How to Test V4 Engine Injector Spray Patterns

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Injector Testing Background and Objectives

Fuel injection technology has evolved significantly since its inception in the early 20th century, transitioning from mechanical systems to sophisticated electronic control mechanisms. V4 engine configurations, while less common than inline-four or V6 designs, represent an important segment in specialized applications such as motorcycles, marine engines, and certain industrial equipment. The testing of injector spray patterns in these engines has become increasingly critical as emission standards tighten globally and fuel efficiency demands escalate.

The evolution of injector testing methodologies has paralleled advancements in fuel delivery systems. Early rudimentary visual inspections have given way to high-precision optical analysis and computational fluid dynamics simulations. This progression reflects the industry's growing understanding of how spray pattern characteristics—including cone angle, droplet size distribution, and penetration depth—directly impact combustion efficiency, emissions formation, and engine longevity.

Current technical objectives in V4 injector spray pattern testing center around achieving optimal atomization for complete combustion while minimizing wall wetting and reducing particulate emissions. Engineers seek to understand the complex interaction between injector design parameters and resulting spray characteristics under varying operating conditions, including different engine loads, temperatures, and fuel compositions.

The unique geometry of V4 engines presents specific challenges for injector placement and spray targeting. The compact V-configuration often necessitates compromises in injector positioning that wouldn't be required in straight engine layouts, making precise spray pattern optimization even more crucial. Testing methodologies must account for these spatial constraints while still providing accurate, reproducible results.

Recent technological developments have enabled more sophisticated testing approaches, including high-speed imaging systems capable of capturing spray development at microsecond intervals, laser-based particle size analyzers, and phase Doppler anemometry for velocity measurements. These tools allow engineers to quantify previously unmeasurable spray characteristics and correlate them with engine performance metrics.

The ultimate goal of V4 injector spray pattern testing extends beyond mere compliance with regulatory standards. It aims to achieve the optimal balance between power output, fuel economy, and emissions control across the engine's entire operating range. This requires a comprehensive understanding of the complex fluid dynamics at play during the injection event and subsequent air-fuel mixing process.

As automotive and industrial sectors continue their transition toward alternative fuels and electrification, the role of precise injector testing remains vital for maximizing the efficiency of internal combustion engines during this transitional period. Testing methodologies must therefore continue to evolve to address the challenges posed by new fuel formulations and hybrid powertrain configurations.

The evolution of injector testing methodologies has paralleled advancements in fuel delivery systems. Early rudimentary visual inspections have given way to high-precision optical analysis and computational fluid dynamics simulations. This progression reflects the industry's growing understanding of how spray pattern characteristics—including cone angle, droplet size distribution, and penetration depth—directly impact combustion efficiency, emissions formation, and engine longevity.

Current technical objectives in V4 injector spray pattern testing center around achieving optimal atomization for complete combustion while minimizing wall wetting and reducing particulate emissions. Engineers seek to understand the complex interaction between injector design parameters and resulting spray characteristics under varying operating conditions, including different engine loads, temperatures, and fuel compositions.

The unique geometry of V4 engines presents specific challenges for injector placement and spray targeting. The compact V-configuration often necessitates compromises in injector positioning that wouldn't be required in straight engine layouts, making precise spray pattern optimization even more crucial. Testing methodologies must account for these spatial constraints while still providing accurate, reproducible results.

Recent technological developments have enabled more sophisticated testing approaches, including high-speed imaging systems capable of capturing spray development at microsecond intervals, laser-based particle size analyzers, and phase Doppler anemometry for velocity measurements. These tools allow engineers to quantify previously unmeasurable spray characteristics and correlate them with engine performance metrics.

The ultimate goal of V4 injector spray pattern testing extends beyond mere compliance with regulatory standards. It aims to achieve the optimal balance between power output, fuel economy, and emissions control across the engine's entire operating range. This requires a comprehensive understanding of the complex fluid dynamics at play during the injection event and subsequent air-fuel mixing process.

As automotive and industrial sectors continue their transition toward alternative fuels and electrification, the role of precise injector testing remains vital for maximizing the efficiency of internal combustion engines during this transitional period. Testing methodologies must therefore continue to evolve to address the challenges posed by new fuel formulations and hybrid powertrain configurations.

Market Demand Analysis for Precision Injector Testing

The global market for precision injector testing systems is experiencing robust growth, driven primarily by stringent emission regulations and the automotive industry's shift toward more efficient engine technologies. Current market estimates value the precision injector testing equipment sector at approximately $2.3 billion, with projections indicating a compound annual growth rate of 6.8% through 2028. This growth trajectory reflects the increasing demand for advanced testing solutions that can accurately evaluate V4 engine injector spray patterns.

Automotive manufacturers represent the largest market segment, accounting for nearly 58% of the total demand. These companies require sophisticated testing equipment to ensure their engines meet increasingly strict environmental standards while maintaining optimal performance. The aftermarket service sector constitutes roughly 22% of the market, as maintenance facilities upgrade their diagnostic capabilities to service modern fuel injection systems effectively.

Geographically, Europe leads the market with a 34% share, attributed to its early adoption of stringent emission standards and the presence of premium automotive manufacturers who prioritize precision engineering. North America follows at 28%, with Asia-Pacific showing the fastest growth rate at 9.2% annually, driven by rapid industrialization and automotive sector expansion in countries like China and India.

