How to Assess V4 Engine Gasket Performance

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Gasket Technology Background and Objectives

Engine gaskets have evolved significantly since the introduction of internal combustion engines in the late 19th century. Initially, simple materials like paper, cork, and asbestos were used, but as engine performance demands increased, gasket technology has undergone continuous refinement. The V4 engine configuration, while less common than inline-four or V6 designs, presents unique gasket performance challenges due to its compact layout and specific thermal expansion characteristics.

The evolution of V4 engine gasket technology has been driven by increasing power density, higher operating temperatures, and stricter emission regulations. Modern gaskets must withstand temperatures exceeding 1000°F (538°C) in some areas while maintaining perfect seals under varying pressure conditions. The transition from asbestos-based materials to advanced composites and multi-layer steel (MLS) designs represents a significant technological leap in this field.

Current technical objectives in V4 engine gasket performance assessment focus on developing standardized testing protocols that accurately predict real-world performance. These objectives include establishing reliable methods for evaluating thermal cycling resistance, chemical compatibility with modern engine fluids, and long-term compression set resistance under dynamic load conditions.

Another critical objective is the development of non-destructive testing methodologies that can assess gasket integrity without engine disassembly. This includes advanced imaging techniques, pressure decay testing, and thermal signature analysis that can identify potential failure points before catastrophic leakage occurs.

The industry also aims to correlate laboratory testing with field performance more accurately. Historical data shows that traditional bench tests often fail to predict certain failure modes that emerge only after thousands of operating hours. Bridging this gap requires sophisticated test rigs that can simulate the complex interplay of thermal, mechanical, and chemical stresses experienced in actual engine operation.

Environmental considerations have become increasingly important in gasket technology development. The elimination of environmentally harmful materials while maintaining or improving performance represents a significant technical challenge. This includes finding alternatives to certain fluoroelastomers and developing manufacturing processes with lower environmental impacts.

Digitalization of gasket performance assessment is an emerging objective, with computational fluid dynamics (CFD) and finite element analysis (FEA) becoming essential tools for predicting gasket behavior. These simulation approaches aim to reduce development time and costs while improving reliability predictions across diverse operating conditions.

The evolution of V4 engine gasket technology has been driven by increasing power density, higher operating temperatures, and stricter emission regulations. Modern gaskets must withstand temperatures exceeding 1000°F (538°C) in some areas while maintaining perfect seals under varying pressure conditions. The transition from asbestos-based materials to advanced composites and multi-layer steel (MLS) designs represents a significant technological leap in this field.

Current technical objectives in V4 engine gasket performance assessment focus on developing standardized testing protocols that accurately predict real-world performance. These objectives include establishing reliable methods for evaluating thermal cycling resistance, chemical compatibility with modern engine fluids, and long-term compression set resistance under dynamic load conditions.

Another critical objective is the development of non-destructive testing methodologies that can assess gasket integrity without engine disassembly. This includes advanced imaging techniques, pressure decay testing, and thermal signature analysis that can identify potential failure points before catastrophic leakage occurs.

The industry also aims to correlate laboratory testing with field performance more accurately. Historical data shows that traditional bench tests often fail to predict certain failure modes that emerge only after thousands of operating hours. Bridging this gap requires sophisticated test rigs that can simulate the complex interplay of thermal, mechanical, and chemical stresses experienced in actual engine operation.

Environmental considerations have become increasingly important in gasket technology development. The elimination of environmentally harmful materials while maintaining or improving performance represents a significant technical challenge. This includes finding alternatives to certain fluoroelastomers and developing manufacturing processes with lower environmental impacts.

Digitalization of gasket performance assessment is an emerging objective, with computational fluid dynamics (CFD) and finite element analysis (FEA) becoming essential tools for predicting gasket behavior. These simulation approaches aim to reduce development time and costs while improving reliability predictions across diverse operating conditions.

Market Demand Analysis for High-Performance Engine Gaskets

The global market for high-performance engine gaskets has experienced significant growth in recent years, driven by increasing demand for more efficient and powerful engines across various industries. The automotive sector represents the largest market segment, with a strong emphasis on performance vehicles requiring specialized gasket solutions that can withstand extreme conditions. This demand is particularly evident in racing applications, luxury vehicles, and high-performance consumer automobiles where engine reliability under stress is paramount.

