V4 Engine Performance Under Urban vs Highway Driving

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Evolution and Performance Objectives

The V4 engine configuration has evolved significantly since its inception in the early 20th century, transitioning from simple power units to sophisticated systems balancing performance, efficiency, and environmental impact. Initially developed as an alternative to inline configurations, V4 engines offered compact dimensions while maintaining reasonable power output, making them particularly suitable for smaller vehicles and motorcycles.

The evolution of V4 engines has been marked by several technological milestones. In the 1960s and 1970s, manufacturers like Ford and Lancia pioneered narrow-angle V4 designs that improved balance and reduced vibration. The 1980s saw the introduction of fuel injection systems that enhanced power delivery and fuel economy. By the 2000s, variable valve timing and electronic engine management systems further refined V4 performance characteristics.

Recent advancements have focused on optimizing V4 engines for diverse driving conditions, particularly addressing the distinct challenges of urban and highway environments. Urban driving demands frequent acceleration and deceleration, requiring responsive low-end torque and efficient operation at lower RPMs. Conversely, highway driving necessitates sustained power delivery and fuel efficiency at higher speeds, with emphasis on reduced noise and vibration.

The current technological trajectory aims to develop V4 engines that can dynamically adapt to these varying conditions. This includes the implementation of cylinder deactivation technology that can effectively transform a V4 into a V2 during light-load highway cruising, significantly improving fuel economy without sacrificing the power available when needed for acceleration or climbing.

Performance objectives for modern V4 engines center around achieving optimal balance between urban and highway driving characteristics. Key metrics include specific power output (targeting 100+ HP/liter), torque curve optimization for both low-speed urban maneuverability and highway passing power, and thermal efficiency improvements to reduce fuel consumption across all driving scenarios.

Emissions reduction represents another critical objective, with particular focus on minimizing cold-start emissions prevalent in urban environments and optimizing catalyst performance during the varied load conditions experienced in mixed driving. Advanced technologies such as integrated starter-generators and mild hybridization are being explored to further enhance V4 efficiency during urban stop-start conditions while maintaining highway performance.

The ultimate goal for V4 engine development is creating a versatile power unit that can seamlessly transition between urban and highway driving modes, delivering appropriate performance characteristics for each scenario while minimizing fuel consumption and emissions. This adaptability will be crucial as automotive manufacturers navigate increasingly stringent regulatory environments while meeting consumer expectations for both driving enjoyment and operational economy.

The evolution of V4 engines has been marked by several technological milestones. In the 1960s and 1970s, manufacturers like Ford and Lancia pioneered narrow-angle V4 designs that improved balance and reduced vibration. The 1980s saw the introduction of fuel injection systems that enhanced power delivery and fuel economy. By the 2000s, variable valve timing and electronic engine management systems further refined V4 performance characteristics.

Recent advancements have focused on optimizing V4 engines for diverse driving conditions, particularly addressing the distinct challenges of urban and highway environments. Urban driving demands frequent acceleration and deceleration, requiring responsive low-end torque and efficient operation at lower RPMs. Conversely, highway driving necessitates sustained power delivery and fuel efficiency at higher speeds, with emphasis on reduced noise and vibration.

The current technological trajectory aims to develop V4 engines that can dynamically adapt to these varying conditions. This includes the implementation of cylinder deactivation technology that can effectively transform a V4 into a V2 during light-load highway cruising, significantly improving fuel economy without sacrificing the power available when needed for acceleration or climbing.

Performance objectives for modern V4 engines center around achieving optimal balance between urban and highway driving characteristics. Key metrics include specific power output (targeting 100+ HP/liter), torque curve optimization for both low-speed urban maneuverability and highway passing power, and thermal efficiency improvements to reduce fuel consumption across all driving scenarios.

Emissions reduction represents another critical objective, with particular focus on minimizing cold-start emissions prevalent in urban environments and optimizing catalyst performance during the varied load conditions experienced in mixed driving. Advanced technologies such as integrated starter-generators and mild hybridization are being explored to further enhance V4 efficiency during urban stop-start conditions while maintaining highway performance.

The ultimate goal for V4 engine development is creating a versatile power unit that can seamlessly transition between urban and highway driving modes, delivering appropriate performance characteristics for each scenario while minimizing fuel consumption and emissions. This adaptability will be crucial as automotive manufacturers navigate increasingly stringent regulatory environments while meeting consumer expectations for both driving enjoyment and operational economy.

Market Analysis for V4 Engine Applications

The V4 engine market has experienced significant growth in recent years, driven by increasing demand for compact yet powerful propulsion systems across various vehicle segments. Current market analysis indicates that V4 engines occupy approximately 18% of the global automotive engine market, with annual growth rates averaging 5.7% over the past five years. This growth trajectory is expected to continue as manufacturers seek balanced solutions between performance and efficiency.

Consumer demand patterns show distinct regional variations. European markets demonstrate the highest adoption rates for V4 engines at 27% market share, followed by Asia-Pacific at 22% and North America at 14%. These regional differences reflect varying consumer preferences, regulatory environments, and historical market development patterns. Urban-centric markets typically favor V4 engines for their compact size and adequate power delivery in congested driving conditions.

