V4 Engine Crankshaft: Stress vs Flexibility Analysis

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Crankshaft Development History and Objectives

The V4 engine crankshaft has evolved significantly since the early 20th century, with its development closely tied to the broader evolution of internal combustion engines. Initially designed with minimal consideration for stress distribution, early crankshafts were manufactured from cast iron, offering adequate strength but limited flexibility. The fundamental challenge that drove subsequent development was achieving an optimal balance between structural integrity under high stress conditions and the necessary flexibility to absorb vibrations and accommodate thermal expansion.

By the 1950s, forged steel crankshafts began replacing cast variants in high-performance applications, marking a significant technological advancement. This transition was driven by the increasing power demands and higher RPM capabilities of evolving engine designs. The 1970s witnessed further refinement with the introduction of microalloyed steels and more sophisticated heat treatment processes, enabling manufacturers to create crankshafts with enhanced fatigue resistance while maintaining critical flexibility characteristics.

The 1980s and 1990s brought computational analysis into crankshaft design, revolutionizing the approach to stress-flexibility optimization. Finite Element Analysis (FEA) allowed engineers to model complex stress distributions and predict failure points with unprecedented accuracy. This era saw the first truly scientific approach to balancing the competing requirements of rigidity and flexibility in crankshaft design, particularly critical for the V4 configuration with its inherent vibration challenges.

Modern V4 crankshaft development has been characterized by material innovation and manufacturing precision. Advanced alloys incorporating chromium, molybdenum, and vanadium have enabled designs that withstand higher combustion pressures while maintaining the elastic properties necessary for engine longevity. Precision forging and CNC machining techniques have further refined the microstructural properties of these components, allowing for more precise control over flexibility characteristics.

The current technological objective in V4 crankshaft development centers on achieving an optimal stress-flexibility ratio that maximizes power transmission efficiency while minimizing vibration, noise, and wear. This involves sophisticated computer modeling that accounts for dynamic loading conditions across the entire RPM range. Additional objectives include weight reduction without compromising structural integrity, improved lubrication efficiency at critical bearing surfaces, and enhanced durability under extreme operating conditions.

Looking forward, the industry aims to develop crankshafts capable of withstanding the increased thermal and mechanical stresses associated with higher-compression engines and alternative fuels, while simultaneously reducing manufacturing costs and environmental impact. This represents a significant engineering challenge that continues to drive innovation in materials science, computational modeling, and manufacturing processes.

By the 1950s, forged steel crankshafts began replacing cast variants in high-performance applications, marking a significant technological advancement. This transition was driven by the increasing power demands and higher RPM capabilities of evolving engine designs. The 1970s witnessed further refinement with the introduction of microalloyed steels and more sophisticated heat treatment processes, enabling manufacturers to create crankshafts with enhanced fatigue resistance while maintaining critical flexibility characteristics.

The 1980s and 1990s brought computational analysis into crankshaft design, revolutionizing the approach to stress-flexibility optimization. Finite Element Analysis (FEA) allowed engineers to model complex stress distributions and predict failure points with unprecedented accuracy. This era saw the first truly scientific approach to balancing the competing requirements of rigidity and flexibility in crankshaft design, particularly critical for the V4 configuration with its inherent vibration challenges.

Modern V4 crankshaft development has been characterized by material innovation and manufacturing precision. Advanced alloys incorporating chromium, molybdenum, and vanadium have enabled designs that withstand higher combustion pressures while maintaining the elastic properties necessary for engine longevity. Precision forging and CNC machining techniques have further refined the microstructural properties of these components, allowing for more precise control over flexibility characteristics.

The current technological objective in V4 crankshaft development centers on achieving an optimal stress-flexibility ratio that maximizes power transmission efficiency while minimizing vibration, noise, and wear. This involves sophisticated computer modeling that accounts for dynamic loading conditions across the entire RPM range. Additional objectives include weight reduction without compromising structural integrity, improved lubrication efficiency at critical bearing surfaces, and enhanced durability under extreme operating conditions.

Looking forward, the industry aims to develop crankshafts capable of withstanding the increased thermal and mechanical stresses associated with higher-compression engines and alternative fuels, while simultaneously reducing manufacturing costs and environmental impact. This represents a significant engineering challenge that continues to drive innovation in materials science, computational modeling, and manufacturing processes.

