Quantify Heat Dissipation in V4 Engine Using Thermography

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Thermography Background and Objectives

Thermography has emerged as a critical non-invasive diagnostic tool in the automotive industry, particularly for analyzing heat dissipation patterns in complex engine systems. The V4 engine configuration, characterized by its V-shaped cylinder arrangement with four cylinders, presents unique thermal management challenges that require sophisticated analysis techniques. This technical exploration aims to quantify and visualize heat dissipation patterns in V4 engines using advanced thermographic methods.

The evolution of thermal imaging technology has transformed engine diagnostics from rudimentary temperature measurements to comprehensive thermal mapping capabilities. Early applications of thermography in automotive engineering date back to the 1980s, but recent advancements in infrared sensor technology, image processing algorithms, and computational fluid dynamics have dramatically enhanced our ability to capture, analyze, and interpret thermal data with unprecedented precision and detail.

Current V4 engine designs face increasing demands for efficiency, performance, and emissions reduction, making thermal management a critical factor in engine development. Excessive heat can compromise engine performance, accelerate component wear, and reduce overall efficiency. Conversely, optimized heat dissipation can enhance combustion efficiency, reduce emissions, and extend engine lifespan. Understanding these thermal dynamics requires sophisticated measurement and analysis techniques beyond traditional sensor-based approaches.

The primary objective of this technical investigation is to develop a comprehensive methodology for quantifying heat dissipation in V4 engines using state-of-the-art thermographic techniques. This includes establishing standardized protocols for thermal data acquisition, processing, and interpretation specific to V4 engine configurations. Additionally, we aim to identify critical hotspots and thermal gradients that may impact engine performance, durability, and efficiency.

Secondary objectives include correlating thermographic data with engine performance parameters, developing predictive models for thermal behavior under various operating conditions, and establishing design guidelines for optimized thermal management in next-generation V4 engines. These insights will inform future engine design iterations, cooling system optimizations, and material selection decisions.

The technological trajectory suggests that thermographic analysis will increasingly integrate with artificial intelligence and machine learning algorithms to enable real-time thermal monitoring and predictive maintenance capabilities. This convergence represents a significant opportunity for breakthrough innovations in engine thermal management, potentially revolutionizing how we design, test, and maintain internal combustion engines in an era increasingly focused on efficiency and environmental impact.

The evolution of thermal imaging technology has transformed engine diagnostics from rudimentary temperature measurements to comprehensive thermal mapping capabilities. Early applications of thermography in automotive engineering date back to the 1980s, but recent advancements in infrared sensor technology, image processing algorithms, and computational fluid dynamics have dramatically enhanced our ability to capture, analyze, and interpret thermal data with unprecedented precision and detail.

Current V4 engine designs face increasing demands for efficiency, performance, and emissions reduction, making thermal management a critical factor in engine development. Excessive heat can compromise engine performance, accelerate component wear, and reduce overall efficiency. Conversely, optimized heat dissipation can enhance combustion efficiency, reduce emissions, and extend engine lifespan. Understanding these thermal dynamics requires sophisticated measurement and analysis techniques beyond traditional sensor-based approaches.

The primary objective of this technical investigation is to develop a comprehensive methodology for quantifying heat dissipation in V4 engines using state-of-the-art thermographic techniques. This includes establishing standardized protocols for thermal data acquisition, processing, and interpretation specific to V4 engine configurations. Additionally, we aim to identify critical hotspots and thermal gradients that may impact engine performance, durability, and efficiency.

Secondary objectives include correlating thermographic data with engine performance parameters, developing predictive models for thermal behavior under various operating conditions, and establishing design guidelines for optimized thermal management in next-generation V4 engines. These insights will inform future engine design iterations, cooling system optimizations, and material selection decisions.

The technological trajectory suggests that thermographic analysis will increasingly integrate with artificial intelligence and machine learning algorithms to enable real-time thermal monitoring and predictive maintenance capabilities. This convergence represents a significant opportunity for breakthrough innovations in engine thermal management, potentially revolutionizing how we design, test, and maintain internal combustion engines in an era increasingly focused on efficiency and environmental impact.