The demand for precision injector testing is further segmented by technology type. Optical measurement systems dominate with 45% market share due to their non-intrusive nature and high accuracy in analyzing spray patterns. Pressure-based systems account for 30%, while flow measurement technologies represent 25% of the market.

Key market drivers include the implementation of Euro 7 and equivalent global emission standards, which require unprecedented precision in fuel delivery systems. Additionally, the growing complexity of direct injection systems in modern engines necessitates more sophisticated testing equipment capable of analyzing spray patterns at higher pressures and with greater resolution.

Customer requirements are evolving toward testing solutions that offer real-time analysis, integration with digital platforms, and predictive maintenance capabilities. There is also increasing demand for portable testing equipment that can be used in field conditions, particularly from the aftermarket segment.

Market challenges include the high initial investment cost for advanced testing equipment, which creates barriers for smaller service providers. Technical complexity in accurately measuring microscopic spray patterns at high pressures also presents ongoing challenges for equipment manufacturers.

Automotive manufacturers represent the largest market segment, accounting for nearly 58% of the total demand. These companies require sophisticated testing equipment to ensure their engines meet increasingly strict environmental standards while maintaining optimal performance. The aftermarket service sector constitutes roughly 22% of the market, as maintenance facilities upgrade their diagnostic capabilities to service modern fuel injection systems effectively.

Geographically, Europe leads the market with a 34% share, attributed to its early adoption of stringent emission standards and the presence of premium automotive manufacturers who prioritize precision engineering. North America follows at 28%, with Asia-Pacific showing the fastest growth rate at 9.2% annually, driven by rapid industrialization and automotive sector expansion in countries like China and India.

The demand for precision injector testing is further segmented by technology type. Optical measurement systems dominate with 45% market share due to their non-intrusive nature and high accuracy in analyzing spray patterns. Pressure-based systems account for 30%, while flow measurement technologies represent 25% of the market.

Key market drivers include the implementation of Euro 7 and equivalent global emission standards, which require unprecedented precision in fuel delivery systems. Additionally, the growing complexity of direct injection systems in modern engines necessitates more sophisticated testing equipment capable of analyzing spray patterns at higher pressures and with greater resolution.

Customer requirements are evolving toward testing solutions that offer real-time analysis, integration with digital platforms, and predictive maintenance capabilities. There is also increasing demand for portable testing equipment that can be used in field conditions, particularly from the aftermarket segment.

Market challenges include the high initial investment cost for advanced testing equipment, which creates barriers for smaller service providers. Technical complexity in accurately measuring microscopic spray patterns at high pressures also presents ongoing challenges for equipment manufacturers.

Current Challenges in Fuel Injector Spray Pattern Testing

Despite significant advancements in fuel injection technology, testing V4 engine injector spray patterns continues to face numerous technical challenges that impede accurate measurement and analysis. The primary challenge lies in the visualization of high-speed, microscopic spray formations under realistic operating conditions. Current optical measurement systems struggle to capture the complete temporal and spatial evolution of spray patterns, particularly during the critical initial stages of injection where atomization begins.

Environmental control presents another significant hurdle. Creating test conditions that accurately replicate the high-temperature, high-pressure environment of a combustion chamber while maintaining optical access for measurement instruments requires complex test chambers. These chambers often introduce their own variables that can affect spray formation and measurement accuracy.

The transient nature of fuel injection events compounds these difficulties. Modern V4 engine injectors operate at extremely high pressures (exceeding 2,000 bar in some cases) with injection durations measured in microseconds. Capturing these ultra-fast events requires sophisticated synchronization between injection timing and measurement equipment, with timing errors as small as a microsecond potentially invalidating test results.

Data processing and interpretation remain bottlenecks in the testing workflow. The massive datasets generated during spray pattern analysis—often including thousands of high-resolution images per injection event—require advanced algorithms for meaningful pattern recognition and quantification. Current software solutions frequently struggle with distinguishing actual spray characteristics from measurement artifacts.

Standardization issues further complicate testing procedures. The industry lacks universally accepted metrics for spray quality assessment, making cross-comparison between different testing methodologies problematic. Parameters such as spray angle, penetration length, and droplet size distribution are measured using varying techniques across different research institutions and manufacturers.

Miniaturization of V4 engine components has introduced additional challenges. As injector nozzle diameters decrease to improve atomization, the precision requirements for manufacturing and testing equipment increase exponentially. Microscopic manufacturing variations that were once negligible now significantly impact spray formation, requiring testing methodologies with higher resolution and sensitivity.

Finally, the increasing complexity of multi-hole injectors with variable spray patterns demands more sophisticated testing approaches. Modern V4 engine injectors may feature up to 12 individual spray holes with different geometries and flow characteristics, creating complex three-dimensional spray patterns that cannot be adequately characterized using traditional two-dimensional imaging techniques.

Environmental control presents another significant hurdle. Creating test conditions that accurately replicate the high-temperature, high-pressure environment of a combustion chamber while maintaining optical access for measurement instruments requires complex test chambers. These chambers often introduce their own variables that can affect spray formation and measurement accuracy.

