V4 Engine Variable Valve Timing Impact on Emissions

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine VVT Technology Evolution and Objectives

Variable Valve Timing (VVT) technology has evolved significantly since its inception in the automotive industry. Initially developed in the 1980s, VVT systems were primarily focused on improving engine performance rather than emissions control. The first-generation systems featured simple mechanical mechanisms that could adjust valve timing between two fixed positions. By the 1990s, continuous variable valve timing systems emerged, allowing for more precise control across the entire operating range of the engine.

The evolution of VVT technology in V4 engines specifically has followed a trajectory from basic systems to highly sophisticated electronic control mechanisms. Early V4 implementations utilized hydraulic actuation methods with limited adjustment capabilities. These systems could only modify intake valve timing, leaving exhaust valve timing fixed. The technological breakthrough came in the early 2000s when dual independent variable valve timing was introduced, enabling separate control of both intake and exhaust valve operations.

Recent advancements have led to the development of electronic variable valve timing (e-VVT) systems that offer millisecond-level response times and unprecedented precision. These systems utilize solenoid valves and electronic control units to adjust valve timing based on real-time engine operating conditions, including load, speed, temperature, and emissions feedback from oxygen sensors.

The primary objectives of modern VVT technology in V4 engines center around emissions reduction while maintaining or improving performance metrics. Specifically, VVT aims to reduce nitrogen oxide (NOx) emissions by optimizing combustion temperatures and controlling exhaust gas recirculation through valve overlap adjustments. Additionally, it targets hydrocarbon (HC) emissions reduction by improving fuel atomization and combustion efficiency across various engine operating conditions.

Carbon dioxide (CO2) reduction represents another critical objective, achieved through improved thermal efficiency and reduced pumping losses. VVT systems enable engines to operate more efficiently at partial loads, which constitutes the majority of real-world driving conditions. This efficiency translates directly to lower fuel consumption and consequently reduced CO2 emissions.

The technology roadmap for V4 engine VVT systems points toward fully camless valve actuation systems using electromagnetic or electrohydraulic actuators. These next-generation systems promise complete freedom in valve timing, lift, and duration control, potentially enabling advanced combustion strategies like Homogeneous Charge Compression Ignition (HCCI) that could further reduce emissions while improving efficiency. The ultimate goal is to develop VVT systems that can dynamically optimize valve events for each individual cylinder based on instantaneous operating conditions and emissions requirements.

The evolution of VVT technology in V4 engines specifically has followed a trajectory from basic systems to highly sophisticated electronic control mechanisms. Early V4 implementations utilized hydraulic actuation methods with limited adjustment capabilities. These systems could only modify intake valve timing, leaving exhaust valve timing fixed. The technological breakthrough came in the early 2000s when dual independent variable valve timing was introduced, enabling separate control of both intake and exhaust valve operations.

Recent advancements have led to the development of electronic variable valve timing (e-VVT) systems that offer millisecond-level response times and unprecedented precision. These systems utilize solenoid valves and electronic control units to adjust valve timing based on real-time engine operating conditions, including load, speed, temperature, and emissions feedback from oxygen sensors.

The primary objectives of modern VVT technology in V4 engines center around emissions reduction while maintaining or improving performance metrics. Specifically, VVT aims to reduce nitrogen oxide (NOx) emissions by optimizing combustion temperatures and controlling exhaust gas recirculation through valve overlap adjustments. Additionally, it targets hydrocarbon (HC) emissions reduction by improving fuel atomization and combustion efficiency across various engine operating conditions.

Carbon dioxide (CO2) reduction represents another critical objective, achieved through improved thermal efficiency and reduced pumping losses. VVT systems enable engines to operate more efficiently at partial loads, which constitutes the majority of real-world driving conditions. This efficiency translates directly to lower fuel consumption and consequently reduced CO2 emissions.

The technology roadmap for V4 engine VVT systems points toward fully camless valve actuation systems using electromagnetic or electrohydraulic actuators. These next-generation systems promise complete freedom in valve timing, lift, and duration control, potentially enabling advanced combustion strategies like Homogeneous Charge Compression Ignition (HCCI) that could further reduce emissions while improving efficiency. The ultimate goal is to develop VVT systems that can dynamically optimize valve events for each individual cylinder based on instantaneous operating conditions and emissions requirements.

