V4 Engine Block Casting: Techniques for Strength

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Block Casting Evolution and Objectives

The evolution of V4 engine block casting techniques has undergone significant transformation since the early 20th century. Initially, engine blocks were predominantly cast using traditional sand casting methods, which offered limited precision and strength characteristics. The 1950s marked a pivotal shift with the introduction of semi-permanent mold casting, enhancing dimensional accuracy and surface finish quality while reducing porosity defects that had plagued earlier casting methods.

By the 1970s, high-pressure die casting emerged as a revolutionary technique for V4 engine blocks, enabling manufacturers to achieve thinner wall sections while maintaining structural integrity. This period also witnessed the integration of computer-aided design tools that optimized mold filling and solidification processes, substantially reducing casting defects and improving overall block strength.

The 1990s brought significant advancements in metallurgical understanding, leading to the development of specialized aluminum alloys specifically engineered for V4 engine applications. These alloys, including the A356 and A319 series, offered superior strength-to-weight ratios and enhanced thermal conductivity properties, addressing the increasing performance demands of modern engines.

Recent technological innovations have focused on microstructural control during the casting process. Techniques such as controlled cooling rates, grain refinement through inoculation, and modification of eutectic silicon morphology have collectively contributed to substantial improvements in mechanical properties without necessitating significant changes in chemical composition.

The primary objective of modern V4 engine block casting research centers on achieving optimal strength characteristics while simultaneously reducing weight. This balance is crucial for meeting increasingly stringent fuel efficiency standards without compromising engine durability or performance. Secondary objectives include enhancing thermal management capabilities, improving vibration damping characteristics, and extending service life under high-stress operating conditions.

Current research trajectories are exploring advanced casting methodologies such as low-pressure permanent mold casting with vacuum assistance and rheocasting techniques that manipulate the semi-solid state of metals. These approaches aim to minimize porosity defects while optimizing microstructural uniformity throughout complex V4 block geometries.

The industry is also witnessing a growing emphasis on computational modeling and simulation tools that predict casting outcomes with unprecedented accuracy. These digital twins of the casting process enable engineers to virtually test multiple design iterations and process parameters before physical implementation, significantly accelerating development cycles while ensuring consistent strength characteristics across production runs.

By the 1970s, high-pressure die casting emerged as a revolutionary technique for V4 engine blocks, enabling manufacturers to achieve thinner wall sections while maintaining structural integrity. This period also witnessed the integration of computer-aided design tools that optimized mold filling and solidification processes, substantially reducing casting defects and improving overall block strength.

The 1990s brought significant advancements in metallurgical understanding, leading to the development of specialized aluminum alloys specifically engineered for V4 engine applications. These alloys, including the A356 and A319 series, offered superior strength-to-weight ratios and enhanced thermal conductivity properties, addressing the increasing performance demands of modern engines.

Recent technological innovations have focused on microstructural control during the casting process. Techniques such as controlled cooling rates, grain refinement through inoculation, and modification of eutectic silicon morphology have collectively contributed to substantial improvements in mechanical properties without necessitating significant changes in chemical composition.

The primary objective of modern V4 engine block casting research centers on achieving optimal strength characteristics while simultaneously reducing weight. This balance is crucial for meeting increasingly stringent fuel efficiency standards without compromising engine durability or performance. Secondary objectives include enhancing thermal management capabilities, improving vibration damping characteristics, and extending service life under high-stress operating conditions.

Current research trajectories are exploring advanced casting methodologies such as low-pressure permanent mold casting with vacuum assistance and rheocasting techniques that manipulate the semi-solid state of metals. These approaches aim to minimize porosity defects while optimizing microstructural uniformity throughout complex V4 block geometries.

The industry is also witnessing a growing emphasis on computational modeling and simulation tools that predict casting outcomes with unprecedented accuracy. These digital twins of the casting process enable engineers to virtually test multiple design iterations and process parameters before physical implementation, significantly accelerating development cycles while ensuring consistent strength characteristics across production runs.

Market Demand Analysis for High-Strength Engine Blocks

The global market for high-strength engine blocks has experienced significant growth over the past decade, driven primarily by the automotive industry's push for more efficient, lightweight, yet durable powertrains. Current market valuations indicate that the high-performance engine block segment represents approximately 18% of the overall engine component market, with annual growth rates consistently outpacing general automotive parts at 5.7% compared to 3.2%.

