How to Measure V4 Engine Vibration for NVH Analysis

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Vibration Measurement Background and Objectives

Engine vibration measurement for Noise, Vibration, and Harshness (NVH) analysis has evolved significantly over the past decades, transitioning from basic mechanical measurements to sophisticated digital analysis systems. The V4 engine configuration, characterized by its compact design and balance between performance and efficiency, presents unique vibration characteristics that require specialized measurement approaches. Historically, vibration analysis began with simple mechanical indicators in the early 20th century, progressing through analog sensors in the mid-century, and eventually to today's advanced digital measurement systems incorporating multiple sensor types and real-time analysis capabilities.

The technological evolution in this field has been driven by increasingly stringent customer expectations for comfort, regulatory requirements for noise pollution, and manufacturer competition based on refinement metrics. Modern NVH analysis represents a critical competitive differentiator in automotive engineering, with vibration characteristics directly impacting perceived quality and brand reputation in the marketplace.

Current trends in V4 engine vibration measurement include the integration of wireless sensor networks, machine learning algorithms for predictive analysis, and holistic measurement approaches that consider the entire powertrain as an integrated system. The miniaturization of sensors has enabled more comprehensive measurement points without adding significant weight or altering the vibration characteristics being measured.

The primary objectives of V4 engine vibration measurement for NVH analysis encompass several dimensions. First, accurate characterization of vibration signatures across the engine's operating range is essential for identifying problematic frequencies and conditions. Second, isolation of vibration sources between combustion events, mechanical components, and structural resonances allows for targeted engineering solutions. Third, correlation between measured vibration data and subjective human perception enables meaningful improvements in perceived quality.

Additionally, modern measurement objectives include real-time monitoring capabilities for production quality control, development of digital twins for virtual testing environments, and the establishment of standardized measurement protocols that enable consistent evaluation across different testing facilities and conditions.

The ultimate goal of these measurements is to enable engineering teams to develop effective countermeasures for unwanted vibrations, including optimized engine mounting systems, structural reinforcements, tuned mass dampers, and active cancellation technologies. By comprehensively understanding the vibration characteristics of V4 engines, manufacturers can achieve the delicate balance between performance, efficiency, and refinement that modern markets demand.

The technological evolution in this field has been driven by increasingly stringent customer expectations for comfort, regulatory requirements for noise pollution, and manufacturer competition based on refinement metrics. Modern NVH analysis represents a critical competitive differentiator in automotive engineering, with vibration characteristics directly impacting perceived quality and brand reputation in the marketplace.

Current trends in V4 engine vibration measurement include the integration of wireless sensor networks, machine learning algorithms for predictive analysis, and holistic measurement approaches that consider the entire powertrain as an integrated system. The miniaturization of sensors has enabled more comprehensive measurement points without adding significant weight or altering the vibration characteristics being measured.

The primary objectives of V4 engine vibration measurement for NVH analysis encompass several dimensions. First, accurate characterization of vibration signatures across the engine's operating range is essential for identifying problematic frequencies and conditions. Second, isolation of vibration sources between combustion events, mechanical components, and structural resonances allows for targeted engineering solutions. Third, correlation between measured vibration data and subjective human perception enables meaningful improvements in perceived quality.

Additionally, modern measurement objectives include real-time monitoring capabilities for production quality control, development of digital twins for virtual testing environments, and the establishment of standardized measurement protocols that enable consistent evaluation across different testing facilities and conditions.

The ultimate goal of these measurements is to enable engineering teams to develop effective countermeasures for unwanted vibrations, including optimized engine mounting systems, structural reinforcements, tuned mass dampers, and active cancellation technologies. By comprehensively understanding the vibration characteristics of V4 engines, manufacturers can achieve the delicate balance between performance, efficiency, and refinement that modern markets demand.

Market Demand for Advanced NVH Analysis Solutions

The global market for advanced NVH (Noise, Vibration, and Harshness) analysis solutions has experienced significant growth in recent years, driven primarily by increasing consumer expectations for vehicle comfort and regulatory pressures for reduced noise pollution. The automotive industry's shift toward premium experiences has elevated NVH performance from a secondary consideration to a critical differentiator in competitive markets.

