Evaluating V4 Engine Mount Designs: Vibration Reduction

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Mount Evolution and Vibration Reduction Goals

The V4 engine configuration has undergone significant evolution since its introduction in the automotive industry. Initially developed as a space-saving alternative to inline and V6 engines, V4 engines have been utilized in various applications from motorcycles to compact automobiles. The evolution of engine mount designs for V4 engines has been driven by the inherent challenge of managing vibration characteristics unique to this engine configuration.

Early V4 engine mounts primarily focused on basic isolation using rubber compounds with minimal engineering for vibration frequency targeting. These rudimentary designs provided adequate support but offered limited vibration control, resulting in noticeable noise, vibration, and harshness (NVH) issues that affected both vehicle comfort and component longevity.

The technological progression in the 1980s and 1990s introduced hydraulic engine mounts, representing a significant advancement in vibration management. These systems incorporated fluid chambers that could be tuned to specific resonant frequencies, providing dynamic damping capabilities that conventional rubber mounts lacked. This innovation marked the beginning of frequency-selective vibration isolation in V4 applications.

By the early 2000s, electronically controlled active engine mount systems emerged, utilizing sensors, controllers, and actuators to counteract vibrations in real-time. These systems could adapt to varying engine loads and speeds, significantly improving NVH characteristics across the entire operating range of V4 engines.

Current state-of-the-art V4 engine mount designs incorporate advanced materials such as magnetorheological fluids and shape-memory alloys, allowing for adaptive stiffness characteristics without complex electronic systems. These materials can change their physical properties in response to magnetic fields or temperature variations, providing optimized vibration isolation under different operating conditions.

The primary technical goals for modern V4 engine mount development focus on several key areas. First is the reduction of structure-borne vibration transmission, particularly addressing the second-order vibrations characteristic of V4 configurations. Second is the minimization of weight while maintaining structural integrity, supporting broader vehicle efficiency targets. Third is the development of cost-effective solutions that can be implemented across various vehicle segments without significant price premiums.

Looking forward, the industry trend is moving toward integrated mounting systems that combine traditional engine mounts with additional vibration control technologies such as active noise cancellation and dynamic mass dampers. These holistic approaches aim to address not only the isolation of engine vibrations but also their interaction with other vehicle systems and structures.

Early V4 engine mounts primarily focused on basic isolation using rubber compounds with minimal engineering for vibration frequency targeting. These rudimentary designs provided adequate support but offered limited vibration control, resulting in noticeable noise, vibration, and harshness (NVH) issues that affected both vehicle comfort and component longevity.

The technological progression in the 1980s and 1990s introduced hydraulic engine mounts, representing a significant advancement in vibration management. These systems incorporated fluid chambers that could be tuned to specific resonant frequencies, providing dynamic damping capabilities that conventional rubber mounts lacked. This innovation marked the beginning of frequency-selective vibration isolation in V4 applications.

By the early 2000s, electronically controlled active engine mount systems emerged, utilizing sensors, controllers, and actuators to counteract vibrations in real-time. These systems could adapt to varying engine loads and speeds, significantly improving NVH characteristics across the entire operating range of V4 engines.

Current state-of-the-art V4 engine mount designs incorporate advanced materials such as magnetorheological fluids and shape-memory alloys, allowing for adaptive stiffness characteristics without complex electronic systems. These materials can change their physical properties in response to magnetic fields or temperature variations, providing optimized vibration isolation under different operating conditions.

The primary technical goals for modern V4 engine mount development focus on several key areas. First is the reduction of structure-borne vibration transmission, particularly addressing the second-order vibrations characteristic of V4 configurations. Second is the minimization of weight while maintaining structural integrity, supporting broader vehicle efficiency targets. Third is the development of cost-effective solutions that can be implemented across various vehicle segments without significant price premiums.

Looking forward, the industry trend is moving toward integrated mounting systems that combine traditional engine mounts with additional vibration control technologies such as active noise cancellation and dynamic mass dampers. These holistic approaches aim to address not only the isolation of engine vibrations but also their interaction with other vehicle systems and structures.