Consumer demand for V4 engine blocks with enhanced strength characteristics stems from several converging market trends. First, the increasing popularity of turbocharged smaller displacement engines has created a need for blocks that can withstand higher internal pressures and thermal loads. This shift is particularly evident in markets like Europe and parts of Asia, where fuel efficiency regulations have accelerated the adoption of downsized engines with higher specific outputs.

Commercial vehicle manufacturers constitute another significant market segment, with demand for durable V4 blocks growing at 6.3% annually. These customers prioritize longevity and reliability under continuous heavy-load conditions, making strength-enhanced casting techniques particularly valuable. Survey data from fleet operators indicates willingness to pay premium prices for engine blocks with documented improvements in service life and reduced warranty claims.

The aftermarket performance sector represents a smaller but highly profitable niche, where specialized high-strength V4 blocks command premium prices. This segment has shown resilience even during economic downturns, growing steadily at 4.8% annually over the past five years. Performance enthusiasts and racing applications demand blocks capable of handling extreme conditions, creating opportunities for advanced casting technologies.

Regional analysis reveals varying demand patterns, with North American markets focusing on performance applications, European markets prioritizing efficiency and emissions compliance, and emerging Asian markets seeking cost-effective durability improvements. The Chinese market in particular has shown accelerated growth in demand for higher-quality engine components as domestic manufacturers move upmarket.

Industry forecasts suggest that market penetration of advanced high-strength casting techniques will reach 37% of all new V4 engine block production by 2026, representing a substantial opportunity for early adopters of superior casting technologies. This growth is supported by increasing regulatory pressures for vehicle lightweighting to improve fuel economy and reduce emissions, while maintaining or improving durability standards.

The economic value proposition for strength-enhanced engine blocks is compelling, with manufacturers reporting that premium casting techniques typically add 15-22% to production costs while enabling price premiums of 25-40% in appropriate market segments. This favorable cost-benefit ratio is driving investment in advanced casting research and production capacity expansion among leading manufacturers.

Consumer demand for V4 engine blocks with enhanced strength characteristics stems from several converging market trends. First, the increasing popularity of turbocharged smaller displacement engines has created a need for blocks that can withstand higher internal pressures and thermal loads. This shift is particularly evident in markets like Europe and parts of Asia, where fuel efficiency regulations have accelerated the adoption of downsized engines with higher specific outputs.

Commercial vehicle manufacturers constitute another significant market segment, with demand for durable V4 blocks growing at 6.3% annually. These customers prioritize longevity and reliability under continuous heavy-load conditions, making strength-enhanced casting techniques particularly valuable. Survey data from fleet operators indicates willingness to pay premium prices for engine blocks with documented improvements in service life and reduced warranty claims.

The aftermarket performance sector represents a smaller but highly profitable niche, where specialized high-strength V4 blocks command premium prices. This segment has shown resilience even during economic downturns, growing steadily at 4.8% annually over the past five years. Performance enthusiasts and racing applications demand blocks capable of handling extreme conditions, creating opportunities for advanced casting technologies.

Regional analysis reveals varying demand patterns, with North American markets focusing on performance applications, European markets prioritizing efficiency and emissions compliance, and emerging Asian markets seeking cost-effective durability improvements. The Chinese market in particular has shown accelerated growth in demand for higher-quality engine components as domestic manufacturers move upmarket.

Industry forecasts suggest that market penetration of advanced high-strength casting techniques will reach 37% of all new V4 engine block production by 2026, representing a substantial opportunity for early adopters of superior casting technologies. This growth is supported by increasing regulatory pressures for vehicle lightweighting to improve fuel economy and reduce emissions, while maintaining or improving durability standards.

The economic value proposition for strength-enhanced engine blocks is compelling, with manufacturers reporting that premium casting techniques typically add 15-22% to production costs while enabling price premiums of 25-40% in appropriate market segments. This favorable cost-benefit ratio is driving investment in advanced casting research and production capacity expansion among leading manufacturers.

