Measuring V4 Engine Exhaust Back Pressure Levels

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Exhaust Back Pressure Background and Objectives

Exhaust back pressure measurement in V4 engines has evolved significantly over the past decades, transitioning from rudimentary mechanical gauges to sophisticated electronic sensors and computational fluid dynamics (CFD) modeling. This technological progression has been driven by increasingly stringent emission regulations, performance optimization requirements, and the automotive industry's push toward more efficient engine designs.

The V4 engine configuration, while less common than inline-4 or V6 designs, presents unique exhaust flow characteristics that necessitate specialized back pressure monitoring approaches. Historically, back pressure was primarily considered a performance limitation factor, but modern understanding recognizes its complex relationship with fuel efficiency, emissions control, and overall engine longevity.

Recent technological advancements have shifted the focus from simply measuring absolute pressure values to understanding dynamic pressure patterns throughout the exhaust system under various operating conditions. This paradigm shift has been facilitated by miniaturized pressure transducers, high-frequency data acquisition systems, and advanced signal processing algorithms capable of real-time analysis.

The primary objective of exhaust back pressure measurement in V4 engines is to establish optimal pressure levels that balance performance requirements with emissions compliance. Excessive back pressure reduces engine efficiency by increasing pumping losses, while insufficient back pressure may compromise emissions control systems such as exhaust gas recirculation (EGR) and catalytic converter performance.

Secondary objectives include identifying potential design improvements in exhaust manifolds, catalytic converters, mufflers, and tailpipes specific to V4 configurations. By precisely quantifying pressure variations across different engine speeds and loads, engineers can optimize component geometries and material selections to achieve ideal flow characteristics.

From a development perspective, accurate back pressure measurement enables predictive maintenance capabilities, as gradual increases in back pressure often indicate system degradation or component failure. This preventive approach extends engine lifespan and maintains optimal performance throughout the vehicle's operational life.

The technological trajectory suggests movement toward integrated measurement systems that combine traditional pressure sensors with temperature, flow rate, and exhaust composition monitoring. These comprehensive systems provide a holistic view of exhaust dynamics, enabling more sophisticated control strategies and adaptive engine management systems tailored to V4 engine architectures.

As automotive manufacturers continue pursuing electrification and hybridization, understanding exhaust back pressure becomes increasingly critical for optimizing the performance of internal combustion components within hybrid powertrains, where V4 engines often serve as range extenders or primary power sources operating under variable load conditions.

The V4 engine configuration, while less common than inline-4 or V6 designs, presents unique exhaust flow characteristics that necessitate specialized back pressure monitoring approaches. Historically, back pressure was primarily considered a performance limitation factor, but modern understanding recognizes its complex relationship with fuel efficiency, emissions control, and overall engine longevity.

Recent technological advancements have shifted the focus from simply measuring absolute pressure values to understanding dynamic pressure patterns throughout the exhaust system under various operating conditions. This paradigm shift has been facilitated by miniaturized pressure transducers, high-frequency data acquisition systems, and advanced signal processing algorithms capable of real-time analysis.

The primary objective of exhaust back pressure measurement in V4 engines is to establish optimal pressure levels that balance performance requirements with emissions compliance. Excessive back pressure reduces engine efficiency by increasing pumping losses, while insufficient back pressure may compromise emissions control systems such as exhaust gas recirculation (EGR) and catalytic converter performance.

Secondary objectives include identifying potential design improvements in exhaust manifolds, catalytic converters, mufflers, and tailpipes specific to V4 configurations. By precisely quantifying pressure variations across different engine speeds and loads, engineers can optimize component geometries and material selections to achieve ideal flow characteristics.

From a development perspective, accurate back pressure measurement enables predictive maintenance capabilities, as gradual increases in back pressure often indicate system degradation or component failure. This preventive approach extends engine lifespan and maintains optimal performance throughout the vehicle's operational life.

The technological trajectory suggests movement toward integrated measurement systems that combine traditional pressure sensors with temperature, flow rate, and exhaust composition monitoring. These comprehensive systems provide a holistic view of exhaust dynamics, enabling more sophisticated control strategies and adaptive engine management systems tailored to V4 engine architectures.