Market research indicates that the automotive NVH testing market was valued at approximately $1.7 billion in 2021 and is projected to reach $2.5 billion by 2027, growing at a CAGR of around 6.5%. This growth is particularly pronounced in the specialized segment of engine vibration analysis systems, where precision measurement technologies are in high demand.

The V4 engine configuration presents unique vibration characteristics that require specialized analysis solutions. Automotive manufacturers are increasingly seeking comprehensive NVH analysis tools that can identify and address vibration issues specific to V4 engines, which differ significantly from inline-four or V6 configurations in their vibration signatures.

A key market driver is the industry-wide push toward electrification and hybrid powertrains. As manufacturers develop hybrid vehicles that combine traditional internal combustion engines with electric motors, the need for sophisticated vibration analysis becomes more critical. These hybrid systems introduce complex vibration patterns that require advanced measurement and analysis capabilities to ensure optimal performance and passenger comfort.

Regulatory factors are also significantly influencing market demand. Stricter noise emission standards in Europe, North America, and Asia have compelled manufacturers to invest in more sophisticated NVH analysis tools. The European Union's regulation on sound levels of motor vehicles (EU 540/2014) has particularly accelerated demand for precision vibration measurement systems.

Premium and luxury vehicle segments represent the largest market share for advanced NVH solutions, with manufacturers willing to invest substantially in technologies that enhance perceived quality through vibration reduction. However, the mid-market segment is showing the fastest growth rate as these technologies become more accessible and as consumer expectations rise across all vehicle categories.

Geographically, the market shows strong regional variations. North America and Europe currently lead in adoption of advanced NVH analysis solutions, while the Asia-Pacific region, particularly China and India, demonstrates the highest growth potential as local manufacturers increasingly compete on quality rather than solely on price.

The aftermarket and service sectors also represent significant growth opportunities, with specialized diagnostic equipment for vibration analysis becoming essential tools for maintenance and repair operations dealing with increasingly complex powertrain systems.

Market research indicates that the automotive NVH testing market was valued at approximately $1.7 billion in 2021 and is projected to reach $2.5 billion by 2027, growing at a CAGR of around 6.5%. This growth is particularly pronounced in the specialized segment of engine vibration analysis systems, where precision measurement technologies are in high demand.

The V4 engine configuration presents unique vibration characteristics that require specialized analysis solutions. Automotive manufacturers are increasingly seeking comprehensive NVH analysis tools that can identify and address vibration issues specific to V4 engines, which differ significantly from inline-four or V6 configurations in their vibration signatures.

A key market driver is the industry-wide push toward electrification and hybrid powertrains. As manufacturers develop hybrid vehicles that combine traditional internal combustion engines with electric motors, the need for sophisticated vibration analysis becomes more critical. These hybrid systems introduce complex vibration patterns that require advanced measurement and analysis capabilities to ensure optimal performance and passenger comfort.

Regulatory factors are also significantly influencing market demand. Stricter noise emission standards in Europe, North America, and Asia have compelled manufacturers to invest in more sophisticated NVH analysis tools. The European Union's regulation on sound levels of motor vehicles (EU 540/2014) has particularly accelerated demand for precision vibration measurement systems.

Premium and luxury vehicle segments represent the largest market share for advanced NVH solutions, with manufacturers willing to invest substantially in technologies that enhance perceived quality through vibration reduction. However, the mid-market segment is showing the fastest growth rate as these technologies become more accessible and as consumer expectations rise across all vehicle categories.

Geographically, the market shows strong regional variations. North America and Europe currently lead in adoption of advanced NVH analysis solutions, while the Asia-Pacific region, particularly China and India, demonstrates the highest growth potential as local manufacturers increasingly compete on quality rather than solely on price.

The aftermarket and service sectors also represent significant growth opportunities, with specialized diagnostic equipment for vibration analysis becoming essential tools for maintenance and repair operations dealing with increasingly complex powertrain systems.

Current Vibration Measurement Technologies and Challenges

The field of engine vibration measurement for NVH (Noise, Vibration, and Harshness) analysis has evolved significantly over the past decades. Current technologies can be broadly categorized into contact and non-contact measurement methods, each with distinct advantages and limitations when applied to V4 engine configurations.

Accelerometers remain the most widely used contact sensors for vibration measurement, with piezoelectric accelerometers dominating the market due to their robust performance across a wide frequency range (typically 1 Hz to 10 kHz). For V4 engine applications, tri-axial accelerometers are particularly valuable as they can simultaneously capture vibration in multiple directions, providing comprehensive data about complex engine dynamics. Modern MEMS-based accelerometers offer improved miniaturization but may struggle with the high-temperature environments near engine blocks.