Commercial transportation has emerged as another substantial market segment, with fleet operators seeking gasket solutions that extend maintenance intervals and improve fuel efficiency. The aviation and marine industries similarly require high-performance gaskets capable of maintaining seal integrity under variable pressure and temperature conditions, contributing to overall market expansion.

Market research indicates that the performance characteristics most valued by end-users include temperature resistance, pressure tolerance, chemical compatibility, and longevity. V4 engine configurations, while less common than inline or V6/V8 layouts, represent a specialized market with unique gasket requirements due to their compact design and specific thermal expansion patterns.

Regional analysis shows North America and Europe leading in market value, primarily due to the concentration of performance vehicle manufacturers and motorsport industries. However, the Asia-Pacific region demonstrates the fastest growth rate, attributed to expanding automotive manufacturing capabilities and increasing consumer preference for high-performance vehicles in emerging economies like China and India.

The aftermarket segment for high-performance gaskets shows particularly strong potential, with consumers increasingly willing to invest in premium components that offer improved engine performance and reliability. This trend is supported by the growing DIY automotive culture and online communities focused on engine modifications and performance enhancements.

Material innovation is driving significant market evolution, with manufacturers moving beyond traditional materials toward advanced composites, multi-layer steel designs, and specialized coatings that enhance gasket performance. These innovations command premium pricing, contributing to overall market value growth despite relatively stable unit sales in mature markets.

Environmental regulations and efficiency standards are creating additional market opportunities, as manufacturers develop gasket solutions that help engines meet stricter emissions requirements while maintaining performance characteristics. This regulatory pressure is expected to continue influencing product development and market dynamics in the coming years.

Commercial transportation has emerged as another substantial market segment, with fleet operators seeking gasket solutions that extend maintenance intervals and improve fuel efficiency. The aviation and marine industries similarly require high-performance gaskets capable of maintaining seal integrity under variable pressure and temperature conditions, contributing to overall market expansion.

Market research indicates that the performance characteristics most valued by end-users include temperature resistance, pressure tolerance, chemical compatibility, and longevity. V4 engine configurations, while less common than inline or V6/V8 layouts, represent a specialized market with unique gasket requirements due to their compact design and specific thermal expansion patterns.

Regional analysis shows North America and Europe leading in market value, primarily due to the concentration of performance vehicle manufacturers and motorsport industries. However, the Asia-Pacific region demonstrates the fastest growth rate, attributed to expanding automotive manufacturing capabilities and increasing consumer preference for high-performance vehicles in emerging economies like China and India.

The aftermarket segment for high-performance gaskets shows particularly strong potential, with consumers increasingly willing to invest in premium components that offer improved engine performance and reliability. This trend is supported by the growing DIY automotive culture and online communities focused on engine modifications and performance enhancements.

Material innovation is driving significant market evolution, with manufacturers moving beyond traditional materials toward advanced composites, multi-layer steel designs, and specialized coatings that enhance gasket performance. These innovations command premium pricing, contributing to overall market value growth despite relatively stable unit sales in mature markets.

Environmental regulations and efficiency standards are creating additional market opportunities, as manufacturers develop gasket solutions that help engines meet stricter emissions requirements while maintaining performance characteristics. This regulatory pressure is expected to continue influencing product development and market dynamics in the coming years.

Current Gasket Assessment Methodologies and Challenges

The assessment of V4 engine gasket performance currently employs a combination of laboratory testing, field trials, and computational methods. Standard laboratory evaluations include compression set testing, which measures a gasket's ability to recover after prolonged compression, and sealability testing that evaluates leakage prevention under various pressure conditions. Thermal cycling tests are particularly critical for V4 engine applications, as they simulate the repeated heating and cooling cycles that gaskets experience during normal engine operation.

Pressure resistance testing represents another cornerstone methodology, where gaskets are subjected to pressures exceeding normal operating conditions to determine their failure points. This is complemented by chemical compatibility assessments that evaluate gasket material degradation when exposed to engine fluids such as coolant, oil, and fuel.