Current Casting Technologies and Strength Challenges

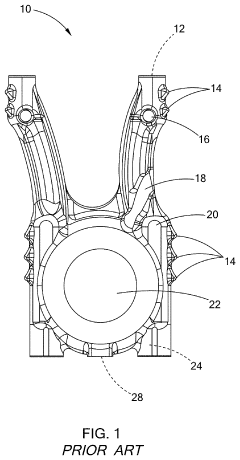

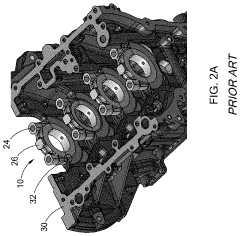

The current landscape of V4 engine block casting is dominated by several key technologies, each with distinct advantages and limitations regarding strength characteristics. Sand casting remains the most traditional method, offering flexibility and cost-effectiveness for small to medium production runs. However, this process often results in lower dimensional accuracy and potential porosity issues that can compromise structural integrity under high-stress conditions.

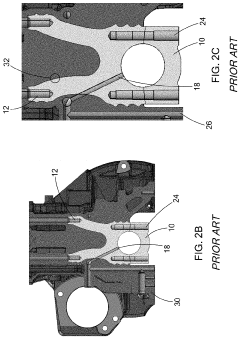

Die casting has emerged as a preferred method for many manufacturers due to its superior surface finish and dimensional precision. The process involves injecting molten metal into reusable metal molds under high pressure, creating denser castings with fewer defects. For V4 engine blocks specifically, high-pressure die casting (HPDC) has demonstrated significant improvements in mechanical properties, though challenges remain in managing solidification rates across varying wall thicknesses.

Lost foam casting represents an evolution in casting technology that addresses some traditional limitations. This process utilizes foam patterns that vaporize when molten metal is introduced, resulting in complex internal geometries without the need for cores or parting lines. While offering design flexibility, lost foam castings can suffer from carbon residue issues that potentially weaken critical stress points in engine blocks.

The industry currently faces several significant strength-related challenges. Porosity remains perhaps the most persistent issue, with gas and shrinkage pores creating stress concentration points that can lead to premature failure under cyclic loading conditions. Modern V4 engines operating at higher temperatures and pressures amplify these concerns, requiring increasingly sophisticated solutions.

Material selection presents another critical challenge. While aluminum alloys (particularly A356 and A319) have become standard for their excellent strength-to-weight ratios, achieving optimal mechanical properties requires precise control of silicon content, modification treatments, and heat treatment protocols. Compacted graphite iron (CGI) offers superior strength characteristics but introduces casting complexity and cost considerations.

Thermal management during solidification represents a significant technical hurdle. Uneven cooling rates across the engine block's varying wall thicknesses can create residual stresses and microstructural inconsistencies. Advanced simulation tools have improved predictive capabilities, but practical implementation of optimized cooling strategies remains challenging in production environments.

Recent developments in hybrid casting techniques show promise in addressing these challenges. Processes combining the advantages of multiple casting methods, such as low-pressure permanent mold casting with strategic core placement, demonstrate improved strength characteristics while maintaining production efficiency. However, these approaches require substantial capital investment and specialized expertise.

Die casting has emerged as a preferred method for many manufacturers due to its superior surface finish and dimensional precision. The process involves injecting molten metal into reusable metal molds under high pressure, creating denser castings with fewer defects. For V4 engine blocks specifically, high-pressure die casting (HPDC) has demonstrated significant improvements in mechanical properties, though challenges remain in managing solidification rates across varying wall thicknesses.

Lost foam casting represents an evolution in casting technology that addresses some traditional limitations. This process utilizes foam patterns that vaporize when molten metal is introduced, resulting in complex internal geometries without the need for cores or parting lines. While offering design flexibility, lost foam castings can suffer from carbon residue issues that potentially weaken critical stress points in engine blocks.

The industry currently faces several significant strength-related challenges. Porosity remains perhaps the most persistent issue, with gas and shrinkage pores creating stress concentration points that can lead to premature failure under cyclic loading conditions. Modern V4 engines operating at higher temperatures and pressures amplify these concerns, requiring increasingly sophisticated solutions.

Material selection presents another critical challenge. While aluminum alloys (particularly A356 and A319) have become standard for their excellent strength-to-weight ratios, achieving optimal mechanical properties requires precise control of silicon content, modification treatments, and heat treatment protocols. Compacted graphite iron (CGI) offers superior strength characteristics but introduces casting complexity and cost considerations.