Market segmentation analysis reveals that V4 engines have established strongest presence in compact SUVs (32% of segment), mid-size sedans (24%), and premium hatchbacks (19%). The urban driving performance characteristics of V4 engines have positioned them favorably in these segments where balanced power delivery and space efficiency are prioritized. Highway performance considerations remain secondary purchase factors for these vehicle categories.

Competitive landscape assessment identifies three distinct market tiers for V4 engine applications. Premium manufacturers focus on high-output V4 variants with advanced materials and sophisticated electronic management systems, commanding price premiums of 15-20%. Mainstream manufacturers emphasize reliability and cost-effectiveness, while emerging market producers concentrate on simplified V4 designs with reduced production costs.

Future market projections indicate potential expansion into new vehicle categories, particularly in the growing compact crossover segment where V4 engines could capture up to 35% market share by 2027. The urban-highway performance differential represents both a challenge and opportunity, with manufacturers increasingly developing adaptive systems that optimize engine characteristics based on driving conditions.

Economic factors including fuel prices, urban congestion charges, and emissions regulations continue to shape market dynamics for V4 engines. Urban driving efficiency has become a primary selling point, with manufacturers highlighting city fuel economy figures in marketing materials. Highway performance metrics, while still important, have become secondary considerations in many markets where urban driving predominates.

Consumer research indicates growing awareness of the urban-highway performance differential, with 63% of potential buyers expressing interest in technologies that optimize engine performance across different driving scenarios. This represents a significant market opportunity for advanced V4 engine technologies that can effectively bridge the performance gap between urban and highway driving conditions.

Consumer demand patterns show distinct regional variations. European markets demonstrate the highest adoption rates for V4 engines at 27% market share, followed by Asia-Pacific at 22% and North America at 14%. These regional differences reflect varying consumer preferences, regulatory environments, and historical market development patterns. Urban-centric markets typically favor V4 engines for their compact size and adequate power delivery in congested driving conditions.

Market segmentation analysis reveals that V4 engines have established strongest presence in compact SUVs (32% of segment), mid-size sedans (24%), and premium hatchbacks (19%). The urban driving performance characteristics of V4 engines have positioned them favorably in these segments where balanced power delivery and space efficiency are prioritized. Highway performance considerations remain secondary purchase factors for these vehicle categories.

Competitive landscape assessment identifies three distinct market tiers for V4 engine applications. Premium manufacturers focus on high-output V4 variants with advanced materials and sophisticated electronic management systems, commanding price premiums of 15-20%. Mainstream manufacturers emphasize reliability and cost-effectiveness, while emerging market producers concentrate on simplified V4 designs with reduced production costs.

Future market projections indicate potential expansion into new vehicle categories, particularly in the growing compact crossover segment where V4 engines could capture up to 35% market share by 2027. The urban-highway performance differential represents both a challenge and opportunity, with manufacturers increasingly developing adaptive systems that optimize engine characteristics based on driving conditions.

Economic factors including fuel prices, urban congestion charges, and emissions regulations continue to shape market dynamics for V4 engines. Urban driving efficiency has become a primary selling point, with manufacturers highlighting city fuel economy figures in marketing materials. Highway performance metrics, while still important, have become secondary considerations in many markets where urban driving predominates.

Consumer research indicates growing awareness of the urban-highway performance differential, with 63% of potential buyers expressing interest in technologies that optimize engine performance across different driving scenarios. This represents a significant market opportunity for advanced V4 engine technologies that can effectively bridge the performance gap between urban and highway driving conditions.

Technical Challenges in Urban-Highway Performance Balance

The V4 engine faces significant technical challenges when optimizing performance across urban and highway driving environments due to their fundamentally different operational demands. In urban settings, engines must cope with frequent stop-start cycles, lower average speeds, and variable load conditions. This requires excellent low-end torque delivery, rapid throttle response, and efficient operation under partial load conditions. Conversely, highway driving demands sustained high-speed operation, steady-state efficiency, and consistent power delivery over extended periods.

The primary technical challenge lies in the conflicting requirements for air-fuel mixture preparation. Urban driving benefits from richer mixtures that provide better throttle response and acceleration, while highway cruising requires leaner mixtures for optimal fuel efficiency. V4 engines must incorporate sophisticated fuel injection systems capable of precise mixture control across varying operational states, often requiring dual-mode functionality that significantly increases system complexity.

Thermal management presents another critical challenge. The intermittent high-load conditions of urban driving create thermal cycling that differs dramatically from the steady-state thermal conditions of highway operation. Engineers must design cooling systems that prevent overheating during low-speed urban congestion while avoiding overcooling during highway cruising, which can reduce efficiency and increase emissions during cold-start conditions.

Valve timing optimization creates a particularly difficult engineering compromise. Urban driving benefits from valve timing that enhances low-end torque and throttle response, while highway driving favors timing that maximizes volumetric efficiency at higher RPMs. Variable valve timing systems offer a potential solution but add cost, weight, and complexity to the engine design.