As automotive manufacturers continue pursuing electrification and hybridization, understanding exhaust back pressure becomes increasingly critical for optimizing the performance of internal combustion components within hybrid powertrains, where V4 engines often serve as range extenders or primary power sources operating under variable load conditions.

Market Demand Analysis for Precise Back Pressure Measurement

The global market for precise exhaust back pressure measurement systems in V4 engines has experienced significant growth over the past five years, driven primarily by increasingly stringent emissions regulations and the automotive industry's focus on engine efficiency optimization. Current market analysis indicates that the demand for advanced back pressure measurement technologies is expanding at a compound annual growth rate of approximately 7.8% and is projected to reach $3.2 billion by 2028.

This growth is particularly pronounced in regions with strict emissions standards, such as the European Union, North America, and parts of Asia, where automotive manufacturers must ensure compliance with Euro 7, EPA Tier 3, and equivalent regulations. The need for precise back pressure measurement has become critical as these standards impose lower limits on particulate matter and NOx emissions, which are directly affected by exhaust system performance.

Performance vehicle manufacturers represent a premium segment of this market, where high-precision back pressure measurement is essential for optimizing engine power output and throttle response. Racing teams and high-performance vehicle developers typically demand measurement systems with accuracy within ±0.5% and response times under 10 milliseconds, creating a specialized niche with higher profit margins.

Commercial fleet operators have emerged as another significant market segment, driven by fuel efficiency concerns. Studies have shown that optimized exhaust back pressure can improve fuel economy by 2-4%, representing substantial operational cost savings for large fleets. This has created demand for integrated measurement systems that provide real-time data for fleet management systems.

The aftermarket sector shows considerable potential, with increasing interest from performance enthusiasts and repair shops seeking diagnostic tools for exhaust system evaluation. This segment is expected to grow at 9.3% annually, outpacing the overall market as consumer awareness of exhaust system efficiency increases.

From a technological perspective, market demand is shifting toward wireless, compact, and heat-resistant measurement solutions that can be permanently installed for continuous monitoring. Traditional mechanical gauges are being rapidly replaced by digital sensors with IoT connectivity, allowing for remote diagnostics and predictive maintenance applications.

Industry surveys indicate that customers prioritize durability in harsh environments, with 78% of professional users citing reliability under extreme temperature conditions as a critical purchasing factor. Additionally, 65% of respondents expressed interest in systems that integrate with existing engine management computers for comprehensive performance analysis.

This growth is particularly pronounced in regions with strict emissions standards, such as the European Union, North America, and parts of Asia, where automotive manufacturers must ensure compliance with Euro 7, EPA Tier 3, and equivalent regulations. The need for precise back pressure measurement has become critical as these standards impose lower limits on particulate matter and NOx emissions, which are directly affected by exhaust system performance.

Performance vehicle manufacturers represent a premium segment of this market, where high-precision back pressure measurement is essential for optimizing engine power output and throttle response. Racing teams and high-performance vehicle developers typically demand measurement systems with accuracy within ±0.5% and response times under 10 milliseconds, creating a specialized niche with higher profit margins.

Commercial fleet operators have emerged as another significant market segment, driven by fuel efficiency concerns. Studies have shown that optimized exhaust back pressure can improve fuel economy by 2-4%, representing substantial operational cost savings for large fleets. This has created demand for integrated measurement systems that provide real-time data for fleet management systems.

The aftermarket sector shows considerable potential, with increasing interest from performance enthusiasts and repair shops seeking diagnostic tools for exhaust system evaluation. This segment is expected to grow at 9.3% annually, outpacing the overall market as consumer awareness of exhaust system efficiency increases.

From a technological perspective, market demand is shifting toward wireless, compact, and heat-resistant measurement solutions that can be permanently installed for continuous monitoring. Traditional mechanical gauges are being rapidly replaced by digital sensors with IoT connectivity, allowing for remote diagnostics and predictive maintenance applications.

Industry surveys indicate that customers prioritize durability in harsh environments, with 78% of professional users citing reliability under extreme temperature conditions as a critical purchasing factor. Additionally, 65% of respondents expressed interest in systems that integrate with existing engine management computers for comprehensive performance analysis.

Current Challenges in Exhaust Back Pressure Measurement

Despite significant advancements in engine diagnostics, measuring exhaust back pressure in V4 engines continues to present several technical challenges that impact both accuracy and reliability. The primary difficulty stems from the complex flow dynamics within the exhaust system, where pulsating gas flows create non-linear pressure patterns that are difficult to capture with conventional measurement techniques. These pulsations vary significantly with engine speed and load, making consistent measurement particularly challenging across different operating conditions.