Market Demand for Low-Emission Engine Technologies

The global automotive industry is experiencing a significant shift towards environmentally friendly technologies, driven by increasingly stringent emission regulations and growing consumer awareness about environmental impacts. The market for low-emission engine technologies has expanded substantially over the past decade, with variable valve timing (VVT) systems emerging as a critical component in meeting these demands, particularly in V4 engine configurations.

Regulatory frameworks worldwide, including Euro 7 standards in Europe, China 6 in Asia, and Tier 3 standards in North America, are pushing manufacturers to develop engines with dramatically reduced nitrogen oxide (NOx), carbon monoxide (CO), and particulate matter emissions. This regulatory pressure has created a market estimated at $45 billion for emission control technologies, with annual growth rates exceeding 8% according to recent industry analyses.

Consumer preferences have also evolved significantly, with surveys indicating that over 65% of new vehicle buyers now consider fuel efficiency and environmental impact as "very important" factors in their purchasing decisions. This represents a 20% increase from just five years ago, demonstrating a clear market pull alongside regulatory push factors.

The commercial vehicle sector presents particularly strong demand for advanced VVT systems in V4 engines, as fleet operators face both regulatory compliance requirements and economic pressures to reduce fuel consumption. With fuel representing approximately 30% of operating costs for commercial fleets, technologies that can deliver even modest efficiency improvements while reducing emissions have compelling value propositions.

Emerging markets represent the fastest-growing segment for low-emission engine technologies, with countries like India, Brazil, and Indonesia implementing more stringent emission standards. These markets are projected to grow at compound annual rates of 12-15% through 2030, creating substantial opportunities for VVT technology deployment in cost-sensitive V4 engine applications.

Aftermarket solutions for retrofitting existing V4 engines with improved valve timing systems have also gained traction, particularly in regions with aging vehicle fleets. This segment represents a $3.2 billion opportunity that is expected to grow as older vehicles face compliance challenges with new urban emission zones and regulations.

The integration of VVT systems with other engine technologies, such as direct injection, turbocharging, and cylinder deactivation, has created demand for comprehensive emission control solutions rather than standalone technologies. This system-level approach is reshaping the competitive landscape, favoring suppliers who can deliver integrated solutions that optimize the entire combustion process rather than individual components.

Regulatory frameworks worldwide, including Euro 7 standards in Europe, China 6 in Asia, and Tier 3 standards in North America, are pushing manufacturers to develop engines with dramatically reduced nitrogen oxide (NOx), carbon monoxide (CO), and particulate matter emissions. This regulatory pressure has created a market estimated at $45 billion for emission control technologies, with annual growth rates exceeding 8% according to recent industry analyses.

Consumer preferences have also evolved significantly, with surveys indicating that over 65% of new vehicle buyers now consider fuel efficiency and environmental impact as "very important" factors in their purchasing decisions. This represents a 20% increase from just five years ago, demonstrating a clear market pull alongside regulatory push factors.

The commercial vehicle sector presents particularly strong demand for advanced VVT systems in V4 engines, as fleet operators face both regulatory compliance requirements and economic pressures to reduce fuel consumption. With fuel representing approximately 30% of operating costs for commercial fleets, technologies that can deliver even modest efficiency improvements while reducing emissions have compelling value propositions.

Emerging markets represent the fastest-growing segment for low-emission engine technologies, with countries like India, Brazil, and Indonesia implementing more stringent emission standards. These markets are projected to grow at compound annual rates of 12-15% through 2030, creating substantial opportunities for VVT technology deployment in cost-sensitive V4 engine applications.

Aftermarket solutions for retrofitting existing V4 engines with improved valve timing systems have also gained traction, particularly in regions with aging vehicle fleets. This segment represents a $3.2 billion opportunity that is expected to grow as older vehicles face compliance challenges with new urban emission zones and regulations.

The integration of VVT systems with other engine technologies, such as direct injection, turbocharging, and cylinder deactivation, has created demand for comprehensive emission control solutions rather than standalone technologies. This system-level approach is reshaping the competitive landscape, favoring suppliers who can deliver integrated solutions that optimize the entire combustion process rather than individual components.