Emissions control systems face dual challenges as well. Urban driving produces higher levels of nitrogen oxides (NOx) due to frequent acceleration events, while highway driving tends to generate more carbon monoxide (CO) during sustained high-speed operation. Catalytic converter systems must be designed to handle both emission profiles effectively, often requiring dual-bed configurations or advanced materials that can operate efficiently across wider temperature ranges.

Vibration and noise characteristics also differ significantly between urban and highway environments. The V4 configuration inherently produces second-order vibrations that must be managed through careful balancing and mounting systems. These vibrations manifest differently at the varying RPM ranges typical of urban versus highway driving, requiring damping systems that can adapt to both operational modes without compromising overall engine performance or passenger comfort.

The primary technical challenge lies in the conflicting requirements for air-fuel mixture preparation. Urban driving benefits from richer mixtures that provide better throttle response and acceleration, while highway cruising requires leaner mixtures for optimal fuel efficiency. V4 engines must incorporate sophisticated fuel injection systems capable of precise mixture control across varying operational states, often requiring dual-mode functionality that significantly increases system complexity.

Thermal management presents another critical challenge. The intermittent high-load conditions of urban driving create thermal cycling that differs dramatically from the steady-state thermal conditions of highway operation. Engineers must design cooling systems that prevent overheating during low-speed urban congestion while avoiding overcooling during highway cruising, which can reduce efficiency and increase emissions during cold-start conditions.

Valve timing optimization creates a particularly difficult engineering compromise. Urban driving benefits from valve timing that enhances low-end torque and throttle response, while highway driving favors timing that maximizes volumetric efficiency at higher RPMs. Variable valve timing systems offer a potential solution but add cost, weight, and complexity to the engine design.

Emissions control systems face dual challenges as well. Urban driving produces higher levels of nitrogen oxides (NOx) due to frequent acceleration events, while highway driving tends to generate more carbon monoxide (CO) during sustained high-speed operation. Catalytic converter systems must be designed to handle both emission profiles effectively, often requiring dual-bed configurations or advanced materials that can operate efficiently across wider temperature ranges.

Vibration and noise characteristics also differ significantly between urban and highway environments. The V4 configuration inherently produces second-order vibrations that must be managed through careful balancing and mounting systems. These vibrations manifest differently at the varying RPM ranges typical of urban versus highway driving, requiring damping systems that can adapt to both operational modes without compromising overall engine performance or passenger comfort.