Temperature-related issues further complicate measurement efforts, as exhaust gases in V4 engines can reach temperatures exceeding 900°C. This extreme thermal environment degrades sensor performance over time and necessitates specialized high-temperature materials that often compromise measurement sensitivity. The trade-off between thermal durability and measurement precision remains a significant engineering challenge.

Spatial constraints within modern V4 engine compartments create additional complications for sensor placement. The optimal measurement locations are frequently inaccessible or require significant modification to the exhaust system, potentially altering the very parameters being measured. This creates a paradoxical situation where the act of measurement can distort the results, particularly in compact engine designs where space optimization is critical.

Calibration drift represents another persistent challenge, as sensors exposed to the harsh exhaust environment experience accelerated aging and performance degradation. This necessitates frequent recalibration or replacement, increasing maintenance costs and potentially introducing measurement inconsistencies over time. The development of self-calibrating systems remains an active area of research but has yet to yield fully reliable solutions.

Signal noise interference from engine vibration, electromagnetic fields from ignition systems, and thermal fluctuations further compromises measurement accuracy. Filtering these unwanted signals without losing critical pressure data requires sophisticated signal processing algorithms that must be carefully tuned to specific engine characteristics.

Cost considerations also present significant barriers to implementing comprehensive back pressure monitoring systems. High-precision sensors capable of withstanding the harsh exhaust environment come at premium prices, making widespread adoption economically challenging, particularly in consumer-grade vehicles where cost sensitivity is high.

Finally, there remains a standardization gap in measurement methodologies across the industry. Different manufacturers employ varying approaches to back pressure measurement, making cross-platform comparisons difficult and hindering the development of universal diagnostic standards. This fragmentation slows the overall advancement of exhaust back pressure measurement technology and its integration into mainstream engine management systems.

Temperature-related issues further complicate measurement efforts, as exhaust gases in V4 engines can reach temperatures exceeding 900°C. This extreme thermal environment degrades sensor performance over time and necessitates specialized high-temperature materials that often compromise measurement sensitivity. The trade-off between thermal durability and measurement precision remains a significant engineering challenge.

Spatial constraints within modern V4 engine compartments create additional complications for sensor placement. The optimal measurement locations are frequently inaccessible or require significant modification to the exhaust system, potentially altering the very parameters being measured. This creates a paradoxical situation where the act of measurement can distort the results, particularly in compact engine designs where space optimization is critical.

Calibration drift represents another persistent challenge, as sensors exposed to the harsh exhaust environment experience accelerated aging and performance degradation. This necessitates frequent recalibration or replacement, increasing maintenance costs and potentially introducing measurement inconsistencies over time. The development of self-calibrating systems remains an active area of research but has yet to yield fully reliable solutions.

Signal noise interference from engine vibration, electromagnetic fields from ignition systems, and thermal fluctuations further compromises measurement accuracy. Filtering these unwanted signals without losing critical pressure data requires sophisticated signal processing algorithms that must be carefully tuned to specific engine characteristics.

Cost considerations also present significant barriers to implementing comprehensive back pressure monitoring systems. High-precision sensors capable of withstanding the harsh exhaust environment come at premium prices, making widespread adoption economically challenging, particularly in consumer-grade vehicles where cost sensitivity is high.

Finally, there remains a standardization gap in measurement methodologies across the industry. Different manufacturers employ varying approaches to back pressure measurement, making cross-platform comparisons difficult and hindering the development of universal diagnostic standards. This fragmentation slows the overall advancement of exhaust back pressure measurement technology and its integration into mainstream engine management systems.