Thermal management during solidification represents a significant technical hurdle. Uneven cooling rates across the engine block's varying wall thicknesses can create residual stresses and microstructural inconsistencies. Advanced simulation tools have improved predictive capabilities, but practical implementation of optimized cooling strategies remains challenging in production environments.

Recent developments in hybrid casting techniques show promise in addressing these challenges. Processes combining the advantages of multiple casting methods, such as low-pressure permanent mold casting with strategic core placement, demonstrate improved strength characteristics while maintaining production efficiency. However, these approaches require substantial capital investment and specialized expertise.

Contemporary Strength Enhancement Casting Solutions

01 Material composition for V4 engine block casting

The material composition plays a crucial role in determining the strength of V4 engine block castings. Various alloys, particularly aluminum alloys with specific additives like silicon, copper, and magnesium, are used to enhance the mechanical properties of the engine block. These compositions are carefully formulated to provide optimal tensile strength, thermal conductivity, and resistance to fatigue while maintaining good castability characteristics necessary for complex V4 engine block geometries.- Material selection for V4 engine block casting: The choice of materials significantly impacts the strength of V4 engine block castings. Various alloys, particularly aluminum alloys with specific compositions, are used to enhance casting strength while maintaining appropriate weight characteristics. These materials are selected for their thermal conductivity, resistance to high temperatures, and ability to withstand mechanical stress during engine operation. Advanced metallurgical techniques ensure optimal material properties for engine block applications.

- Casting process optimization for strength enhancement: Various casting processes are employed to improve the strength of V4 engine blocks. These include precision sand casting, die casting, and lost foam casting techniques. The casting parameters such as temperature control, cooling rates, and mold design significantly influence the microstructure and mechanical properties of the final product. Advanced process controls during solidification help minimize defects and enhance the overall structural integrity of the engine block.

- Structural design improvements for V4 engine blocks: Innovative structural designs are implemented to enhance the strength of V4 engine blocks. These include optimized rib configurations, strategic wall thickness distribution, and reinforced mounting points. Computer-aided engineering tools are used to analyze stress distribution and identify critical areas requiring additional support. The integration of webbing structures and load-bearing elements helps distribute forces more evenly throughout the engine block, improving overall durability and performance.

- Heat treatment and post-casting processes: Post-casting treatments significantly enhance the strength properties of V4 engine blocks. These processes include solution heat treatment, aging, and various thermal processing techniques that modify the microstructure of the cast material. Controlled cooling protocols and stress relief procedures help eliminate internal stresses and improve dimensional stability. Additional surface treatments may be applied to increase wear resistance and fatigue strength in critical areas of the engine block.

- Quality control and testing methods for strength verification: Comprehensive testing methodologies are employed to verify and ensure the strength of V4 engine block castings. These include non-destructive testing techniques such as ultrasonic inspection, X-ray analysis, and dye penetrant testing to detect internal defects. Mechanical property testing, including tensile strength, hardness, and fatigue resistance measurements, provides quantitative data on casting strength. Advanced simulation tools are used to predict performance under various operating conditions, allowing for optimization before physical production.

02 Casting process techniques for improved strength

Advanced casting techniques significantly impact the strength of V4 engine blocks. Methods such as high-pressure die casting, low-pressure casting, and gravity casting are employed with specific parameters to control solidification rates and minimize defects. Vacuum-assisted casting and controlled cooling processes help reduce porosity and improve the microstructure of the cast material, resulting in enhanced mechanical properties and overall strength of the engine block.Expand Specific Solutions03 Heat treatment and post-casting processes

Post-casting heat treatment processes are essential for optimizing the strength of V4 engine blocks. Treatments such as solution heat treatment, quenching, and aging (T6 or T7 processes) significantly improve the mechanical properties by altering the microstructure of the cast material. Additional processes like hot isostatic pressing (HIP) can eliminate internal porosity, while surface treatments may be applied to enhance wear resistance and durability of critical areas within the engine block.Expand Specific Solutions04 Structural design for strength optimization

The structural design of V4 engine blocks incorporates specific features to maximize strength while minimizing weight. Ribbing patterns, wall thickness variations, and strategic reinforcement in high-stress areas are carefully engineered. Computer-aided design and finite element analysis are used to optimize the distribution of material, identify potential weak points, and ensure adequate strength throughout the engine block, particularly around cylinder bores, main bearing supports, and mounting points.Expand Specific Solutions05 Testing and quality control methods