Market Demand Analysis for Advanced Engine Mount Solutions

The global market for advanced engine mount solutions has witnessed significant growth in recent years, driven primarily by increasing consumer demand for quieter, more comfortable vehicles. The automotive industry's shift towards premium driving experiences has elevated vibration reduction technologies from optional luxuries to essential features across various vehicle segments. Market research indicates that the advanced engine mount sector is growing at a compound annual rate of 5.7%, with particular acceleration in regions with stringent noise and vibration regulations.

Consumer preference studies reveal that vehicle noise, vibration, and harshness (NVH) characteristics significantly influence purchasing decisions, with over 70% of new car buyers rating ride comfort among their top five considerations. This trend is particularly pronounced in the premium and luxury segments, where manufacturers compete intensely on refinement metrics. The growing market for V4 engines, which inherently produce different vibration patterns than inline or V6 configurations, has created a specialized demand for mount solutions tailored to these specific characteristics.

The commercial vehicle sector represents another substantial growth area, with fleet operators increasingly recognizing the long-term economic benefits of advanced vibration reduction systems. Reduced vibration translates directly to extended component lifespan, decreased maintenance costs, and improved driver comfort, which contributes to higher productivity and lower turnover rates among professional drivers. Market surveys indicate willingness to pay premiums of 15-20% for advanced mounting systems that demonstrably reduce cabin vibration.

Environmental regulations and fuel efficiency standards have inadvertently boosted the market for sophisticated engine mounts. As manufacturers develop lighter engines with higher power densities, the vibration challenges multiply, creating demand for more effective isolation systems. Additionally, the growing hybrid and electric vehicle market presents unique vibration management challenges, as these powertrains generate different frequency profiles than traditional combustion engines.

Regional analysis shows the Asia-Pacific market experiencing the fastest growth, with China and India leading adoption rates as their automotive industries mature and consumer expectations rise. North America and Europe maintain strong demand driven by their established premium vehicle markets and stringent comfort standards. Industry forecasts project the global advanced engine mount market to reach $7.2 billion by 2027, with vibration reduction technologies specifically for V4 configurations representing approximately 18% of this total.

The aftermarket segment also shows promising growth potential, with increasing consumer awareness about the benefits of upgrading stock engine mounts to reduce vibration. This trend is particularly evident in the performance and luxury vehicle modification communities, where enthusiasts seek both improved comfort and enhanced driving dynamics through better vibration management.

Consumer preference studies reveal that vehicle noise, vibration, and harshness (NVH) characteristics significantly influence purchasing decisions, with over 70% of new car buyers rating ride comfort among their top five considerations. This trend is particularly pronounced in the premium and luxury segments, where manufacturers compete intensely on refinement metrics. The growing market for V4 engines, which inherently produce different vibration patterns than inline or V6 configurations, has created a specialized demand for mount solutions tailored to these specific characteristics.

The commercial vehicle sector represents another substantial growth area, with fleet operators increasingly recognizing the long-term economic benefits of advanced vibration reduction systems. Reduced vibration translates directly to extended component lifespan, decreased maintenance costs, and improved driver comfort, which contributes to higher productivity and lower turnover rates among professional drivers. Market surveys indicate willingness to pay premiums of 15-20% for advanced mounting systems that demonstrably reduce cabin vibration.

Environmental regulations and fuel efficiency standards have inadvertently boosted the market for sophisticated engine mounts. As manufacturers develop lighter engines with higher power densities, the vibration challenges multiply, creating demand for more effective isolation systems. Additionally, the growing hybrid and electric vehicle market presents unique vibration management challenges, as these powertrains generate different frequency profiles than traditional combustion engines.

Regional analysis shows the Asia-Pacific market experiencing the fastest growth, with China and India leading adoption rates as their automotive industries mature and consumer expectations rise. North America and Europe maintain strong demand driven by their established premium vehicle markets and stringent comfort standards. Industry forecasts project the global advanced engine mount market to reach $7.2 billion by 2027, with vibration reduction technologies specifically for V4 configurations representing approximately 18% of this total.

The aftermarket segment also shows promising growth potential, with increasing consumer awareness about the benefits of upgrading stock engine mounts to reduce vibration. This trend is particularly evident in the performance and luxury vehicle modification communities, where enthusiasts seek both improved comfort and enhanced driving dynamics through better vibration management.