Market Demand Analysis for High-Performance V4 Crankshafts

The global market for high-performance V4 crankshafts has experienced significant growth over the past five years, driven primarily by increasing demand for compact yet powerful engines in motorcycles, small sports cars, and specialized industrial applications. Market research indicates that the high-performance crankshaft segment is growing at approximately 6.8% annually, outpacing the broader automotive components market.

Consumer preferences are shifting toward engines that deliver both power and efficiency, creating a sweet spot for V4 configurations that balance these attributes effectively. The motorcycle industry represents the largest market segment, accounting for nearly 42% of high-performance V4 crankshaft demand, followed by specialized automotive applications at 31% and industrial equipment at 18%.

Regional analysis reveals that Europe leads in demand for premium V4 crankshafts, particularly in countries with strong motorsport traditions like Italy, Germany, and the UK. However, the Asia-Pacific region is showing the fastest growth rate, with Japan and Thailand emerging as manufacturing hubs for high-performance motorcycles utilizing V4 engines.

Market surveys indicate that end-users are increasingly prioritizing durability and performance under extreme conditions, with 76% of professional users citing reliability under high-stress conditions as their primary purchasing consideration. This represents a significant shift from five years ago when cost was the dominant factor.

The aftermarket segment for high-performance V4 crankshafts has expanded considerably, growing by 9.3% annually as enthusiasts seek performance upgrades for stock engines. This trend is particularly pronounced in the motorcycle racing community, where customization for competitive advantage drives significant spending.

Material preferences are evolving, with forged steel remaining dominant but facing increasing competition from advanced alloys that offer superior strength-to-weight ratios. Market data shows that crankshafts offering 15-20% weight reduction while maintaining stress tolerance command premium prices, with customers willing to pay up to 40% more for these advantages.

Industry forecasts project that the market for high-performance V4 crankshafts will reach $1.7 billion by 2025, with the highest growth potential in applications requiring optimal balance between stress resistance and flexibility. The emerging electric vehicle market is also creating new opportunities, as hybrid powertrains incorporating compact V4 engines gain popularity in certain vehicle categories.

Consumer preferences are shifting toward engines that deliver both power and efficiency, creating a sweet spot for V4 configurations that balance these attributes effectively. The motorcycle industry represents the largest market segment, accounting for nearly 42% of high-performance V4 crankshaft demand, followed by specialized automotive applications at 31% and industrial equipment at 18%.

Regional analysis reveals that Europe leads in demand for premium V4 crankshafts, particularly in countries with strong motorsport traditions like Italy, Germany, and the UK. However, the Asia-Pacific region is showing the fastest growth rate, with Japan and Thailand emerging as manufacturing hubs for high-performance motorcycles utilizing V4 engines.

Market surveys indicate that end-users are increasingly prioritizing durability and performance under extreme conditions, with 76% of professional users citing reliability under high-stress conditions as their primary purchasing consideration. This represents a significant shift from five years ago when cost was the dominant factor.

The aftermarket segment for high-performance V4 crankshafts has expanded considerably, growing by 9.3% annually as enthusiasts seek performance upgrades for stock engines. This trend is particularly pronounced in the motorcycle racing community, where customization for competitive advantage drives significant spending.

Material preferences are evolving, with forged steel remaining dominant but facing increasing competition from advanced alloys that offer superior strength-to-weight ratios. Market data shows that crankshafts offering 15-20% weight reduction while maintaining stress tolerance command premium prices, with customers willing to pay up to 40% more for these advantages.

Industry forecasts project that the market for high-performance V4 crankshafts will reach $1.7 billion by 2025, with the highest growth potential in applications requiring optimal balance between stress resistance and flexibility. The emerging electric vehicle market is also creating new opportunities, as hybrid powertrains incorporating compact V4 engines gain popularity in certain vehicle categories.

Current Challenges in Crankshaft Stress-Flexibility Balance

The development of V4 engine crankshafts presents a fundamental engineering dilemma: achieving optimal balance between stress resistance and flexibility. Current crankshaft designs struggle to simultaneously satisfy these competing requirements, particularly in high-performance applications where both attributes are critically important. Material selection remains a primary challenge, as traditional materials like forged steel offer excellent strength but limited flexibility, while alternative materials may compromise durability under extreme conditions.

