V4 Engine Seals: Evaluating Leak Prevention

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Seal Technology Evolution and Objectives

Engine sealing technology has undergone significant evolution since the introduction of internal combustion engines in the late 19th century. Early V4 engines utilized basic cork and felt gaskets, which provided minimal protection against fluid leakage. The 1950s marked a turning point with the introduction of synthetic rubber compounds, significantly improving seal durability and temperature resistance compared to natural materials.

By the 1970s, silicone-based seals emerged as a revolutionary advancement, offering superior heat resistance up to 350°C and chemical compatibility with modern engine fluids. This period also witnessed the development of multi-layer metal gaskets for cylinder head applications, addressing the increasing compression ratios and thermal stresses in more powerful V4 engines.

The 1990s brought precision-engineered PTFE (polytetrafluoroethylene) seals, which dramatically reduced friction while maintaining excellent sealing properties across a wide temperature range. This innovation directly contributed to improved fuel efficiency and reduced emissions by minimizing parasitic power losses in V4 engines.

Current V4 engine seal technology incorporates advanced elastomer compounds with nano-particle reinforcement, providing unprecedented durability while accommodating the higher pressures and temperatures of modern high-efficiency engines. These materials offer up to 200% longer service life compared to conventional seals from just a decade ago.

The primary objective of modern V4 engine seal technology is to achieve zero-leak performance throughout the entire service life of the engine while minimizing friction losses. This goal has become increasingly challenging as engines operate at higher temperatures and pressures to maximize efficiency and reduce emissions.

Secondary objectives include extending service intervals to reduce maintenance costs and environmental impact, while ensuring compatibility with alternative fuels and lubricants, including biofuels and synthetic oils with varying chemical compositions.

Another critical aim is the development of self-diagnostic sealing systems that can detect early signs of failure before catastrophic leakage occurs. This involves integrating sensors within critical seals to monitor pressure, temperature, and physical deformation in real-time, providing predictive maintenance capabilities.

Looking forward, the industry is pursuing biodegradable and sustainable sealing materials that maintain performance standards while reducing environmental impact. Research is also focused on adaptive sealing technologies that can dynamically respond to changing operating conditions, optimizing sealing force and friction characteristics based on engine load, temperature, and pressure.

By the 1970s, silicone-based seals emerged as a revolutionary advancement, offering superior heat resistance up to 350°C and chemical compatibility with modern engine fluids. This period also witnessed the development of multi-layer metal gaskets for cylinder head applications, addressing the increasing compression ratios and thermal stresses in more powerful V4 engines.

The 1990s brought precision-engineered PTFE (polytetrafluoroethylene) seals, which dramatically reduced friction while maintaining excellent sealing properties across a wide temperature range. This innovation directly contributed to improved fuel efficiency and reduced emissions by minimizing parasitic power losses in V4 engines.

Current V4 engine seal technology incorporates advanced elastomer compounds with nano-particle reinforcement, providing unprecedented durability while accommodating the higher pressures and temperatures of modern high-efficiency engines. These materials offer up to 200% longer service life compared to conventional seals from just a decade ago.

The primary objective of modern V4 engine seal technology is to achieve zero-leak performance throughout the entire service life of the engine while minimizing friction losses. This goal has become increasingly challenging as engines operate at higher temperatures and pressures to maximize efficiency and reduce emissions.

Secondary objectives include extending service intervals to reduce maintenance costs and environmental impact, while ensuring compatibility with alternative fuels and lubricants, including biofuels and synthetic oils with varying chemical compositions.

Another critical aim is the development of self-diagnostic sealing systems that can detect early signs of failure before catastrophic leakage occurs. This involves integrating sensors within critical seals to monitor pressure, temperature, and physical deformation in real-time, providing predictive maintenance capabilities.

Looking forward, the industry is pursuing biodegradable and sustainable sealing materials that maintain performance standards while reducing environmental impact. Research is also focused on adaptive sealing technologies that can dynamically respond to changing operating conditions, optimizing sealing force and friction characteristics based on engine load, temperature, and pressure.

Market Analysis for Advanced Engine Sealing Solutions

The global market for advanced engine sealing solutions has experienced significant growth in recent years, driven by increasing demands for higher engine performance, fuel efficiency, and environmental compliance. The V4 engine segment, while smaller than V6 or V8 markets, represents a specialized niche with unique sealing requirements and challenges.