The transient nature of fuel injection events compounds these difficulties. Modern V4 engine injectors operate at extremely high pressures (exceeding 2,000 bar in some cases) with injection durations measured in microseconds. Capturing these ultra-fast events requires sophisticated synchronization between injection timing and measurement equipment, with timing errors as small as a microsecond potentially invalidating test results.

Data processing and interpretation remain bottlenecks in the testing workflow. The massive datasets generated during spray pattern analysis—often including thousands of high-resolution images per injection event—require advanced algorithms for meaningful pattern recognition and quantification. Current software solutions frequently struggle with distinguishing actual spray characteristics from measurement artifacts.

Standardization issues further complicate testing procedures. The industry lacks universally accepted metrics for spray quality assessment, making cross-comparison between different testing methodologies problematic. Parameters such as spray angle, penetration length, and droplet size distribution are measured using varying techniques across different research institutions and manufacturers.

Miniaturization of V4 engine components has introduced additional challenges. As injector nozzle diameters decrease to improve atomization, the precision requirements for manufacturing and testing equipment increase exponentially. Microscopic manufacturing variations that were once negligible now significantly impact spray formation, requiring testing methodologies with higher resolution and sensitivity.

Finally, the increasing complexity of multi-hole injectors with variable spray patterns demands more sophisticated testing approaches. Modern V4 engine injectors may feature up to 12 individual spray holes with different geometries and flow characteristics, creating complex three-dimensional spray patterns that cannot be adequately characterized using traditional two-dimensional imaging techniques.

Current Methodologies for V4 Injector Spray Pattern Analysis

01 Multi-hole injector designs for V4 engines

Multi-hole injector designs are used in V4 engines to optimize fuel atomization and distribution. These designs feature multiple orifices arranged in specific patterns to create ideal spray formations. The number, size, and arrangement of these holes significantly impact combustion efficiency, emissions, and engine performance. Advanced multi-hole designs can create overlapping spray patterns that ensure complete fuel coverage in the combustion chamber.- Multi-hole injector designs for V4 engines: Multi-hole injector designs are used in V4 engines to optimize fuel atomization and combustion efficiency. These designs feature multiple spray holes arranged in specific patterns to create optimal fuel distribution within the combustion chamber. The number, size, and arrangement of these holes significantly impact the engine's performance, emissions, and fuel economy. Advanced multi-hole injectors can be designed with varying hole diameters and angles to target specific areas of the combustion chamber.

- Spray pattern optimization for direct injection systems: Spray pattern optimization in direct injection systems for V4 engines involves tailoring the fuel spray characteristics to match specific combustion chamber geometries. This includes controlling spray penetration, cone angle, and droplet size distribution to enhance air-fuel mixing. Advanced injectors incorporate features that create specific spray patterns designed to reduce wall wetting, improve combustion stability, and minimize emissions across various engine operating conditions.

- Swirl and tumble flow enhancement through spray patterns: Specialized injector spray patterns are designed to enhance in-cylinder air motion, particularly swirl and tumble flows in V4 engines. These patterns work in conjunction with the intake port design and piston geometry to create organized air movement that improves fuel-air mixing. By strategically directing fuel sprays to reinforce these flow structures, combustion efficiency is improved, particularly at low engine loads and speeds where mixing is traditionally more challenging.

- Temperature-responsive spray pattern adaptation: Advanced V4 engine injector systems incorporate temperature-responsive spray pattern adaptation to optimize performance across varying operating conditions. These systems can modify spray characteristics based on engine temperature, ambient conditions, and operating parameters. This adaptive capability ensures optimal atomization during cold starts, prevents fuel condensation at low temperatures, and maintains efficient combustion during high-temperature operation, resulting in improved emissions control and fuel efficiency throughout the engine's operating range.

- Pressure-modulated spray pattern control: Pressure-modulated spray pattern control systems for V4 engine injectors dynamically adjust fuel delivery patterns by varying injection pressure. These systems can create different spray patterns at different pressure levels, allowing for optimization across the engine's operating map. High-pressure injection produces finer atomization and different spray penetration characteristics compared to lower pressure operation. This technology enables precise control of the combustion process, resulting in improved power output, reduced emissions, and better fuel economy.

02 Spray pattern optimization for direct injection systems

Direct injection systems in V4 engines require carefully optimized spray patterns to ensure efficient combustion. These patterns are designed to match the specific combustion chamber geometry and operating conditions. Spray pattern optimization involves controlling the spray angle, penetration depth, and droplet size distribution. Advanced injectors can adjust spray patterns based on engine load and speed to maintain optimal combustion efficiency across various operating conditions.Expand Specific Solutions03 Swirl and tumble flow enhancement techniques

Injector spray patterns in V4 engines are designed to enhance swirl and tumble flow within the combustion chamber. These flow patterns improve air-fuel mixing and combustion efficiency. Specialized injector designs create spray patterns that work in harmony with the intake port design and piston crown geometry to generate optimal in-cylinder motion. Enhanced swirl and tumble flow leads to more complete combustion, reduced emissions, and improved fuel economy.Expand Specific Solutions04 Electronically controlled spray pattern adaptation

Modern V4 engine injectors utilize electronic control systems to adapt spray patterns based on operating conditions. These systems can modify injection timing, duration, and pressure to optimize the spray pattern for different engine loads and speeds. Some advanced systems incorporate multiple injection events per cycle with varying spray patterns to enhance combustion stability. This adaptive capability allows for optimized performance across the entire operating range of the engine.Expand Specific Solutions05 Spray pattern design for emissions reduction