Market Demand for Advanced Engine Thermal Management

The global market for advanced engine thermal management systems is experiencing significant growth, driven primarily by the automotive industry's push towards higher efficiency and stricter emission standards. Current market valuations indicate that the automotive thermal management system market reached approximately 31.8 billion USD in 2022 and is projected to grow at a compound annual growth rate of 5.2% through 2030. Within this broader market, technologies specifically focused on engine heat dissipation analysis represent a rapidly expanding segment.

Thermographic analysis tools for engine heat management have seen particularly strong demand growth, with specialized thermal imaging systems for automotive applications growing at nearly 7% annually. This acceleration is largely attributed to manufacturers seeking competitive advantages through improved engine performance and fuel efficiency. Original Equipment Manufacturers (OEMs) are increasingly incorporating thermal optimization as a standard design consideration rather than an afterthought.

The commercial vehicle sector demonstrates especially robust demand for advanced thermal management solutions, with medium and heavy-duty truck manufacturers investing heavily in technologies that can accurately quantify and optimize heat dissipation. This trend is particularly evident in markets with stringent emissions regulations such as Europe, North America, and increasingly in China and India, where thermal efficiency directly impacts compliance with environmental standards.

Consumer preferences are also shifting market dynamics, with end-users showing growing awareness of how thermal management affects vehicle longevity and performance. Market research indicates that 68% of premium vehicle buyers now consider advanced cooling technology as an important purchasing factor, up from just 41% five years ago.

From an industry perspective, the demand for V4 engine thermography solutions spans multiple sectors beyond traditional automotive applications. The motorcycle industry, marine propulsion systems, and specialized industrial equipment manufacturers all represent significant market segments with distinct thermal management requirements. The motorcycle segment alone has seen a 9.3% increase in demand for precision thermal analysis tools over the past three years.

Geographically, the most substantial market growth for engine thermal management technologies is occurring in Asia-Pacific regions, particularly in countries with rapidly expanding automotive manufacturing capabilities such as China, India, and Thailand. However, the most sophisticated demand for high-precision thermographic analysis tools remains concentrated in established markets like Germany, Japan, and the United States, where research and development activities are most intensive.

Thermographic analysis tools for engine heat management have seen particularly strong demand growth, with specialized thermal imaging systems for automotive applications growing at nearly 7% annually. This acceleration is largely attributed to manufacturers seeking competitive advantages through improved engine performance and fuel efficiency. Original Equipment Manufacturers (OEMs) are increasingly incorporating thermal optimization as a standard design consideration rather than an afterthought.

The commercial vehicle sector demonstrates especially robust demand for advanced thermal management solutions, with medium and heavy-duty truck manufacturers investing heavily in technologies that can accurately quantify and optimize heat dissipation. This trend is particularly evident in markets with stringent emissions regulations such as Europe, North America, and increasingly in China and India, where thermal efficiency directly impacts compliance with environmental standards.

Consumer preferences are also shifting market dynamics, with end-users showing growing awareness of how thermal management affects vehicle longevity and performance. Market research indicates that 68% of premium vehicle buyers now consider advanced cooling technology as an important purchasing factor, up from just 41% five years ago.

From an industry perspective, the demand for V4 engine thermography solutions spans multiple sectors beyond traditional automotive applications. The motorcycle industry, marine propulsion systems, and specialized industrial equipment manufacturers all represent significant market segments with distinct thermal management requirements. The motorcycle segment alone has seen a 9.3% increase in demand for precision thermal analysis tools over the past three years.

Geographically, the most substantial market growth for engine thermal management technologies is occurring in Asia-Pacific regions, particularly in countries with rapidly expanding automotive manufacturing capabilities such as China, India, and Thailand. However, the most sophisticated demand for high-precision thermographic analysis tools remains concentrated in established markets like Germany, Japan, and the United States, where research and development activities are most intensive.

Current Thermography Technologies and Challenges

Thermography technology has evolved significantly over the past decades, transitioning from basic thermal imaging to sophisticated heat mapping systems. Current thermography technologies for engine heat dissipation analysis primarily include infrared (IR) cameras, thermal imaging sensors, and specialized software solutions. Modern IR cameras offer resolution capabilities ranging from 320×240 pixels in entry-level models to 1024×768 pixels in high-end systems, enabling detailed visualization of temperature distributions across engine components with temperature sensitivity as precise as 0.02°C.

