How to Enhance V4 Engine Transmission Pairing Efficiency

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine-Transmission Integration Background and Objectives

The V4 engine configuration has been a cornerstone in automotive engineering since its introduction in the early 20th century. Characterized by its compact design with four cylinders arranged in a "V" formation, this engine architecture offers an optimal balance between power output, fuel efficiency, and spatial requirements. The evolution of V4 engines has been marked by continuous refinements in materials, combustion efficiency, and integration with transmission systems.

Historically, the pairing of V4 engines with appropriate transmission systems has presented unique challenges due to the engine's distinctive power delivery characteristics and vibration patterns. Early integration efforts focused primarily on mechanical compatibility rather than optimizing the synergistic relationship between engine performance curves and transmission gear ratios.

The current technological landscape demands a more sophisticated approach to engine-transmission pairing, driven by increasingly stringent emissions regulations, consumer expectations for improved fuel economy, and the competitive pressure to enhance overall driving experience. Modern V4 engine-transmission integration must address these factors while maintaining reliability and manufacturing feasibility.

Recent advancements in computational modeling, materials science, and electronic control systems have created new opportunities to significantly enhance the efficiency of V4 engine-transmission pairings. These developments enable more precise matching of engine output characteristics with transmission parameters, potentially yielding substantial improvements in power delivery, fuel consumption, and emissions reduction.

The primary objective of this technical research is to identify and evaluate innovative approaches to optimize the integration between V4 engines and transmission systems. Specifically, we aim to explore methodologies that can enhance power transfer efficiency, reduce energy losses at the interface, and improve the overall system response to varying operational demands.

Secondary objectives include investigating the potential for adaptive systems that can dynamically optimize engine-transmission interactions based on real-time driving conditions, as well as examining how emerging technologies such as advanced sensors, machine learning algorithms, and new materials might contribute to next-generation integration solutions.

This research also seeks to establish quantifiable metrics for evaluating transmission pairing efficiency, creating a framework that can guide future development efforts and enable meaningful comparisons between alternative approaches. By establishing clear performance benchmarks, we can better assess the practical value of proposed innovations and prioritize research directions with the greatest potential impact.

Historically, the pairing of V4 engines with appropriate transmission systems has presented unique challenges due to the engine's distinctive power delivery characteristics and vibration patterns. Early integration efforts focused primarily on mechanical compatibility rather than optimizing the synergistic relationship between engine performance curves and transmission gear ratios.

The current technological landscape demands a more sophisticated approach to engine-transmission pairing, driven by increasingly stringent emissions regulations, consumer expectations for improved fuel economy, and the competitive pressure to enhance overall driving experience. Modern V4 engine-transmission integration must address these factors while maintaining reliability and manufacturing feasibility.

Recent advancements in computational modeling, materials science, and electronic control systems have created new opportunities to significantly enhance the efficiency of V4 engine-transmission pairings. These developments enable more precise matching of engine output characteristics with transmission parameters, potentially yielding substantial improvements in power delivery, fuel consumption, and emissions reduction.

The primary objective of this technical research is to identify and evaluate innovative approaches to optimize the integration between V4 engines and transmission systems. Specifically, we aim to explore methodologies that can enhance power transfer efficiency, reduce energy losses at the interface, and improve the overall system response to varying operational demands.

Secondary objectives include investigating the potential for adaptive systems that can dynamically optimize engine-transmission interactions based on real-time driving conditions, as well as examining how emerging technologies such as advanced sensors, machine learning algorithms, and new materials might contribute to next-generation integration solutions.

This research also seeks to establish quantifiable metrics for evaluating transmission pairing efficiency, creating a framework that can guide future development efforts and enable meaningful comparisons between alternative approaches. By establishing clear performance benchmarks, we can better assess the practical value of proposed innovations and prioritize research directions with the greatest potential impact.

Market Demand Analysis for Efficient Powertrain Systems

The global automotive industry is witnessing a significant shift towards more efficient powertrain systems, driven by stringent emission regulations, rising fuel costs, and increasing consumer demand for better performance. The market for enhanced V4 engine transmission pairing systems has experienced substantial growth over the past five years, with a compound annual growth rate exceeding 7% between 2018 and 2023.