Specialized injector spray patterns are developed for V4 engines to reduce harmful emissions. These designs focus on minimizing wall wetting and optimizing air-fuel mixture formation to reduce unburned hydrocarbons and particulate matter. The spray patterns are engineered to ensure complete fuel vaporization before combustion begins. Some designs incorporate stratified charge strategies with specific spray patterns that create fuel-rich and fuel-lean zones within the combustion chamber to reduce NOx emissions while maintaining combustion stability.Expand Specific Solutions

Major Players in Fuel Injection Testing Equipment

The V4 engine injector spray pattern testing market is in a growth phase, with increasing demand driven by stringent emission regulations and fuel efficiency requirements. The competitive landscape features established automotive giants like Toyota, Mercedes-Benz, and Volkswagen alongside specialized component manufacturers such as Continental Automotive, Robert Bosch, and Delphi Technologies. These companies are investing in advanced testing technologies including high-speed imaging, laser-based measurement systems, and computational fluid dynamics simulation. Market maturity varies by region, with developed markets focusing on precision optimization while emerging markets prioritize cost-effective solutions. Technical innovation is concentrated among tier-1 suppliers like Bosch and Continental, who are developing integrated testing platforms that combine physical testing with digital simulation capabilities to accelerate development cycles and improve accuracy.

Toyota Motor Corp.

Technical Solution: Toyota has developed an innovative V4 engine injector spray pattern testing system that combines optical visualization with advanced computational analysis. Their approach utilizes a specialized transparent combustion chamber that replicates actual engine geometry while providing multiple optical access points for imaging equipment. Toyota's system employs synchronized high-speed cameras (operating at up to 200,000 frames per second) with pulsed laser illumination to capture the temporal evolution of spray formation with exceptional clarity. Their testing methodology incorporates both qualitative visual assessment and quantitative measurement of key spray characteristics including cone angle, penetration depth, and atomization quality. Toyota has pioneered the use of particle image velocimetry (PIV) in injector testing to map velocity fields within the spray, providing insights into air-fuel mixing dynamics. Their system includes automated image processing algorithms that extract and analyze spray metrics across thousands of injection events to ensure statistical validity. Toyota's testing protocol evaluates injector performance across the full operating envelope, from cold-start conditions to high-load operation, with particular attention to spray stability during transient operations.

Strengths: Exceptional repeatability and precision in measurement; seamless integration with Toyota's engine development workflow and quality control systems. Weaknesses: Substantial initial investment in specialized equipment; requires highly trained personnel to operate effectively.

GM Global Technology Operations LLC

Technical Solution: GM has implemented a comprehensive V4 engine injector spray pattern testing methodology that combines traditional optical techniques with advanced digital analysis. Their testing facilities feature specialized spray chambers that can simulate the full range of engine operating conditions, including cylinder pressures up to 200 bar and temperatures exceeding 600°C. GM's approach utilizes dual-mode imaging that simultaneously captures both the global spray structure and localized atomization characteristics. The system employs laser-induced exciplex fluorescence (LIEF) technology that differentiates between liquid and vapor phases of the fuel spray, providing crucial insights into evaporation behavior. Their testing protocol includes evaluation of spray symmetry, penetration dynamics, and droplet size distribution across various fuel types including gasoline, ethanol blends, and alternative fuels. GM has also developed proprietary software algorithms that quantify cycle-to-cycle variations in spray patterns, helping engineers identify potential causes of combustion instability. The company's testing methodology incorporates correlation studies between spray characteristics and engine-out emissions to establish clear relationships between injection parameters and environmental performance.

Strengths: Comprehensive testing capabilities across diverse fuels and operating conditions; strong integration with powertrain development processes. Weaknesses: Highly specialized equipment requirements; significant expertise needed for data interpretation.

Key Technical Innovations in Spray Pattern Visualization

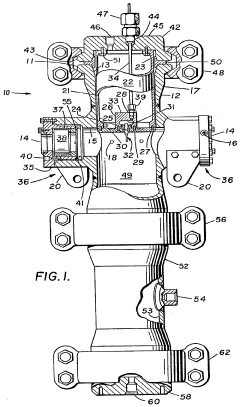

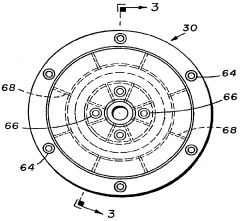

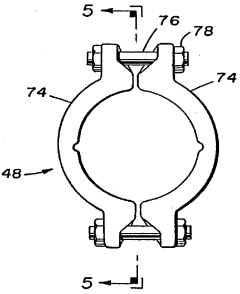

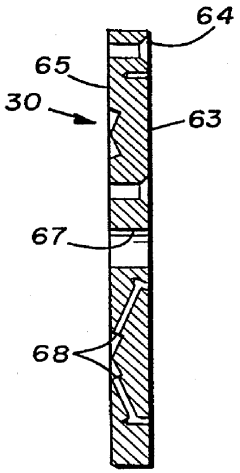

Apparatus for testing high pressure injector elements

PatentInactiveUS5412981A

Innovation

- A high-pressure fluid injector test apparatus with a robust design that includes a purge system to prevent frosting and misting, allows simultaneous use of two fluids, and features adjustable window orientations for improved diagnostics, utilizing a combination of clamps, stud/nut assemblies, and a purge plate to secure and test injector elements effectively.