Proximity probes and velocity transducers represent alternative contact measurement options, with the former being particularly useful for measuring relative displacement between engine components. However, their application in V4 engines is often limited by mounting constraints and sensitivity to environmental factors.

Non-contact measurement technologies have gained significant traction in recent years. Laser Doppler Vibrometers (LDVs) enable high-precision measurements without mass loading effects, which is particularly advantageous for analyzing lightweight components in modern V4 engines. Scanning LDVs can create detailed vibration maps across engine surfaces, though their implementation requires careful setup and controlled environmental conditions.

Digital Image Correlation (DIC) systems represent another emerging non-contact approach, allowing for full-field strain and displacement measurements by tracking patterns on engine surfaces during operation. This technology provides unprecedented spatial resolution but demands sophisticated image processing capabilities.

Despite these technological advances, several challenges persist in V4 engine vibration measurement. Temperature variations during engine operation significantly affect sensor performance, with many devices exhibiting drift or calibration issues under thermal stress. The complex geometry of V4 engines creates accessibility limitations for sensor placement, particularly at critical interfaces between components.

Signal processing challenges also remain prominent, as separating meaningful vibration data from background noise requires advanced filtering techniques. The transient nature of engine operations further complicates analysis, necessitating time-frequency methods like wavelet transforms or short-time Fourier transforms to capture non-stationary vibration phenomena.

Data integration represents another significant hurdle, as modern NVH analysis increasingly requires synchronization between multiple sensor types (accelerometers, microphones, tachometers) to correlate vibration patterns with specific engine events and acoustic emissions. This multi-domain approach demands sophisticated data acquisition systems with precise timing capabilities.

Accelerometers remain the most widely used contact sensors for vibration measurement, with piezoelectric accelerometers dominating the market due to their robust performance across a wide frequency range (typically 1 Hz to 10 kHz). For V4 engine applications, tri-axial accelerometers are particularly valuable as they can simultaneously capture vibration in multiple directions, providing comprehensive data about complex engine dynamics. Modern MEMS-based accelerometers offer improved miniaturization but may struggle with the high-temperature environments near engine blocks.

Proximity probes and velocity transducers represent alternative contact measurement options, with the former being particularly useful for measuring relative displacement between engine components. However, their application in V4 engines is often limited by mounting constraints and sensitivity to environmental factors.

Non-contact measurement technologies have gained significant traction in recent years. Laser Doppler Vibrometers (LDVs) enable high-precision measurements without mass loading effects, which is particularly advantageous for analyzing lightweight components in modern V4 engines. Scanning LDVs can create detailed vibration maps across engine surfaces, though their implementation requires careful setup and controlled environmental conditions.

Digital Image Correlation (DIC) systems represent another emerging non-contact approach, allowing for full-field strain and displacement measurements by tracking patterns on engine surfaces during operation. This technology provides unprecedented spatial resolution but demands sophisticated image processing capabilities.

Despite these technological advances, several challenges persist in V4 engine vibration measurement. Temperature variations during engine operation significantly affect sensor performance, with many devices exhibiting drift or calibration issues under thermal stress. The complex geometry of V4 engines creates accessibility limitations for sensor placement, particularly at critical interfaces between components.

Signal processing challenges also remain prominent, as separating meaningful vibration data from background noise requires advanced filtering techniques. The transient nature of engine operations further complicates analysis, necessitating time-frequency methods like wavelet transforms or short-time Fourier transforms to capture non-stationary vibration phenomena.

Data integration represents another significant hurdle, as modern NVH analysis increasingly requires synchronization between multiple sensor types (accelerometers, microphones, tachometers) to correlate vibration patterns with specific engine events and acoustic emissions. This multi-domain approach demands sophisticated data acquisition systems with precise timing capabilities.