Current market valuations place the advanced engine sealing industry at approximately $7.2 billion globally, with projections indicating a compound annual growth rate of 5.3% through 2028. The automotive sector accounts for roughly 68% of this market, with aerospace, marine, and industrial applications comprising the remainder. Within the automotive segment, V4 engine sealing solutions represent about 14% of total market share.

Regional analysis reveals that Asia-Pacific dominates the market with 42% share, followed by Europe (31%), North America (21%), and other regions (6%). China and India are experiencing the fastest growth rates due to expanding automotive manufacturing capabilities and increasing consumer demand for fuel-efficient vehicles.

Key market drivers include increasingly stringent emission regulations worldwide, which necessitate more effective sealing solutions to prevent fluid leaks and reduce environmental impact. The push toward engine downsizing for improved fuel economy has also elevated the importance of high-performance seals in smaller engines like the V4 configuration.

Consumer demand patterns indicate growing preference for vehicles with extended warranty periods and reduced maintenance requirements, placing additional pressure on manufacturers to develop more durable sealing solutions. This trend is particularly evident in premium vehicle segments where V4 engines are often deployed.

Market segmentation by material type shows silicone-based seals leading with 37% market share, followed by fluoroelastomer (28%), nitrile rubber (19%), and emerging advanced composites (16%). The fastest growth is observed in high-temperature resistant composite materials that can withstand extreme operating conditions while maintaining seal integrity.

Price sensitivity analysis reveals that while initial cost remains important for mass-market applications, total cost of ownership calculations increasingly favor premium sealing solutions that offer extended service life and reduced warranty claims. This shift benefits manufacturers of advanced sealing technologies that can demonstrate superior performance metrics in leak prevention.

Distribution channels are evolving, with OEM partnerships accounting for 63% of sales, aftermarket channels at 31%, and direct-to-consumer options emerging at 6%. Digital marketplaces are gaining traction, particularly in the aftermarket segment, allowing for more efficient matching of specific engine sealing requirements with appropriate solutions.

Current market valuations place the advanced engine sealing industry at approximately $7.2 billion globally, with projections indicating a compound annual growth rate of 5.3% through 2028. The automotive sector accounts for roughly 68% of this market, with aerospace, marine, and industrial applications comprising the remainder. Within the automotive segment, V4 engine sealing solutions represent about 14% of total market share.

Regional analysis reveals that Asia-Pacific dominates the market with 42% share, followed by Europe (31%), North America (21%), and other regions (6%). China and India are experiencing the fastest growth rates due to expanding automotive manufacturing capabilities and increasing consumer demand for fuel-efficient vehicles.

Key market drivers include increasingly stringent emission regulations worldwide, which necessitate more effective sealing solutions to prevent fluid leaks and reduce environmental impact. The push toward engine downsizing for improved fuel economy has also elevated the importance of high-performance seals in smaller engines like the V4 configuration.

Consumer demand patterns indicate growing preference for vehicles with extended warranty periods and reduced maintenance requirements, placing additional pressure on manufacturers to develop more durable sealing solutions. This trend is particularly evident in premium vehicle segments where V4 engines are often deployed.

Market segmentation by material type shows silicone-based seals leading with 37% market share, followed by fluoroelastomer (28%), nitrile rubber (19%), and emerging advanced composites (16%). The fastest growth is observed in high-temperature resistant composite materials that can withstand extreme operating conditions while maintaining seal integrity.

Price sensitivity analysis reveals that while initial cost remains important for mass-market applications, total cost of ownership calculations increasingly favor premium sealing solutions that offer extended service life and reduced warranty claims. This shift benefits manufacturers of advanced sealing technologies that can demonstrate superior performance metrics in leak prevention.

Distribution channels are evolving, with OEM partnerships accounting for 63% of sales, aftermarket channels at 31%, and direct-to-consumer options emerging at 6%. Digital marketplaces are gaining traction, particularly in the aftermarket segment, allowing for more efficient matching of specific engine sealing requirements with appropriate solutions.