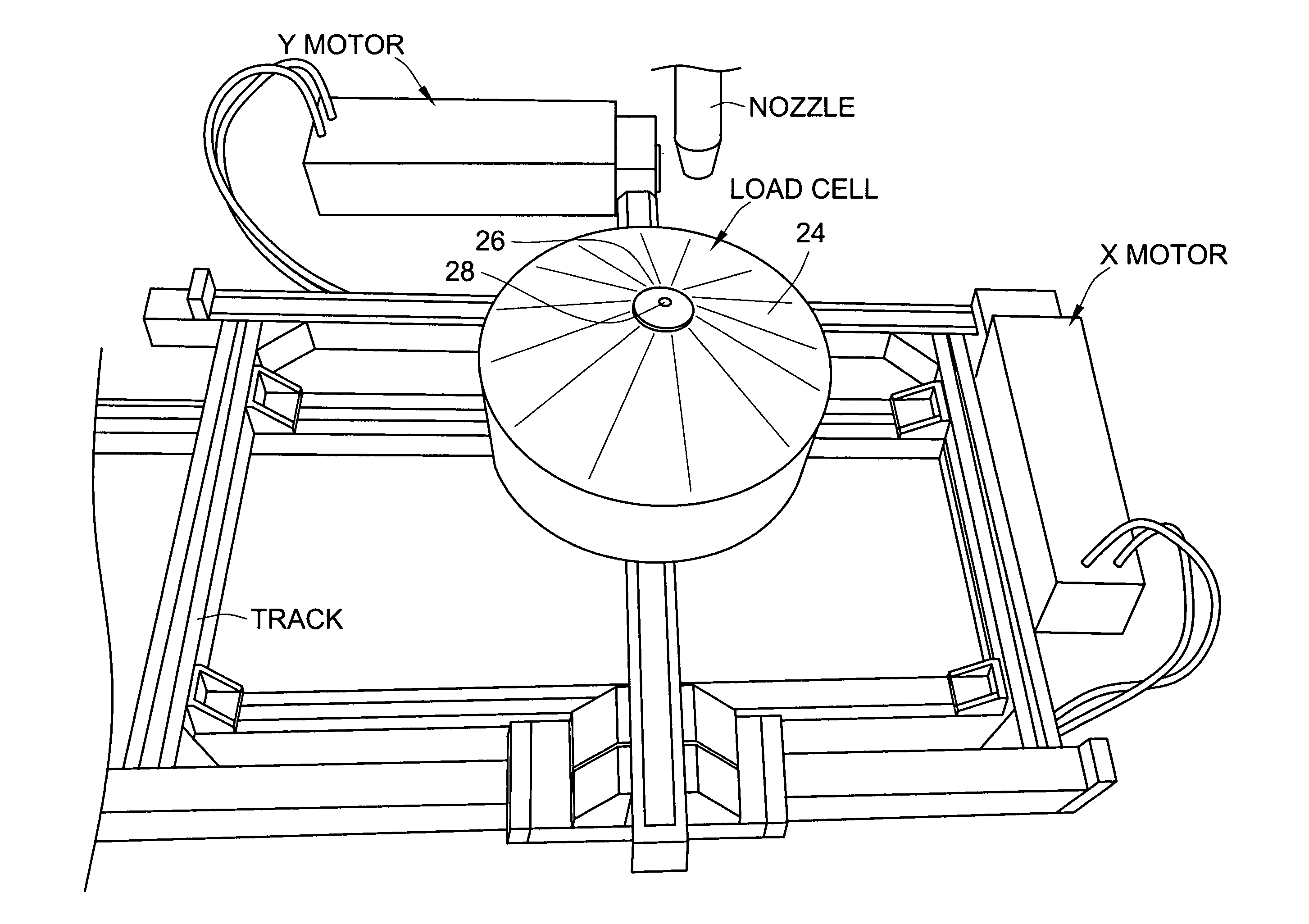

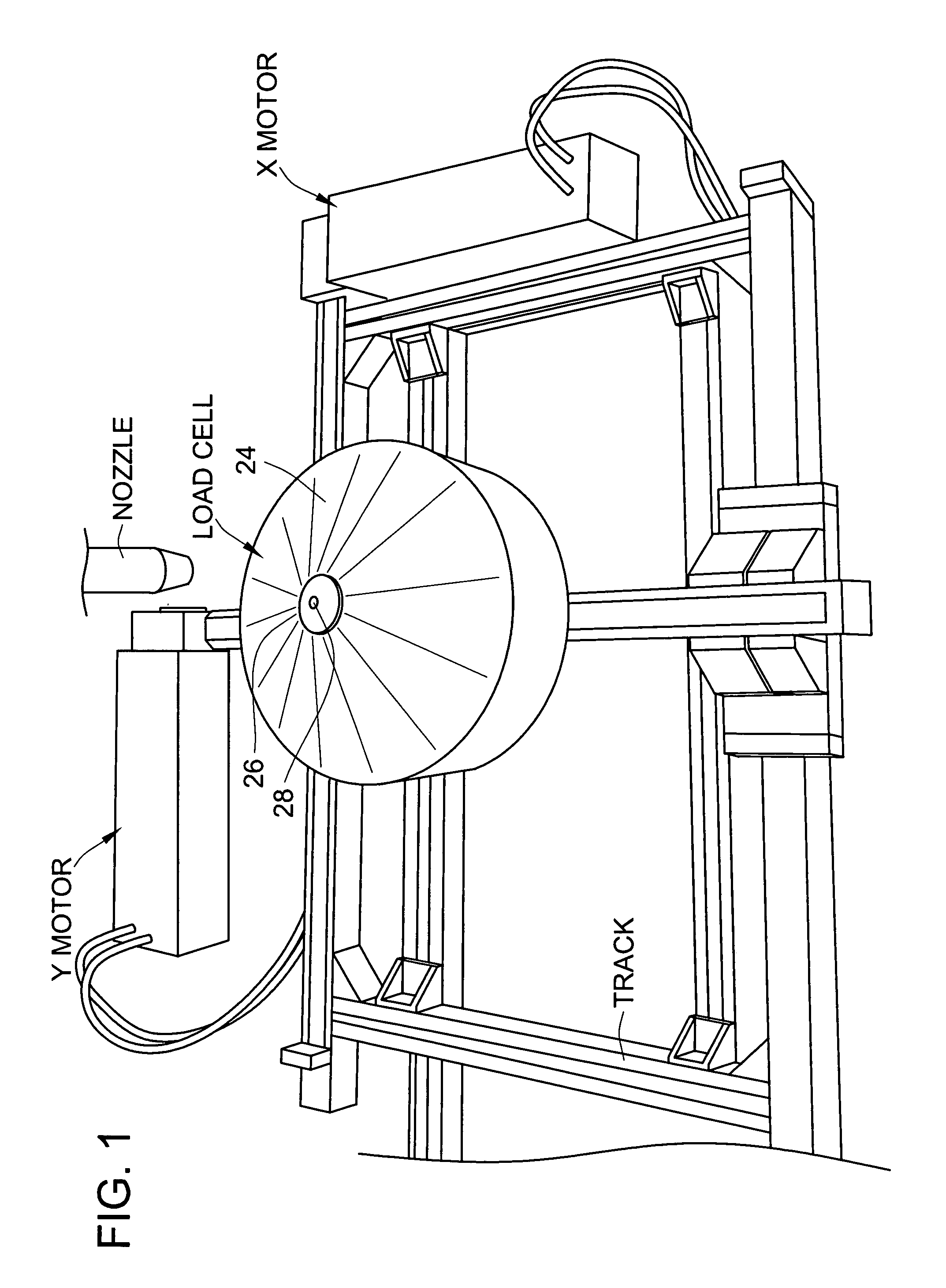

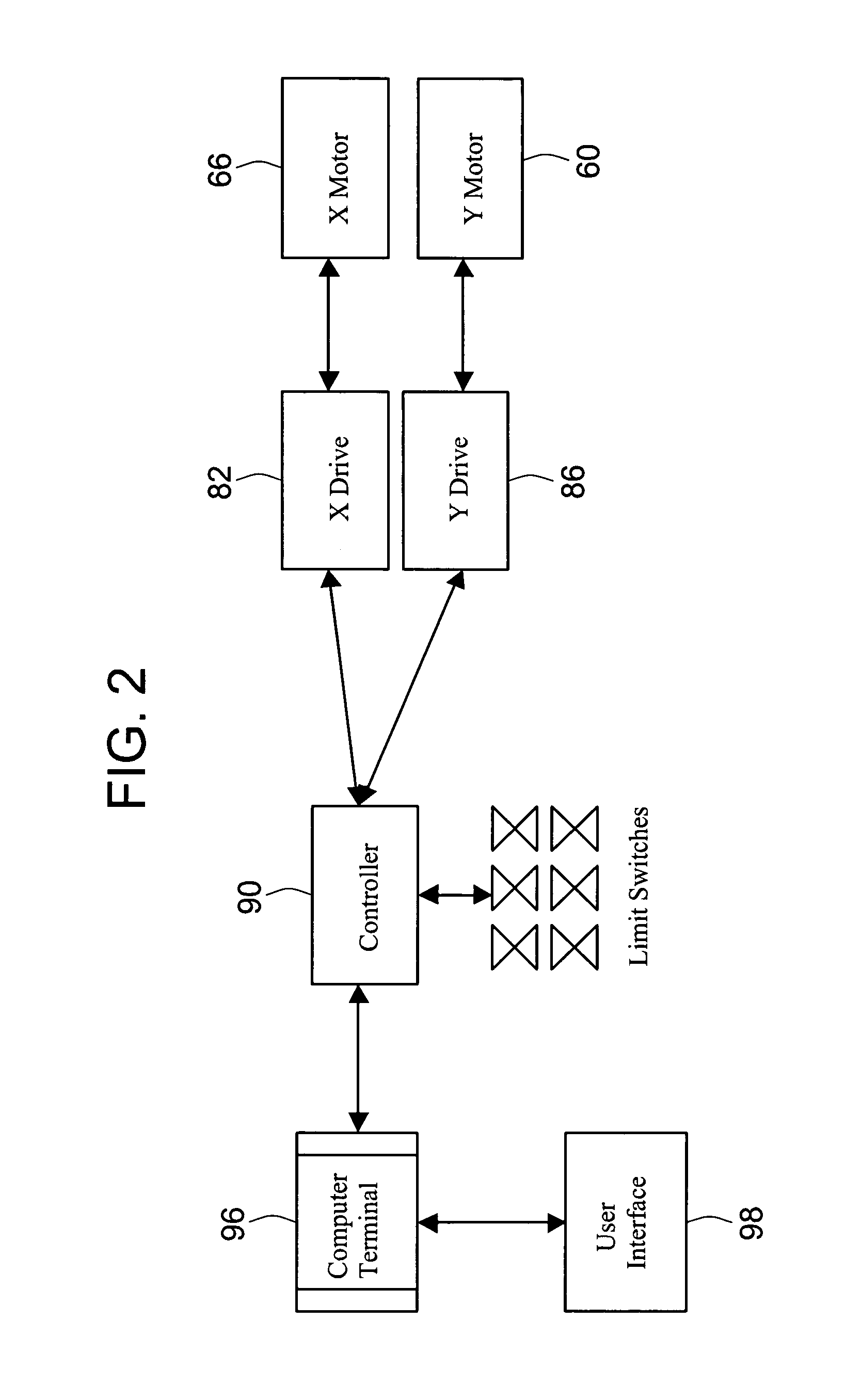

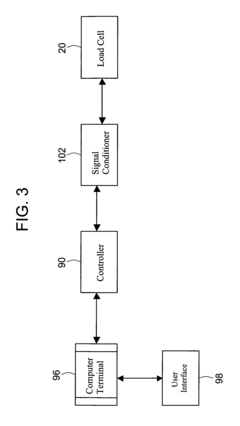

Apparatus and method for measuring characteristics of fluid spray patterns

PatentInactiveUS6962070B1

Innovation

- An impact testing system with a load cell mounted on a transport system for controlled two-dimensional movement, equipped with a sensing pin and aperture geometry that allows for precise measurement of fluid impact without noise or erroneous data, using a strain gauge to record pressure readings.

Environmental Impact of Fuel Injection Testing Procedures

Fuel injection testing procedures, while essential for engine performance optimization, carry significant environmental implications that warrant careful consideration. The testing of V4 engine injector spray patterns typically involves the atomization of fuel under controlled conditions, which can release volatile organic compounds (VOCs), particulate matter, and other pollutants into the atmosphere. Traditional testing methods often utilize open-air spray chambers where unburned fuel is released, contributing to air pollution and potential soil contamination when not properly contained.

Recent environmental impact assessments have identified that a single comprehensive injector testing session can release between 0.5-2 liters of aerosolized fuel, depending on the testing duration and methodology. These emissions contain benzene, toluene, and other hydrocarbons classified as hazardous air pollutants by environmental protection agencies worldwide. The cumulative effect of these testing procedures across thousands of automotive research facilities globally represents a non-trivial environmental burden.