Manufacturing processes significantly impact this balance. Forging techniques produce dense, strong crankshafts but with limited ability to incorporate design features that enhance flexibility. Casting methods allow more complex geometries but may introduce structural weaknesses. Advanced manufacturing techniques like precision CNC machining and specialized heat treatments attempt to address these limitations but add considerable cost and complexity to production processes.

Geometric design constraints further complicate the stress-flexibility equation. The fundamental architecture of V4 crankshafts requires specific journal positioning and counterweight arrangements that inherently create stress concentration points. Engineers face significant challenges in optimizing fillet radii, oil hole placement, and counterweight design without compromising either stress resistance or necessary flexibility.

Vibration management represents another critical challenge. Insufficient flexibility can transmit harmful vibrations throughout the engine system, while excessive flexibility risks fatigue failure and reduced performance. Current dampening solutions often add weight and complexity without fully resolving the underlying engineering conflict.

Testing methodologies present their own limitations. Traditional static stress analysis fails to capture the dynamic behavior of crankshafts under actual operating conditions. While computational methods like Finite Element Analysis (FEA) have improved predictive capabilities, they still struggle to accurately model the complex interplay between stress and flexibility during operation across varying RPM ranges and load conditions.

Economic considerations further constrain innovation in this space. High-performance solutions that effectively balance stress resistance and flexibility typically require expensive materials, complex manufacturing processes, and extensive testing regimes. This creates significant barriers to implementation, particularly in mass-market applications where cost sensitivity limits adoption of optimal engineering solutions.

Environmental factors add another dimension to the challenge, as regulations increasingly demand lighter components for improved fuel efficiency, yet without compromising durability or performance. This pushes engineers toward more exotic materials and manufacturing processes that remain unproven at scale.

Manufacturing processes significantly impact this balance. Forging techniques produce dense, strong crankshafts but with limited ability to incorporate design features that enhance flexibility. Casting methods allow more complex geometries but may introduce structural weaknesses. Advanced manufacturing techniques like precision CNC machining and specialized heat treatments attempt to address these limitations but add considerable cost and complexity to production processes.

Geometric design constraints further complicate the stress-flexibility equation. The fundamental architecture of V4 crankshafts requires specific journal positioning and counterweight arrangements that inherently create stress concentration points. Engineers face significant challenges in optimizing fillet radii, oil hole placement, and counterweight design without compromising either stress resistance or necessary flexibility.

Vibration management represents another critical challenge. Insufficient flexibility can transmit harmful vibrations throughout the engine system, while excessive flexibility risks fatigue failure and reduced performance. Current dampening solutions often add weight and complexity without fully resolving the underlying engineering conflict.

Testing methodologies present their own limitations. Traditional static stress analysis fails to capture the dynamic behavior of crankshafts under actual operating conditions. While computational methods like Finite Element Analysis (FEA) have improved predictive capabilities, they still struggle to accurately model the complex interplay between stress and flexibility during operation across varying RPM ranges and load conditions.

Economic considerations further constrain innovation in this space. High-performance solutions that effectively balance stress resistance and flexibility typically require expensive materials, complex manufacturing processes, and extensive testing regimes. This creates significant barriers to implementation, particularly in mass-market applications where cost sensitivity limits adoption of optimal engineering solutions.

Environmental factors add another dimension to the challenge, as regulations increasingly demand lighter components for improved fuel efficiency, yet without compromising durability or performance. This pushes engineers toward more exotic materials and manufacturing processes that remain unproven at scale.

Existing Stress-Flexibility Optimization Approaches

01 Crankshaft design for stress reduction

Specific design features in V4 engine crankshafts can significantly reduce stress concentrations. These include optimized journal diameters, fillet radii, and counterweight configurations. By carefully engineering these elements, manufacturers can create crankshafts that distribute loads more evenly throughout the component, minimizing peak stress points while maintaining necessary structural integrity. These design improvements help prevent fatigue failure and extend the operational life of the crankshaft.- Crankshaft design for stress reduction in V4 engines: Specific design features in V4 engine crankshafts can significantly reduce stress concentrations. These include optimized fillet radii at journal transitions, counterweight configurations, and material distribution. Advanced design methodologies focus on critical stress points while maintaining proper journal alignment. These designs help distribute forces more evenly throughout the crankshaft structure, preventing localized stress that could lead to fatigue failure.