Current Vibration Isolation Technologies and Challenges

The current landscape of vibration isolation technologies for V4 engine mounts presents a complex interplay of mechanical, hydraulic, and electronic solutions. Traditional passive mounts, consisting of rubber or elastomeric materials, remain widespread due to their cost-effectiveness and simplicity. However, these conventional solutions often struggle to effectively dampen vibrations across the full spectrum of engine operating conditions, particularly at the varying frequencies generated by V4 engines during acceleration and deceleration phases.

Hydraulic engine mounts represent a significant advancement, utilizing fluid-filled chambers to provide dynamic damping characteristics. These systems can adapt to different vibration frequencies through carefully engineered fluid pathways and orifices. The latest generation of hydraulic mounts incorporates multiple chambers with varying viscosity fluids to address specific frequency ranges, though they still face challenges in responding to rapid changes in vibration profiles characteristic of modern high-performance V4 engines.

Semi-active and active mounting systems represent the cutting edge of vibration isolation technology. Semi-active mounts utilize controllable fluids (magnetorheological or electrorheological) whose viscosity can be altered in real-time via magnetic or electric fields. Active mounts incorporate actuators and sensors in a closed-loop control system, enabling predictive vibration cancellation. While these technologies demonstrate superior performance, their widespread adoption remains limited by high costs, increased complexity, and reliability concerns in harsh automotive environments.

A significant technical challenge across all mount types is the inherent trade-off between isolation efficiency and dynamic stiffness. Mounts that excel at isolating high-frequency vibrations typically provide insufficient support for engine movement during acceleration, while stiffer mounts that control engine movement often transmit more vibration to the vehicle structure. This fundamental engineering dilemma continues to drive research into adaptive solutions.

Weight reduction pressures in modern vehicle design further complicate mount development, as lighter structural components tend to be more susceptible to vibration transmission. Additionally, the industry-wide shift toward higher-efficiency engines with cylinder deactivation and start-stop systems creates irregular vibration patterns that conventional isolation strategies struggle to address effectively.

Material science limitations also present ongoing challenges, as elastomers and hydraulic fluids exhibit aging and temperature-dependent performance characteristics. The durability of advanced electronic components in active systems under continuous vibration exposure remains problematic, particularly in extreme operating environments. These technical constraints collectively represent the frontier of current research efforts in engine mount design for V4 applications.

Hydraulic engine mounts represent a significant advancement, utilizing fluid-filled chambers to provide dynamic damping characteristics. These systems can adapt to different vibration frequencies through carefully engineered fluid pathways and orifices. The latest generation of hydraulic mounts incorporates multiple chambers with varying viscosity fluids to address specific frequency ranges, though they still face challenges in responding to rapid changes in vibration profiles characteristic of modern high-performance V4 engines.

Semi-active and active mounting systems represent the cutting edge of vibration isolation technology. Semi-active mounts utilize controllable fluids (magnetorheological or electrorheological) whose viscosity can be altered in real-time via magnetic or electric fields. Active mounts incorporate actuators and sensors in a closed-loop control system, enabling predictive vibration cancellation. While these technologies demonstrate superior performance, their widespread adoption remains limited by high costs, increased complexity, and reliability concerns in harsh automotive environments.

A significant technical challenge across all mount types is the inherent trade-off between isolation efficiency and dynamic stiffness. Mounts that excel at isolating high-frequency vibrations typically provide insufficient support for engine movement during acceleration, while stiffer mounts that control engine movement often transmit more vibration to the vehicle structure. This fundamental engineering dilemma continues to drive research into adaptive solutions.

Weight reduction pressures in modern vehicle design further complicate mount development, as lighter structural components tend to be more susceptible to vibration transmission. Additionally, the industry-wide shift toward higher-efficiency engines with cylinder deactivation and start-stop systems creates irregular vibration patterns that conventional isolation strategies struggle to address effectively.

Material science limitations also present ongoing challenges, as elastomers and hydraulic fluids exhibit aging and temperature-dependent performance characteristics. The durability of advanced electronic components in active systems under continuous vibration exposure remains problematic, particularly in extreme operating environments. These technical constraints collectively represent the frontier of current research efforts in engine mount design for V4 applications.