Current VVT Systems and Emission Reduction Challenges

Variable Valve Timing (VVT) systems have evolved significantly over the past two decades, with current implementations varying widely across manufacturers. The most prevalent VVT technologies include cam-phasing systems, which adjust the timing of valve events relative to crankshaft position, and more advanced systems that can modify both timing and lift characteristics. Leading implementations include BMW's Valvetronic, Honda's VTEC, Toyota's VVT-i, and Audi's Valvelift systems, each offering unique approaches to valve control optimization.

Despite these technological advancements, significant challenges remain in balancing performance improvements with emission reductions. Current VVT systems struggle with cold-start emissions, which account for approximately 60-80% of total emissions in standardized test cycles. The thermal inefficiency during engine warm-up phases limits the effectiveness of catalytic converters, resulting in higher hydrocarbon (HC) and nitrogen oxide (NOx) emissions during the first 120 seconds of operation.

Another critical challenge is the trade-off between NOx reduction and particulate matter (PM) formation, particularly in direct injection engines. When VVT systems are calibrated for lower combustion temperatures to reduce NOx, they often inadvertently increase PM emissions due to incomplete fuel atomization and combustion. This balance becomes increasingly difficult to maintain across the wide operating range of modern engines.

Real-world driving conditions present additional complications for emission control through VVT systems. Laboratory-optimized calibrations frequently underperform in variable ambient conditions, altitude changes, and dynamic driving patterns. Studies indicate that NOx emissions can be 4-7 times higher in real-world driving compared to laboratory certification tests, highlighting the limitations of current VVT calibration strategies.

The integration of VVT with other emission control technologies presents both opportunities and challenges. While VVT can complement exhaust gas recirculation (EGR) systems to further reduce NOx emissions, the coordination between these systems requires sophisticated control algorithms that many current engine management systems struggle to implement effectively. The complexity increases exponentially when considering the interaction with aftertreatment systems such as three-way catalysts, selective catalytic reduction, and particulate filters.

Regulatory pressures continue to drive innovation in this space, with Euro 7 and upcoming EPA standards requiring near-zero emissions across all operating conditions. Current VVT technologies, while advanced, still fall short of meeting these future requirements without significant supplementary aftertreatment systems, indicating a technological gap that requires innovative approaches to valve timing and combustion management.

Despite these technological advancements, significant challenges remain in balancing performance improvements with emission reductions. Current VVT systems struggle with cold-start emissions, which account for approximately 60-80% of total emissions in standardized test cycles. The thermal inefficiency during engine warm-up phases limits the effectiveness of catalytic converters, resulting in higher hydrocarbon (HC) and nitrogen oxide (NOx) emissions during the first 120 seconds of operation.

Another critical challenge is the trade-off between NOx reduction and particulate matter (PM) formation, particularly in direct injection engines. When VVT systems are calibrated for lower combustion temperatures to reduce NOx, they often inadvertently increase PM emissions due to incomplete fuel atomization and combustion. This balance becomes increasingly difficult to maintain across the wide operating range of modern engines.

Real-world driving conditions present additional complications for emission control through VVT systems. Laboratory-optimized calibrations frequently underperform in variable ambient conditions, altitude changes, and dynamic driving patterns. Studies indicate that NOx emissions can be 4-7 times higher in real-world driving compared to laboratory certification tests, highlighting the limitations of current VVT calibration strategies.

The integration of VVT with other emission control technologies presents both opportunities and challenges. While VVT can complement exhaust gas recirculation (EGR) systems to further reduce NOx emissions, the coordination between these systems requires sophisticated control algorithms that many current engine management systems struggle to implement effectively. The complexity increases exponentially when considering the interaction with aftertreatment systems such as three-way catalysts, selective catalytic reduction, and particulate filters.

Regulatory pressures continue to drive innovation in this space, with Euro 7 and upcoming EPA standards requiring near-zero emissions across all operating conditions. Current VVT technologies, while advanced, still fall short of meeting these future requirements without significant supplementary aftertreatment systems, indicating a technological gap that requires innovative approaches to valve timing and combustion management.