Comprehensive testing and quality control methods are implemented to ensure V4 engine block castings meet strength requirements. Non-destructive testing techniques such as X-ray inspection, ultrasonic testing, and dye penetrant inspection are used to detect internal and surface defects. Mechanical testing including tensile strength, hardness, and fatigue testing provides quantitative data on casting strength. Statistical process control and advanced monitoring systems during production help maintain consistent quality and strength characteristics.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The V4 engine block casting market is in a mature growth phase, with established players dominating the landscape. Major automotive manufacturers like Ford, GM, Toyota, and Volkswagen (through International Engine IP) lead technological innovation, focusing on advanced strength-enhancing techniques. The market is characterized by a mix of traditional OEMs and specialized casting companies like ASIMCO International Foundry and Eisenwerk Brühl. Technical maturity varies, with companies like Cummins and Mazda pushing boundaries in lightweight yet durable casting methods, while newer entrants from China (Chery, Suzhou Mingzhi) are rapidly advancing their capabilities. The global market continues to expand as strength-to-weight optimization remains critical for meeting increasingly stringent emissions and performance standards.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered advanced V4 engine block casting techniques focusing on their EcoBoost architecture. Their technology employs high-pressure die casting with specialized aluminum alloys containing silicon and copper for optimal strength-to-weight ratios. Ford utilizes computer-aided engineering to optimize wall thickness distribution, creating strategic reinforcements at high-stress points while maintaining lightweight design. Their patented core-making process enables complex internal cooling passages that enhance thermal management without compromising structural integrity. Ford has also developed proprietary heat treatment protocols that significantly improve fatigue resistance and long-term durability of their cast engine blocks. Recent innovations include the integration of composite materials in strategic locations within the casting process to create hybrid metal-composite structures that provide additional strength in critical areas.

Strengths: Superior strength-to-weight ratio through optimized alloy composition; excellent thermal management capabilities; advanced computer modeling for stress optimization. Weaknesses: Higher production costs compared to traditional casting methods; requires specialized equipment and expertise; more complex manufacturing process with potential for increased defect rates.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive V4 engine block casting approach centered on their "Precision Sand Casting" technology. This method utilizes robotically-controlled sand core assembly with proprietary binder systems that enable more precise internal geometries than conventional casting. GM's technique incorporates real-time X-ray monitoring during the casting process to detect and prevent defects before solidification completes. Their metallurgical innovations include a specialized aluminum-silicon alloy with carefully controlled strontium and titanium additions that form microscopic strengthening precipitates throughout the casting. GM has also pioneered the use of localized cooling control during solidification to optimize grain structure in high-stress areas of the engine block. Their post-casting treatment includes a multi-stage heat treatment process that significantly enhances mechanical properties while maintaining dimensional stability.

Strengths: Exceptional dimensional accuracy; superior defect detection and prevention; optimized microstructure in critical areas; excellent balance of strength and weight. Weaknesses: Higher initial tooling investment; longer production cycle times; requires sophisticated quality control systems; more complex supply chain for specialized alloy components.

Critical Patents and Metallurgical Innovations

Aluminum casting design with alloy set cores for improved intermetallic bond strength

PatentActiveUS20200391284A1

Innovation

- A method involving diffusion bonding with a bond material like copper or nickel between the insert and the engine block, using processes such as electroforming or plasma vapor deposition, to create a molecular bond that enhances load transmission and distribution, eliminating the need for serrations and reducing intermetallic phase formation.