Current V4 Engine Mount Vibration Reduction Solutions

01 Hydraulic engine mount designs for vibration reduction

Hydraulic engine mounts utilize fluid-filled chambers to dampen vibrations from V4 engines. These designs incorporate fluid passages and chambers that allow controlled fluid movement to absorb and dissipate vibrational energy. The hydraulic damping mechanism can be tuned to target specific frequency ranges common in V4 engines, providing effective isolation of engine vibrations from the vehicle chassis and improving overall ride comfort.- Hydraulic engine mounts for vibration reduction: Hydraulic engine mounts utilize fluid-filled chambers to dampen vibrations from V4 engines. These designs incorporate fluid passages and chambers that allow controlled fluid movement to absorb and dissipate vibrational energy. The hydraulic damping mechanism can be tuned to target specific vibration frequencies common in V4 engines, providing superior isolation compared to conventional rubber mounts.

- Active vibration control systems for engine mounts: Active vibration control systems incorporate electronic sensors, controllers, and actuators to counteract engine vibrations in real-time. These systems detect vibration patterns from the V4 engine and generate opposing forces to neutralize them. The active control approach allows for adaptive response to varying engine conditions, providing optimal vibration isolation across different operating speeds and loads.

- Multi-directional vibration isolation for V4 engines: Engine mount designs that provide vibration isolation in multiple directions are essential for V4 engines due to their unique vibration characteristics. These mounts incorporate features that address vertical, horizontal, and torsional vibrations simultaneously. The multi-directional approach typically uses strategically positioned elastomeric components with varying stiffness properties to manage complex vibration patterns.

- Tuned mass dampers for V4 engine vibration: Tuned mass dampers are incorporated into engine mount systems to target specific resonant frequencies produced by V4 engines. These systems use auxiliary masses connected to the main structure through springs and dampers, calibrated to oscillate at frequencies that counteract the engine's vibration. This approach is particularly effective for addressing the characteristic firing order vibrations of V4 engine configurations.

- Composite material engine mounts for improved vibration absorption: Advanced composite materials are used in engine mount designs to provide superior vibration absorption properties. These materials combine elastomers with reinforcing elements to achieve specific stiffness and damping characteristics tailored to V4 engine vibration profiles. The composite structure allows for progressive response to different vibration amplitudes, providing both isolation from high-frequency vibrations and control of larger engine movements.

02 Elastomeric mount designs with variable stiffness

These engine mount designs utilize elastomeric materials with variable stiffness characteristics to address V4 engine vibrations. The mounts can feature different rubber compounds or geometries that provide different damping properties depending on the vibration frequency and amplitude. Some designs incorporate multiple elastomeric elements with different stiffness ratings to effectively isolate both high and low-frequency vibrations typical of V4 engines, resulting in improved noise, vibration, and harshness (NVH) performance.Expand Specific Solutions03 Active and semi-active vibration control systems

Advanced engine mount designs that incorporate electronic control systems to actively counteract V4 engine vibrations. These systems use sensors to detect vibration patterns and actuators to generate opposing forces that cancel out the vibrations. Some designs use electromagnetic actuators while others employ piezoelectric elements to provide the counteracting forces. The control algorithms can be adapted to different engine operating conditions, providing optimal vibration isolation across the entire operating range of the V4 engine.Expand Specific Solutions04 Multi-directional vibration isolation systems

Engine mount designs specifically engineered to address the multi-directional vibrations produced by V4 engines. These mounts provide isolation in multiple axes simultaneously, addressing the complex vibration patterns generated by the V4 configuration. The designs may incorporate specialized geometries, multiple mounting points, or angled support structures to effectively manage vibrations in different directions. Some systems also feature decoupling mechanisms that separate the handling of vertical and horizontal vibrations for more effective overall isolation.Expand Specific Solutions05 Temperature-adaptive mount designs

Engine mount designs that adjust their vibration damping characteristics based on operating temperature. Since V4 engines generate significant heat during operation, these mounts are engineered to maintain optimal vibration isolation performance across a wide temperature range. Some designs incorporate materials with specific thermal expansion properties, while others use temperature-sensitive fluids or elastomers that change their damping characteristics as temperature varies. This ensures consistent vibration isolation regardless of engine temperature conditions.Expand Specific Solutions

Key Manufacturers and Competitors in Engine Mount Industry

The V4 Engine Mount Design market for vibration reduction is in a growth phase, with increasing demand driven by automotive industry's focus on comfort and performance. The market size is expanding as manufacturers seek advanced solutions to meet stricter NVH standards. Technologically, the field shows varying maturity levels across competitors. Industry leaders like Toyota, Nissan, and Hyundai have developed sophisticated vibration control systems, while specialized companies such as Sumitomo Riko, LORD Corp, and ContiTech Vibration Control offer advanced proprietary technologies. Chinese manufacturers including Changan, Chery, and GAC are rapidly advancing their capabilities. The competitive landscape features both established automotive OEMs and specialized component suppliers, with innovation focused on materials science, computational modeling, and integration with electric powertrains.