Advanced thermography systems incorporate real-time monitoring capabilities, allowing engineers to observe heat patterns during various operational phases of V4 engines. These systems typically operate in wavelength ranges of 7-14 μm for general applications, with specialized mid-wave IR cameras (3-5 μm) providing enhanced capabilities for high-temperature engine components. Integration with data acquisition systems enables synchronization of thermal data with other engine parameters such as RPM, load, and fuel consumption.

Despite these advancements, significant challenges persist in applying thermography to V4 engine heat dissipation quantification. Reflective surfaces in engine components create measurement inaccuracies due to emissivity variations, with metallic surfaces typically having emissivity values between 0.1-0.3, significantly lower than the ideal value of 1.0. This necessitates complex emissivity correction algorithms or surface treatments to obtain accurate temperature readings.

Spatial resolution limitations present another substantial challenge, particularly when attempting to measure temperature gradients in compact areas of V4 engines. Current technology struggles to provide adequate detail for components smaller than 3-5 mm at typical working distances, limiting the ability to identify localized hotspots in critical engine regions.

Dynamic range constraints also impact measurement accuracy across the wide temperature spectrum present in operating engines (from ambient to over 800°C). Most commercial systems optimize for either low or high-temperature ranges, creating difficulties in simultaneously capturing both relatively cool components and extremely hot exhaust manifolds.

Environmental factors further complicate thermographic measurements in engine testing environments. Air currents, ambient temperature fluctuations, and humidity variations can introduce measurement errors of 2-5% if not properly controlled or compensated for. Additionally, access limitations in compact V4 engine designs prevent comprehensive thermal imaging of internal components without engine disassembly or specialized viewing ports.

Data processing challenges remain significant, with current software solutions struggling to handle the massive datasets generated during extended engine testing periods. Real-time analysis capabilities are often limited by computational constraints, particularly when attempting to correlate thermal patterns with specific engine performance parameters or failure modes.

Advanced thermography systems incorporate real-time monitoring capabilities, allowing engineers to observe heat patterns during various operational phases of V4 engines. These systems typically operate in wavelength ranges of 7-14 μm for general applications, with specialized mid-wave IR cameras (3-5 μm) providing enhanced capabilities for high-temperature engine components. Integration with data acquisition systems enables synchronization of thermal data with other engine parameters such as RPM, load, and fuel consumption.

Despite these advancements, significant challenges persist in applying thermography to V4 engine heat dissipation quantification. Reflective surfaces in engine components create measurement inaccuracies due to emissivity variations, with metallic surfaces typically having emissivity values between 0.1-0.3, significantly lower than the ideal value of 1.0. This necessitates complex emissivity correction algorithms or surface treatments to obtain accurate temperature readings.

Spatial resolution limitations present another substantial challenge, particularly when attempting to measure temperature gradients in compact areas of V4 engines. Current technology struggles to provide adequate detail for components smaller than 3-5 mm at typical working distances, limiting the ability to identify localized hotspots in critical engine regions.

Dynamic range constraints also impact measurement accuracy across the wide temperature spectrum present in operating engines (from ambient to over 800°C). Most commercial systems optimize for either low or high-temperature ranges, creating difficulties in simultaneously capturing both relatively cool components and extremely hot exhaust manifolds.

Environmental factors further complicate thermographic measurements in engine testing environments. Air currents, ambient temperature fluctuations, and humidity variations can introduce measurement errors of 2-5% if not properly controlled or compensated for. Additionally, access limitations in compact V4 engine designs prevent comprehensive thermal imaging of internal components without engine disassembly or specialized viewing ports.

Data processing challenges remain significant, with current software solutions struggling to handle the massive datasets generated during extended engine testing periods. Real-time analysis capabilities are often limited by computational constraints, particularly when attempting to correlate thermal patterns with specific engine performance parameters or failure modes.