Despite these established methodologies, significant challenges persist in gasket performance assessment. The complex geometry of V4 engine interfaces creates uneven stress distributions that are difficult to replicate in standardized tests. Temperature gradients across the gasket surface further complicate testing, as different sections experience varying thermal conditions simultaneously.

Long-term durability prediction remains particularly problematic. Accelerated aging tests attempt to compress years of service into weeks of testing, but correlation between accelerated test results and actual field performance is often imprecise. This disconnect between laboratory findings and real-world performance represents one of the industry's most persistent challenges.

The dynamic nature of engine operation presents additional assessment difficulties. Vibration effects, which can cause gasket fretting and micro-movement, are challenging to simulate accurately in controlled environments. Similarly, the combined effects of thermal cycling, chemical exposure, and mechanical stress—conditions that occur simultaneously in actual engines—are difficult to replicate in isolation.

Emerging computational methods, including Finite Element Analysis (FEA) and computational fluid dynamics, offer promising alternatives to physical testing but face validation challenges. These simulation approaches require extensive calibration against physical test data to ensure reliability, creating a circular dependency on the very physical tests they aim to supplement or replace.

Non-destructive evaluation techniques for in-service gaskets represent another frontier in assessment methodology. Technologies such as ultrasonic imaging and infrared thermography show promise for detecting early signs of gasket failure without engine disassembly, but standardization of these techniques remains underdeveloped.

Pressure resistance testing represents another cornerstone methodology, where gaskets are subjected to pressures exceeding normal operating conditions to determine their failure points. This is complemented by chemical compatibility assessments that evaluate gasket material degradation when exposed to engine fluids such as coolant, oil, and fuel.

Despite these established methodologies, significant challenges persist in gasket performance assessment. The complex geometry of V4 engine interfaces creates uneven stress distributions that are difficult to replicate in standardized tests. Temperature gradients across the gasket surface further complicate testing, as different sections experience varying thermal conditions simultaneously.

Long-term durability prediction remains particularly problematic. Accelerated aging tests attempt to compress years of service into weeks of testing, but correlation between accelerated test results and actual field performance is often imprecise. This disconnect between laboratory findings and real-world performance represents one of the industry's most persistent challenges.

The dynamic nature of engine operation presents additional assessment difficulties. Vibration effects, which can cause gasket fretting and micro-movement, are challenging to simulate accurately in controlled environments. Similarly, the combined effects of thermal cycling, chemical exposure, and mechanical stress—conditions that occur simultaneously in actual engines—are difficult to replicate in isolation.

Emerging computational methods, including Finite Element Analysis (FEA) and computational fluid dynamics, offer promising alternatives to physical testing but face validation challenges. These simulation approaches require extensive calibration against physical test data to ensure reliability, creating a circular dependency on the very physical tests they aim to supplement or replace.

Non-destructive evaluation techniques for in-service gaskets represent another frontier in assessment methodology. Technologies such as ultrasonic imaging and infrared thermography show promise for detecting early signs of gasket failure without engine disassembly, but standardization of these techniques remains underdeveloped.

Contemporary V4 Engine Gasket Performance Evaluation Methods

01 Advanced gasket materials for V4 engines

Various advanced materials are used in V4 engine gaskets to improve performance and durability. These materials include composite materials, metal-reinforced elastomers, and specialized coatings that can withstand high temperatures and pressures. The selection of appropriate gasket materials is crucial for ensuring proper sealing, preventing leakage, and maintaining engine efficiency under various operating conditions.- Advanced gasket materials for V4 engines: Modern V4 engine gaskets utilize advanced materials to enhance performance and durability. These materials include multi-layer steel (MLS), composite materials, and specialized coatings that can withstand high temperatures and pressures. The improved materials help prevent leakage, maintain compression, and extend the service life of the engine. These advanced gaskets are designed specifically to handle the unique stresses and thermal expansion characteristics of V4 engine configurations.