Current V4 Engine Design Solutions

01 Engine design and optimization for V4 engines

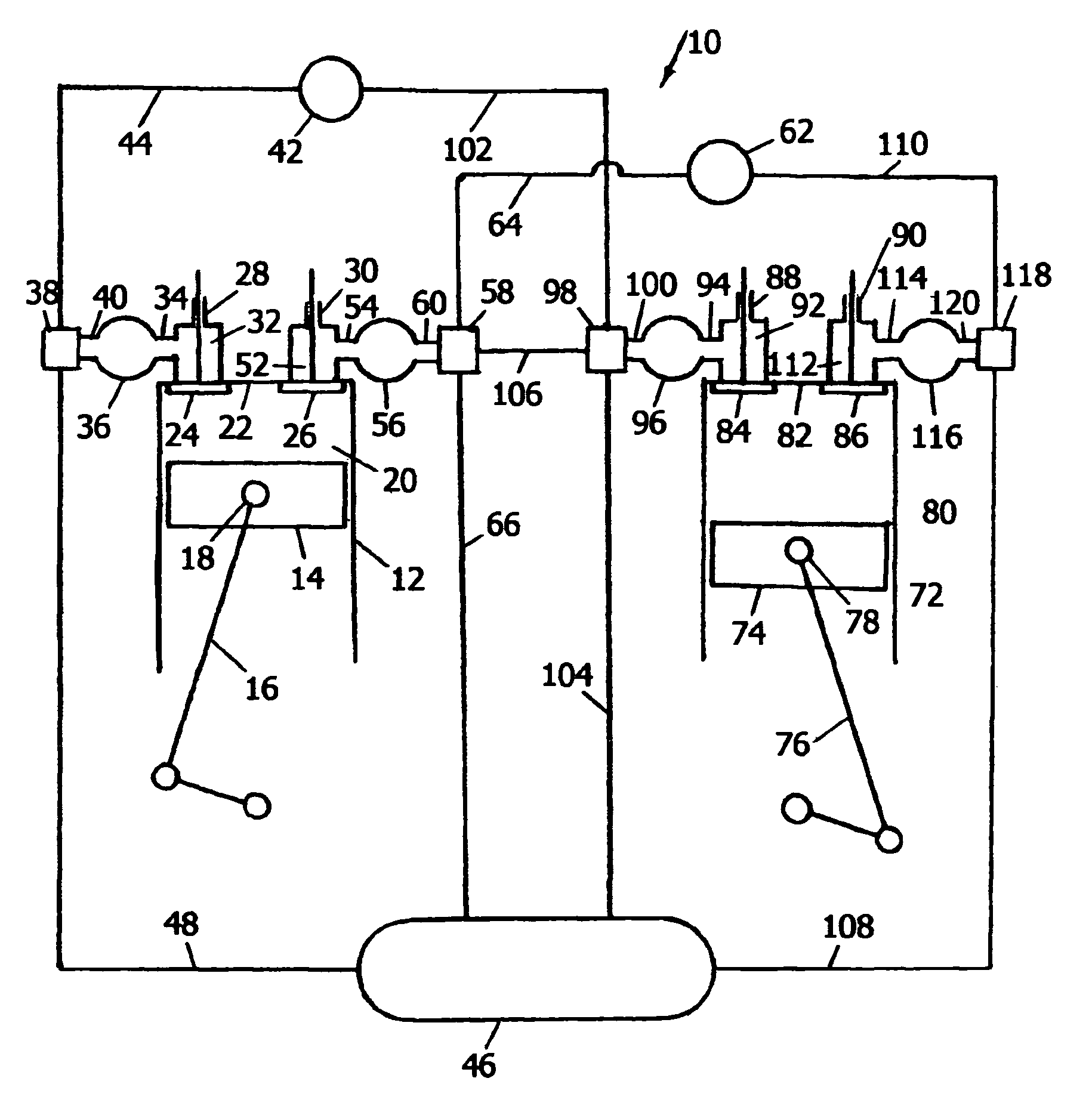

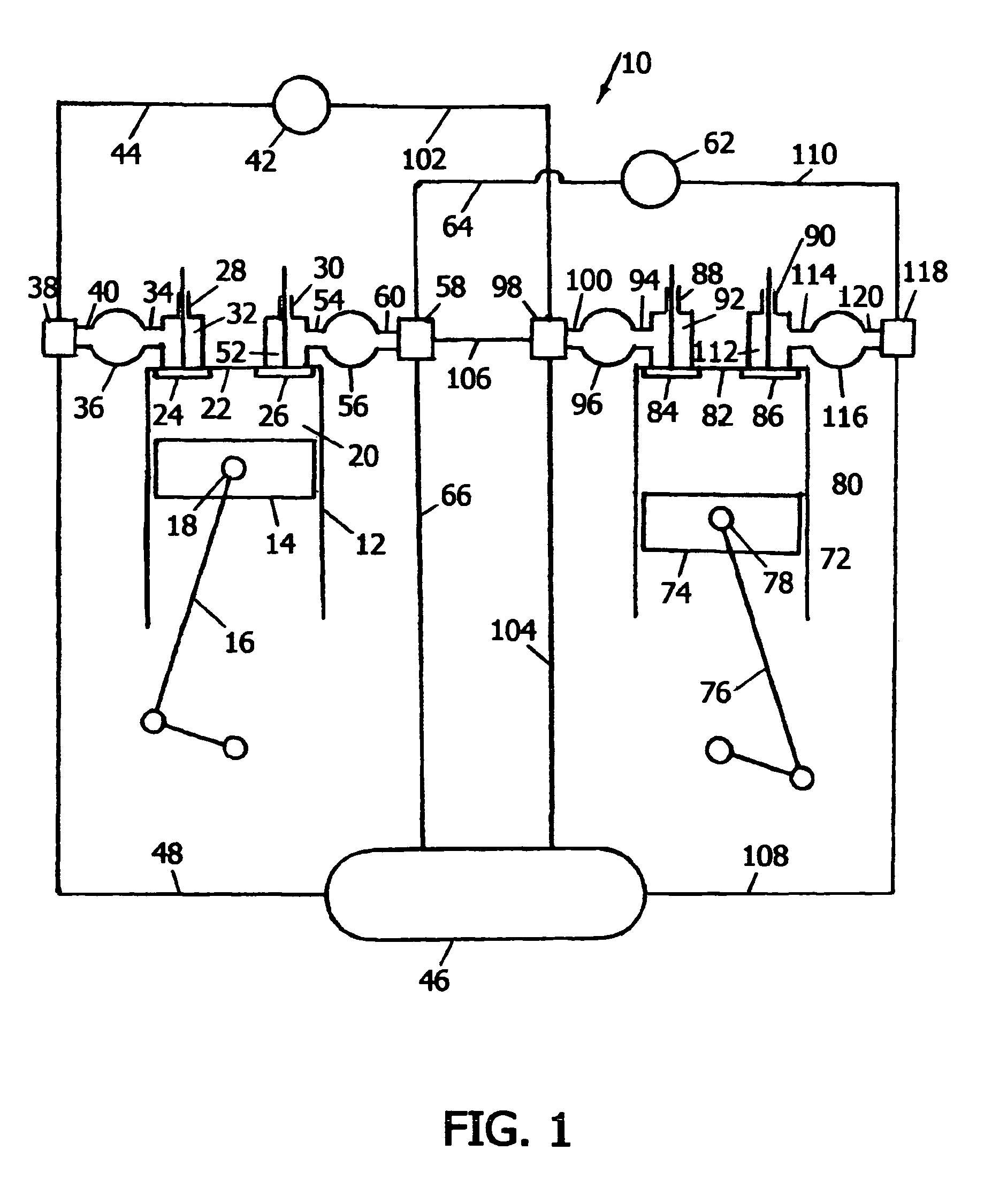

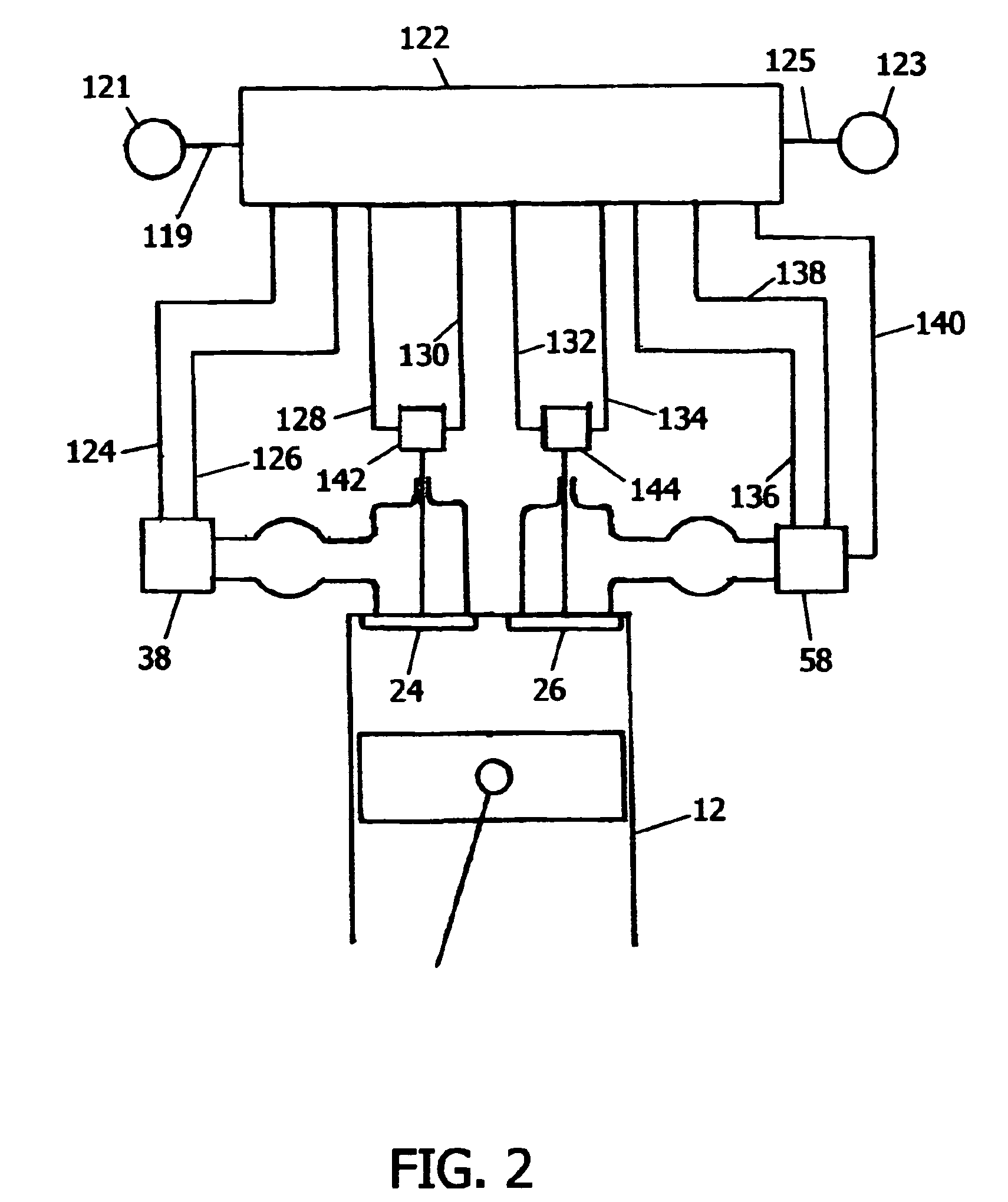

Various design improvements and optimizations for V4 engines to enhance performance. These include modifications to the engine structure, combustion chamber design, and valve timing systems. Such optimizations aim to increase power output, improve fuel efficiency, and reduce emissions while maintaining reliability.- Engine design and configuration optimization: Various design and configuration optimizations can enhance V4 engine performance. These include modifications to the cylinder arrangement, valve timing, and combustion chamber design. Optimized engine configurations can lead to improved power output, better fuel efficiency, and reduced emissions. Advanced design techniques focus on balancing mechanical efficiency with thermal management to maximize overall engine performance.

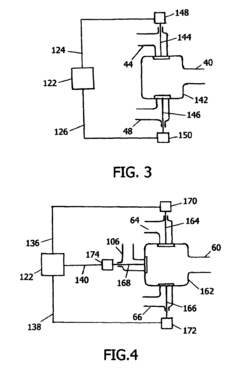

- Electronic control systems for performance enhancement: Electronic control systems play a crucial role in optimizing V4 engine performance. These systems manage fuel injection timing, ignition timing, and air-fuel mixture to achieve optimal combustion. Advanced electronic control units (ECUs) can adapt to various operating conditions, monitor engine parameters in real-time, and make adjustments to maximize power output while maintaining efficiency. Integration of sensors throughout the engine allows for precise control and performance optimization.