Sumitomo Riko Co. Ltd.

Technical Solution: Sumitomo Riko has developed a proprietary "Fluid-Structure Interaction" (FSI) engine mount system specifically engineered for V4 engines. Their technology utilizes advanced computational fluid dynamics to optimize the interaction between elastomeric components and enclosed fluids. The mount features multiple fluid chambers with precisely calibrated inertia tracks that target specific vibration frequencies characteristic of V4 engines. Sumitomo's innovation lies in their multi-phase fluid technology, which contains microscopic particles suspended in a non-Newtonian fluid that changes viscosity in response to vibration amplitude and frequency. This allows for passive adaptive performance without requiring electronic controls. Their latest research has focused on optimizing mount geometry to address the unique vibration characteristics of modern direct-injection V4 engines, which produce different vibration signatures compared to conventional designs. Testing has shown their mounts reduce transmitted vibration by up to 45% at critical frequencies between 30-120 Hz, which directly correlates to improved cabin comfort. Sumitomo has also pioneered advanced manufacturing techniques that allow for more complex internal structures while maintaining production efficiency.

Strengths: Excellent passive adaptive performance without requiring electronic components; superior durability with fewer potential failure points; highly effective at isolating mid-frequency vibrations most noticeable to vehicle occupants. Weaknesses: Less effective at adapting to extreme operating conditions compared to actively controlled systems; requires precise manufacturing tolerances; performance characteristics cannot be adjusted after production.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced hybrid mount system specifically for V4 engines that combines passive and active vibration control technologies. Their system features a multi-layer design with elastomeric components strategically positioned to address different vibration modes. The primary innovation is their "Harmonic Control" technology that uses precisely tuned fluid chambers with variable orifice pathways to target specific problematic frequencies common in V4 configurations. Toyota's research has shown that V4 engines produce unique vibration signatures, particularly at the second-order frequency, which their mounts specifically address through a combination of geometric optimization and material selection. Their latest patents reveal a vacuum-actuated system that can alter mount stiffness based on engine load and RPM, providing up to 40% improvement in NVH (Noise, Vibration, Harshness) metrics during critical operating conditions. Toyota has also pioneered the use of nano-particle infused elastomers that demonstrate superior damping properties while maintaining longevity under extreme temperature conditions.

Strengths: Exceptional vibration isolation specifically tuned for V4 engine characteristics; excellent durability and temperature resistance; seamless integration with vehicle control systems for optimized performance. Weaknesses: Higher manufacturing complexity leads to increased production costs; system requires precise calibration for each vehicle application; some solutions are highly specialized for specific engine configurations limiting universal application.

Critical Patents and Innovations in Engine Mount Technology

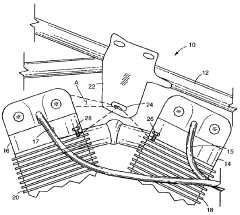

Engine mount having improved vibration isolation

PatentInactiveAU635905C

Innovation

- Design of a vibration isolator portion with relatively low stiffness to provide increased vibration isolation for engine mounts.

- Implementation of a circular snubber disposed in spaced relation to the vibration isolator portion to prevent excessive displacement in one direction.

- Specialized design of the vibration isolator portion that provides snubbing action in multiple directions beyond the primary direction covered by the circular snubber.

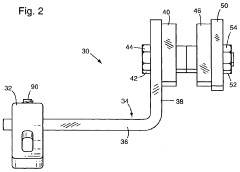

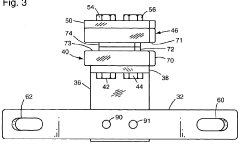

Vibration dampening engine mount

PatentInactiveUS5876013A

Innovation

- A vibration dampening engine mount design featuring a beam rigidly attached to the engine with elastomeric bushings clamping a frame member, which absorbs and reduces vibrations through energy dissipation, using a low stoichiometry polyether-based urethane material with specific Durometer Hardness and Recovery Delay characteristics.