Existing VVT Solutions for Emission Reduction

01 VVT systems for emission reduction in V4 engines

Variable Valve Timing systems in V4 engines can significantly reduce emissions by optimizing valve opening and closing times based on engine operating conditions. These systems allow for better control of the combustion process, resulting in more complete fuel burning and reduced formation of pollutants such as NOx, CO, and unburned hydrocarbons. By adjusting valve timing according to load and speed requirements, VVT systems can maintain optimal air-fuel ratios across different operating conditions, leading to cleaner exhaust emissions while maintaining performance.- VVT systems for emission reduction in V4 engines: Variable Valve Timing systems in V4 engines can significantly reduce emissions by optimizing valve opening and closing times based on engine operating conditions. These systems allow for better control of the combustion process, resulting in more complete fuel burning and reduced formation of pollutants such as NOx, CO, and unburned hydrocarbons. By adjusting valve timing according to engine load and speed, VVT systems can maintain optimal air-fuel ratios across different operating conditions, leading to cleaner exhaust emissions while maintaining performance.

- Dual independent VVT mechanisms for V4 engine emission control: Dual independent Variable Valve Timing mechanisms allow separate control of intake and exhaust valve timing in V4 engines, providing enhanced emission control capabilities. By independently adjusting intake and exhaust valve overlap, these systems can optimize internal exhaust gas recirculation (EGR) at different engine speeds and loads. This technology enables precise control of combustion temperature and pressure, reducing NOx formation during high-load operation while improving combustion stability and reducing hydrocarbon emissions during low-load conditions.

- Integrated VVT and EGR systems for V4 engines: The integration of Variable Valve Timing with Exhaust Gas Recirculation systems in V4 engines creates synergistic effects for emissions reduction. These combined systems allow for precise control of the amount of exhaust gas recirculated into the combustion chamber, diluting the intake charge and reducing combustion temperatures. Lower combustion temperatures result in decreased NOx formation, while the VVT component ensures optimal valve timing to maintain combustion efficiency despite the diluted mixture. This integration provides a comprehensive approach to emissions control across various operating conditions.

- Electronically controlled VVT systems for V4 engines: Electronically controlled Variable Valve Timing systems utilize advanced sensors and control algorithms to optimize valve timing in V4 engines for emissions reduction. These systems continuously monitor engine parameters such as speed, load, temperature, and oxygen content in the exhaust, making real-time adjustments to valve timing. The electronic control enables more precise and responsive valve actuation compared to hydraulic or mechanical systems, allowing for finer optimization of the combustion process. This results in improved fuel efficiency and reduced emissions across a wider range of operating conditions.

- Compact VVT mechanisms for V4 engine configurations: Compact Variable Valve Timing mechanisms are specifically designed for the space constraints of V4 engine configurations while maintaining emission control capabilities. These systems feature reduced size actuators, integrated oil control valves, and optimized phaser designs that fit within the limited space of V4 engine heads. Despite their compact nature, these mechanisms provide effective valve timing control to reduce emissions through optimized combustion. The space-efficient design allows V4 engines to meet stringent emission standards without compromising the packaging advantages of this engine configuration.

02 Dual independent VVT mechanisms for V4 engine emission control

Dual independent Variable Valve Timing mechanisms allow separate control of intake and exhaust valve timing in V4 engines, providing more precise emission management. This configuration enables optimization of valve overlap periods, which affects internal exhaust gas recirculation and combustion efficiency. By independently controlling both intake and exhaust valve timing, these systems can reduce pumping losses, improve volumetric efficiency, and enable more effective emission control strategies across various engine operating conditions, particularly during cold starts and low-load operation when emissions are typically highest.Expand Specific Solutions03 Integrated VVT and EGR systems for emission compliance

The integration of Variable Valve Timing with Exhaust Gas Recirculation (EGR) systems provides enhanced emission control capabilities in V4 engines. This combination allows for precise management of in-cylinder conditions by controlling both fresh air intake and recirculated exhaust gas. The coordinated operation of VVT and EGR systems enables effective reduction of nitrogen oxide (NOx) emissions through controlled combustion temperatures while maintaining fuel efficiency. These integrated systems can be particularly effective for meeting stringent emission standards without significant performance penalties.Expand Specific Solutions04 Electronically controlled VVT actuators for precise emission management

Advanced electronically controlled VVT actuators provide high-precision valve timing adjustment in V4 engines, enabling more effective emission control. These actuators respond rapidly to changing engine conditions and can make fine adjustments to valve timing based on real-time sensor data. The improved response time and accuracy allow the engine management system to maintain optimal combustion parameters under transient conditions, which is critical for minimizing emissions during acceleration, deceleration, and load changes. Electronic control also enables more sophisticated emission reduction strategies through integration with other engine management systems.Expand Specific Solutions05 Compact VVT mechanisms for V4 engine architecture