- Cylinder head gasket sealing innovations: Innovations in cylinder head gasket sealing technology have significantly improved V4 engine performance. These innovations include embossed sealing beads, variable thickness designs, and integrated fire rings that enhance combustion chamber sealing. The improved sealing prevents compression loss, maintains optimal combustion efficiency, and reduces emissions. These technologies are particularly important for V4 engines where the compact design creates unique sealing challenges at the cylinder head interface.

- Thermal management solutions in gasket design: Thermal management is critical for V4 engine gasket performance. Modern gaskets incorporate thermal barriers, heat dissipation channels, and temperature-resistant elastomers to manage heat flow between engine components. These features help maintain consistent operating temperatures, prevent thermal distortion, and protect sensitive components from excessive heat. Effective thermal management in gasket design contributes to improved engine efficiency, reduced wear, and enhanced overall performance of V4 engines.

- Vibration dampening and stress distribution features: V4 engines generate unique vibration patterns that require specialized gasket designs. Modern gaskets incorporate vibration dampening features, stress distribution zones, and variable compression areas to absorb and distribute mechanical forces. These features help prevent gasket failure due to fatigue, maintain proper sealing under dynamic conditions, and reduce noise and vibration. The improved stress management contributes to longer gasket life and more reliable engine performance in various operating conditions.

- Installation and maintenance innovations: Innovations in gasket installation and maintenance have improved V4 engine performance reliability. These include pre-installed positioning guides, torque-limiting features, and condition monitoring capabilities. Some gaskets incorporate wear indicators or smart materials that change properties to signal replacement needs. Improved installation designs ensure proper alignment and compression, reducing the risk of improper installation that could lead to premature failure. These innovations help maintain optimal engine performance throughout the service life of the gasket.

02 Cylinder head gasket design for V4 engines

Specialized cylinder head gasket designs for V4 engines focus on optimizing the sealing between the cylinder head and engine block. These designs incorporate features such as multi-layer steel construction, embossed stopper layers, and variable thickness to accommodate the unique firing order and thermal expansion characteristics of V4 engines. Improved cylinder head gasket designs contribute to better compression ratios, reduced blow-by, and enhanced overall engine performance.Expand Specific Solutions03 Thermal management in V4 engine gaskets

Thermal management is a critical aspect of V4 engine gasket performance. Innovative gasket designs incorporate features that help manage heat distribution, prevent thermal distortion, and maintain proper sealing under varying temperature conditions. These features include thermal barriers, heat-dissipating elements, and materials with controlled thermal expansion properties. Effective thermal management in gaskets contributes to improved engine efficiency, reduced emissions, and extended service life.Expand Specific Solutions04 Sealing technology for V4 engine intake and exhaust systems

Specialized sealing technologies are employed for V4 engine intake and exhaust systems to prevent leakage and maintain optimal performance. These technologies include advanced gasket designs with multiple sealing beads, integrated fire rings, and variable compression zones. The sealing solutions are engineered to withstand the high temperatures and pressure fluctuations characteristic of V4 engine operation, ensuring efficient combustion and power delivery while minimizing emissions.Expand Specific Solutions05 Innovative gasket installation and compression control

Innovative approaches to gasket installation and compression control in V4 engines focus on achieving optimal sealing performance. These approaches include precision-engineered torque sequences, controlled compression limiters, and self-positioning features that ensure proper gasket alignment during assembly. Advanced compression control technologies help maintain consistent gasket pressure distribution, preventing over-compression or under-compression that could lead to sealing failures or engine damage during operation.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Gasket Technology

The V4 engine gasket performance assessment market is currently in a growth phase, with increasing demand driven by automotive efficiency and emissions regulations. The market is characterized by a mix of established automotive manufacturers (Honda, Ford, Hyundai, Kia) and specialized component suppliers (Federal-Mogul, Tenneco). Technical maturity varies significantly across players, with traditional OEMs like Honda, Ford, and Hyundai demonstrating advanced gasket testing capabilities, while specialized suppliers like Federal-Mogul and Bosch lead in innovative materials and testing methodologies. The competitive landscape is evolving as companies like Caterpillar and Weichai Power bring heavy-duty engine expertise to gasket performance assessment, creating a dynamic environment where cross-industry collaboration is increasingly valuable for addressing complex sealing challenges in modern V4 engines.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a comprehensive gasket performance assessment system that combines physical testing and advanced simulation techniques. Their approach includes multi-layer steel (MLS) gasket evaluation using finite element analysis (FEA) to predict thermal and mechanical behavior under various operating conditions. Honda's testing protocol incorporates specialized equipment for measuring micro-deformation under cylinder pressure variations and thermal cycling tests that simulate extreme engine operating conditions. Their proprietary "Gasket Sealing Index" methodology quantifies sealing performance across different engine designs, allowing for standardized comparison across their V4 engine portfolio. Honda also employs optical measurement systems to analyze gasket compression and recovery characteristics during engine operation cycles.