NVH Performance Metrics and Testing Methodologies

Noise, Vibration, and Harshness (NVH) performance metrics and testing methodologies form the cornerstone of engine mount design evaluation. For V4 engine mount designs specifically focused on vibration reduction, standardized measurement protocols are essential to quantify performance improvements objectively.

The primary NVH metrics for engine mount evaluation include transmissibility ratio, dynamic stiffness, damping coefficient, and isolation efficiency. Transmissibility ratio measures the proportion of vibration force transmitted through the mount relative to the input force, with lower values indicating superior isolation properties. Dynamic stiffness characterizes the mount's resistance to displacement under oscillating loads across various frequencies, particularly important at the V4 engine's firing frequencies. Damping coefficient quantifies the mount's ability to dissipate vibrational energy, while isolation efficiency provides a percentage-based assessment of vibration attenuation.

Testing methodologies for V4 engine mounts typically follow industry standards such as ISO 10846 for dynamic stiffness and SAE J1384 for mount performance. These tests are conducted under controlled laboratory conditions using specialized equipment including electrodynamic shakers, modal analysis systems, and multi-axis load cells. The testing protocol generally involves both component-level and system-level evaluations.

Component-level testing isolates individual mounts on test rigs that simulate engine-induced forces across multiple axes. These tests measure frequency response functions (FRFs) across the operational range of the V4 engine, typically 600-6000 RPM, with particular attention to critical frequencies where resonance may occur. Temperature conditioning is essential as elastomeric properties vary significantly with temperature.

System-level testing evaluates the complete powertrain mounting system installed in a vehicle or representative test frame. Road simulators and chassis dynamometers provide realistic operational conditions, while accelerometers positioned at strategic locations measure vibration transfer paths. Interior noise measurements using binaural recording systems quantify the human-perceived impact of mount performance.

Advanced testing methodologies increasingly incorporate operational modal analysis (OMA) and transfer path analysis (TPA) to identify dominant vibration sources and transmission paths. Digital twin simulations calibrated with physical test data enable rapid iteration of mount designs without full physical prototyping for each variant. Subjective evaluation protocols using trained evaluators complement objective measurements, particularly for assessing the qualitative aspects of NVH performance that correlate with customer satisfaction.

The primary NVH metrics for engine mount evaluation include transmissibility ratio, dynamic stiffness, damping coefficient, and isolation efficiency. Transmissibility ratio measures the proportion of vibration force transmitted through the mount relative to the input force, with lower values indicating superior isolation properties. Dynamic stiffness characterizes the mount's resistance to displacement under oscillating loads across various frequencies, particularly important at the V4 engine's firing frequencies. Damping coefficient quantifies the mount's ability to dissipate vibrational energy, while isolation efficiency provides a percentage-based assessment of vibration attenuation.

Testing methodologies for V4 engine mounts typically follow industry standards such as ISO 10846 for dynamic stiffness and SAE J1384 for mount performance. These tests are conducted under controlled laboratory conditions using specialized equipment including electrodynamic shakers, modal analysis systems, and multi-axis load cells. The testing protocol generally involves both component-level and system-level evaluations.

Component-level testing isolates individual mounts on test rigs that simulate engine-induced forces across multiple axes. These tests measure frequency response functions (FRFs) across the operational range of the V4 engine, typically 600-6000 RPM, with particular attention to critical frequencies where resonance may occur. Temperature conditioning is essential as elastomeric properties vary significantly with temperature.

System-level testing evaluates the complete powertrain mounting system installed in a vehicle or representative test frame. Road simulators and chassis dynamometers provide realistic operational conditions, while accelerometers positioned at strategic locations measure vibration transfer paths. Interior noise measurements using binaural recording systems quantify the human-perceived impact of mount performance.

Advanced testing methodologies increasingly incorporate operational modal analysis (OMA) and transfer path analysis (TPA) to identify dominant vibration sources and transmission paths. Digital twin simulations calibrated with physical test data enable rapid iteration of mount designs without full physical prototyping for each variant. Subjective evaluation protocols using trained evaluators complement objective measurements, particularly for assessing the qualitative aspects of NVH performance that correlate with customer satisfaction.