Current Measurement Solutions and Methodologies

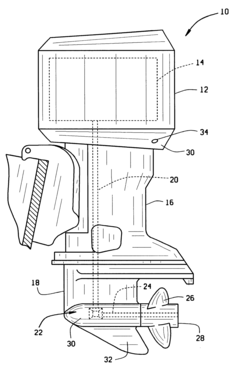

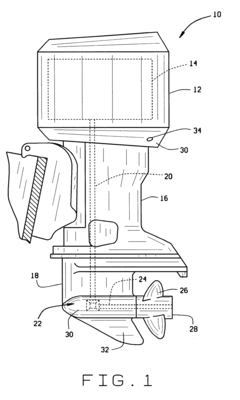

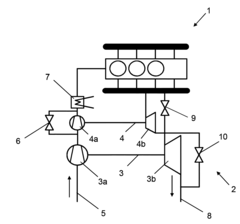

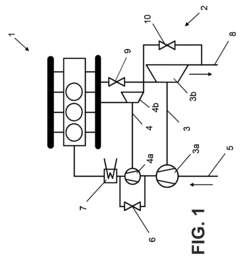

01 Exhaust back pressure control systems for V4 engines

Various control systems are designed to manage exhaust back pressure in V4 engines. These systems typically include sensors to monitor pressure levels and control units that adjust valves or other components to maintain optimal back pressure. By regulating back pressure, these systems can improve engine performance, fuel efficiency, and emissions control across different operating conditions.- Exhaust back pressure control systems for V4 engines: Various control systems are designed to manage exhaust back pressure in V4 engines. These systems typically include sensors to monitor pressure levels and actuators to adjust valves or other components that regulate the flow of exhaust gases. By controlling back pressure, these systems can optimize engine performance, fuel efficiency, and emissions across different operating conditions. Advanced control systems may incorporate electronic control units that adjust back pressure based on multiple engine parameters.

- Exhaust valve configurations for managing back pressure: Specialized exhaust valve designs are implemented to regulate back pressure levels in V4 engines. These include variable position valves, butterfly valves, and multi-stage valve systems that can be adjusted based on engine load and speed. Some designs incorporate bypass channels that open at specific pressure thresholds to prevent excessive back pressure. These valve configurations help maintain optimal back pressure levels for improved engine performance while ensuring compliance with emissions standards.

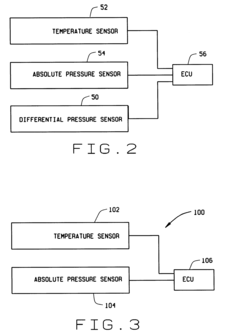

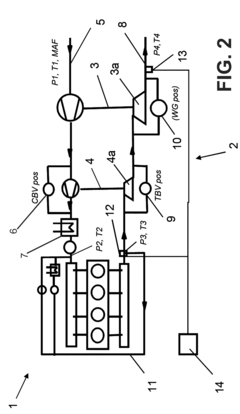

- Measurement and monitoring of exhaust back pressure: Various methods and devices are employed to measure and monitor exhaust back pressure in V4 engines. These include pressure sensors positioned at strategic locations in the exhaust system, diagnostic tools for real-time pressure analysis, and integrated monitoring systems that alert operators to abnormal pressure conditions. Accurate measurement of back pressure is essential for engine management systems to make appropriate adjustments to fuel delivery, timing, and other parameters that affect engine performance and emissions.

- Exhaust manifold designs for optimal back pressure: Specialized exhaust manifold designs are developed to create optimal back pressure levels in V4 engines. These designs consider factors such as runner length, diameter, curvature, and junction configurations. Some manifolds incorporate variable geometry features that can adapt to different engine operating conditions. Properly designed exhaust manifolds help balance the need for sufficient back pressure at low RPMs for torque production while minimizing flow restrictions at higher RPMs for maximum power output.

- Turbocharger integration with back pressure management: Turbocharger systems in V4 engines are designed to work in harmony with back pressure management. These systems often include waste gates, variable geometry turbines, or electronic controllers that help maintain appropriate back pressure levels while harnessing exhaust energy. The integration of turbochargers requires careful balancing of back pressure to ensure efficient turbine operation without creating excessive restriction in the exhaust system. Advanced systems may incorporate multiple turbochargers or hybrid turbocharging solutions to optimize back pressure across the engine's operating range.