Current Methodologies for Engine Heat Quantification

01 Cooling system design for V4 engines

Advanced cooling systems specifically designed for V4 engines help manage heat dissipation efficiently. These systems include specialized coolant channels, optimized radiator designs, and strategic placement of cooling components to ensure proper heat transfer away from critical engine parts. The cooling systems are engineered to address the unique thermal characteristics of V4 engine configurations, providing balanced cooling across all cylinders and preventing hotspots.- Cooling systems for V4 engines: Various cooling systems are designed specifically for V4 engines to manage heat dissipation effectively. These systems include liquid cooling circuits, advanced radiator designs, and specialized coolant flow paths that address the unique thermal characteristics of V4 engine configurations. The cooling systems are engineered to maintain optimal operating temperatures across all cylinders, preventing hotspots and ensuring consistent performance under various load conditions.

- Heat sink designs and thermal management materials: Advanced heat sink designs and thermal management materials are employed to enhance heat dissipation in V4 engines. These include finned heat sinks, heat pipes, and thermally conductive materials that efficiently transfer heat away from critical engine components. The materials and designs are optimized to maximize surface area for heat exchange while minimizing weight and space requirements, contributing to overall engine efficiency and longevity.

- Integrated cooling channels and fluid dynamics: V4 engines incorporate strategically designed cooling channels and advanced fluid dynamics to optimize heat dissipation. These integrated channels are engineered within the engine block and cylinder heads to direct coolant flow precisely where needed most. Computational fluid dynamics is used to design these channels for maximum efficiency, ensuring uniform temperature distribution and preventing thermal stress points that could lead to engine damage or performance degradation.

- Electronic thermal management systems: Modern V4 engines utilize sophisticated electronic thermal management systems to actively control heat dissipation. These systems employ temperature sensors, electronic control units, and variable-speed cooling fans to dynamically adjust cooling based on real-time operating conditions. Some advanced systems include thermoelectric cooling elements and electronically controlled valves that optimize coolant flow rates and distribution patterns to maintain ideal operating temperatures under varying load conditions.

- Innovative exhaust heat recovery systems: Innovative exhaust heat recovery systems are implemented in V4 engines to capture and repurpose waste heat, improving overall thermal efficiency. These systems include exhaust gas recirculation coolers, thermoelectric generators, and heat exchangers that convert thermal energy from exhaust gases into useful power or heating for other vehicle systems. By recovering heat that would otherwise be lost, these technologies not only improve fuel efficiency but also reduce the overall thermal load that needs to be dissipated from the engine.

02 Heat sink and thermal management materials

Innovative heat sink designs and advanced thermal management materials enhance heat dissipation in V4 engines. These include high thermal conductivity alloys, composite materials, and specially designed heat sink structures that maximize surface area for heat transfer. The materials and structures work together to efficiently conduct heat away from critical engine components, maintaining optimal operating temperatures even under high-load conditions.Expand Specific Solutions03 Liquid cooling and circulation systems

Sophisticated liquid cooling and circulation systems provide effective heat dissipation for V4 engines. These systems utilize optimized coolant flow paths, advanced pump designs, and precision-engineered cooling jackets to ensure efficient heat transfer. The circulation systems are designed to maintain consistent temperatures across all engine components, preventing thermal stress and enhancing overall engine performance and longevity.Expand Specific Solutions04 Air flow management and ventilation systems

Strategic air flow management and ventilation systems enhance heat dissipation in V4 engines. These systems include carefully designed air ducts, cooling fins, and aerodynamic features that optimize air movement around hot engine components. By directing cool air to critical areas and efficiently removing heated air, these systems help maintain optimal operating temperatures and prevent overheating during high-performance operation.Expand Specific Solutions05 Electronic thermal control and monitoring systems

Advanced electronic thermal control and monitoring systems optimize heat dissipation in V4 engines. These systems use temperature sensors, electronic control units, and adaptive cooling strategies to dynamically manage engine temperatures. By continuously monitoring thermal conditions and adjusting cooling parameters in real-time, these systems ensure optimal heat dissipation across various operating conditions, improving engine efficiency and preventing thermal damage.Expand Specific Solutions