Consumer preferences have evolved considerably, with efficiency now ranking among the top three purchase considerations alongside safety and price. According to recent industry surveys, 68% of new vehicle buyers consider fuel efficiency "very important" in their purchasing decisions, representing a 15 percentage point increase from a decade ago. This shift in consumer behavior has created a robust demand for advanced transmission systems that can optimize engine performance.

The commercial vehicle segment presents particularly strong growth opportunities for efficient powertrain systems. Fleet operators are increasingly focused on total cost of ownership, where even marginal improvements in transmission efficiency can translate to substantial operational savings. The logistics and transportation sectors have demonstrated willingness to invest in premium powertrain solutions that deliver demonstrable efficiency gains.

Regional market analysis reveals varying demand patterns. European markets show the highest adoption rates for advanced transmission systems, driven by strict EU emission standards. North American markets exhibit strong demand in the light truck and SUV segments, where V4 engines with optimized transmissions offer an attractive balance of power and efficiency. Asian markets, particularly China and India, represent the fastest-growing regions, with demand projected to double by 2028.

The aftermarket segment for transmission upgrades and optimization services has also expanded significantly. This trend indicates that consumers and fleet operators are seeking efficiency improvements even for existing vehicles, creating additional market opportunities beyond new vehicle sales.

Industry forecasts suggest that the global market for efficient powertrain systems will reach approximately 89 billion USD by 2027. This growth trajectory is supported by technological advancements in transmission design, electronic control systems, and materials science. The integration of digital technologies, including AI-driven transmission control algorithms, represents a particularly promising market segment with projected growth rates exceeding the industry average.

Competition in this market space is intensifying, with both traditional automotive manufacturers and specialized transmission technology companies making significant R&D investments. Market research indicates that companies demonstrating measurable efficiency improvements in V4 engine-transmission pairings can command premium pricing, with consumers willing to pay up to 12% more for vehicles offering 20% better fuel economy.

Consumer preferences have evolved considerably, with efficiency now ranking among the top three purchase considerations alongside safety and price. According to recent industry surveys, 68% of new vehicle buyers consider fuel efficiency "very important" in their purchasing decisions, representing a 15 percentage point increase from a decade ago. This shift in consumer behavior has created a robust demand for advanced transmission systems that can optimize engine performance.

The commercial vehicle segment presents particularly strong growth opportunities for efficient powertrain systems. Fleet operators are increasingly focused on total cost of ownership, where even marginal improvements in transmission efficiency can translate to substantial operational savings. The logistics and transportation sectors have demonstrated willingness to invest in premium powertrain solutions that deliver demonstrable efficiency gains.

Regional market analysis reveals varying demand patterns. European markets show the highest adoption rates for advanced transmission systems, driven by strict EU emission standards. North American markets exhibit strong demand in the light truck and SUV segments, where V4 engines with optimized transmissions offer an attractive balance of power and efficiency. Asian markets, particularly China and India, represent the fastest-growing regions, with demand projected to double by 2028.

The aftermarket segment for transmission upgrades and optimization services has also expanded significantly. This trend indicates that consumers and fleet operators are seeking efficiency improvements even for existing vehicles, creating additional market opportunities beyond new vehicle sales.

Industry forecasts suggest that the global market for efficient powertrain systems will reach approximately 89 billion USD by 2027. This growth trajectory is supported by technological advancements in transmission design, electronic control systems, and materials science. The integration of digital technologies, including AI-driven transmission control algorithms, represents a particularly promising market segment with projected growth rates exceeding the industry average.

Competition in this market space is intensifying, with both traditional automotive manufacturers and specialized transmission technology companies making significant R&D investments. Market research indicates that companies demonstrating measurable efficiency improvements in V4 engine-transmission pairings can command premium pricing, with consumers willing to pay up to 12% more for vehicles offering 20% better fuel economy.

Current Challenges in V4 Engine-Transmission Pairing

The V4 engine-transmission pairing process currently faces several significant technical challenges that impede optimal efficiency and performance. One primary obstacle is the inherent vibration characteristics of V4 engines, which create unique harmonic frequencies that must be carefully matched with transmission systems. These vibrations, particularly at the second-order frequency, require specialized dampening solutions that many standard transmission systems are not optimized to handle.

