V4 engines. As these compact powerplants generate significant heat during operation, particularly under boost conditions, implementing sophisticated cooling strategies becomes essential to maintain reliability while maximizing power output and minimizing fuel consumption.

The primary thermal challenges in turbocharged V4 engines stem from the concentrated heat generation in the compact engine bay, with the turbocharger itself operating at temperatures exceeding 900°C. This thermal load necessitates targeted cooling approaches for key components including the cylinder head, exhaust manifold, turbocharger, and intercooler system.

Advanced water-cooling jackets represent a cornerstone of modern thermal management, with precision-engineered channels directing coolant flow to critical hotspots. Contemporary designs employ computational fluid dynamics to optimize these pathways, ensuring uniform temperature distribution across the cylinder head and block. Some manufacturers have implemented dual-circuit cooling systems that maintain different temperature regimes for the cylinder head and block, optimizing combustion efficiency while protecting engine integrity.

Oil cooling systems play a dual role in turbocharged applications, both lubricating moving components and transferring heat away from critical areas. Dedicated oil jets directed at the underside of pistons have proven particularly effective in preventing localized hotspots that can lead to detonation under boost conditions. Additionally, oil-cooled turbochargers help moderate bearing temperatures, extending service life while allowing higher boost pressures.

Intercooler efficiency represents another crucial aspect of thermal management. Air-to-air and air-to-water intercooler designs each offer distinct advantages, with the latter gaining popularity in compact engine installations where packaging constraints limit traditional front-mounted air-to-air units. Water-cooled intercoolers can achieve lower charge temperatures, directly improving volumetric efficiency and reducing the risk of detonation.

Electronic thermal management systems have revolutionized cooling strategy implementation, with variable-speed electric water pumps and thermostatically controlled cooling fans optimizing temperature regulation based on real-time operating conditions. These systems can prioritize rapid warm-up during cold starts to reduce emissions while providing maximum cooling capacity during high-load operation.

Heat-resistant materials and thermal barrier coatings represent the cutting edge of passive thermal management. Ceramic-coated turbocharger housings, exhaust manifolds with integrated water cooling channels, and heat shields utilizing aerospace-derived materials all contribute to controlling thermal energy distribution, protecting sensitive components while harnessing heat for improved turbocharger response and reduced lag.

The primary thermal challenges in turbocharged V4 engines stem from the concentrated heat generation in the compact engine bay, with the turbocharger itself operating at temperatures exceeding 900°C. This thermal load necessitates targeted cooling approaches for key components including the cylinder head, exhaust manifold, turbocharger, and intercooler system.

Advanced water-cooling jackets represent a cornerstone of modern thermal management, with precision-engineered channels directing coolant flow to critical hotspots. Contemporary designs employ computational fluid dynamics to optimize these pathways, ensuring uniform temperature distribution across the cylinder head and block. Some manufacturers have implemented dual-circuit cooling systems that maintain different temperature regimes for the cylinder head and block, optimizing combustion efficiency while protecting engine integrity.

Oil cooling systems play a dual role in turbocharged applications, both lubricating moving components and transferring heat away from critical areas. Dedicated oil jets directed at the underside of pistons have proven particularly effective in preventing localized hotspots that can lead to detonation under boost conditions. Additionally, oil-cooled turbochargers help moderate bearing temperatures, extending service life while allowing higher boost pressures.

Intercooler efficiency represents another crucial aspect of thermal management. Air-to-air and air-to-water intercooler designs each offer distinct advantages, with the latter gaining popularity in compact engine installations where packaging constraints limit traditional front-mounted air-to-air units. Water-cooled intercoolers can achieve lower charge temperatures, directly improving volumetric efficiency and reducing the risk of detonation.

Electronic thermal management systems have revolutionized cooling strategy implementation, with variable-speed electric water pumps and thermostatically controlled cooling fans optimizing temperature regulation based on real-time operating conditions. These systems can prioritize rapid warm-up during cold starts to reduce emissions while providing maximum cooling capacity during high-load operation.

Heat-resistant materials and thermal barrier coatings represent the cutting edge of passive thermal management. Ceramic-coated turbocharger housings, exhaust manifolds with integrated water cooling channels, and heat shields utilizing aerospace-derived materials all contribute to controlling thermal energy distribution, protecting sensitive components while harnessing heat for improved turbocharger response and reduced lag.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!