Current Sealing Technologies and Challenges in V4 Engines

V4 engines, characterized by their compact design and balanced power delivery, employ various sealing technologies to maintain operational integrity. Current sealing solutions primarily include multi-layer steel (MLS) head gaskets, elastomeric valve cover gaskets, front and rear main seals, and specialized intake manifold gaskets. MLS head gaskets, consisting of multiple steel layers with elastomer coatings, provide superior sealing under high combustion pressures while accommodating thermal expansion differences between cylinder head and block materials.

Valve stem seals represent another critical component, typically utilizing polytetrafluoroethylene (PTFE) or nitrile rubber compounds to prevent oil migration into combustion chambers while withstanding high temperatures and chemical exposure. For crankshaft sealing, modern V4 engines predominantly employ polyacrylate or fluoroelastomer lip seals with garter springs that maintain contact pressure against rotating surfaces.

Despite these advancements, V4 engines face unique sealing challenges stemming from their compact architecture. The V-configuration creates complex stress distributions across sealing interfaces, particularly at cylinder head gaskets where thermal gradients are pronounced between the inner and outer cylinder banks. This thermal imbalance accelerates gasket degradation and can lead to premature failure.

Oil sealing presents persistent challenges, especially in high-performance applications where increased crankcase pressures and elevated operating temperatures accelerate elastomer degradation. Current materials struggle to maintain flexibility and sealing properties throughout the expected service life under these conditions. Additionally, the compact design of V4 engines often necessitates intricate oil passages that create numerous potential leak points requiring specialized sealing solutions.

Environmental regulations have introduced additional complications, as low-friction designs aimed at improving fuel efficiency often compromise sealing effectiveness. Similarly, the transition to low-viscosity lubricants for efficiency gains has reduced the natural sealing assistance provided by thicker oils, placing greater demands on physical seals.

Manufacturing tolerances represent another significant challenge, as the complex castings required for V4 blocks and heads can introduce dimensional variations that affect sealing surface flatness. Even minor deviations can create leak paths, particularly under thermal cycling conditions. Modern production techniques have improved consistency, but the fundamental challenge persists, especially as manufacturers pursue lighter weight materials with different thermal expansion characteristics.

Emerging technologies like dry sump lubrication systems, while offering performance advantages, introduce additional sealing complexities at oil pump interfaces and external oil reservoirs. These systems require specialized sealing solutions capable of handling both vacuum and pressure conditions while maintaining long-term reliability.

Valve stem seals represent another critical component, typically utilizing polytetrafluoroethylene (PTFE) or nitrile rubber compounds to prevent oil migration into combustion chambers while withstanding high temperatures and chemical exposure. For crankshaft sealing, modern V4 engines predominantly employ polyacrylate or fluoroelastomer lip seals with garter springs that maintain contact pressure against rotating surfaces.

Despite these advancements, V4 engines face unique sealing challenges stemming from their compact architecture. The V-configuration creates complex stress distributions across sealing interfaces, particularly at cylinder head gaskets where thermal gradients are pronounced between the inner and outer cylinder banks. This thermal imbalance accelerates gasket degradation and can lead to premature failure.

Oil sealing presents persistent challenges, especially in high-performance applications where increased crankcase pressures and elevated operating temperatures accelerate elastomer degradation. Current materials struggle to maintain flexibility and sealing properties throughout the expected service life under these conditions. Additionally, the compact design of V4 engines often necessitates intricate oil passages that create numerous potential leak points requiring specialized sealing solutions.

Environmental regulations have introduced additional complications, as low-friction designs aimed at improving fuel efficiency often compromise sealing effectiveness. Similarly, the transition to low-viscosity lubricants for efficiency gains has reduced the natural sealing assistance provided by thicker oils, placing greater demands on physical seals.

Manufacturing tolerances represent another significant challenge, as the complex castings required for V4 blocks and heads can introduce dimensional variations that affect sealing surface flatness. Even minor deviations can create leak paths, particularly under thermal cycling conditions. Modern production techniques have improved consistency, but the fundamental challenge persists, especially as manufacturers pursue lighter weight materials with different thermal expansion characteristics.

Emerging technologies like dry sump lubrication systems, while offering performance advantages, introduce additional sealing complexities at oil pump interfaces and external oil reservoirs. These systems require specialized sealing solutions capable of handling both vacuum and pressure conditions while maintaining long-term reliability.