02 Exhaust valve configurations for managing back pressure

Specialized exhaust valve designs are implemented to regulate back pressure in V4 engines. These include variable position valves, butterfly valves, and multi-stage valve systems that can be adjusted based on engine load and speed. The valve configurations allow for dynamic control of exhaust flow, enabling optimal back pressure levels for different driving conditions and performance requirements.Expand Specific Solutions03 Back pressure measurement and monitoring techniques

Advanced techniques for measuring and monitoring exhaust back pressure in V4 engines involve pressure sensors placed at strategic locations in the exhaust system. These sensors provide real-time data on pressure levels, which can be used for diagnostic purposes and to optimize engine performance. The monitoring systems can detect abnormal back pressure conditions that might indicate system failures or inefficiencies.Expand Specific Solutions04 Exhaust system designs for optimal back pressure

Specific exhaust system designs are developed to maintain optimal back pressure levels in V4 engines. These designs include carefully calculated pipe diameters, muffler configurations, catalytic converter placements, and resonator chambers. The geometry of these components is engineered to create the ideal balance of back pressure that maximizes power output while minimizing fuel consumption and emissions.Expand Specific Solutions05 Impact of back pressure on V4 engine performance and emissions

Research on the relationship between exhaust back pressure levels and V4 engine performance shows that proper back pressure management significantly affects power output, fuel efficiency, and emissions. Too little back pressure can reduce low-end torque, while excessive back pressure can restrict exhaust flow and reduce high-end power. Finding the optimal balance is crucial for meeting both performance goals and emissions standards across various operating conditions.Expand Specific Solutions

Key Industry Players in Engine Diagnostics Equipment

The exhaust back pressure measurement technology for V4 engines is currently in a growth phase, with an expanding market driven by increasing emission regulations and performance optimization demands. The market is characterized by established automotive giants like Volkswagen AG, Toyota, BMW, and Honda alongside specialized component manufacturers such as Robert Bosch GmbH and Vitesco Technologies. These companies are advancing measurement technologies from basic mechanical gauges to sophisticated electronic sensors with real-time monitoring capabilities. The technology maturity varies significantly across players, with European manufacturers (Bosch, Volkswagen, BMW) generally leading in precision measurement systems, while Asian manufacturers (Toyota, BYD, Chery) are rapidly closing the gap through increased R&D investments. The integration of IoT and AI analytics is emerging as the next frontier in this field.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced exhaust back pressure measurement systems for V4 engines that integrate digital pressure sensors with their Motronic engine management systems. Their solution employs high-temperature resistant piezoelectric sensors positioned strategically in the exhaust manifold to provide real-time pressure readings with accuracy up to ±0.5%. The system incorporates temperature compensation algorithms to ensure measurement stability across the wide thermal range experienced in exhaust systems (from -40°C to +850°C). Bosch's approach includes wireless data transmission capabilities allowing for remote monitoring and diagnostics, with sampling rates up to 1000Hz to capture transient pressure phenomena. Their technology integrates with vehicle OBD-II systems, enabling continuous monitoring and early detection of exhaust system issues such as catalyst clogging or exhaust valve problems.

Strengths: Superior integration with existing engine management systems; high temperature resistance; excellent measurement accuracy across wide operating conditions. Weaknesses: Higher implementation cost compared to simpler solutions; requires specialized calibration procedures; increased system complexity that may impact long-term reliability.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a comprehensive exhaust back pressure measurement system specifically optimized for V4 engine configurations. Their approach utilizes a network of miniaturized silicon-based MEMS pressure sensors with thermal isolation barriers that can withstand the harsh exhaust environment. Toyota's system features dual-redundant sensors at critical measurement points to ensure reliability and data validation. The technology incorporates adaptive sampling rates (10-500Hz) that adjust based on engine operating conditions, conserving processing resources during steady-state operation while capturing detailed data during transients. Toyota's solution includes proprietary signal processing algorithms that filter combustion noise while preserving pressure wave characteristics essential for accurate back pressure analysis. The system is fully integrated with Toyota's ECU architecture, allowing for closed-loop control adjustments based on back pressure readings to optimize engine performance and emissions across various operating conditions.

Strengths: Exceptional durability in harsh exhaust environments; seamless integration with Toyota's engine control systems; adaptive measurement capabilities that balance precision with processing efficiency. Weaknesses: Proprietary nature limits aftermarket compatibility; relatively high component cost; requires specialized diagnostic equipment for service and calibration.