Strengths: Integrated approach combining simulation and physical testing provides comprehensive performance data; proprietary metrics enable standardized comparison across engine families. Weaknesses: System requires significant computational resources and specialized testing equipment, potentially limiting deployment across all manufacturing facilities.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered a multi-phase gasket assessment methodology specifically optimized for V4 engine configurations. Their system employs pressure-sensitive film technology to map contact stress distribution across the entire gasket surface, providing high-resolution data on sealing effectiveness. Ford's approach integrates real-time monitoring during engine operation using embedded microsensors that track gasket compression, temperature gradients, and fluid migration patterns. Their assessment protocol includes accelerated durability testing that simulates up to 150,000 miles of operation in controlled laboratory conditions. Ford has also developed specialized computational fluid dynamics (CFD) models that predict coolant and oil flow behavior around gasket interfaces, helping identify potential leak paths before physical prototyping. Their testing regimen includes chemical compatibility assessment to evaluate gasket material degradation under exposure to modern engine fluids and additives.

Strengths: Real-time monitoring capabilities provide dynamic performance data during actual engine operation; accelerated testing protocols reduce development time. Weaknesses: Complex sensor integration increases costs and may introduce reliability concerns in production environments; system calibration requires extensive baseline data.

Critical Patents and Technical Literature on Gasket Assessment

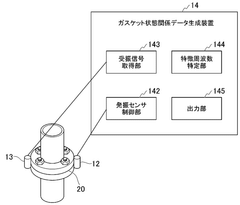

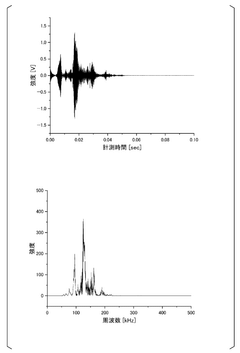

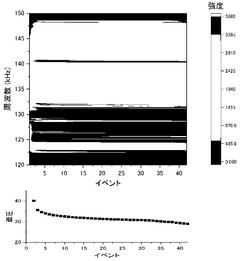

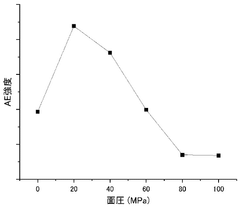

Gasket state estimation method, gasket state estimation device, and program

PatentWO2025070214A1

Innovation

- A method and device that utilize vibrations of a feature frequency to estimate the state of a gasket by measuring the signal strength of received vibrations and correlating it with the gasket's state, using sensors and a control unit to input and measure vibrations.

Method for the assessment of the dispersing capacity of new or used lubricating compositions and of additives for lubricating compositions

PatentActiveUS20230168237A1

Innovation

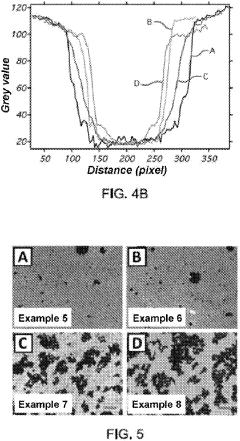

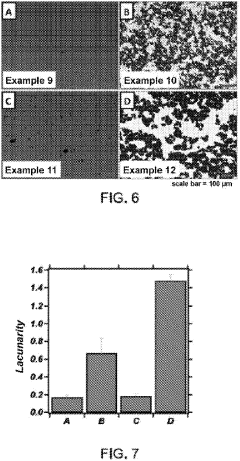

- A laboratory-based method using optical microscopy and lacunarity analysis to assess the dispersing capacity of lubricating compositions and additives, involving the preparation of carbonaceous particulate dispersions and calculation of lacunarity, a parameter measuring image heterogeneity, to quantify dispersion efficiency without requiring engine tests.