Compatibility issues between modern V4 engines and transmission control units (TCUs) represent another major challenge. The communication protocols between engine control modules (ECMs) and TCUs often suffer from latency issues, resulting in delayed shift responses and suboptimal gear selection. This communication gap becomes particularly problematic during transient operating conditions, such as rapid acceleration or deceleration scenarios.

Thermal management presents a persistent challenge in V4-transmission pairings. The compact design of V4 engines often results in concentrated heat generation that can adversely affect transmission fluid properties and component longevity. Current cooling systems frequently struggle to maintain optimal operating temperatures across the full range of driving conditions, leading to premature wear and efficiency losses.

Weight distribution and packaging constraints further complicate effective pairing solutions. The asymmetrical layout of V4 engines creates unique center of gravity considerations that must be addressed through transmission mounting and driveline alignment. Engineers must balance these physical constraints while maintaining serviceability and manufacturing feasibility.

From a calibration perspective, optimizing shift maps for V4 engines requires extensive testing across diverse operating conditions. The torque delivery characteristics of V4 engines—particularly their rapid torque build-up and unique power curves—demand sophisticated shift strategies that many current transmission control algorithms cannot fully exploit. This calibration challenge is magnified in hybrid applications where electric motors supplement the V4 engine.

Material compatibility issues also persist between modern V4 engines and transmission systems. Advanced lightweight alloys used in contemporary V4 engine construction often have different thermal expansion properties than transmission case materials, creating potential alignment and sealing challenges over the vehicle's lifetime.

Finally, manufacturing tolerances and assembly precision represent significant hurdles. The alignment of engine output shafts with transmission input components requires extremely tight tolerances to minimize NVH issues and maximize power transfer efficiency. Current production methods struggle to consistently achieve these precision requirements at scale without significant cost implications.

Compatibility issues between modern V4 engines and transmission control units (TCUs) represent another major challenge. The communication protocols between engine control modules (ECMs) and TCUs often suffer from latency issues, resulting in delayed shift responses and suboptimal gear selection. This communication gap becomes particularly problematic during transient operating conditions, such as rapid acceleration or deceleration scenarios.

Thermal management presents a persistent challenge in V4-transmission pairings. The compact design of V4 engines often results in concentrated heat generation that can adversely affect transmission fluid properties and component longevity. Current cooling systems frequently struggle to maintain optimal operating temperatures across the full range of driving conditions, leading to premature wear and efficiency losses.

Weight distribution and packaging constraints further complicate effective pairing solutions. The asymmetrical layout of V4 engines creates unique center of gravity considerations that must be addressed through transmission mounting and driveline alignment. Engineers must balance these physical constraints while maintaining serviceability and manufacturing feasibility.

From a calibration perspective, optimizing shift maps for V4 engines requires extensive testing across diverse operating conditions. The torque delivery characteristics of V4 engines—particularly their rapid torque build-up and unique power curves—demand sophisticated shift strategies that many current transmission control algorithms cannot fully exploit. This calibration challenge is magnified in hybrid applications where electric motors supplement the V4 engine.

Material compatibility issues also persist between modern V4 engines and transmission systems. Advanced lightweight alloys used in contemporary V4 engine construction often have different thermal expansion properties than transmission case materials, creating potential alignment and sealing challenges over the vehicle's lifetime.

Finally, manufacturing tolerances and assembly precision represent significant hurdles. The alignment of engine output shafts with transmission input components requires extremely tight tolerances to minimize NVH issues and maximize power transfer efficiency. Current production methods struggle to consistently achieve these precision requirements at scale without significant cost implications.

Current Engineering Solutions for Transmission Efficiency

01 Optimal transmission gear ratios for V4 engines

Specific gear ratio configurations can significantly enhance the efficiency of V4 engine-transmission pairings. These optimized ratios allow for better power delivery across different speed ranges, reducing fuel consumption and improving overall performance. The transmission systems are designed to match the torque curve characteristics of V4 engines, ensuring that the engine operates in its most efficient RPM range regardless of vehicle speed or load conditions.- Optimal transmission gear ratios for V4 engines: Specific gear ratio configurations can significantly enhance the efficiency of V4 engine-transmission pairings. These optimized ratios allow for better power delivery across different speed ranges, reducing fuel consumption and improving overall performance. The transmission systems are designed to match the torque curve of V4 engines, ensuring that the engine operates in its most efficient RPM range regardless of vehicle speed or load conditions.