Critical Sensor Technologies for Back Pressure Detection

Methods and apparatus for measuring atmospheric pressure and exhaust back pressure

PatentInactiveUS6283107B1

Innovation

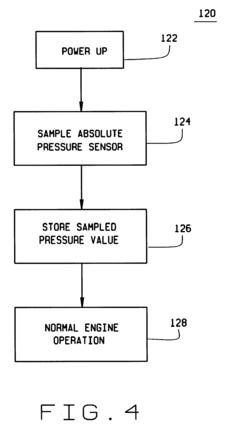

- A single pressure sensor integrated with the electronic control unit (ECU) is used to measure both barometric pressure and exhaust back pressure, with distinct sampling periods to differentiate between the two pressures, eliminating the need for extra sensors.

Determination of exhaust back pressure

PatentInactiveUS20130013166A1

Innovation

- Modeling exhaust back pressure using temperature readings and flow parameters to estimate the overall turbine pressure ratio or difference, allowing for a sensor-free or less vulnerable measurement system that can accommodate aftertreatment devices and improve air path control.

Emissions Regulations Impact on Measurement Standards

The evolution of emissions regulations has fundamentally transformed how exhaust back pressure measurements are conducted and standardized in V4 engine systems. Since the early 2000s, increasingly stringent emissions standards—particularly Euro 6, EPA Tier 3, and China 6—have necessitated more precise and comprehensive measurement methodologies to ensure compliance with lower particulate matter and NOx thresholds.

These regulations have driven the development of standardized measurement protocols that specifically address back pressure as a critical parameter affecting both emissions performance and engine efficiency. The International Organization for Standardization (ISO) has responded by updating ISO 5011 and introducing specialized standards for exhaust system pressure testing, requiring measurements at multiple engine load points rather than single-point evaluations that were previously common.

Regulatory bodies now mandate continuous monitoring capabilities in many markets, shifting measurement standards from periodic laboratory testing to real-time on-board diagnostic systems. This transition has accelerated the adoption of integrated pressure sensors with digital outputs compatible with engine control units (ECUs), replacing traditional analog manometers and pressure gauges that lack the precision required by modern emissions frameworks.

The California Air Resources Board (CARB) has been particularly influential, establishing protocols that specify measurement locations, sensor accuracy requirements, and calibration intervals specifically for back pressure monitoring. These protocols have become de facto global standards, requiring ±1.5% measurement accuracy—a significant increase from the ±5% tolerance previously accepted in the industry.

Temperature compensation has emerged as a critical component of measurement standards, with regulations now requiring pressure readings to be normalized to standard conditions to ensure consistency across varying operating environments. This has led to the development of complex algorithms that account for thermal expansion effects on pressure readings during transient engine operation.

The regulatory landscape has also driven standardization of data reporting formats, with requirements for pressure measurements to be recorded alongside emissions data in standardized units (typically kPa) with specified sampling frequencies. This standardization facilitates regulatory compliance verification and enables meaningful comparisons across different engine designs and testing facilities.

Looking forward, upcoming regulations like Euro 7 and EPA Tier 4 Final are expected to further refine measurement standards, potentially requiring higher sampling rates and integration with predictive emissions models. These evolving standards will continue to shape measurement technologies and methodologies for V4 engine exhaust back pressure evaluation in the coming decade.

These regulations have driven the development of standardized measurement protocols that specifically address back pressure as a critical parameter affecting both emissions performance and engine efficiency. The International Organization for Standardization (ISO) has responded by updating ISO 5011 and introducing specialized standards for exhaust system pressure testing, requiring measurements at multiple engine load points rather than single-point evaluations that were previously common.

Regulatory bodies now mandate continuous monitoring capabilities in many markets, shifting measurement standards from periodic laboratory testing to real-time on-board diagnostic systems. This transition has accelerated the adoption of integrated pressure sensors with digital outputs compatible with engine control units (ECUs), replacing traditional analog manometers and pressure gauges that lack the precision required by modern emissions frameworks.

The California Air Resources Board (CARB) has been particularly influential, establishing protocols that specify measurement locations, sensor accuracy requirements, and calibration intervals specifically for back pressure monitoring. These protocols have become de facto global standards, requiring ±1.5% measurement accuracy—a significant increase from the ±5% tolerance previously accepted in the industry.

Temperature compensation has emerged as a critical component of measurement standards, with regulations now requiring pressure readings to be normalized to standard conditions to ensure consistency across varying operating environments. This has led to the development of complex algorithms that account for thermal expansion effects on pressure readings during transient engine operation.