Contemporary V4 Engine Vibration Measurement Methodologies

01 Vibration measurement systems for V4 engines

Various systems and methods are employed to measure vibrations in V4 engines. These systems typically include sensors strategically placed on the engine to detect and quantify vibrations. The data collected from these measurements can be used to analyze engine performance, identify potential issues, and develop solutions to reduce unwanted vibrations. Advanced measurement systems may incorporate real-time monitoring capabilities and digital signal processing to provide accurate vibration profiles.- Vibration measurement systems for V4 engines: Various systems and methods for measuring vibrations in V4 engines have been developed. These systems typically include sensors strategically placed on the engine to detect and quantify vibrations. The measurement systems can provide real-time data on engine performance and help identify potential issues before they lead to engine failure. Advanced systems may incorporate digital signal processing to filter out noise and focus on specific vibration patterns characteristic of V4 engines.

- Vibration isolation and dampening mechanisms: Vibration isolation and dampening mechanisms are essential for reducing the transmission of vibrations from V4 engines to the vehicle structure. These mechanisms include engine mounts, vibration absorbers, and dampening materials designed specifically for V4 engine configurations. Effective isolation systems can significantly improve vehicle comfort, reduce noise, and extend the lifespan of engine components by minimizing the stress caused by continuous vibrations.

- Diagnostic methods for vibration analysis: Diagnostic methods for analyzing vibrations in V4 engines help identify specific issues such as imbalance, misalignment, or component wear. These methods often involve comparing measured vibration patterns against baseline data to detect anomalies. Advanced diagnostic techniques may include frequency analysis, wavelet transforms, and machine learning algorithms to identify the source and cause of abnormal vibrations. Early detection of vibration-related issues can prevent catastrophic engine failures and reduce maintenance costs.

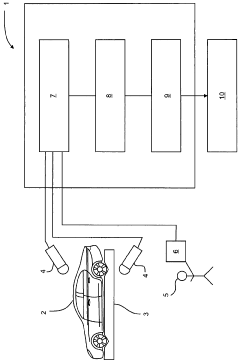

- Testing equipment for engine vibration: Specialized testing equipment has been developed for measuring and analyzing vibrations in V4 engines. This equipment includes accelerometers, vibration meters, data acquisition systems, and analysis software tailored to the unique characteristics of V4 engines. Some testing setups incorporate multiple sensors to capture vibrations in different directions and at various points on the engine. These comprehensive testing systems enable engineers to validate design changes and ensure that vibration levels remain within acceptable limits.

- Vibration reduction through engine design: Innovative engine design approaches can significantly reduce vibrations in V4 engines. These design improvements include optimized firing orders, balanced crankshaft configurations, and strategic placement of counterweights. Some designs incorporate secondary balancing shafts specifically to counteract the inherent vibrations of the V4 layout. Advanced materials and manufacturing techniques also contribute to creating more rigid engine blocks that are less prone to resonance and vibration amplification.

02 Vibration isolation and damping mechanisms

Various mechanisms are designed to isolate and dampen vibrations in V4 engines. These include engine mounts with specific elastomeric materials, hydraulic damping systems, and tuned mass dampers. These mechanisms work by absorbing vibration energy or preventing its transmission to other parts of the vehicle. Effective vibration isolation improves ride comfort, reduces noise, and extends the lifespan of engine components by minimizing stress from continuous vibrations.Expand Specific Solutions03 Electronic control systems for vibration management

Electronic control systems are implemented to manage and reduce vibrations in V4 engines. These systems use sensors to detect vibration patterns and employ algorithms to adjust engine parameters in real-time. By modifying fuel injection timing, ignition timing, or other operational parameters, these control systems can minimize harmful vibration frequencies. Some advanced systems incorporate machine learning to adapt to changing conditions and optimize vibration reduction strategies over time.Expand Specific Solutions04 Structural design modifications for vibration reduction

Specific structural modifications in V4 engine design help reduce vibrations. These include optimized crankshaft balancing, redesigned engine blocks with reinforced areas, and strategic placement of counterweights. Some designs incorporate innovative materials with superior vibration absorption properties. The geometric arrangement of cylinders and firing order can also be modified to minimize vibration generation. These structural approaches address vibration issues at their source rather than merely dampening existing vibrations.Expand Specific Solutions05 Testing and analysis methods for engine vibration

Specialized testing and analysis methods are used to evaluate vibration characteristics in V4 engines. These include modal analysis, operational deflection shape analysis, and frequency response testing. Advanced techniques may employ high-speed cameras, laser vibrometry, or acoustic analysis to visualize and quantify vibration patterns. Computer simulation and finite element analysis allow engineers to predict vibration behavior before physical prototypes are built. These methods enable comprehensive understanding of vibration sources and propagation paths.Expand Specific Solutions