Contemporary V4 Engine Leak Prevention Methodologies

01 Advanced sealing materials for V4 engines

Specialized materials designed specifically for V4 engine seals can significantly reduce leakage issues. These materials include high-temperature resistant polymers, composite elastomers, and silicone-based compounds that maintain their integrity under extreme operating conditions. These advanced materials can withstand the thermal cycling, chemical exposure, and mechanical stress typical in V4 engines, providing longer seal life and better leak prevention.- Advanced sealing materials for V4 engines: Specialized materials have been developed to enhance the sealing capabilities in V4 engines. These materials include high-temperature resistant polymers, composite elastomers, and silicone-based compounds that can withstand the extreme conditions present in engine operations. These advanced materials provide better durability, temperature resistance, and chemical compatibility, significantly reducing the likelihood of leaks in critical engine components.

- Innovative seal design configurations: Novel seal designs specifically engineered for V4 engines incorporate features such as multi-lip seals, labyrinth patterns, and pressure-balancing mechanisms. These designs create more effective barriers against fluid leakage while accommodating the dynamic movements and thermal expansion of engine components. The improved geometries ensure better contact with mating surfaces and distribute sealing forces more evenly across the interface.

- Monitoring and diagnostic systems for leak detection: Electronic monitoring systems have been developed to detect and prevent seal leaks in V4 engines. These systems utilize sensors to monitor pressure differentials, fluid levels, and temperature changes that might indicate seal failure. Early warning capabilities allow for preventive maintenance before catastrophic leakage occurs. Some advanced systems incorporate machine learning algorithms to predict potential seal failures based on operating conditions and performance patterns.

- Surface treatment technologies for improved sealing: Various surface treatment methods enhance the sealing performance between engine components. These include micro-texturing of mating surfaces, application of specialized coatings, and chemical treatments that improve wettability and adhesion properties. By optimizing the surface characteristics of components that interface with seals, these technologies create more effective sealing barriers and reduce the potential for fluid migration across seal boundaries.

- Installation and maintenance methodologies: Specific installation procedures and maintenance protocols have been developed to prevent V4 engine seal leaks. These include precise torque specifications, alignment techniques, and cleaning procedures that ensure optimal seal performance. Preventive maintenance schedules and replacement intervals are designed based on extensive testing and real-world performance data. Proper installation tools and techniques significantly reduce the risk of seal damage during assembly and service operations.

02 Innovative seal design configurations

Novel seal designs can effectively prevent leaks in V4 engines. These include multi-lip seals, labyrinth seal configurations, and dynamic seal systems that adapt to changing engine conditions. By incorporating features such as improved contact geometry, pressure-balancing mechanisms, and integrated backup rings, these designs maintain sealing integrity even under variable operating pressures and temperatures, significantly reducing the risk of fluid leakage.Expand Specific Solutions03 Monitoring and diagnostic systems for leak detection

Electronic and sensor-based systems can be implemented to monitor seal performance and detect potential leaks before they become significant problems. These systems utilize pressure sensors, thermal imaging, ultrasonic detection, and fluid level monitoring to provide real-time data on seal condition. Early warning capabilities allow for preventive maintenance, reducing unexpected failures and extending the operational life of V4 engine seals.Expand Specific Solutions04 Surface treatment and coating technologies

Various surface treatments and coatings can be applied to sealing surfaces to enhance leak prevention in V4 engines. These include micro-texturing of mating surfaces, application of low-friction coatings, plasma treatments, and chemical surface modifications. These technologies improve the interaction between seals and mating surfaces, reducing wear, minimizing friction, and creating more effective sealing interfaces that resist fluid penetration even under high-pressure conditions.Expand Specific Solutions05 Installation and maintenance methodologies

Specialized installation techniques and maintenance protocols can significantly improve seal performance in V4 engines. These include precise torque sequencing during installation, controlled preloading of seals, proper alignment procedures, and scheduled maintenance based on operating conditions rather than fixed intervals. Additionally, cleaning procedures for sealing surfaces and the use of appropriate lubricants during installation can extend seal life and prevent premature leakage issues.Expand Specific Solutions