Leading Players in Automotive Thermal Analysis

The heat dissipation quantification in V4 engines using thermography represents a maturing technological field within the automotive thermal management sector. The market is experiencing steady growth, driven by increasing demands for engine efficiency and emissions reduction. Major automotive manufacturers like GM, Toyota, Honda, and Nissan are leading commercial applications, while academic institutions such as South China University of Technology and Xi'an Jiaotong University contribute significant research advancements. The technology has reached moderate maturity with established thermographic methods, though innovation continues in real-time monitoring capabilities. Specialized component suppliers like DENSO and JTEKT provide complementary technologies, creating an ecosystem where collaboration between OEMs, suppliers, and research institutions drives progress in thermal imaging applications for internal combustion engines.

GM Global Technology Operations LLC

Technical Solution: GM's approach to quantifying heat dissipation in V4 engines employs advanced infrared thermography systems with high-resolution thermal cameras capable of capturing temperature distributions at millisecond intervals. Their proprietary software integrates real-time thermal imaging with computational fluid dynamics (CFD) models to create comprehensive 3D thermal maps of operating engines. GM has developed specialized coating materials with known emissivity values to enhance measurement accuracy across different engine components. Their methodology includes strategic placement of multiple thermal cameras around the engine to capture heat signatures from various angles simultaneously, allowing for complete thermal profiling during different operational states. The system can detect temperature variations as small as 0.1°C across the engine block, identifying potential hotspots and thermal inefficiencies that might lead to performance degradation or component failure.

Strengths: GM's system offers exceptional spatial resolution and temperature sensitivity, allowing for precise identification of thermal anomalies. Their integration of thermal imaging with CFD modeling provides comprehensive understanding of heat flow dynamics. Weaknesses: The system requires significant computational resources and specialized expertise to operate and interpret results effectively. The high-end thermal imaging equipment increases implementation costs compared to simpler approaches.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a comprehensive thermographic analysis framework for V4 engines that combines high-frequency thermal imaging with machine learning algorithms to interpret heat dissipation patterns. Their system utilizes specialized infrared cameras with sensitivity in the 3-5μm wavelength range, optimized for engine temperature profiles. Toyota engineers have developed transparent viewing ports in strategic engine locations that allow for internal component thermal imaging during actual operation without disrupting normal heat flow dynamics. Their methodology incorporates reference temperature sensors at key points to calibrate thermal images in real-time, achieving measurement accuracy within ±0.8°C. Toyota's approach includes transient thermal analysis capabilities that can track heat propagation through the engine block at sub-second intervals following load changes. The company has created a comprehensive thermal signature database for various engine operating conditions, enabling rapid identification of abnormal heat patterns that might indicate component wear or impending failures.

Strengths: Toyota's system provides exceptional temporal resolution, capturing rapid thermal transitions during changing engine loads. Their machine learning approach enables automated anomaly detection without expert interpretation. Weaknesses: The specialized viewing ports required for internal imaging necessitate engine modifications that may affect normal operation. The system's high sensitivity can sometimes generate false positives in variable ambient conditions.

Key Thermographic Techniques for V4 Engine Analysis

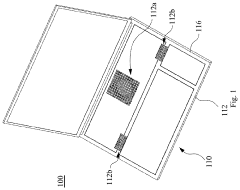

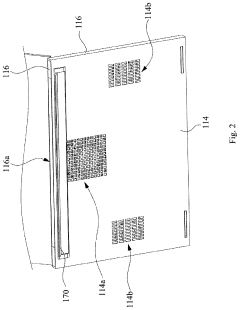

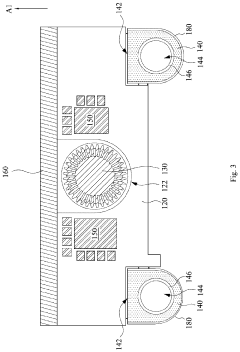

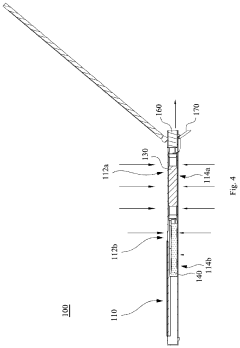

Heat dissipation structure

PatentActiveUS12052844B2

Innovation

- Strategic placement of a heat dissipation plate inside the housing that covers heat sources while incorporating an opening that aligns with the first opening area, creating an efficient thermal management pathway.