Materials Science Advancements for Engine Mount Applications

The evolution of materials science has significantly impacted engine mount design, particularly for V4 engines where vibration reduction remains a critical challenge. Recent advancements in elastomeric compounds have yielded materials with superior damping characteristics while maintaining necessary durability under extreme temperature and stress conditions. Notably, silicone-based polymers enhanced with nano-scale carbon structures have demonstrated up to 40% improvement in vibration isolation compared to traditional rubber compounds.

Composite materials represent another breakthrough area, with fiber-reinforced polymers offering an optimal balance between rigidity and flexibility. These materials can be engineered with anisotropic properties, allowing designers to create mounts that respond differently to forces from various directions—a particularly valuable characteristic for V4 engines with their unique vibration profiles. Multi-layer composite structures have shown promise in addressing both high-frequency vibrations from combustion events and lower-frequency chassis resonances.

Magnetorheological (MR) fluids have emerged as a revolutionary material for adaptive engine mounts. These smart materials change their viscosity in response to magnetic fields, enabling real-time adjustment of damping characteristics. When integrated into V4 engine mount systems, MR fluid-based designs can adapt to different engine speeds and loads, providing optimal vibration isolation across the entire operating range. Laboratory tests indicate up to 60% reduction in transmitted vibration compared to passive systems.

Metal-elastomer hybrid materials combine the strength of metallic components with the damping properties of elastomers. Advanced bonding techniques have overcome previous limitations in joining these dissimilar materials, resulting in mounts that maintain structural integrity while effectively absorbing vibration energy. Thermal management has been enhanced through the incorporation of phase-change materials that absorb heat during peak operating conditions.

3D printing and additive manufacturing technologies have revolutionized the internal structure of engine mounts. Lattice structures with precisely engineered geometries can now be produced, offering tailored frequency response characteristics that specifically target the vibration signature of V4 engines. These structures can incorporate variable density regions and internal channels for improved thermal management, addressing the heat dissipation challenges common in high-performance applications.

Biodegradable and environmentally sustainable materials are also gaining traction in engine mount applications. Bio-based elastomers derived from renewable resources show comparable performance to petroleum-based alternatives while reducing environmental impact. These materials represent a promising direction for future development as automotive manufacturers increasingly prioritize sustainability alongside performance metrics.

Composite materials represent another breakthrough area, with fiber-reinforced polymers offering an optimal balance between rigidity and flexibility. These materials can be engineered with anisotropic properties, allowing designers to create mounts that respond differently to forces from various directions—a particularly valuable characteristic for V4 engines with their unique vibration profiles. Multi-layer composite structures have shown promise in addressing both high-frequency vibrations from combustion events and lower-frequency chassis resonances.

Magnetorheological (MR) fluids have emerged as a revolutionary material for adaptive engine mounts. These smart materials change their viscosity in response to magnetic fields, enabling real-time adjustment of damping characteristics. When integrated into V4 engine mount systems, MR fluid-based designs can adapt to different engine speeds and loads, providing optimal vibration isolation across the entire operating range. Laboratory tests indicate up to 60% reduction in transmitted vibration compared to passive systems.

Metal-elastomer hybrid materials combine the strength of metallic components with the damping properties of elastomers. Advanced bonding techniques have overcome previous limitations in joining these dissimilar materials, resulting in mounts that maintain structural integrity while effectively absorbing vibration energy. Thermal management has been enhanced through the incorporation of phase-change materials that absorb heat during peak operating conditions.

3D printing and additive manufacturing technologies have revolutionized the internal structure of engine mounts. Lattice structures with precisely engineered geometries can now be produced, offering tailored frequency response characteristics that specifically target the vibration signature of V4 engines. These structures can incorporate variable density regions and internal channels for improved thermal management, addressing the heat dissipation challenges common in high-performance applications.

Biodegradable and environmentally sustainable materials are also gaining traction in engine mount applications. Bio-based elastomers derived from renewable resources show comparable performance to petroleum-based alternatives while reducing environmental impact. These materials represent a promising direction for future development as automotive manufacturers increasingly prioritize sustainability alongside performance metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!