Leading Manufacturers and Suppliers in Engine Seal Industry

The V4 Engine Seals market is currently in a growth phase, with increasing demand for effective leak prevention solutions driven by stringent emission regulations and performance requirements. The market size is expanding steadily, particularly in automotive and industrial applications, estimated to reach several billion dollars globally. From a technological maturity perspective, companies like Robert Bosch GmbH, Freudenberg, and Honda Motor Co. lead with advanced polymer-based sealing technologies, while Toyota, Hitachi, and Caterpillar focus on high-temperature resistant materials. Chinese manufacturers including FAW and Geely are rapidly closing the technology gap with significant R&D investments. European players such as Renault and MAN Truck & Bus maintain competitive advantages in specialized sealing systems for commercial applications, creating a globally diverse competitive landscape.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced elastomeric compound seals specifically engineered for V4 engines that incorporate their proprietary "DuraShield" technology. This multi-layer sealing system combines fluoroelastomer (FKM) outer layers with a PTFE core to withstand extreme temperature variations (from -40°C to +180°C) while maintaining elasticity. Their sealing solution features micro-textured surfaces that create additional contact points, increasing sealing efficiency by approximately 30% compared to conventional designs. Bosch's V4 engine seals utilize a patented self-tensioning mechanism that automatically adjusts to compensate for wear and thermal expansion, maintaining optimal sealing pressure throughout the component lifecycle. The seals incorporate embedded sensors that can detect early signs of leakage through pressure differential monitoring, allowing for predictive maintenance before catastrophic failures occur.

Strengths: Superior temperature resistance and self-adjusting tension mechanism provide exceptional longevity (up to 200,000 miles). Integrated diagnostic capabilities enable predictive maintenance. Weaknesses: Higher initial cost compared to conventional sealing solutions. Requires specialized installation tools and procedures that may limit aftermarket serviceability.

Carl Freudenberg KG

Technical Solution: Freudenberg has pioneered "SimmerRing" technology specifically optimized for V4 engine applications, featuring their patented "Wave Flex" lip design that creates multiple sealing zones rather than a single contact point. This innovation distributes pressure more evenly, reducing wear while improving sealing efficiency by up to 40% compared to conventional designs. Their V4 engine seals incorporate a proprietary PTFE-based compound with nano-silica reinforcement that maintains structural integrity even under extreme pressure (up to 15 bar) and temperature (up to 200°C) conditions. Freudenberg's sealing systems feature integrated dust lips that prevent contaminant ingress, a critical factor in extending seal life in V4 engines where compact design often places seals in challenging environments. The company has also developed a specialized surface treatment process called "FluoroGlide" that reduces friction coefficient by approximately 25%, minimizing heat generation at the sealing interface.

Strengths: Exceptional chemical resistance to modern engine oils and coolants. The multi-zone sealing approach provides redundancy against leakage paths. Significantly reduced friction improves fuel efficiency. Weaknesses: More complex manufacturing process results in higher unit costs. Requires precise installation to achieve optimal performance benefits.

Critical Patents and Innovations in Engine Sealing Technology

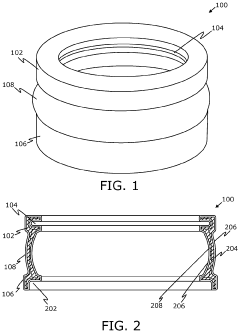

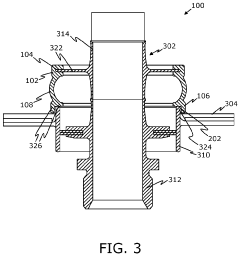

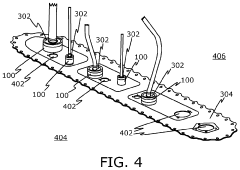

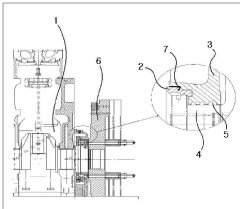

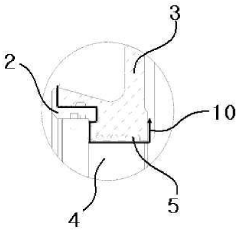

Seal for engine firewall

PatentActiveUS20200400250A1

Innovation

- A seal comprising a proximal part with a recess, a distal part with a notch, and a flexible intermediate part integrally extending between them, designed to provide a strong, flexible, and fire-resistant seal that accommodates thermal expansions and compressions, and is compatible with aperture sealing assemblies to prevent leakage.