Water contamination presents another significant concern, as testing facilities that do not implement proper containment and filtration systems risk allowing fuel residues to enter drainage systems. Studies indicate that even small quantities of fuel components can disrupt aquatic ecosystems, with concentrations as low as 50 parts per billion proving toxic to certain aquatic organisms. The persistence of these compounds in groundwater can extend their environmental impact well beyond the immediate testing period.

Energy consumption associated with testing equipment operation further compounds the environmental footprint of injection testing procedures. High-pressure testing systems, visualization equipment, and climate-controlled testing environments collectively consume substantial electrical power, often derived from fossil fuel sources. A typical testing facility may consume between 50-200 kWh per day of operation, contributing to indirect carbon emissions.

Emerging regulations in Europe, North America, and parts of Asia are increasingly targeting these environmental impacts, mandating closed-loop testing systems, fuel recovery mechanisms, and filtration technologies. The automotive industry has responded with innovations such as digital simulation alternatives, which can reduce physical testing requirements by up to 40%, and closed-cycle testing chambers that capture and recycle up to 95% of test fuels.

The transition toward more sustainable testing methodologies represents both a challenge and opportunity for the automotive sector. While implementation costs for environmentally responsible testing infrastructure can range from $50,000 to $500,000 per facility, the long-term benefits include regulatory compliance, reduced material waste, and enhanced corporate environmental responsibility profiles. Leading manufacturers have begun incorporating these environmental considerations into their testing protocols, recognizing that sustainable testing practices align with broader industry commitments to environmental stewardship.

Recent environmental impact assessments have identified that a single comprehensive injector testing session can release between 0.5-2 liters of aerosolized fuel, depending on the testing duration and methodology. These emissions contain benzene, toluene, and other hydrocarbons classified as hazardous air pollutants by environmental protection agencies worldwide. The cumulative effect of these testing procedures across thousands of automotive research facilities globally represents a non-trivial environmental burden.

Water contamination presents another significant concern, as testing facilities that do not implement proper containment and filtration systems risk allowing fuel residues to enter drainage systems. Studies indicate that even small quantities of fuel components can disrupt aquatic ecosystems, with concentrations as low as 50 parts per billion proving toxic to certain aquatic organisms. The persistence of these compounds in groundwater can extend their environmental impact well beyond the immediate testing period.