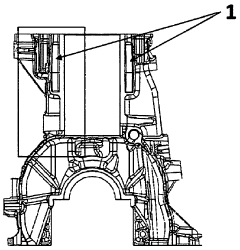

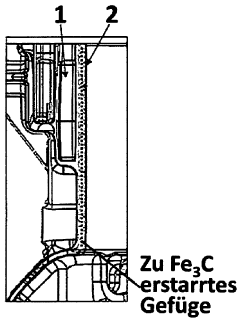

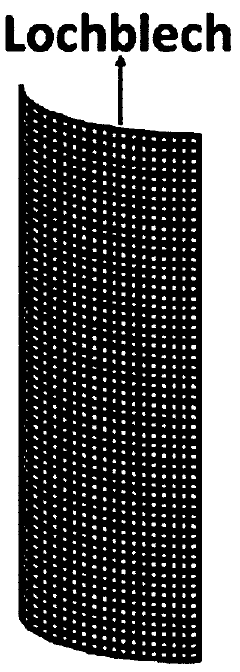

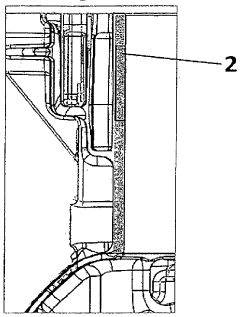

Method of reducing weight and/or increasing mechanical strength of cast iron material used for cylinders in engine blocks, involves increasing elastic modulus of cast iron material locally by structural transformation to cementite

PatentInactiveDE102011002200A1

Innovation

- A method to locally increase the modulus of elasticity of cast iron by transforming the microstructure to cementite, using metal inserts or coatings containing chromium, nickel, manganese, vanadium, titanium, or tellurium/bismuth during the casting process, enhancing stiffness and strength.

Material Science Advancements for Engine Block Applications

The evolution of material science has fundamentally transformed engine block manufacturing, particularly for V4 configurations where strength-to-weight ratio is critical. Recent advancements in metallurgical engineering have introduced aluminum-silicon alloys with enhanced thermal properties, reducing thermal expansion while maintaining structural integrity under high-temperature operating conditions. These alloys typically contain 7-11% silicon content, with additional elements like copper (0.5-4%) and magnesium (0.3-1.2%) to optimize mechanical properties.

Composite metal matrix materials represent another significant breakthrough, incorporating ceramic particles such as silicon carbide and aluminum oxide into traditional aluminum alloys. These composites demonstrate up to 30% higher tensile strength and 25% improved wear resistance compared to conventional alloys, while maintaining excellent castability characteristics essential for complex V4 engine block geometries.

High-pressure die casting (HPDC) techniques have evolved in conjunction with these material innovations, allowing for more precise control of microstructure formation during solidification. The latest HPDC systems operate at pressures exceeding 2000 bar, creating denser castings with fewer porosity defects and more uniform grain structures. This results in engine blocks with superior fatigue resistance and dimensional stability.

Nano-reinforced alloys have emerged as a promising frontier, with research showing that additions of carbon nanotubes or graphene at concentrations of 0.1-0.5% by weight can significantly enhance mechanical properties. These nanomaterials create effective barriers to dislocation movement within the metal matrix, improving yield strength by up to 40% while adding minimal weight.

Heat treatment protocols have been refined specifically for V4 engine block applications, with T6 and T7 treatments optimized to balance hardness and ductility. Advanced controlled cooling techniques during these treatments help minimize residual stresses that could otherwise lead to dimensional distortion or premature failure under thermal cycling.

Computational materials science has accelerated development through predictive modeling of alloy behavior under various casting and operating conditions. These models now incorporate machine learning algorithms that can predict microstructural evolution with over 90% accuracy, enabling materials engineers to rapidly iterate and optimize alloy compositions for specific V4 engine performance requirements.

Composite metal matrix materials represent another significant breakthrough, incorporating ceramic particles such as silicon carbide and aluminum oxide into traditional aluminum alloys. These composites demonstrate up to 30% higher tensile strength and 25% improved wear resistance compared to conventional alloys, while maintaining excellent castability characteristics essential for complex V4 engine block geometries.

High-pressure die casting (HPDC) techniques have evolved in conjunction with these material innovations, allowing for more precise control of microstructure formation during solidification. The latest HPDC systems operate at pressures exceeding 2000 bar, creating denser castings with fewer porosity defects and more uniform grain structures. This results in engine blocks with superior fatigue resistance and dimensional stability.

Nano-reinforced alloys have emerged as a promising frontier, with research showing that additions of carbon nanotubes or graphene at concentrations of 0.1-0.5% by weight can significantly enhance mechanical properties. These nanomaterials create effective barriers to dislocation movement within the metal matrix, improving yield strength by up to 40% while adding minimal weight.

Heat treatment protocols have been refined specifically for V4 engine block applications, with T6 and T7 treatments optimized to balance hardness and ductility. Advanced controlled cooling techniques during these treatments help minimize residual stresses that could otherwise lead to dimensional distortion or premature failure under thermal cycling.