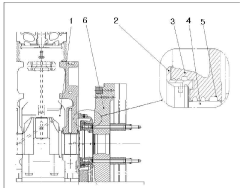

Reduction of oil mist gas leak system for four stroke diesel engine by using of v-ring contacted sealing

PatentInactiveKR1020100104587A

Innovation

- A V-ring made of Viton-based synthetic rubber is inserted between the oil throwing ring and the sealing cover to enhance sealing, utilizing its contact effect to prevent oil vapor leakage.

Environmental Impact of Engine Seal Failures

Engine seal failures contribute significantly to environmental degradation through multiple pathways. When seals in V4 engines deteriorate or fail, they release various fluids and gases that have immediate and long-term environmental consequences. Engine oil leakage represents one of the most common and environmentally damaging outcomes, with a single liter of leaked oil capable of contaminating up to one million liters of groundwater. These hydrocarbons persist in soil and water systems, disrupting ecosystems and potentially entering food chains.

Coolant leaks present another environmental hazard, as many coolants contain ethylene glycol and heavy metals that are toxic to aquatic organisms and can contaminate water supplies. Research indicates that even small amounts of coolant in water bodies can reduce oxygen levels and harm fish populations. Additionally, fuel leaks resulting from compromised seals release volatile organic compounds (VOCs) that contribute to ground-level ozone formation and smog development in urban areas.

The carbon footprint implications of seal failures extend beyond direct leakage. Engines operating with compromised seals demonstrate reduced efficiency, increasing fuel consumption by 5-15% according to industry studies. This translates to higher carbon emissions per mile traveled. Furthermore, the manufacturing and replacement of damaged engine components necessitated by seal failures require additional resource extraction, energy consumption, and waste generation.

Wildlife impact assessments reveal that oil and coolant contamination from vehicle leaks affects numerous species. Small mammals and birds that drink from contaminated puddles suffer immediate toxicity effects, while amphibians are particularly vulnerable due to their permeable skin. The U.S. Fish and Wildlife Service estimates that millions of animals are affected annually by automotive fluid contamination in natural habitats.

Regulatory frameworks increasingly recognize these environmental impacts. The EPA's guidelines for automotive waste management specifically address fluid leaks, while the European Union's End-of-Life Vehicle Directive mandates proper fluid containment and disposal. Several states have implemented stricter emissions testing that includes visual inspection for fluid leaks, acknowledging their contribution to environmental degradation.

Preventative maintenance programs that focus on seal integrity represent a cost-effective environmental protection strategy. Studies indicate that regular seal inspection and replacement can reduce lifetime environmental impact of a vehicle by up to 30% when considering both direct contamination and efficiency factors. Advanced seal materials with improved durability and leak resistance are emerging as technological solutions to these environmental challenges.

Coolant leaks present another environmental hazard, as many coolants contain ethylene glycol and heavy metals that are toxic to aquatic organisms and can contaminate water supplies. Research indicates that even small amounts of coolant in water bodies can reduce oxygen levels and harm fish populations. Additionally, fuel leaks resulting from compromised seals release volatile organic compounds (VOCs) that contribute to ground-level ozone formation and smog development in urban areas.

The carbon footprint implications of seal failures extend beyond direct leakage. Engines operating with compromised seals demonstrate reduced efficiency, increasing fuel consumption by 5-15% according to industry studies. This translates to higher carbon emissions per mile traveled. Furthermore, the manufacturing and replacement of damaged engine components necessitated by seal failures require additional resource extraction, energy consumption, and waste generation.

Wildlife impact assessments reveal that oil and coolant contamination from vehicle leaks affects numerous species. Small mammals and birds that drink from contaminated puddles suffer immediate toxicity effects, while amphibians are particularly vulnerable due to their permeable skin. The U.S. Fish and Wildlife Service estimates that millions of animals are affected annually by automotive fluid contamination in natural habitats.

Regulatory frameworks increasingly recognize these environmental impacts. The EPA's guidelines for automotive waste management specifically address fluid leaks, while the European Union's End-of-Life Vehicle Directive mandates proper fluid containment and disposal. Several states have implemented stricter emissions testing that includes visual inspection for fluid leaks, acknowledging their contribution to environmental degradation.