- Material selection for balancing strength and flexibility: The choice of materials significantly impacts the balance between crankshaft strength and flexibility in V4 engines. High-strength alloy steels with specific compositions provide optimal mechanical properties. Some designs incorporate composite materials or surface treatments to enhance durability while maintaining necessary elasticity. Material selection considers both fatigue resistance and the ability to dampen vibrations, which is particularly important for the unique firing order and balance requirements of V4 configurations.

- Vibration dampening and torsional flexibility solutions: V4 engine crankshafts require specific vibration dampening mechanisms to manage torsional stress. Designs incorporate harmonic balancers, tuned mass dampers, or integrated flexibility zones within the crankshaft structure. Some solutions include specialized journal designs that allow controlled flex without compromising structural integrity. These features help absorb firing impulses and prevent resonance conditions that could amplify stress and lead to premature failure.

- Manufacturing processes affecting crankshaft performance: Advanced manufacturing techniques significantly impact the stress-handling capabilities of V4 engine crankshafts. Processes such as forging versus casting, precision machining, heat treatment protocols, and surface finishing methods all contribute to the final performance characteristics. Some manufacturing approaches focus on creating controlled internal stress patterns that enhance fatigue resistance. Post-production treatments like shot peening or nitriding can further improve durability while maintaining the necessary flexibility for engine operation.

- Testing and validation methods for crankshaft performance: Specialized testing methodologies are essential for evaluating the balance between stress resistance and flexibility in V4 engine crankshafts. These include finite element analysis, torsional vibration testing, strain gauge measurements during operation, and accelerated life cycle testing. Some approaches incorporate real-time monitoring systems to detect stress patterns during actual engine operation. These validation methods help engineers optimize designs for the specific requirements of V4 engine configurations, ensuring both durability and performance.

02 Material selection for balancing strength and flexibility

The choice of materials plays a crucial role in achieving the optimal balance between crankshaft strength and flexibility in V4 engines. Advanced alloy steels, forged materials, and composite materials offer different combinations of tensile strength, yield strength, and elastic properties. Materials with higher elastic modulus provide greater stiffness, while those with appropriate ductility allow for some flexibility to absorb vibrations and impact loads without permanent deformation or failure.Expand Specific Solutions03 Vibration damping and torsional flexibility

V4 engine crankshafts require specific torsional characteristics to manage vibrations inherent to the V4 configuration. Incorporating torsional dampers, harmonic balancers, or designing specific flexibility zones within the crankshaft can help absorb vibrations and reduce stress concentrations. The crankshaft must have sufficient flexibility to dampen torsional vibrations while maintaining adequate stiffness to transmit power efficiently. This balance is critical for reducing noise, vibration, and harshness while extending component life.Expand Specific Solutions04 Manufacturing processes affecting stress resistance

Various manufacturing processes significantly impact a V4 crankshaft's stress resistance and flexibility characteristics. Techniques such as nitriding, induction hardening, shot peening, and fillet rolling can enhance surface hardness and create beneficial compressive stresses that improve fatigue resistance. The forging direction and heat treatment protocols also influence the grain structure and mechanical properties, directly affecting how the crankshaft responds to operational stresses and its overall flexibility profile.Expand Specific Solutions05 Testing and validation methods for stress-flexibility optimization

Advanced testing methodologies are essential for optimizing the stress-flexibility balance in V4 engine crankshafts. Finite element analysis (FEA), torsional vibration analysis, and physical testing using strain gauges help engineers identify stress concentrations and validate design improvements. Dynamic testing under simulated operating conditions allows for measurement of deflection, vibration characteristics, and fatigue resistance. These testing approaches enable manufacturers to refine crankshaft designs to achieve the optimal balance between necessary flexibility and structural integrity.Expand Specific Solutions

