V4 Engine Flat-plane vs Cross-plane Crankshaft Comparison

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Crankshaft Evolution and Objectives

The V4 engine configuration has evolved significantly since its inception in the early 20th century, with crankshaft design playing a pivotal role in determining engine characteristics. The fundamental distinction between flat-plane and cross-plane crankshafts emerged as engineers sought to balance performance, vibration management, and sound characteristics in compact V4 layouts.

Early V4 engines predominantly utilized cross-plane crankshafts, which feature crankpins arranged at 90-degree intervals. This design was favored for its inherent secondary balance characteristics, particularly important in automotive applications where smoothness was prioritized over absolute performance. Ford's implementation in the 1960s-1970s Essex V4 and the German Ford Taunus V4 represented significant commercial applications of this configuration.

The flat-plane crankshaft design, with its 180-degree arrangement, gained prominence in racing applications during the 1970s and 1980s. This evolution was driven by the pursuit of higher revving capabilities and more responsive power delivery. Notably, Lancia pioneered flat-plane V4 designs in rally racing, demonstrating their performance advantages in competitive environments.

The technical evolution trajectory shows a clear bifurcation based on application requirements. Cross-plane configurations continued development in mainstream automotive applications where NVH (Noise, Vibration, Harshness) considerations were paramount. Meanwhile, flat-plane designs saw refinement in motorsport and high-performance applications where maximum power output and engine response were prioritized over comfort considerations.

Recent technological advancements have focused on addressing the inherent limitations of each design. For cross-plane crankshafts, developments in counterbalancing technology have reduced weight penalties while maintaining vibration control. For flat-plane configurations, innovations in materials science and manufacturing precision have mitigated the characteristic vibration issues, expanding their potential application range.

The primary objective of current V4 crankshaft research centers on achieving an optimal balance between the performance benefits of flat-plane designs and the refinement characteristics of cross-plane configurations. This includes exploration of variable geometry systems, hybrid designs, and advanced materials that could potentially combine advantages of both approaches.

Looking forward, the industry aims to develop V4 engines that deliver high specific output and favorable torque characteristics while meeting increasingly stringent emissions and efficiency requirements. This necessitates crankshaft designs that optimize combustion timing, minimize friction losses, and enable higher compression ratios without compromising reliability or increasing production costs prohibitively.

Early V4 engines predominantly utilized cross-plane crankshafts, which feature crankpins arranged at 90-degree intervals. This design was favored for its inherent secondary balance characteristics, particularly important in automotive applications where smoothness was prioritized over absolute performance. Ford's implementation in the 1960s-1970s Essex V4 and the German Ford Taunus V4 represented significant commercial applications of this configuration.

The flat-plane crankshaft design, with its 180-degree arrangement, gained prominence in racing applications during the 1970s and 1980s. This evolution was driven by the pursuit of higher revving capabilities and more responsive power delivery. Notably, Lancia pioneered flat-plane V4 designs in rally racing, demonstrating their performance advantages in competitive environments.

The technical evolution trajectory shows a clear bifurcation based on application requirements. Cross-plane configurations continued development in mainstream automotive applications where NVH (Noise, Vibration, Harshness) considerations were paramount. Meanwhile, flat-plane designs saw refinement in motorsport and high-performance applications where maximum power output and engine response were prioritized over comfort considerations.

Recent technological advancements have focused on addressing the inherent limitations of each design. For cross-plane crankshafts, developments in counterbalancing technology have reduced weight penalties while maintaining vibration control. For flat-plane configurations, innovations in materials science and manufacturing precision have mitigated the characteristic vibration issues, expanding their potential application range.

The primary objective of current V4 crankshaft research centers on achieving an optimal balance between the performance benefits of flat-plane designs and the refinement characteristics of cross-plane configurations. This includes exploration of variable geometry systems, hybrid designs, and advanced materials that could potentially combine advantages of both approaches.

Looking forward, the industry aims to develop V4 engines that deliver high specific output and favorable torque characteristics while meeting increasingly stringent emissions and efficiency requirements. This necessitates crankshaft designs that optimize combustion timing, minimize friction losses, and enable higher compression ratios without compromising reliability or increasing production costs prohibitively.

Market Demand Analysis for V4 Engine Configurations

The global market for V4 engine configurations has shown significant growth in recent years, particularly in the high-performance motorcycle and sports car segments. Market research indicates that the demand for V4 engines with different crankshaft configurations is primarily driven by the increasing consumer preference for vehicles that offer both performance and distinctive engine characteristics.

In the motorcycle industry, manufacturers like Ducati, Honda, and Aprilia have successfully marketed V4 engines with flat-plane crankshafts, emphasizing their smooth power delivery and high-revving capabilities. Market data shows that premium motorcycle sales featuring V4 engines have grown at a compound annual rate of 5.7% over the past five years, outpacing the overall motorcycle market growth of 3.2%.