Preventative maintenance programs that focus on seal integrity represent a cost-effective environmental protection strategy. Studies indicate that regular seal inspection and replacement can reduce lifetime environmental impact of a vehicle by up to 30% when considering both direct contamination and efficiency factors. Advanced seal materials with improved durability and leak resistance are emerging as technological solutions to these environmental challenges.

Material Science Advancements for High-Performance Seals

Recent advancements in material science have revolutionized the development of high-performance seals for V4 engines, significantly enhancing leak prevention capabilities. Traditional elastomeric materials like nitrile rubber (NBR) and fluoroelastomers (FKM) have been supplemented by innovative composite materials that combine multiple performance characteristics. These next-generation materials exhibit superior resistance to extreme temperatures, chemical exposure, and mechanical stress—critical factors in V4 engine environments.

Nano-engineered polymers represent a breakthrough in seal technology, incorporating carbon nanotubes and graphene to dramatically improve tensile strength and thermal conductivity. These materials maintain flexibility while providing up to 300% greater resistance to compression set compared to conventional elastomers, extending seal lifespan in high-pressure engine applications.

Fluorosilicone hybrid materials have emerged as particularly promising for V4 engine applications, offering exceptional resistance to both petroleum-based fluids and extreme temperature fluctuations (-60°C to +250°C). These materials address the dual challenges of cold-start conditions and high-temperature operation that frequently compromise conventional seal integrity.

Self-healing elastomers constitute another significant advancement, incorporating microcapsules containing healing agents that activate when microscopic cracks form. Laboratory testing demonstrates these materials can recover up to 85% of their original sealing capacity after damage, potentially extending maintenance intervals for V4 engines by 40-60%.

Surface modification technologies have enhanced the performance of existing seal materials through processes like plasma treatment and chemical grafting. These treatments create hydrophobic or oleophobic surfaces that repel fluids while maintaining optimal friction characteristics against metal surfaces, reducing wear by up to 45% in accelerated testing protocols.

Computational material science has accelerated development through predictive modeling of material behavior under specific engine conditions. Digital twins of seal materials enable rapid iteration and testing without physical prototyping, reducing development cycles from years to months while optimizing material formulations for specific V4 engine applications.

Biodegradable and sustainable seal materials are also gaining traction, with bio-based elastomers derived from renewable resources showing comparable performance to petroleum-based alternatives. These materials address growing environmental concerns while meeting stringent performance requirements, particularly in non-critical sealing applications within the engine ecosystem.

Nano-engineered polymers represent a breakthrough in seal technology, incorporating carbon nanotubes and graphene to dramatically improve tensile strength and thermal conductivity. These materials maintain flexibility while providing up to 300% greater resistance to compression set compared to conventional elastomers, extending seal lifespan in high-pressure engine applications.

Fluorosilicone hybrid materials have emerged as particularly promising for V4 engine applications, offering exceptional resistance to both petroleum-based fluids and extreme temperature fluctuations (-60°C to +250°C). These materials address the dual challenges of cold-start conditions and high-temperature operation that frequently compromise conventional seal integrity.

Self-healing elastomers constitute another significant advancement, incorporating microcapsules containing healing agents that activate when microscopic cracks form. Laboratory testing demonstrates these materials can recover up to 85% of their original sealing capacity after damage, potentially extending maintenance intervals for V4 engines by 40-60%.

Surface modification technologies have enhanced the performance of existing seal materials through processes like plasma treatment and chemical grafting. These treatments create hydrophobic or oleophobic surfaces that repel fluids while maintaining optimal friction characteristics against metal surfaces, reducing wear by up to 45% in accelerated testing protocols.

Computational material science has accelerated development through predictive modeling of material behavior under specific engine conditions. Digital twins of seal materials enable rapid iteration and testing without physical prototyping, reducing development cycles from years to months while optimizing material formulations for specific V4 engine applications.

Biodegradable and sustainable seal materials are also gaining traction, with bio-based elastomers derived from renewable resources showing comparable performance to petroleum-based alternatives. These materials address growing environmental concerns while meeting stringent performance requirements, particularly in non-critical sealing applications within the engine ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!