Environmental Impact and Sustainability Considerations

The environmental impact of V4 engine gasket performance assessment extends beyond mere functionality testing to encompass broader sustainability considerations. Modern automotive engineering increasingly recognizes that gasket materials and their lifecycle management significantly contribute to a vehicle's overall environmental footprint. Traditional gasket materials often contain non-biodegradable compounds, heavy metals, and petroleum-based elastomers that pose disposal challenges and environmental hazards when they reach end-of-life.

Performance assessment methodologies must now incorporate leachate analysis to determine potential soil and groundwater contamination risks from discarded gaskets. Studies indicate that certain gasket compounds can release harmful substances when exposed to environmental conditions, with degradation rates varying significantly based on material composition. Advanced assessment protocols now measure these degradation patterns and resulting emissions under simulated environmental stress conditions.

Manufacturing processes for high-performance gaskets typically involve energy-intensive procedures and chemical treatments that generate considerable carbon emissions. Life cycle assessment (LCA) has become an essential component of comprehensive gasket evaluation, quantifying environmental impacts from raw material extraction through manufacturing, use phase, and eventual disposal. Recent industry data suggests that gasket production contributes approximately 2-5% of a complete engine's manufacturing carbon footprint.

Sustainable alternatives are emerging in response to these concerns. Bio-based elastomers derived from renewable resources show promising performance characteristics while reducing dependency on petroleum-based compounds. Recycled metal content in composite gaskets offers another pathway toward sustainability, with some manufacturers achieving up to 40% recycled content without compromising performance integrity.

Water consumption during gasket manufacturing and testing represents another critical environmental consideration. Traditional wet-processing techniques can consume significant water resources and generate contaminated wastewater requiring specialized treatment. Advanced dry-processing methods and closed-loop water systems are being developed to address these impacts, reducing water usage by up to 70% in some facilities.

Regulatory frameworks increasingly mandate environmental performance metrics alongside traditional mechanical specifications. The EU's End-of-Life Vehicle Directive and similar regulations worldwide have established strict requirements for material recoverability and recyclability, directly impacting gasket design and material selection criteria. Performance assessment protocols must now verify compliance with these environmental regulations as part of standard evaluation procedures.

Performance assessment methodologies must now incorporate leachate analysis to determine potential soil and groundwater contamination risks from discarded gaskets. Studies indicate that certain gasket compounds can release harmful substances when exposed to environmental conditions, with degradation rates varying significantly based on material composition. Advanced assessment protocols now measure these degradation patterns and resulting emissions under simulated environmental stress conditions.

Manufacturing processes for high-performance gaskets typically involve energy-intensive procedures and chemical treatments that generate considerable carbon emissions. Life cycle assessment (LCA) has become an essential component of comprehensive gasket evaluation, quantifying environmental impacts from raw material extraction through manufacturing, use phase, and eventual disposal. Recent industry data suggests that gasket production contributes approximately 2-5% of a complete engine's manufacturing carbon footprint.

Sustainable alternatives are emerging in response to these concerns. Bio-based elastomers derived from renewable resources show promising performance characteristics while reducing dependency on petroleum-based compounds. Recycled metal content in composite gaskets offers another pathway toward sustainability, with some manufacturers achieving up to 40% recycled content without compromising performance integrity.

Water consumption during gasket manufacturing and testing represents another critical environmental consideration. Traditional wet-processing techniques can consume significant water resources and generate contaminated wastewater requiring specialized treatment. Advanced dry-processing methods and closed-loop water systems are being developed to address these impacts, reducing water usage by up to 70% in some facilities.

Regulatory frameworks increasingly mandate environmental performance metrics alongside traditional mechanical specifications. The EU's End-of-Life Vehicle Directive and similar regulations worldwide have established strict requirements for material recoverability and recyclability, directly impacting gasket design and material selection criteria. Performance assessment protocols must now verify compliance with these environmental regulations as part of standard evaluation procedures.