Specialized compact Variable Valve Timing mechanisms designed specifically for V4 engine architecture help optimize emission performance while accommodating space constraints. These compact designs integrate efficiently within the V4 configuration, allowing for effective valve timing control without compromising the engine's packaging advantages. The space-efficient VVT systems maintain the V4 engine's inherent balance characteristics while providing the valve timing flexibility needed for emission reduction across various operating conditions. These mechanisms are particularly important for applications where engine compartment space is limited but emission compliance is mandatory.Expand Specific Solutions

Leading Manufacturers in VVT Emission Control Systems

Variable valve timing technology in V4 engines has reached a mature stage in emission control applications, with major players like Ford Global Technologies, Toyota Motor Corp., and BorgWarner leading innovation. The market is experiencing steady growth as stringent emission regulations drive adoption across global automotive sectors. Companies such as Mercedes-Benz, Hyundai, and DENSO have established strong competitive positions through proprietary VVT systems that optimize combustion efficiency and reduce pollutants. Research institutions like Tianjin University and Beihang University contribute significant academic advancements, while tier-one suppliers including Hitachi Automotive Systems and Astemo provide specialized components. The technology continues to evolve toward integration with hybrid and electrification strategies.

Ford Global Technologies LLC

Technical Solution: Ford's Variable Camshaft Timing (VCT) technology for V4 engines employs a hydraulic-mechanical system that allows continuous adjustment of camshaft timing relative to the crankshaft. Their dual-equal VCT system independently controls intake and exhaust valve timing, optimizing combustion across various engine loads. Ford has implemented this in their EcoBoost engines, where the VCT works in conjunction with direct fuel injection and turbocharging to reduce emissions by up to 15% compared to conventional systems. The technology enables precise control of valve overlap periods, allowing for improved internal EGR (Exhaust Gas Recirculation) which significantly reduces NOx emissions while maintaining performance. Ford's system includes advanced electronic control modules that adjust timing based on real-time engine parameters and driving conditions, enabling dynamic emission control strategies across the entire operating range.

Strengths: Excellent integration with EcoBoost technology creating synergistic benefits for both performance and emissions; sophisticated electronic control systems allowing real-time optimization. Weaknesses: Higher system complexity increases manufacturing costs; potential reliability concerns with hydraulic actuators in cold-start conditions.

Toyota Motor Corp.

Technical Solution: Toyota's VVT-i (Variable Valve Timing with intelligence) system for V4 engines represents one of the most refined variable valve timing implementations in the industry. Their technology employs an oil pressure-actuated vane-type camshaft phaser that continuously adjusts intake valve timing. For emissions control specifically, Toyota has evolved this into Dual VVT-i which manages both intake and exhaust valve timing independently. This system achieves remarkable emission reductions by optimizing combustion efficiency across all engine operating conditions. Toyota's implementation includes sophisticated oil control valves that respond to signals from the ECU based on multiple sensor inputs including exhaust gas composition. Their latest iteration incorporates VVT-iE which uses an electric motor instead of hydraulic pressure to adjust the intake camshaft timing, providing more precise control especially during cold starts when emissions are typically highest. This electric actuation enables a 7-8% reduction in cold-start emissions compared to conventional hydraulic systems.

Strengths: Exceptional reliability even after high mileage; electric actuation in VVT-iE provides superior cold-start emission control; seamless integration with Toyota's hybrid systems. Weaknesses: Higher production costs compared to simpler systems; electric actuators add complexity to the electrical system architecture.

Key Patents in V4 Engine VVT Emission Control

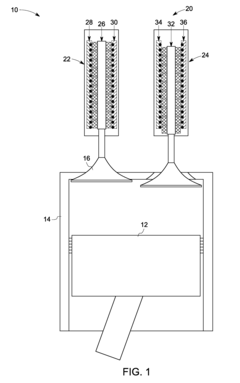

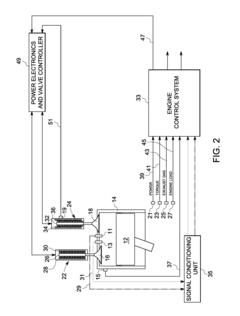

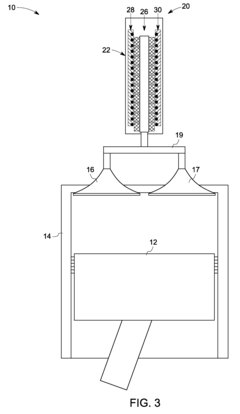

Electric valve actuation system

PatentActiveUS8047166B2

Innovation

- A magnetically-geared valve actuation system that includes sensors and a control system to dynamically control valve timing, providing flexible operation and reduced valve losses by using magnetic gearing to actuate intake and exhaust valves in engines and suction and discharge valves in compressors.