Energy consumption associated with testing equipment operation further compounds the environmental footprint of injection testing procedures. High-pressure testing systems, visualization equipment, and climate-controlled testing environments collectively consume substantial electrical power, often derived from fossil fuel sources. A typical testing facility may consume between 50-200 kWh per day of operation, contributing to indirect carbon emissions.

Emerging regulations in Europe, North America, and parts of Asia are increasingly targeting these environmental impacts, mandating closed-loop testing systems, fuel recovery mechanisms, and filtration technologies. The automotive industry has responded with innovations such as digital simulation alternatives, which can reduce physical testing requirements by up to 40%, and closed-cycle testing chambers that capture and recycle up to 95% of test fuels.

The transition toward more sustainable testing methodologies represents both a challenge and opportunity for the automotive sector. While implementation costs for environmentally responsible testing infrastructure can range from $50,000 to $500,000 per facility, the long-term benefits include regulatory compliance, reduced material waste, and enhanced corporate environmental responsibility profiles. Leading manufacturers have begun incorporating these environmental considerations into their testing protocols, recognizing that sustainable testing practices align with broader industry commitments to environmental stewardship.

Quality Control Standards for Injector Performance Testing

Quality control standards for injector performance testing in V4 engine systems must adhere to rigorous protocols to ensure consistent fuel delivery and optimal engine performance. These standards typically encompass multiple dimensions of injector functionality, with spray pattern analysis being a critical component. Industry benchmarks such as ISO 22241 and SAE J1832 provide foundational guidelines that manufacturers must follow when establishing testing procedures.

The primary quality parameters for injector spray pattern testing include atomization quality, spray angle consistency, penetration depth, and symmetrical distribution. Modern testing facilities implement automated optical measurement systems capable of capturing high-speed imagery at rates exceeding 100,000 frames per second, allowing for precise quantification of these parameters. The acceptable variance threshold for spray angle typically ranges between ±2° to ±3° from the manufacturer's specification, while droplet size distribution must maintain a Sauter Mean Diameter (SMD) within predetermined ranges specific to engine design requirements.

Temporal consistency represents another crucial quality metric, with injectors required to demonstrate repeatable spray patterns across multiple injection events. Statistical process control methods are employed to monitor this consistency, with Coefficient of Variation (CV) values generally required to remain below 3% for premium automotive applications. Testing protocols typically mandate a minimum sample size of 100 consecutive injection events to establish statistical validity.

Environmental condition standardization is equally important in quality control frameworks. Testing chambers must maintain precise temperature control (±2°C), pressure regulation (±0.5 bar), and humidity levels (45-55% relative humidity) to ensure reproducible results. Many advanced testing facilities implement climate simulation capabilities to evaluate injector performance across the full operational temperature spectrum from cold-start conditions (-30°C) to maximum operating temperatures (150°C).

Contamination resistance testing constitutes a supplementary quality control measure, with injectors subjected to standardized particulate challenges to evaluate their susceptibility to clogging and performance degradation. The ISO 4406 cleanliness code often serves as the reference standard for these evaluations, with injectors required to maintain performance specifications after exposure to controlled contamination levels.

Documentation requirements for quality control certification include comprehensive spray pattern visualization records, quantitative measurement data, statistical analysis reports, and traceability information linking each injector to its specific test results. These records must be maintained according to industry-standard retention policies, typically ranging from five to seven years depending on regulatory jurisdiction.

The primary quality parameters for injector spray pattern testing include atomization quality, spray angle consistency, penetration depth, and symmetrical distribution. Modern testing facilities implement automated optical measurement systems capable of capturing high-speed imagery at rates exceeding 100,000 frames per second, allowing for precise quantification of these parameters. The acceptable variance threshold for spray angle typically ranges between ±2° to ±3° from the manufacturer's specification, while droplet size distribution must maintain a Sauter Mean Diameter (SMD) within predetermined ranges specific to engine design requirements.

Temporal consistency represents another crucial quality metric, with injectors required to demonstrate repeatable spray patterns across multiple injection events. Statistical process control methods are employed to monitor this consistency, with Coefficient of Variation (CV) values generally required to remain below 3% for premium automotive applications. Testing protocols typically mandate a minimum sample size of 100 consecutive injection events to establish statistical validity.

Environmental condition standardization is equally important in quality control frameworks. Testing chambers must maintain precise temperature control (±2°C), pressure regulation (±0.5 bar), and humidity levels (45-55% relative humidity) to ensure reproducible results. Many advanced testing facilities implement climate simulation capabilities to evaluate injector performance across the full operational temperature spectrum from cold-start conditions (-30°C) to maximum operating temperatures (150°C).

Contamination resistance testing constitutes a supplementary quality control measure, with injectors subjected to standardized particulate challenges to evaluate their susceptibility to clogging and performance degradation. The ISO 4406 cleanliness code often serves as the reference standard for these evaluations, with injectors required to maintain performance specifications after exposure to controlled contamination levels.

Documentation requirements for quality control certification include comprehensive spray pattern visualization records, quantitative measurement data, statistical analysis reports, and traceability information linking each injector to its specific test results. These records must be maintained according to industry-standard retention policies, typically ranging from five to seven years depending on regulatory jurisdiction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!