- Dual-directional airflow system utilizing a first fan positioned inside the opening of the heat dissipation plate and multiple second fans arranged near the plate, creating a comprehensive cooling solution.

- Housing design with opposing sidewalls featuring strategically positioned opening areas that facilitate directional airflow through the entire structure for optimal heat evacuation.

Environmental Impact of Optimized Engine Cooling

Optimizing engine cooling systems has significant environmental implications that extend beyond mere performance metrics. The reduction in heat generation and more efficient thermal management in V4 engines directly correlates with decreased fuel consumption, as thermal efficiency improvements of even 2-3% can translate to substantial fuel savings across vehicle fleets. This efficiency gain contributes to reduced carbon dioxide emissions, with estimates suggesting that advanced cooling technologies could potentially reduce CO2 emissions by 5-8 g/km per vehicle.

The environmental benefits also manifest in reduced dependency on cooling fluids, many of which contain ethylene glycol and other chemicals that pose environmental hazards when improperly disposed of. Thermography-guided optimization allows for more precise cooling system designs that require less coolant volume, potentially reducing coolant-related environmental contamination by up to 15% according to recent industry analyses.

Furthermore, optimized cooling systems derived from thermographic analysis enable more effective heat recovery systems. Waste heat, which traditionally dissipates into the environment as thermal pollution, can be captured and repurposed through technologies like thermoelectric generators or Rankine cycle systems. These technologies can convert waste heat into usable electricity, improving overall vehicle efficiency and reducing the thermal footprint of transportation systems.

Material consumption represents another environmental dimension affected by cooling optimization. Enhanced thermal management allows for more precise material selection and potentially reduced material usage in engine components. This translates to lower environmental impacts from manufacturing processes and resource extraction. Studies indicate that thermography-guided design can reduce material requirements for cooling components by 8-12% while maintaining or improving performance.

The noise pollution aspect should not be overlooked either. Traditional cooling systems often require powerful fans that contribute significantly to vehicle noise profiles. Thermography-optimized cooling can reduce fan operation requirements, potentially lowering noise pollution in urban environments where traffic noise remains a significant environmental and public health concern.

Lifecycle assessment studies suggest that implementing thermography-optimized cooling systems in V4 engines could reduce the overall environmental impact by 7-10% across the product lifecycle, with particularly notable improvements in the use phase. These benefits compound when considering fleet-wide implementation across millions of vehicles, representing a significant opportunity for environmental impact reduction in the transportation sector.

The environmental benefits also manifest in reduced dependency on cooling fluids, many of which contain ethylene glycol and other chemicals that pose environmental hazards when improperly disposed of. Thermography-guided optimization allows for more precise cooling system designs that require less coolant volume, potentially reducing coolant-related environmental contamination by up to 15% according to recent industry analyses.

Furthermore, optimized cooling systems derived from thermographic analysis enable more effective heat recovery systems. Waste heat, which traditionally dissipates into the environment as thermal pollution, can be captured and repurposed through technologies like thermoelectric generators or Rankine cycle systems. These technologies can convert waste heat into usable electricity, improving overall vehicle efficiency and reducing the thermal footprint of transportation systems.

Material consumption represents another environmental dimension affected by cooling optimization. Enhanced thermal management allows for more precise material selection and potentially reduced material usage in engine components. This translates to lower environmental impacts from manufacturing processes and resource extraction. Studies indicate that thermography-guided design can reduce material requirements for cooling components by 8-12% while maintaining or improving performance.

The noise pollution aspect should not be overlooked either. Traditional cooling systems often require powerful fans that contribute significantly to vehicle noise profiles. Thermography-optimized cooling can reduce fan operation requirements, potentially lowering noise pollution in urban environments where traffic noise remains a significant environmental and public health concern.