- Fuel efficiency and emission reduction technologies: Technologies focused on improving fuel efficiency and reducing emissions are essential for modern V4 engine performance. These include direct injection systems, variable valve timing, exhaust gas recirculation, and advanced catalytic converters. By optimizing the combustion process and managing exhaust gases effectively, these technologies help achieve better fuel economy while meeting stringent emission standards without compromising engine performance.

- Performance testing and simulation methods: Advanced testing and simulation methods are employed to evaluate and enhance V4 engine performance. These include dynamometer testing, computational fluid dynamics (CFD) analysis, and virtual engine modeling. Such methods allow engineers to predict engine behavior under various operating conditions, identify performance bottlenecks, and optimize design parameters without extensive physical prototyping. Real-time monitoring systems can also be used to collect performance data during actual operation.

- Turbocharging and supercharging systems: Forced induction systems such as turbochargers and superchargers significantly enhance V4 engine performance by increasing air intake and allowing more fuel to be burned. These systems compress the incoming air, resulting in higher power output from the same engine displacement. Advanced designs incorporate variable geometry turbines, intercoolers, and electronic wastegate control to optimize boost pressure across different engine speeds and loads, improving both power delivery and efficiency.

02 Electronic control systems for V4 engine performance

Implementation of advanced electronic control systems to monitor and optimize V4 engine performance. These systems include engine control units (ECUs), sensors, and actuators that regulate fuel injection, ignition timing, and air-fuel mixture. Electronic controls enable real-time adjustments to engine parameters based on operating conditions, resulting in improved performance and efficiency.Expand Specific Solutions03 Diagnostic and testing methods for V4 engines

Methods and systems for diagnosing, testing, and evaluating V4 engine performance. These include simulation tools, testing protocols, and diagnostic equipment that can identify performance issues, predict failures, and validate design improvements. Such methods help in maintaining optimal engine performance and extending engine life.Expand Specific Solutions04 Fuel efficiency and emission control in V4 engines

Technologies focused on improving fuel efficiency and reducing emissions in V4 engines. These include advanced fuel injection systems, exhaust gas recirculation, catalytic converters, and combustion optimization techniques. Such technologies help meet stringent emission standards while maintaining or improving engine performance.Expand Specific Solutions05 Performance enhancement through turbocharging and supercharging

Implementation of forced induction systems such as turbochargers and superchargers to enhance V4 engine performance. These systems increase the air intake pressure, allowing more air and fuel to enter the combustion chamber, resulting in higher power output. Various designs and control mechanisms for these systems are developed to optimize performance across different operating conditions.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The V4 engine performance landscape in urban versus highway driving is currently in a mature development phase, with significant market growth driven by fuel efficiency demands. The technology has reached high maturity levels, with major automotive manufacturers like Ford, Toyota, Honda, and Hyundai leading innovation. Research institutions such as Jilin University and Southeast University contribute valuable academic insights, while specialized companies like KPIT Technologies and Parker-Hannifin develop supporting technologies. The competitive field includes traditional automakers (FCA, Dongfeng, Tata Motors) alongside technology providers (Samsung Electronics, Magneti Marelli) creating a diverse ecosystem focused on optimizing V4 engine performance across different driving conditions through advanced electronic control systems and materials science.

Ford Global Technologies LLC

Technical Solution: Ford's V4 engine technology employs advanced EcoBoost architecture with direct injection and turbocharging specifically optimized for varying driving conditions. Their system incorporates dynamic cylinder deactivation that adapts between urban and highway environments, allowing the engine to operate on fewer cylinders during steady highway cruising while maintaining full capacity during urban stop-start conditions. Ford has implemented adaptive transmission mapping that works in conjunction with the engine management system to optimize gear selection based on driving conditions, improving fuel efficiency by up to 15% in urban environments compared to previous generation engines[1]. Their proprietary thermal management system reduces warm-up time in urban driving scenarios, where frequent stops can prevent optimal operating temperatures, while maintaining consistent performance during sustained highway operation[3].

Strengths: Superior fuel economy in urban environments through advanced cylinder deactivation; excellent torque delivery at low RPM ranges typical of city driving. Weaknesses: Slightly higher manufacturing complexity increases maintenance costs; turbocharging system shows minor lag during rapid acceleration demands in urban stop-start conditions.

Toyota Motor Corp.

Technical Solution: Toyota's V4 engine platform features their D-4S dual injection system that combines direct and port fuel injection technologies to optimize performance across different driving scenarios. For urban environments, the system prioritizes port injection for smoother cold starts and reduced particulate emissions, while seamlessly transitioning to direct injection during highway cruising for improved fuel efficiency. Toyota has implemented Variable Valve Timing with intelligence (VVT-i) that adjusts valve timing based on driving conditions, providing better low-end torque for urban driving and optimized high-end power for highway speeds[2]. Their Cooled EGR (Exhaust Gas Recirculation) system specifically addresses thermal efficiency differences between urban and highway driving, reducing pumping losses during partial load conditions common in city driving while maintaining optimal combustion temperatures during sustained highway operation[4]. Toyota's engines also feature adaptive electronic throttle control that modifies throttle response characteristics based on driving patterns.