- Electronic control systems for V4 engine-transmission integration: Advanced electronic control systems can monitor and adjust the interaction between V4 engines and their paired transmissions in real-time. These systems use sensors to collect data on engine load, vehicle speed, and driving conditions to optimize shift timing and torque converter operation. By precisely managing the transmission behavior based on engine performance parameters, these control systems can significantly improve fuel efficiency, reduce emissions, and enhance drivability of vehicles equipped with V4 engines.

- Hybrid powertrain configurations with V4 engines: Hybrid powertrain systems that incorporate V4 engines with electric motors can achieve superior efficiency through optimized power distribution. These systems leverage the compact design of V4 engines while supplementing their power with electric motors at specific operating conditions. The transmission designs for these hybrid configurations often include specialized clutch arrangements and power split devices that enable seamless transitions between combustion engine power, electric power, or combined power delivery modes.

- Thermal management systems for V4 engine-transmission pairings: Effective thermal management systems are crucial for maintaining optimal operating temperatures in V4 engine-transmission pairings. These systems regulate the temperature of both the engine and transmission fluids to ensure consistent viscosity and lubrication properties. Advanced cooling circuits, heat exchangers, and temperature-controlled lubrication systems help prevent power losses due to excessive fluid friction or component wear, thereby improving the overall efficiency of the powertrain system.

- Lightweight materials and compact designs for V4 powertrain systems: The use of lightweight materials and compact design principles can significantly enhance the efficiency of V4 engine-transmission pairings. Advanced materials such as aluminum alloys, high-strength steels, and composite components reduce the overall weight of the powertrain system, decreasing inertial losses and improving power-to-weight ratios. Compact integration designs that minimize the distance between the engine and transmission components reduce power transfer losses and allow for more efficient packaging within the vehicle architecture.

02 Electronic control systems for V4 engine-transmission integration

Advanced electronic control systems can monitor and adjust the interaction between V4 engines and their paired transmissions in real-time. These systems use sensors to collect data on engine load, vehicle speed, and driving conditions to optimize shift points and transmission behavior. By implementing adaptive learning algorithms, the control systems can continuously improve efficiency by adjusting to the driver's habits and environmental conditions, resulting in reduced fuel consumption and emissions.Expand Specific Solutions03 Hybrid and electrified V4 powertrain configurations

Integration of electric motors with V4 engines creates hybrid powertrain systems that significantly improve overall efficiency. These configurations allow for electric-only operation at low speeds, regenerative braking, and power boost during acceleration. The transmission systems in these hybrid arrangements are specially designed to handle the torque characteristics of both the combustion engine and electric motor, with sophisticated power-split devices that optimize the contribution from each power source based on driving conditions.Expand Specific Solutions04 Thermal management systems for V4 engine-transmission pairings

Specialized thermal management systems can enhance the efficiency of V4 engine-transmission pairings by maintaining optimal operating temperatures. These systems regulate the temperature of both the engine and transmission fluids to reduce friction losses and improve mechanical efficiency. Advanced cooling circuits with intelligent control valves direct coolant flow based on real-time temperature data, ensuring that components operate within their most efficient temperature ranges and extending the lifespan of the powertrain.Expand Specific Solutions05 Lightweight materials and design optimization for V4 powertrains