Leading Companies in NVH Analysis Equipment and Software

The V4 engine vibration measurement for NVH analysis market is in a growth phase, driven by increasing demand for refined vehicle performance. The market size is expanding as automotive manufacturers prioritize noise and vibration reduction to enhance customer experience. Technologically, this field shows moderate maturity with established methodologies, though innovations continue to emerge. Key players include traditional automakers like Ford Motor Co., Changan Automobile, and GAC Group who have developed sophisticated in-house NVH capabilities, alongside specialized equipment providers like Fluke Corp. offering advanced measurement solutions. Chinese manufacturers including Chery, Dongfeng, and FAW are rapidly advancing their expertise, while research institutions such as South China University of Technology and China Automotive Research Center provide critical technical support through collaborative industry partnerships.

Ford Global Technologies LLC

Technical Solution: Ford Global Technologies has developed a comprehensive V4 engine vibration measurement system that integrates multiple sensor types for complete NVH analysis. Their approach uses accelerometers strategically placed at engine mounting points, cylinder heads, and the engine block to capture vibration in three axes. The system incorporates advanced signal processing algorithms that can isolate specific vibration frequencies related to different engine components and operating conditions. Ford's technology includes real-time data acquisition systems capable of high sampling rates (up to 25,600 Hz) to capture transient vibration events during various engine operating conditions. Their method also incorporates specialized modal analysis techniques to identify resonance frequencies and mode shapes specific to V4 engine configurations. The data is processed through proprietary software that generates detailed vibration maps and identifies potential NVH issues before they become perceptible to drivers.

Strengths: Highly integrated system with multi-point measurement capability providing comprehensive vibration profiles across the entire engine. Advanced signal processing algorithms effectively filter out environmental noise. Weaknesses: System complexity requires specialized training for proper implementation and data interpretation. Higher implementation cost compared to simpler measurement solutions.

Fluke Corp.

Technical Solution: Fluke Corporation has developed specialized vibration measurement equipment specifically optimized for V4 engine NVH analysis. Their solution centers around portable vibration analyzers with tri-axial accelerometers that can be quickly deployed at multiple measurement points. Fluke's technology features high-resolution FFT analysis capabilities that can identify frequency components as low as 0.25 Hz, critical for detecting subtle V4 engine imbalances. Their system incorporates automated diagnostic algorithms that can identify specific vibration signatures associated with common V4 engine issues such as misfire, imbalance, and mounting problems. The equipment includes wireless data transmission capabilities allowing for real-time monitoring during road tests, with data synchronized to engine RPM and vehicle speed. Fluke's solution also includes specialized software for trend analysis, allowing engineers to track vibration changes over time and predict potential failures before they occur.

Strengths: Highly portable and user-friendly equipment requiring minimal setup time. Excellent diagnostic capabilities with automated issue identification specific to V4 engines. Weaknesses: Less comprehensive than fully integrated laboratory systems. Limited customization options for specialized research applications beyond standard diagnostics.

Critical Sensor Technologies for Precise Vibration Detection

Noise vibration harshness measuring system for collecting and recording of noise vibration harshness emissions of product particularly of vehicle, has receiving medium formed to accommodate subjective feeling of one or more test person

PatentInactiveDE102007023118A1

Innovation

- An NVH measurement system that synchronously records both objective measurement signals from sensors and subjective feedback from test persons, allowing for time-correlated analysis of both types of data in the same assessment situation, using a digital system with multiple sensors and a recording module for simultaneous data capture.

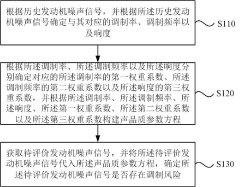

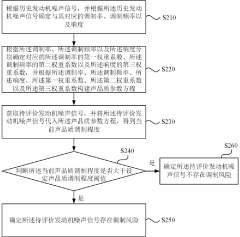

Engine sound quality evaluation method and device, electronic equipment and storage medium

PatentActiveCN117990378A

Innovation

- By determining the modulation rate, modulation frequency and loudness based on historical engine noise signals, calculating the corresponding weight coefficients, and constructing a sound quality parameter equation, it is possible to determine whether there is a modulation risk in the engine noise signal to be evaluated and optimize it.