Durability and Lifecycle Testing Protocols

Durability testing protocols for V4 engine gaskets must follow systematic methodologies to accurately predict field performance. The primary testing framework involves accelerated aging tests where gaskets undergo thermal cycling between -40°C and 150°C for 1,000 cycles, simulating years of operational stress in weeks. This protocol identifies potential failure modes related to thermal expansion and contraction that might occur during normal engine operation.

Pressure resistance testing represents another critical protocol, subjecting gaskets to pressures 1.5-2 times the maximum operating pressure of the engine. These tests typically run for 500 hours continuously, with pressure fluctuations programmed to simulate various driving conditions. Modern testing facilities incorporate real-time monitoring systems that detect even microscopic leaks, providing valuable data on gasket integrity under sustained pressure conditions.

Chemical compatibility assessment forms an essential component of gasket lifecycle evaluation. Test specimens are immersed in engine oil, coolant, and fuel at elevated temperatures (120-140°C) for periods ranging from 500 to 1,000 hours. Weight change, dimensional stability, and mechanical property retention are measured to determine resistance to chemical degradation. This protocol has proven particularly valuable for identifying compatibility issues with newer biofuel blends and synthetic oils.

Vibration endurance testing employs multi-axis vibration tables that reproduce the complex vibrational patterns experienced in actual V4 engine applications. Gaskets are subjected to frequencies ranging from 10Hz to 2000Hz at varying amplitudes for durations of 100-200 hours. High-speed imaging during these tests reveals potential areas of gasket movement or fretting that could lead to premature failure.

Compression set resistance represents a key performance indicator for gasket materials. Standard testing involves compressing gaskets to their specified torque values and maintaining this compression at elevated temperatures (typically 100-125°C) for 1,000 hours. Recovery measurements taken after decompression provide critical data on the gasket's ability to maintain sealing force over time. Industry standards typically require at least 70% recovery after testing to ensure adequate long-term sealing performance.

Combined environmental testing protocols integrate multiple stressors simultaneously, creating more realistic test conditions. These protocols typically include thermal cycling while under pressure, with periodic introduction of vibration profiles and chemical exposure. While more complex to implement, these integrated tests have demonstrated superior correlation with actual field performance compared to isolated single-factor tests.

Pressure resistance testing represents another critical protocol, subjecting gaskets to pressures 1.5-2 times the maximum operating pressure of the engine. These tests typically run for 500 hours continuously, with pressure fluctuations programmed to simulate various driving conditions. Modern testing facilities incorporate real-time monitoring systems that detect even microscopic leaks, providing valuable data on gasket integrity under sustained pressure conditions.

Chemical compatibility assessment forms an essential component of gasket lifecycle evaluation. Test specimens are immersed in engine oil, coolant, and fuel at elevated temperatures (120-140°C) for periods ranging from 500 to 1,000 hours. Weight change, dimensional stability, and mechanical property retention are measured to determine resistance to chemical degradation. This protocol has proven particularly valuable for identifying compatibility issues with newer biofuel blends and synthetic oils.

Vibration endurance testing employs multi-axis vibration tables that reproduce the complex vibrational patterns experienced in actual V4 engine applications. Gaskets are subjected to frequencies ranging from 10Hz to 2000Hz at varying amplitudes for durations of 100-200 hours. High-speed imaging during these tests reveals potential areas of gasket movement or fretting that could lead to premature failure.

Compression set resistance represents a key performance indicator for gasket materials. Standard testing involves compressing gaskets to their specified torque values and maintaining this compression at elevated temperatures (typically 100-125°C) for 1,000 hours. Recovery measurements taken after decompression provide critical data on the gasket's ability to maintain sealing force over time. Industry standards typically require at least 70% recovery after testing to ensure adequate long-term sealing performance.

Combined environmental testing protocols integrate multiple stressors simultaneously, creating more realistic test conditions. These protocols typically include thermal cycling while under pressure, with periodic introduction of vibration profiles and chemical exposure. While more complex to implement, these integrated tests have demonstrated superior correlation with actual field performance compared to isolated single-factor tests.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!