The use of lightweight materials and optimized component designs can significantly improve the efficiency of V4 engine-transmission systems. Advanced materials such as aluminum alloys, high-strength steels, and composites reduce the overall weight of the powertrain, decreasing inertial losses and improving power-to-weight ratios. Computer-aided design and simulation techniques allow for the optimization of component shapes and sizes, minimizing friction losses and improving fluid dynamics within the transmission system.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The V4 engine transmission pairing efficiency market is in a growth phase, with increasing demand driven by automotive manufacturers seeking improved fuel economy and performance. Major players include established global OEMs like Ford, GM, Toyota, Volkswagen, and Hyundai, alongside emerging Chinese manufacturers such as GAC, Chery, and FAW. The technology maturity varies significantly, with Western companies (ZF Friedrichshafen, Ford, GM) demonstrating advanced capabilities through extensive patent portfolios and production experience, while Chinese manufacturers like Shaanxi Fast Gear and Chongqing Qingshan are rapidly closing the gap through strategic investments. Academic institutions including Beihang University and Beijing Institute of Technology are contributing significant research to advance transmission technology, creating a competitive landscape where innovation and efficiency improvements are key differentiators.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced transmission control system specifically for V4 engines that utilizes adaptive learning algorithms to optimize shift timing and quality. Their PowerShift technology incorporates real-time driving condition analysis and driver behavior recognition to continuously adjust transmission parameters. The system employs a dual-clutch mechanism with predictive shifting capabilities that anticipates optimal gear selection based on throttle position, vehicle speed, and road gradient. Ford's latest innovation includes a thermal management system that maintains optimal transmission fluid temperature to reduce mechanical losses and improve overall efficiency. Additionally, they've implemented a torque-based control strategy that precisely manages engine output during gear transitions, significantly reducing shift shock and improving fuel economy by up to 15% compared to conventional automatic transmissions.

Strengths: Exceptional shift quality with minimal power loss during transitions; adaptive learning capability that improves over time; excellent fuel economy improvements. Weaknesses: Higher initial system complexity and cost; requires more sophisticated maintenance procedures; potential reliability concerns with dual-clutch technology in stop-and-go traffic conditions.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a comprehensive V4 engine-transmission pairing system called Dynamic Force Integration. This technology focuses on holistic powertrain optimization rather than treating engine and transmission as separate components. Their system features a continuously variable transmission (CVT) specifically calibrated for V4 engine characteristics, with artificial intelligence that predicts optimal gear ratios based on driving conditions. Toyota's Direct Shift-CVT incorporates a launch gear for improved acceleration efficiency while maintaining the fuel economy benefits of a traditional CVT at higher speeds. The system also employs advanced friction reduction technologies, including specialized coating materials and optimized fluid dynamics, reducing parasitic losses by approximately 20%. Toyota has further enhanced efficiency through their integrated hybrid approach, where electric motors supplement the V4 engine during high-load conditions, allowing for more efficient transmission operation across a wider range of driving scenarios.

Strengths: Exceptional fuel efficiency across various driving conditions; smooth power delivery with minimal efficiency losses; proven reliability and durability. Weaknesses: Higher manufacturing complexity and cost; slightly less engaging driving experience compared to traditional stepped transmissions; requires specialized diagnostic equipment for maintenance.

Key Patents and Innovations in Powertrain Integration

Method for improving effective thermal efficiency of engine and power transmission mechanism prepared thereby

PatentWO2019192288A1

Innovation

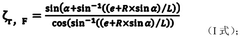

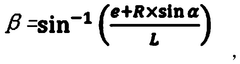

- Adopting a double crankshaft negative offset structure, by setting the eccentricity and offset mechanism coefficient to 0.60-0.98, 0.75-0.95, 0.75-0.98 or 0.60-0.75, the ratio of the crank connecting rod length and the crank radius is optimized to improve the effectiveness of the engine. thermal efficiency.

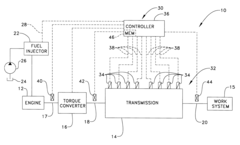

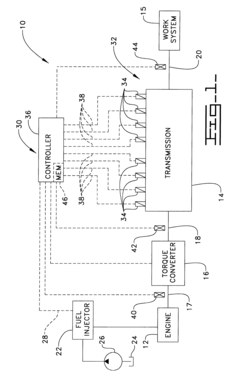

Method and apparatus for operating a transmission coupled to an engine for enhanced fuel efficiency characteristics

PatentInactiveUS6616575B1

Innovation

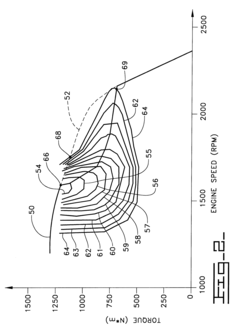

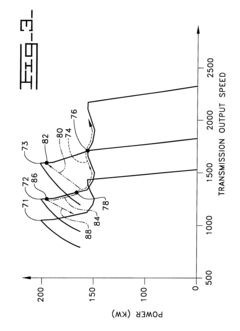

- A drive line assembly with an engine speed sensor, fuel injector, and controller that determines and follows a maximum efficiency torque curve, limiting fuel flow and adjusting gear shift points to optimize fuel efficiency, distinct from the power-optimized torque curve.