Regulatory Compliance and Emission Standards

The global automotive industry faces increasingly stringent emission regulations that directly impact variable valve timing (VVT) technology development in V4 engines. The European Union's Euro 6d standards, implemented in 2020, mandate significant reductions in nitrogen oxides (NOx) and particulate matter emissions, with real driving emissions (RDE) testing ensuring compliance under actual driving conditions. These regulations have pushed manufacturers to optimize VVT systems for both performance and emissions control.

In the United States, the Environmental Protection Agency (EPA) and California Air Resources Board (CARB) have established comprehensive frameworks governing vehicle emissions. The EPA's Tier 3 standards and CARB's LEV III regulations specifically target reductions in non-methane organic gases (NMOG), NOx, and carbon monoxide. These standards have become progressively more stringent, requiring V4 engines with VVT to demonstrate consistent emissions performance across a wider range of operating conditions.

China's implementation of China 6 standards represents one of the world's most rigorous regulatory frameworks, combining elements from both European and American approaches. These standards have accelerated the adoption of advanced VVT technologies in the rapidly growing Chinese automotive market, particularly for smaller displacement V4 engines popular in urban environments.

The regulatory landscape has evolved to include not only tailpipe emissions but also lifecycle carbon footprint considerations. This holistic approach has prompted manufacturers to optimize VVT systems for reduced CO2 emissions alongside traditional pollutants. The World Harmonized Light Vehicle Test Procedure (WLTP) and its companion Real Driving Emissions (RDE) test have standardized emissions testing globally, creating more realistic assessment conditions that better reflect VVT performance in everyday driving scenarios.

Compliance strategies have necessitated sophisticated on-board diagnostics (OBD) systems that continuously monitor VVT operation and emissions control systems. These systems must detect malfunctions that could lead to emissions exceeding regulatory thresholds by 1.5 to 2 times the standard. The integration of OBD with VVT control systems represents a significant technical challenge for manufacturers.

Looking forward, proposed regulations for 2025-2030 will likely require further refinements to VVT technology. The trend toward electrification has not eliminated the need for advanced VVT systems, as hybrid powertrains still rely on internal combustion engines with stringent emissions requirements. Manufacturers must balance the cost of compliance with performance expectations, making VVT optimization a critical factor in meeting future regulatory challenges while maintaining market competitiveness.

In the United States, the Environmental Protection Agency (EPA) and California Air Resources Board (CARB) have established comprehensive frameworks governing vehicle emissions. The EPA's Tier 3 standards and CARB's LEV III regulations specifically target reductions in non-methane organic gases (NMOG), NOx, and carbon monoxide. These standards have become progressively more stringent, requiring V4 engines with VVT to demonstrate consistent emissions performance across a wider range of operating conditions.

China's implementation of China 6 standards represents one of the world's most rigorous regulatory frameworks, combining elements from both European and American approaches. These standards have accelerated the adoption of advanced VVT technologies in the rapidly growing Chinese automotive market, particularly for smaller displacement V4 engines popular in urban environments.

The regulatory landscape has evolved to include not only tailpipe emissions but also lifecycle carbon footprint considerations. This holistic approach has prompted manufacturers to optimize VVT systems for reduced CO2 emissions alongside traditional pollutants. The World Harmonized Light Vehicle Test Procedure (WLTP) and its companion Real Driving Emissions (RDE) test have standardized emissions testing globally, creating more realistic assessment conditions that better reflect VVT performance in everyday driving scenarios.

Compliance strategies have necessitated sophisticated on-board diagnostics (OBD) systems that continuously monitor VVT operation and emissions control systems. These systems must detect malfunctions that could lead to emissions exceeding regulatory thresholds by 1.5 to 2 times the standard. The integration of OBD with VVT control systems represents a significant technical challenge for manufacturers.