Lifecycle assessment studies suggest that implementing thermography-optimized cooling systems in V4 engines could reduce the overall environmental impact by 7-10% across the product lifecycle, with particularly notable improvements in the use phase. These benefits compound when considering fleet-wide implementation across millions of vehicles, representing a significant opportunity for environmental impact reduction in the transportation sector.

Thermal Data Integration with Engine Management Systems

The integration of thermal data with Engine Management Systems (EMS) represents a critical advancement in modern V4 engine monitoring and control. Current EMS architectures typically incorporate multiple sensor inputs including air intake temperature, coolant temperature, and exhaust gas temperature, but often lack comprehensive thermal profile data that thermography can provide. Establishing robust data pipelines between thermographic imaging systems and the EMS requires specialized protocols and interfaces capable of handling high-resolution thermal data streams.

Leading engine management system providers have begun implementing dedicated thermal data processing modules that can accept and interpret thermographic data in real-time. These systems typically utilize high-speed CAN bus networks or dedicated Ethernet connections to maintain the necessary bandwidth for thermal image processing. The integration challenge lies in converting complex thermal matrices into actionable parameters that the EMS can utilize for combustion optimization and thermal management.

Data fusion algorithms play a pivotal role in this integration, combining traditional sensor inputs with thermographic data to create comprehensive thermal models of the engine. Machine learning approaches, particularly convolutional neural networks, have demonstrated significant promise in processing thermographic images to extract meaningful thermal signatures that correlate with specific engine conditions. These algorithms can identify thermal anomalies that might indicate impending component failures before they manifest in traditional sensor readings.

Real-time processing requirements present substantial challenges, as thermographic data streams can exceed several gigabytes per minute at high frame rates. Edge computing solutions positioned near the thermal imaging hardware can perform initial data reduction and feature extraction before transmitting essential thermal parameters to the main EMS. This distributed architecture helps balance the computational load while maintaining system responsiveness.

Calibration and synchronization between thermographic systems and the EMS timing reference represent another critical integration aspect. Precise temporal alignment ensures that thermal events can be correctly associated with specific engine cycles and operating conditions. Advanced systems implement phase-locked timing circuits that coordinate thermographic image capture with engine position signals from the crankshaft position sensor.

Standardization efforts are emerging to facilitate broader adoption of thermal data integration. The SAE J1939 protocol has been extended with specific Parameter Group Numbers (PGNs) for thermal imaging data, while AUTOSAR-compliant software components for thermal data processing are being developed to ensure compatibility across different vehicle platforms and manufacturer ecosystems.

Leading engine management system providers have begun implementing dedicated thermal data processing modules that can accept and interpret thermographic data in real-time. These systems typically utilize high-speed CAN bus networks or dedicated Ethernet connections to maintain the necessary bandwidth for thermal image processing. The integration challenge lies in converting complex thermal matrices into actionable parameters that the EMS can utilize for combustion optimization and thermal management.

Data fusion algorithms play a pivotal role in this integration, combining traditional sensor inputs with thermographic data to create comprehensive thermal models of the engine. Machine learning approaches, particularly convolutional neural networks, have demonstrated significant promise in processing thermographic images to extract meaningful thermal signatures that correlate with specific engine conditions. These algorithms can identify thermal anomalies that might indicate impending component failures before they manifest in traditional sensor readings.

Real-time processing requirements present substantial challenges, as thermographic data streams can exceed several gigabytes per minute at high frame rates. Edge computing solutions positioned near the thermal imaging hardware can perform initial data reduction and feature extraction before transmitting essential thermal parameters to the main EMS. This distributed architecture helps balance the computational load while maintaining system responsiveness.

Calibration and synchronization between thermographic systems and the EMS timing reference represent another critical integration aspect. Precise temporal alignment ensures that thermal events can be correctly associated with specific engine cycles and operating conditions. Advanced systems implement phase-locked timing circuits that coordinate thermographic image capture with engine position signals from the crankshaft position sensor.

Standardization efforts are emerging to facilitate broader adoption of thermal data integration. The SAE J1939 protocol has been extended with specific Parameter Group Numbers (PGNs) for thermal imaging data, while AUTOSAR-compliant software components for thermal data processing are being developed to ensure compatibility across different vehicle platforms and manufacturer ecosystems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!