Standardization and Testing Protocols for NVH Measurements

Standardized testing protocols are essential for ensuring the reliability, repeatability, and comparability of NVH (Noise, Vibration, and Harshness) measurements across different V4 engine configurations. The industry has developed several key standards that govern these measurements, with ISO 16063 series and SAE J1060 being among the most widely adopted frameworks for vibration testing methodologies.

For V4 engine vibration measurements, the testing environment must be carefully controlled. Ambient temperature should be maintained between 20-25°C with humidity levels of 40-60% to minimize environmental influences on measurement accuracy. Background noise levels must not exceed 35 dBA to prevent contamination of acoustic data during combined NVH assessments.

Sensor placement protocols require standardized mounting positions for accelerometers. Primary measurement points include cylinder head mounting points, engine block sides, crankshaft bearings, and transmission interface. The SAE J211 standard specifies that triaxial accelerometers should be used with sensitivity ratings between 10-100 mV/g depending on the expected vibration amplitude range. Mounting techniques must follow ISO 5348 guidelines to prevent measurement artifacts.

Data acquisition parameters must be standardized across testing scenarios. Sampling rates of at least 10 kHz are recommended to capture high-frequency vibration components, with anti-aliasing filters set at 40% of the sampling frequency. The minimum recording duration should be 60 seconds at steady-state conditions to ensure statistical validity of the frequency analysis.

Calibration procedures represent another critical aspect of standardization. All measurement equipment must undergo calibration at intervals not exceeding 12 months, with reference accelerometers traceable to national standards institutes. Pre-test and post-test calibration verification is mandatory to validate measurement integrity throughout the testing session.

Test sequence protocols typically include measurements at multiple engine speeds (idle, 1500 rpm, 3000 rpm, and maximum rated speed) and under various load conditions (no load, 25%, 50%, 75%, and 100% of maximum torque). Each test point requires stabilization periods of at least 2 minutes before data collection begins to ensure thermal equilibrium and steady-state operation.

Signal processing standards for vibration analysis specify the use of Hanning windows for FFT analysis with minimum 75% overlap between adjacent windows. Frequency resolution should be at least 1 Hz for low-frequency analysis (below 200 Hz) where most critical V4 engine vibration modes occur. Order analysis techniques must follow ISO 18431-4 guidelines for rotating machinery diagnostics.

Reporting requirements mandate the inclusion of coherence functions, transfer functions, and statistical confidence intervals for all measured data. Test reports must document all environmental conditions, engine specifications, measurement equipment details, and any deviations from standard protocols.

For V4 engine vibration measurements, the testing environment must be carefully controlled. Ambient temperature should be maintained between 20-25°C with humidity levels of 40-60% to minimize environmental influences on measurement accuracy. Background noise levels must not exceed 35 dBA to prevent contamination of acoustic data during combined NVH assessments.

Sensor placement protocols require standardized mounting positions for accelerometers. Primary measurement points include cylinder head mounting points, engine block sides, crankshaft bearings, and transmission interface. The SAE J211 standard specifies that triaxial accelerometers should be used with sensitivity ratings between 10-100 mV/g depending on the expected vibration amplitude range. Mounting techniques must follow ISO 5348 guidelines to prevent measurement artifacts.

Data acquisition parameters must be standardized across testing scenarios. Sampling rates of at least 10 kHz are recommended to capture high-frequency vibration components, with anti-aliasing filters set at 40% of the sampling frequency. The minimum recording duration should be 60 seconds at steady-state conditions to ensure statistical validity of the frequency analysis.

Calibration procedures represent another critical aspect of standardization. All measurement equipment must undergo calibration at intervals not exceeding 12 months, with reference accelerometers traceable to national standards institutes. Pre-test and post-test calibration verification is mandatory to validate measurement integrity throughout the testing session.

Test sequence protocols typically include measurements at multiple engine speeds (idle, 1500 rpm, 3000 rpm, and maximum rated speed) and under various load conditions (no load, 25%, 50%, 75%, and 100% of maximum torque). Each test point requires stabilization periods of at least 2 minutes before data collection begins to ensure thermal equilibrium and steady-state operation.