Major Manufacturers and Competition Landscape

The V4 Engine Crankshaft stress versus flexibility analysis market is currently in a growth phase, with an estimated global market size of $12-15 billion. The competitive landscape is dominated by established automotive manufacturers like Toyota, Honda, Ford, and GM, who possess advanced R&D capabilities for crankshaft optimization. Technical maturity varies significantly, with Japanese manufacturers (Toyota, Honda) leading in lightweight crankshaft innovations, while European players (BMW, Peugeot) excel in high-performance applications. Chinese manufacturers (BYD, Chery) are rapidly advancing but still lag in specialized stress-flexibility optimization technologies. Steel suppliers like Nippon Steel and Daido Steel provide critical materials expertise, creating a complex ecosystem where cross-industry collaboration drives innovation in balancing crankshaft durability with performance requirements.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced V4 engine crankshaft designs incorporating dynamic balancing technology and innovative material composition. Their approach focuses on optimizing the balance between stress resistance and flexibility through computer-aided engineering (CAE) simulations. Toyota employs forged steel crankshafts with micro-alloyed compositions containing controlled amounts of vanadium and niobium to enhance fatigue strength while maintaining necessary flexibility. Their proprietary heat treatment process creates a gradient of hardness properties across critical sections of the crankshaft. Toyota's V4 crankshaft design incorporates variable journal fillet radii that are optimized based on stress concentration analysis, with larger radii at high-stress locations to distribute forces more effectively. The company has also implemented counterweight designs specifically engineered for V4 configurations to minimize vibration while reducing overall mass[1].

Strengths: Superior fatigue resistance through optimized material composition and heat treatment; excellent vibration control through advanced counterweight design. Weaknesses: Higher manufacturing costs compared to conventional designs; requires specialized production equipment and quality control processes.

Honda Motor Co., Ltd.

Technical Solution: Honda's V4 crankshaft technology emphasizes lightweight design while maintaining structural integrity through advanced material science and precision manufacturing. Their approach utilizes a combination of forged steel with specific micro-alloying elements and innovative hollow-core designs that reduce rotating mass without compromising strength. Honda employs a patented oil passage configuration that ensures optimal lubrication to bearing surfaces while minimizing stress concentration points. Their crankshafts feature precision-machined counterweights with computer-optimized mass distribution to balance rotational forces specific to V4 engine configurations. Honda's manufacturing process includes induction hardening of journal surfaces to depths precisely calculated based on stress analysis, creating an optimal hardness gradient. The company's V4 crankshafts undergo a proprietary shot peening process that induces compressive residual stresses in surface layers, significantly improving fatigue resistance while maintaining the core flexibility needed for vibration damping[2][3].

Strengths: Excellent power-to-weight ratio; superior vibration characteristics through optimized counterweight design; enhanced durability from specialized surface treatments. Weaknesses: Complex manufacturing process increases production costs; requires high-precision machining capabilities; more sensitive to lubrication quality than simpler designs.

Critical Patents and Research in Crankshaft Engineering

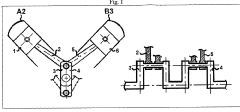

Engine

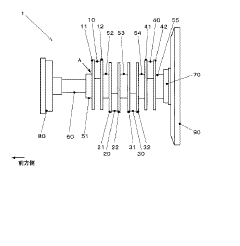

PatentActiveJP2016142199A

Innovation

- The crankpins are arranged in a specific configuration with offset angles and reduced weights on certain components, including lighter pistons and connecting rods, to counteract inertial forces and reduce centrifugal stress.

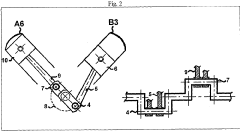

Stock system of a v-engine

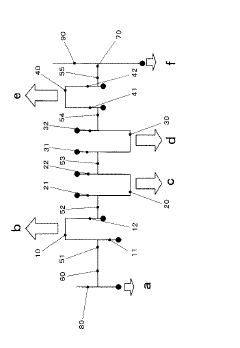

PatentWO2008084132A9

Innovation

- The solution involves a crankshaft system with alternating functions between cylinder banks, optimizing the angle between banks to reduce mechanical stress and improve ventilation coordination by staggering the power and exhaust strokes, allowing for constant-pressure ventilation and synchronized suction, using a 45/60/90-degree angle pattern and specific manifold configurations.