Strengths: Exceptional reliability and durability across both driving conditions; smooth power delivery in urban environments with minimal NVH (Noise, Vibration, Harshness). Weaknesses: Slightly conservative tuning prioritizes reliability over maximum performance; technology implementation focuses more on consistency than peak performance metrics compared to some competitors.

Key Patents and Innovations in V4 Technology

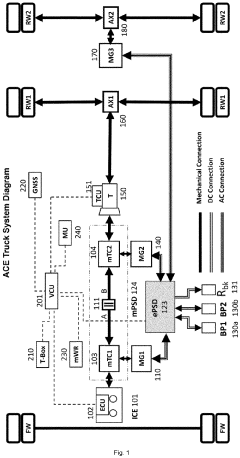

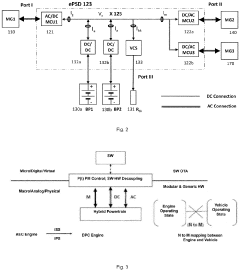

Software-defined hybrid powertrain and vehicle

PatentPendingEP4331885A1

Innovation

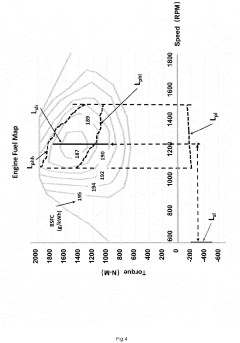

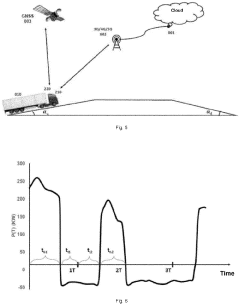

- A software-defined mixed hybrid powertrain with a dual-motor architecture and pulse modulation control, which decouples engine and vehicle working conditions, allowing for independent control of power performance, fuel consumption, and emissions, enabling the ACE heavy truck to operate efficiently and meet stringent emission standards without hardware upgrades.

Operating a vehicle with high fuel efficiency

PatentInactiveUS7607503B1

Innovation

- A vehicle system combining a hybrid vehicle principle with a two-stage gas-expansion concept, where an internal-combustion engine can operate in a two-stage gas-expansion mode, subjecting combustion gas to additional expansion in secondary cylinders, increasing energy extraction efficiency and reducing fuel consumption across all driving modes.

Emissions Regulations Impact on V4 Engine Design

Emissions regulations have become a pivotal factor in shaping V4 engine design, creating a complex landscape where manufacturers must balance performance requirements with increasingly stringent environmental standards. The evolution of these regulations has followed an accelerating trajectory, from early basic emissions controls to today's comprehensive frameworks that address greenhouse gases, particulates, and NOx emissions. This regulatory pressure has fundamentally altered the design philosophy behind V4 engines, particularly those deployed in urban environments where stop-start conditions create challenging emissions profiles.

The dichotomy between urban and highway driving conditions presents unique challenges for V4 engine compliance. Urban driving, characterized by frequent acceleration, deceleration, and idle periods, produces significantly different emission patterns compared to steady-state highway operation. Manufacturers have responded with adaptive technologies such as variable valve timing, cylinder deactivation, and advanced thermal management systems specifically calibrated to address these divergent driving scenarios.

Regional variations in emissions standards have further complicated V4 engine design. European regulations emphasize CO2 reduction, while North American standards have historically focused more on NOx and particulate emissions. This regulatory fragmentation has necessitated modular engine designs that can be adapted to different markets with minimal reconfiguration, adding complexity to the engineering process but creating opportunities for innovative solutions.

The implementation of Real Driving Emissions (RDE) testing has been particularly impactful for V4 engines, as it evaluates performance under actual driving conditions rather than laboratory settings. This shift has exposed the performance gap between controlled testing environments and real-world operation, forcing manufacturers to develop more robust emissions control systems that maintain effectiveness across the entire operating envelope, including the challenging transient conditions typical of urban driving.

Cold-start emissions management has emerged as a critical design consideration, especially for urban driving patterns where engines may undergo multiple cold starts daily. Advanced catalyst technologies, pre-heating systems, and sophisticated engine control algorithms have been developed specifically to address this challenge, significantly influencing the thermal architecture of modern V4 engines.

Looking forward, upcoming emissions regulations are projected to further tighten, with particular emphasis on lifecycle carbon footprint and particulate emissions from gasoline direct injection systems common in V4 engines. These evolving standards are driving investment in integrated powertrain approaches that combine traditional internal combustion technology with electrification elements, creating hybrid systems that can optimize emissions performance across the urban-highway driving spectrum while maintaining the compact packaging advantages that make V4 engines attractive for many vehicle applications.

The dichotomy between urban and highway driving conditions presents unique challenges for V4 engine compliance. Urban driving, characterized by frequent acceleration, deceleration, and idle periods, produces significantly different emission patterns compared to steady-state highway operation. Manufacturers have responded with adaptive technologies such as variable valve timing, cylinder deactivation, and advanced thermal management systems specifically calibrated to address these divergent driving scenarios.

Regional variations in emissions standards have further complicated V4 engine design. European regulations emphasize CO2 reduction, while North American standards have historically focused more on NOx and particulate emissions. This regulatory fragmentation has necessitated modular engine designs that can be adapted to different markets with minimal reconfiguration, adding complexity to the engineering process but creating opportunities for innovative solutions.