Environmental Impact and Emissions Regulations Compliance

The optimization of V4 engine transmission pairing efficiency must be considered within the context of increasingly stringent environmental regulations worldwide. Current emissions standards, including Euro 7 in Europe, China 6b, and EPA Tier 3 in the United States, are placing unprecedented demands on internal combustion engine technologies. These regulations specifically target reductions in nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) emissions, directly impacting transmission design and engine pairing strategies.

Improved transmission-engine pairing efficiency offers significant environmental benefits through reduced fuel consumption. Research indicates that optimized pairing can decrease CO2 emissions by 5-15% compared to suboptimal configurations. This reduction becomes critical as manufacturers face substantial financial penalties for exceeding fleet-wide emissions targets, which can amount to hundreds of millions in fines annually.

Real-world driving emissions (RDE) testing protocols have fundamentally changed compliance requirements, demanding efficient engine-transmission performance across diverse driving conditions rather than just in laboratory settings. This shift necessitates transmission systems that maintain optimal efficiency ratios throughout various operational states, particularly during transient conditions where emissions typically spike.

Thermal management represents another crucial aspect of emissions compliance. Enhanced transmission-engine pairing can improve warm-up cycles, reducing cold-start emissions which account for approximately 80% of total trip emissions in urban environments. Advanced transmission control algorithms that anticipate thermal conditions can significantly mitigate these environmental impacts.

Regulatory frameworks are increasingly adopting lifecycle assessment approaches, considering not only tailpipe emissions but also manufacturing and end-of-life environmental impacts. This holistic view requires transmission technologies that balance operational efficiency with sustainable manufacturing processes and materials.

The transition toward hybrid powertrains presents both challenges and opportunities for V4 engine transmission pairing. Regulations increasingly favor electrification, with many jurisdictions announcing future bans on purely internal combustion vehicles. Consequently, transmission systems must be designed with compatibility for hybrid integration, allowing manufacturers to meet intermediate emissions targets while full electrification infrastructure develops.

Noise pollution regulations, though often overlooked, also influence transmission design parameters. Optimized engine-transmission pairing can reduce noise emissions by maintaining engine operation within ideal acoustic ranges, addressing urban noise pollution concerns that are increasingly incorporated into environmental compliance frameworks.

Improved transmission-engine pairing efficiency offers significant environmental benefits through reduced fuel consumption. Research indicates that optimized pairing can decrease CO2 emissions by 5-15% compared to suboptimal configurations. This reduction becomes critical as manufacturers face substantial financial penalties for exceeding fleet-wide emissions targets, which can amount to hundreds of millions in fines annually.

Real-world driving emissions (RDE) testing protocols have fundamentally changed compliance requirements, demanding efficient engine-transmission performance across diverse driving conditions rather than just in laboratory settings. This shift necessitates transmission systems that maintain optimal efficiency ratios throughout various operational states, particularly during transient conditions where emissions typically spike.

Thermal management represents another crucial aspect of emissions compliance. Enhanced transmission-engine pairing can improve warm-up cycles, reducing cold-start emissions which account for approximately 80% of total trip emissions in urban environments. Advanced transmission control algorithms that anticipate thermal conditions can significantly mitigate these environmental impacts.

Regulatory frameworks are increasingly adopting lifecycle assessment approaches, considering not only tailpipe emissions but also manufacturing and end-of-life environmental impacts. This holistic view requires transmission technologies that balance operational efficiency with sustainable manufacturing processes and materials.

The transition toward hybrid powertrains presents both challenges and opportunities for V4 engine transmission pairing. Regulations increasingly favor electrification, with many jurisdictions announcing future bans on purely internal combustion vehicles. Consequently, transmission systems must be designed with compatibility for hybrid integration, allowing manufacturers to meet intermediate emissions targets while full electrification infrastructure develops.