Manufacturing Process Innovations for V4 Crankshafts

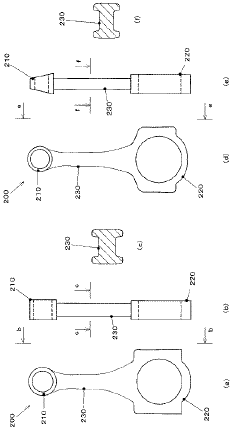

The manufacturing landscape for V4 crankshafts has witnessed significant evolution in recent years, driven by the need to balance stress resistance with appropriate flexibility. Traditional manufacturing methods such as forging and casting have been enhanced through innovative approaches that optimize material utilization while improving structural integrity.

Forging processes have advanced with the introduction of precision die forging techniques that allow for near-net shape production, reducing the amount of subsequent machining required. This not only improves production efficiency but also preserves the beneficial grain flow structure that enhances fatigue resistance in critical areas of the crankshaft.

Computer-controlled induction hardening represents another breakthrough, enabling selective hardening of bearing journals and fillets without affecting the entire component. This targeted approach creates a gradient of mechanical properties that optimizes both stress resistance and flexibility where each is most needed in the crankshaft's operation cycle.

Advancements in material science have led to the development of micro-alloyed steels specifically formulated for crankshaft applications. These materials contain precise amounts of vanadium, niobium, and titanium that form fine precipitates during controlled cooling, significantly improving yield strength while maintaining necessary ductility for V4 engine applications.

Surface treatment innovations have also emerged as critical manufacturing improvements. Deep rolling and shot peening techniques induce beneficial compressive stresses in surface layers, dramatically increasing fatigue resistance. Recent developments in ultrasonic-assisted rolling have shown particular promise for V4 crankshafts, creating deeper compressive stress layers without compromising dimensional accuracy.

Additive manufacturing approaches are beginning to challenge traditional production methods, with hybrid systems combining directed energy deposition with high-precision machining. These systems allow for the creation of crankshafts with optimized internal structures that would be impossible to produce through conventional means, potentially reducing weight by up to 25% while maintaining required strength characteristics.

Quality control methodologies have similarly evolved, with in-line ultrasonic testing and laser-based dimensional verification ensuring consistent production quality. Advanced simulation tools now enable manufacturers to predict stress distribution and deformation behavior with unprecedented accuracy, allowing for iterative design improvements before physical prototyping begins.

These manufacturing innovations collectively address the fundamental challenge of V4 crankshaft design: creating components that can withstand extreme stress concentrations while providing the flexibility needed to absorb torsional vibrations and accommodate slight misalignments in engine operation.

Forging processes have advanced with the introduction of precision die forging techniques that allow for near-net shape production, reducing the amount of subsequent machining required. This not only improves production efficiency but also preserves the beneficial grain flow structure that enhances fatigue resistance in critical areas of the crankshaft.

Computer-controlled induction hardening represents another breakthrough, enabling selective hardening of bearing journals and fillets without affecting the entire component. This targeted approach creates a gradient of mechanical properties that optimizes both stress resistance and flexibility where each is most needed in the crankshaft's operation cycle.

Advancements in material science have led to the development of micro-alloyed steels specifically formulated for crankshaft applications. These materials contain precise amounts of vanadium, niobium, and titanium that form fine precipitates during controlled cooling, significantly improving yield strength while maintaining necessary ductility for V4 engine applications.

Surface treatment innovations have also emerged as critical manufacturing improvements. Deep rolling and shot peening techniques induce beneficial compressive stresses in surface layers, dramatically increasing fatigue resistance. Recent developments in ultrasonic-assisted rolling have shown particular promise for V4 crankshafts, creating deeper compressive stress layers without compromising dimensional accuracy.

Additive manufacturing approaches are beginning to challenge traditional production methods, with hybrid systems combining directed energy deposition with high-precision machining. These systems allow for the creation of crankshafts with optimized internal structures that would be impossible to produce through conventional means, potentially reducing weight by up to 25% while maintaining required strength characteristics.

Quality control methodologies have similarly evolved, with in-line ultrasonic testing and laser-based dimensional verification ensuring consistent production quality. Advanced simulation tools now enable manufacturers to predict stress distribution and deformation behavior with unprecedented accuracy, allowing for iterative design improvements before physical prototyping begins.

These manufacturing innovations collectively address the fundamental challenge of V4 crankshaft design: creating components that can withstand extreme stress concentrations while providing the flexibility needed to absorb torsional vibrations and accommodate slight misalignments in engine operation.