The regulatory landscape has also driven standardization of data reporting formats, with requirements for pressure measurements to be recorded alongside emissions data in standardized units (typically kPa) with specified sampling frequencies. This standardization facilitates regulatory compliance verification and enables meaningful comparisons across different engine designs and testing facilities.

Looking forward, upcoming regulations like Euro 7 and EPA Tier 4 Final are expected to further refine measurement standards, potentially requiring higher sampling rates and integration with predictive emissions models. These evolving standards will continue to shape measurement technologies and methodologies for V4 engine exhaust back pressure evaluation in the coming decade.

Performance Optimization Through Back Pressure Management

Effective management of exhaust back pressure represents a critical frontier in V4 engine performance optimization. The delicate balance between necessary back pressure for optimal scavenging and excessive restriction that hampers power output demands sophisticated measurement and control strategies. Engineers have discovered that maintaining back pressure within the 8-12 psi range typically yields optimal performance for most V4 configurations, though this varies based on specific engine design parameters.

Advanced electronic control systems now enable real-time back pressure monitoring and adjustment, creating opportunities for dynamic performance optimization across varying operating conditions. These systems utilize pressure sensors strategically positioned throughout the exhaust system, communicating with the engine control unit to make millisecond adjustments to valve timing, fuel delivery, and in some cases, variable geometry components within the exhaust system itself.

Material science advancements have significantly contributed to back pressure management solutions. High-temperature alloys and ceramic composites allow for thinner-walled exhaust components that maintain structural integrity while reducing flow restrictions. These materials also offer superior thermal management properties, reducing heat-induced performance degradation during extended high-load operation.

Computational fluid dynamics (CFD) modeling has revolutionized exhaust system design, enabling engineers to visualize and optimize gas flow patterns before physical prototyping. This approach has led to innovative header designs and collector geometries that maintain necessary back pressure while minimizing flow turbulence and energy losses. The integration of CFD with engine dynamometer testing has shortened development cycles while improving performance outcomes.

Variable geometry exhaust systems represent the cutting edge of back pressure management technology. These systems incorporate electronically controlled valves or movable baffles that can alter exhaust flow characteristics based on engine speed, load, and temperature conditions. In high-performance applications, such systems can provide low back pressure at high RPM for maximum power while maintaining higher back pressure at lower RPM for improved torque and throttle response.

Acoustic considerations must also be integrated into back pressure management strategies, as noise reduction components like mufflers and resonators significantly impact system pressure. Modern designs increasingly employ Helmholtz resonator principles and multiple-chamber configurations that achieve noise cancellation with minimal flow restriction, preserving performance while meeting increasingly stringent noise regulations.

Advanced electronic control systems now enable real-time back pressure monitoring and adjustment, creating opportunities for dynamic performance optimization across varying operating conditions. These systems utilize pressure sensors strategically positioned throughout the exhaust system, communicating with the engine control unit to make millisecond adjustments to valve timing, fuel delivery, and in some cases, variable geometry components within the exhaust system itself.

Material science advancements have significantly contributed to back pressure management solutions. High-temperature alloys and ceramic composites allow for thinner-walled exhaust components that maintain structural integrity while reducing flow restrictions. These materials also offer superior thermal management properties, reducing heat-induced performance degradation during extended high-load operation.

Computational fluid dynamics (CFD) modeling has revolutionized exhaust system design, enabling engineers to visualize and optimize gas flow patterns before physical prototyping. This approach has led to innovative header designs and collector geometries that maintain necessary back pressure while minimizing flow turbulence and energy losses. The integration of CFD with engine dynamometer testing has shortened development cycles while improving performance outcomes.

Variable geometry exhaust systems represent the cutting edge of back pressure management technology. These systems incorporate electronically controlled valves or movable baffles that can alter exhaust flow characteristics based on engine speed, load, and temperature conditions. In high-performance applications, such systems can provide low back pressure at high RPM for maximum power while maintaining higher back pressure at lower RPM for improved torque and throttle response.

Acoustic considerations must also be integrated into back pressure management strategies, as noise reduction components like mufflers and resonators significantly impact system pressure. Modern designs increasingly employ Helmholtz resonator principles and multiple-chamber configurations that achieve noise cancellation with minimal flow restriction, preserving performance while meeting increasingly stringent noise regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!