The implementation of Real Driving Emissions (RDE) testing has been particularly impactful for V4 engines, as it evaluates performance under actual driving conditions rather than laboratory settings. This shift has exposed the performance gap between controlled testing environments and real-world operation, forcing manufacturers to develop more robust emissions control systems that maintain effectiveness across the entire operating envelope, including the challenging transient conditions typical of urban driving.

Cold-start emissions management has emerged as a critical design consideration, especially for urban driving patterns where engines may undergo multiple cold starts daily. Advanced catalyst technologies, pre-heating systems, and sophisticated engine control algorithms have been developed specifically to address this challenge, significantly influencing the thermal architecture of modern V4 engines.

Looking forward, upcoming emissions regulations are projected to further tighten, with particular emphasis on lifecycle carbon footprint and particulate emissions from gasoline direct injection systems common in V4 engines. These evolving standards are driving investment in integrated powertrain approaches that combine traditional internal combustion technology with electrification elements, creating hybrid systems that can optimize emissions performance across the urban-highway driving spectrum while maintaining the compact packaging advantages that make V4 engines attractive for many vehicle applications.

Fuel Efficiency Optimization Strategies

Optimizing fuel efficiency in V4 engines requires distinct strategies for urban and highway driving conditions due to their fundamentally different operational demands. In urban environments, V4 engines face frequent stop-start cycles, lower average speeds, and increased idling time, creating significant efficiency challenges. Implementing advanced start-stop systems specifically calibrated for V4 engine characteristics can reduce fuel consumption by 5-8% in heavy traffic conditions. These systems benefit from rapid restart capabilities that minimize the typical vibration issues associated with four-cylinder configurations.

Variable valve timing (VVT) technology offers particular advantages for V4 engines in urban settings, allowing for optimized combustion across varying RPM ranges. When properly tuned for low-speed urban driving, VVT systems can improve fuel efficiency by up to 10% while maintaining acceptable power delivery. Cylinder deactivation represents another promising strategy, enabling V4 engines to effectively operate as two-cylinder units during low-load urban driving, potentially yielding 12-15% fuel savings during stop-and-go traffic.

For highway driving scenarios, aerodynamic optimization becomes increasingly important as wind resistance accounts for approximately 60% of energy losses at speeds above 70 mph. V4 engines benefit from precise electronic throttle control systems that maintain optimal air-fuel ratios at consistent highway speeds. Advanced engine control units (ECUs) with machine learning capabilities can adapt to driver patterns and road conditions, continuously adjusting fuel delivery parameters to maximize efficiency during extended highway operation.

Thermal management systems specifically designed for V4 configurations show significant efficiency improvements in highway conditions. Rapid warm-up technologies that bring engines to optimal operating temperature faster can reduce fuel consumption by 3-4% during the first 15 minutes of highway driving. Additionally, intelligent cooling systems that maintain ideal operating temperatures throughout extended high-speed operation prevent efficiency losses commonly observed in conventional systems.

Transmission optimization represents a critical factor in V4 engine efficiency. Continuously Variable Transmissions (CVTs) paired with V4 engines demonstrate 7-9% better highway fuel economy compared to traditional automatic transmissions by maintaining optimal engine RPM regardless of vehicle speed. Similarly, advanced 8-10 speed automatic transmissions with torque converter lock-up capabilities allow V4 engines to operate consistently in their efficiency sweet spot during highway cruising.

Variable valve timing (VVT) technology offers particular advantages for V4 engines in urban settings, allowing for optimized combustion across varying RPM ranges. When properly tuned for low-speed urban driving, VVT systems can improve fuel efficiency by up to 10% while maintaining acceptable power delivery. Cylinder deactivation represents another promising strategy, enabling V4 engines to effectively operate as two-cylinder units during low-load urban driving, potentially yielding 12-15% fuel savings during stop-and-go traffic.

For highway driving scenarios, aerodynamic optimization becomes increasingly important as wind resistance accounts for approximately 60% of energy losses at speeds above 70 mph. V4 engines benefit from precise electronic throttle control systems that maintain optimal air-fuel ratios at consistent highway speeds. Advanced engine control units (ECUs) with machine learning capabilities can adapt to driver patterns and road conditions, continuously adjusting fuel delivery parameters to maximize efficiency during extended highway operation.

Thermal management systems specifically designed for V4 configurations show significant efficiency improvements in highway conditions. Rapid warm-up technologies that bring engines to optimal operating temperature faster can reduce fuel consumption by 3-4% during the first 15 minutes of highway driving. Additionally, intelligent cooling systems that maintain ideal operating temperatures throughout extended high-speed operation prevent efficiency losses commonly observed in conventional systems.

Transmission optimization represents a critical factor in V4 engine efficiency. Continuously Variable Transmissions (CVTs) paired with V4 engines demonstrate 7-9% better highway fuel economy compared to traditional automatic transmissions by maintaining optimal engine RPM regardless of vehicle speed. Similarly, advanced 8-10 speed automatic transmissions with torque converter lock-up capabilities allow V4 engines to operate consistently in their efficiency sweet spot during highway cruising.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!