Computational materials science has accelerated development through predictive modeling of alloy behavior under various casting and operating conditions. These models now incorporate machine learning algorithms that can predict microstructural evolution with over 90% accuracy, enabling materials engineers to rapidly iterate and optimize alloy compositions for specific V4 engine performance requirements.

Environmental Impact and Sustainability Considerations

The environmental impact of V4 engine block casting processes has become increasingly significant as automotive manufacturers face stricter regulations and growing consumer demand for sustainable products. Traditional casting methods, particularly sand casting and die casting, generate substantial environmental concerns through high energy consumption, greenhouse gas emissions, and waste production. The melting of aluminum alloys for V4 blocks typically requires temperatures exceeding 700°C, consuming between 4-7 kWh of energy per kilogram of processed material.

Material efficiency presents another critical environmental challenge, with conventional casting techniques generating 8-15% scrap rates. This waste not only represents lost resources but also creates disposal issues. Additionally, the use of release agents, binders, and other chemical additives in the casting process introduces potential environmental contaminants that require proper management and disposal.

Water usage in casting operations, particularly for cooling and cleaning processes, ranges from 2-5 cubic meters per ton of cast material. This consumption, coupled with the potential for contaminated wastewater discharge, places additional pressure on local water resources and treatment facilities. Modern facilities have begun implementing closed-loop water systems, reducing freshwater requirements by up to 80%.

Recent advancements in sustainable casting technologies offer promising alternatives for V4 engine block production. Digital sand printing eliminates the need for traditional patterns and cores, reducing material waste by up to 70% while enabling more complex internal cooling channels that improve engine efficiency. Inorganic binder systems have emerged as replacements for conventional phenolic urethane binders, reducing volatile organic compound (VOC) emissions by approximately 90%.

The transition to recycled aluminum feedstock represents another significant sustainability improvement. Using secondary aluminum in V4 engine block production reduces energy consumption by approximately 95% compared to primary aluminum, while maintaining comparable mechanical properties when proper alloy control and degassing procedures are implemented. Several major manufacturers have committed to increasing recycled content in their engine blocks to 75% or higher by 2025.

Carbon footprint assessments of modern V4 engine block casting reveal that implementing best available technologies can reduce lifecycle emissions by 30-40% compared to industry standard practices. These improvements stem from combined enhancements in energy efficiency, material utilization, and process optimization. Furthermore, end-of-life considerations have gained prominence, with design modifications facilitating easier disassembly and material separation for future recycling.

Material efficiency presents another critical environmental challenge, with conventional casting techniques generating 8-15% scrap rates. This waste not only represents lost resources but also creates disposal issues. Additionally, the use of release agents, binders, and other chemical additives in the casting process introduces potential environmental contaminants that require proper management and disposal.

Water usage in casting operations, particularly for cooling and cleaning processes, ranges from 2-5 cubic meters per ton of cast material. This consumption, coupled with the potential for contaminated wastewater discharge, places additional pressure on local water resources and treatment facilities. Modern facilities have begun implementing closed-loop water systems, reducing freshwater requirements by up to 80%.

Recent advancements in sustainable casting technologies offer promising alternatives for V4 engine block production. Digital sand printing eliminates the need for traditional patterns and cores, reducing material waste by up to 70% while enabling more complex internal cooling channels that improve engine efficiency. Inorganic binder systems have emerged as replacements for conventional phenolic urethane binders, reducing volatile organic compound (VOC) emissions by approximately 90%.

The transition to recycled aluminum feedstock represents another significant sustainability improvement. Using secondary aluminum in V4 engine block production reduces energy consumption by approximately 95% compared to primary aluminum, while maintaining comparable mechanical properties when proper alloy control and degassing procedures are implemented. Several major manufacturers have committed to increasing recycled content in their engine blocks to 75% or higher by 2025.

Carbon footprint assessments of modern V4 engine block casting reveal that implementing best available technologies can reduce lifecycle emissions by 30-40% compared to industry standard practices. These improvements stem from combined enhancements in energy efficiency, material utilization, and process optimization. Furthermore, end-of-life considerations have gained prominence, with design modifications facilitating easier disassembly and material separation for future recycling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!