Looking forward, proposed regulations for 2025-2030 will likely require further refinements to VVT technology. The trend toward electrification has not eliminated the need for advanced VVT systems, as hybrid powertrains still rely on internal combustion engines with stringent emissions requirements. Manufacturers must balance the cost of compliance with performance expectations, making VVT optimization a critical factor in meeting future regulatory challenges while maintaining market competitiveness.

Cost-Benefit Analysis of VVT Implementation

The implementation of Variable Valve Timing (VVT) technology in V4 engines represents a significant investment for manufacturers, necessitating a thorough cost-benefit analysis. Initial implementation costs typically range from $300-600 per unit, encompassing hardware components such as advanced camshaft actuators, oil control valves, and enhanced ECU capabilities. Engineering development expenses add approximately $5-15 million to the overall project budget, while production line modifications may require an additional $2-7 million investment depending on existing infrastructure.

These substantial upfront costs are counterbalanced by several quantifiable benefits. Fuel efficiency improvements of 4-8% translate to significant lifetime savings for consumers and contribute to manufacturer fleet average compliance with increasingly stringent fuel economy regulations. Emissions reductions of 5-12% for NOx and 3-7% for CO2 help manufacturers meet Euro 6d, EPA Tier 3, and upcoming regulatory standards, potentially avoiding non-compliance penalties that can exceed $100 million annually.

Performance enhancements delivered by VVT technology create marketable advantages, with torque improvements of 7-10% across a broader RPM range and horsepower gains of 3-6%. These performance benefits can command price premiums of $200-500 per vehicle, depending on market segment and brand positioning. Additionally, the improved combustion efficiency reduces warranty claims related to carbon buildup and valve deposits by approximately 15-20%, representing significant long-term cost savings.

Return on investment calculations indicate that VVT implementation typically achieves breakeven within 2-3 years of production, with premium vehicle segments reaching profitability more rapidly. The technology's maturity has progressively reduced implementation costs, with second-generation systems costing 30-40% less than initial offerings while delivering enhanced functionality.

Regulatory compliance represents perhaps the most compelling economic justification, as non-VVT engines increasingly struggle to meet emissions standards without costly after-treatment systems. The alternative approach of enhanced catalytic conversion and exhaust gas recirculation systems often exceeds VVT implementation costs by 40-60% while delivering inferior performance characteristics and fuel economy.

For manufacturers with diverse global markets, scalable VVT solutions offer particular value, allowing technology deployment across multiple vehicle platforms and reducing per-unit costs through economies of scale. The most favorable cost-benefit ratios are achieved when VVT implementation coincides with planned engine redesign cycles, minimizing incremental engineering and tooling expenses.

These substantial upfront costs are counterbalanced by several quantifiable benefits. Fuel efficiency improvements of 4-8% translate to significant lifetime savings for consumers and contribute to manufacturer fleet average compliance with increasingly stringent fuel economy regulations. Emissions reductions of 5-12% for NOx and 3-7% for CO2 help manufacturers meet Euro 6d, EPA Tier 3, and upcoming regulatory standards, potentially avoiding non-compliance penalties that can exceed $100 million annually.

Performance enhancements delivered by VVT technology create marketable advantages, with torque improvements of 7-10% across a broader RPM range and horsepower gains of 3-6%. These performance benefits can command price premiums of $200-500 per vehicle, depending on market segment and brand positioning. Additionally, the improved combustion efficiency reduces warranty claims related to carbon buildup and valve deposits by approximately 15-20%, representing significant long-term cost savings.

Return on investment calculations indicate that VVT implementation typically achieves breakeven within 2-3 years of production, with premium vehicle segments reaching profitability more rapidly. The technology's maturity has progressively reduced implementation costs, with second-generation systems costing 30-40% less than initial offerings while delivering enhanced functionality.

Regulatory compliance represents perhaps the most compelling economic justification, as non-VVT engines increasingly struggle to meet emissions standards without costly after-treatment systems. The alternative approach of enhanced catalytic conversion and exhaust gas recirculation systems often exceeds VVT implementation costs by 40-60% while delivering inferior performance characteristics and fuel economy.

For manufacturers with diverse global markets, scalable VVT solutions offer particular value, allowing technology deployment across multiple vehicle platforms and reducing per-unit costs through economies of scale. The most favorable cost-benefit ratios are achieved when VVT implementation coincides with planned engine redesign cycles, minimizing incremental engineering and tooling expenses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!