Signal processing standards for vibration analysis specify the use of Hanning windows for FFT analysis with minimum 75% overlap between adjacent windows. Frequency resolution should be at least 1 Hz for low-frequency analysis (below 200 Hz) where most critical V4 engine vibration modes occur. Order analysis techniques must follow ISO 18431-4 guidelines for rotating machinery diagnostics.

Reporting requirements mandate the inclusion of coherence functions, transfer functions, and statistical confidence intervals for all measured data. Test reports must document all environmental conditions, engine specifications, measurement equipment details, and any deviations from standard protocols.

Environmental Impact of Engine Vibration Optimization

Engine vibration optimization not only enhances vehicle performance and passenger comfort but also yields significant environmental benefits. The reduction of engine vibration directly correlates with improved fuel efficiency, as excessive vibration represents wasted energy that could otherwise contribute to propulsion. Studies indicate that optimized V4 engines can achieve 3-7% better fuel economy compared to their unoptimized counterparts, resulting in proportional decreases in carbon emissions.

Furthermore, vibration optimization extends engine lifespan by reducing mechanical wear on components. This longevity translates to fewer replacement parts being manufactured and fewer engines being disposed of prematurely, thereby conserving raw materials and reducing industrial waste. The environmental impact assessment of a typical V4 engine shows that extending its operational life by 20% through vibration optimization can reduce its lifetime carbon footprint by approximately 15%.

Noise pollution, often overlooked in environmental discussions, represents another area where vibration optimization delivers tangible benefits. Excessive engine vibration generates both structural-borne and airborne noise that contributes to urban noise pollution. Advanced vibration isolation systems can reduce external noise emissions by up to 12 decibels, significantly improving the acoustic environment in densely populated areas.

The manufacturing processes for vibration dampening components have also evolved to become more environmentally friendly. Modern elastomeric mounts and dynamic absorbers increasingly utilize recycled materials and bio-based polymers. These sustainable manufacturing practices reduce the environmental impact of NVH solutions themselves, creating a virtuous cycle of environmental benefit.

From a regulatory perspective, stricter environmental standards worldwide are driving manufacturers to prioritize vibration optimization. The European Union's Environmental Noise Directive and similar regulations in North America and Asia have established specific thresholds for vehicle noise emissions, with non-compliance resulting in significant penalties. These regulatory frameworks have accelerated research and implementation of advanced vibration measurement and mitigation technologies.

Looking forward, the integration of vibration optimization with other green technologies presents promising opportunities. For instance, hybrid and electric powertrains benefit substantially from refined NVH analysis techniques originally developed for conventional engines. The knowledge transfer between these domains accelerates the overall transition to more sustainable transportation solutions while ensuring that environmental benefits are maximized across all vehicle types.

Furthermore, vibration optimization extends engine lifespan by reducing mechanical wear on components. This longevity translates to fewer replacement parts being manufactured and fewer engines being disposed of prematurely, thereby conserving raw materials and reducing industrial waste. The environmental impact assessment of a typical V4 engine shows that extending its operational life by 20% through vibration optimization can reduce its lifetime carbon footprint by approximately 15%.

Noise pollution, often overlooked in environmental discussions, represents another area where vibration optimization delivers tangible benefits. Excessive engine vibration generates both structural-borne and airborne noise that contributes to urban noise pollution. Advanced vibration isolation systems can reduce external noise emissions by up to 12 decibels, significantly improving the acoustic environment in densely populated areas.

The manufacturing processes for vibration dampening components have also evolved to become more environmentally friendly. Modern elastomeric mounts and dynamic absorbers increasingly utilize recycled materials and bio-based polymers. These sustainable manufacturing practices reduce the environmental impact of NVH solutions themselves, creating a virtuous cycle of environmental benefit.

From a regulatory perspective, stricter environmental standards worldwide are driving manufacturers to prioritize vibration optimization. The European Union's Environmental Noise Directive and similar regulations in North America and Asia have established specific thresholds for vehicle noise emissions, with non-compliance resulting in significant penalties. These regulatory frameworks have accelerated research and implementation of advanced vibration measurement and mitigation technologies.

Looking forward, the integration of vibration optimization with other green technologies presents promising opportunities. For instance, hybrid and electric powertrains benefit substantially from refined NVH analysis techniques originally developed for conventional engines. The knowledge transfer between these domains accelerates the overall transition to more sustainable transportation solutions while ensuring that environmental benefits are maximized across all vehicle types.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!