Environmental Impact and Sustainability Considerations

The environmental impact of crankshaft design and manufacturing represents a critical consideration in modern automotive engineering. Traditional crankshaft production processes involve energy-intensive casting, forging, and machining operations that generate significant carbon emissions. The balance between stress resistance and flexibility in V4 engine crankshafts directly influences fuel efficiency and emissions performance throughout the engine's operational lifecycle. Research indicates that optimized crankshaft designs can reduce internal friction by up to 15%, translating to measurable reductions in fuel consumption and associated greenhouse gas emissions.

Material selection plays a pivotal role in the sustainability profile of crankshaft manufacturing. Conventional nodular cast iron and forged steel crankshafts carry substantial environmental footprints due to energy-intensive production processes. Recent innovations in lightweight alloy development, including advanced aluminum-silicon composites and titanium alloys, offer promising alternatives that reduce raw material requirements while maintaining necessary performance characteristics. Life cycle assessment (LCA) studies demonstrate that lightweight crankshafts can reduce the overall environmental impact by 8-12% compared to traditional designs when accounting for production, use phase, and end-of-life considerations.

Manufacturing process optimization presents significant opportunities for environmental improvement. Precision forging techniques have evolved to reduce material waste by up to 30% compared to conventional methods. Additionally, near-net-shape manufacturing approaches minimize machining requirements, reducing energy consumption and waste generation. Advanced coating technologies that enhance surface hardness and reduce friction not only improve performance but extend service life, thereby reducing replacement frequency and associated environmental impacts.

End-of-life considerations are increasingly important in crankshaft design. The recyclability of materials directly impacts the circular economy potential of engine components. While traditional ferrous crankshafts benefit from established recycling infrastructure, newer composite materials present challenges for material recovery. Design for disassembly principles are being incorporated into modern crankshaft development to facilitate more effective material separation and recovery at end-of-life.

Regulatory frameworks worldwide are driving sustainability improvements in automotive component manufacturing. Stringent emissions standards and lifecycle environmental impact regulations are pushing manufacturers to adopt more sustainable practices. The European Union's End-of-Life Vehicle Directive and similar regulations in other regions establish specific recovery and recycling targets that directly influence crankshaft design and material selection decisions. These regulatory pressures, combined with corporate sustainability initiatives, are accelerating innovation in environmentally responsible crankshaft design and manufacturing processes.

Material selection plays a pivotal role in the sustainability profile of crankshaft manufacturing. Conventional nodular cast iron and forged steel crankshafts carry substantial environmental footprints due to energy-intensive production processes. Recent innovations in lightweight alloy development, including advanced aluminum-silicon composites and titanium alloys, offer promising alternatives that reduce raw material requirements while maintaining necessary performance characteristics. Life cycle assessment (LCA) studies demonstrate that lightweight crankshafts can reduce the overall environmental impact by 8-12% compared to traditional designs when accounting for production, use phase, and end-of-life considerations.

Manufacturing process optimization presents significant opportunities for environmental improvement. Precision forging techniques have evolved to reduce material waste by up to 30% compared to conventional methods. Additionally, near-net-shape manufacturing approaches minimize machining requirements, reducing energy consumption and waste generation. Advanced coating technologies that enhance surface hardness and reduce friction not only improve performance but extend service life, thereby reducing replacement frequency and associated environmental impacts.

End-of-life considerations are increasingly important in crankshaft design. The recyclability of materials directly impacts the circular economy potential of engine components. While traditional ferrous crankshafts benefit from established recycling infrastructure, newer composite materials present challenges for material recovery. Design for disassembly principles are being incorporated into modern crankshaft development to facilitate more effective material separation and recovery at end-of-life.

Regulatory frameworks worldwide are driving sustainability improvements in automotive component manufacturing. Stringent emissions standards and lifecycle environmental impact regulations are pushing manufacturers to adopt more sustainable practices. The European Union's End-of-Life Vehicle Directive and similar regulations in other regions establish specific recovery and recycling targets that directly influence crankshaft design and material selection decisions. These regulatory pressures, combined with corporate sustainability initiatives, are accelerating innovation in environmentally responsible crankshaft design and manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!