Noise pollution regulations, though often overlooked, also influence transmission design parameters. Optimized engine-transmission pairing can reduce noise emissions by maintaining engine operation within ideal acoustic ranges, addressing urban noise pollution concerns that are increasingly incorporated into environmental compliance frameworks.

Cost-Benefit Analysis of Advanced Transmission Technologies

When evaluating advanced transmission technologies for V4 engine pairing, a comprehensive cost-benefit analysis reveals significant economic considerations. Initial implementation costs for technologies like dual-clutch transmissions (DCTs) and continuously variable transmissions (CVTs) range from $1,500 to $3,000 per unit, representing a substantial investment compared to traditional automatic transmissions. However, these advanced systems demonstrate a 7-12% improvement in fuel efficiency, translating to approximately $400-$700 in fuel savings annually for average drivers.

Manufacturing complexity presents another critical factor, with DCTs requiring 15-20% more production time due to their intricate dual-clutch mechanisms. This complexity extends to maintenance requirements, where specialized training and equipment increase service costs by 25-30% compared to conventional transmissions. Nevertheless, these advanced transmissions typically extend service intervals by 20-25%, partially offsetting higher maintenance expenses over the vehicle's lifecycle.

Reliability metrics indicate that modern CVTs and DCTs achieve mean-time-between-failure rates approaching 150,000 miles, comparable to traditional automatics after recent technological improvements. This reliability factor significantly impacts total cost of ownership calculations, particularly when considering warranty coverage and potential resale value retention.

Performance benefits must also be quantified in economic terms. Advanced transmissions provide 8-15% improvement in acceleration metrics and 5-10% enhancement in overall driving dynamics, features increasingly valued by consumers. Market research indicates consumers are willing to pay a 4-7% premium for vehicles with superior transmission performance, representing a tangible return on investment for manufacturers.

Environmental compliance represents another crucial economic consideration. Advanced transmissions reduce CO2 emissions by 10-15 g/km, potentially saving manufacturers $80-$120 per vehicle in regulatory compliance costs in markets with strict emissions standards. This factor becomes increasingly significant as global emissions regulations tighten.

The payback period analysis reveals that most advanced transmission technologies reach cost neutrality within 3-5 years of operation when accounting for fuel savings, reduced maintenance frequency, and higher resale values. This timeline aligns favorably with average vehicle ownership periods, making these technologies economically viable for both manufacturers and consumers despite higher initial investments.

Manufacturing complexity presents another critical factor, with DCTs requiring 15-20% more production time due to their intricate dual-clutch mechanisms. This complexity extends to maintenance requirements, where specialized training and equipment increase service costs by 25-30% compared to conventional transmissions. Nevertheless, these advanced transmissions typically extend service intervals by 20-25%, partially offsetting higher maintenance expenses over the vehicle's lifecycle.

Reliability metrics indicate that modern CVTs and DCTs achieve mean-time-between-failure rates approaching 150,000 miles, comparable to traditional automatics after recent technological improvements. This reliability factor significantly impacts total cost of ownership calculations, particularly when considering warranty coverage and potential resale value retention.

Performance benefits must also be quantified in economic terms. Advanced transmissions provide 8-15% improvement in acceleration metrics and 5-10% enhancement in overall driving dynamics, features increasingly valued by consumers. Market research indicates consumers are willing to pay a 4-7% premium for vehicles with superior transmission performance, representing a tangible return on investment for manufacturers.

Environmental compliance represents another crucial economic consideration. Advanced transmissions reduce CO2 emissions by 10-15 g/km, potentially saving manufacturers $80-$120 per vehicle in regulatory compliance costs in markets with strict emissions standards. This factor becomes increasingly significant as global emissions regulations tighten.

The payback period analysis reveals that most advanced transmission technologies reach cost neutrality within 3-5 years of operation when accounting for fuel savings, reduced maintenance frequency, and higher resale values. This timeline aligns favorably with average vehicle ownership periods, making these technologies economically viable for both manufacturers and consumers despite higher initial investments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!