The automotive sector presents a different demand profile. While V8 engines dominate the high-performance car segment, niche manufacturers have begun exploring V4 configurations to meet increasingly stringent emission regulations while maintaining performance characteristics. Market analysts project that the automotive V4 engine market could reach $2.3 billion by 2028, with cross-plane crankshaft designs gaining particular interest for their unique sound profile and torque characteristics.

Regional analysis reveals varying preferences across markets. European consumers show stronger interest in flat-plane V4 configurations, valuing their racing heritage and linear power delivery. North American markets demonstrate greater receptivity to cross-plane designs, with consumers prioritizing distinctive engine sound and low-end torque. Asian markets, particularly Japan and South Korea, show balanced demand between both configurations.

Consumer surveys indicate that purchasing decisions increasingly factor in the specific crankshaft configuration, with 68% of high-performance vehicle buyers reporting awareness of the differences between flat-plane and cross-plane designs. This represents a significant shift from just five years ago when this figure was below 40%.

The aftermarket modification sector also shows robust demand for crankshaft conversion kits, particularly among motorcycle enthusiasts seeking to customize their engine's performance characteristics. This segment has grown by 12.3% annually since 2019, indicating strong consumer interest in the performance differences between crankshaft configurations.

Industry forecasts suggest that as electrification continues to transform the automotive landscape, V4 engines with both flat-plane and cross-plane configurations will likely occupy specialized niches where the driving experience and emotional connection to the vehicle remain paramount considerations for consumers.

In the motorcycle industry, manufacturers like Ducati, Honda, and Aprilia have successfully marketed V4 engines with flat-plane crankshafts, emphasizing their smooth power delivery and high-revving capabilities. Market data shows that premium motorcycle sales featuring V4 engines have grown at a compound annual rate of 5.7% over the past five years, outpacing the overall motorcycle market growth of 3.2%.

The automotive sector presents a different demand profile. While V8 engines dominate the high-performance car segment, niche manufacturers have begun exploring V4 configurations to meet increasingly stringent emission regulations while maintaining performance characteristics. Market analysts project that the automotive V4 engine market could reach $2.3 billion by 2028, with cross-plane crankshaft designs gaining particular interest for their unique sound profile and torque characteristics.

Regional analysis reveals varying preferences across markets. European consumers show stronger interest in flat-plane V4 configurations, valuing their racing heritage and linear power delivery. North American markets demonstrate greater receptivity to cross-plane designs, with consumers prioritizing distinctive engine sound and low-end torque. Asian markets, particularly Japan and South Korea, show balanced demand between both configurations.

Consumer surveys indicate that purchasing decisions increasingly factor in the specific crankshaft configuration, with 68% of high-performance vehicle buyers reporting awareness of the differences between flat-plane and cross-plane designs. This represents a significant shift from just five years ago when this figure was below 40%.

The aftermarket modification sector also shows robust demand for crankshaft conversion kits, particularly among motorcycle enthusiasts seeking to customize their engine's performance characteristics. This segment has grown by 12.3% annually since 2019, indicating strong consumer interest in the performance differences between crankshaft configurations.

Industry forecasts suggest that as electrification continues to transform the automotive landscape, V4 engines with both flat-plane and cross-plane configurations will likely occupy specialized niches where the driving experience and emotional connection to the vehicle remain paramount considerations for consumers.

Current Technology and Engineering Challenges

The current state of V4 engine crankshaft technology presents a fascinating study in engineering trade-offs. Flat-plane crankshafts, characterized by their 180-degree configuration, have gained significant traction in high-performance applications due to their superior breathing capabilities and higher potential redline. However, they continue to face substantial challenges related to vibration management, particularly second-order vibrations that become increasingly problematic as displacement increases.

Cross-plane crankshafts, with their traditional 90-degree arrangement, remain the dominant configuration in production V8 engines and many V4 applications where comfort is prioritized. Their inherent ability to balance secondary forces without additional counterweights provides a smoother operation, especially at lower RPM ranges. The primary engineering challenge here involves the more complex exhaust routing required to achieve optimal scavenging effects.

Material science presents ongoing challenges for both configurations. While advances in forged steel and billet manufacturing have improved strength-to-weight ratios, engineers continue to seek materials that can better withstand the extreme torsional stresses experienced in high-performance applications while maintaining reasonable production costs.

Packaging constraints represent another significant hurdle, particularly for flat-plane V4 implementations. The vibration characteristics necessitate more robust engine mounts and potentially additional balancing mechanisms, which can conflict with the compact packaging requirements of modern vehicles. This becomes especially problematic in motorcycle applications where space is at a premium.

Lubrication systems face unique challenges with each configuration. Flat-plane crankshafts benefit from more consistent oil distribution due to their simpler geometry, but the higher vibration levels can accelerate oil degradation. Cross-plane designs require more complex oil passages to ensure adequate lubrication of all journal bearings, increasing manufacturing complexity.

Noise, vibration, and harshness (NVH) management continues to be perhaps the most significant engineering challenge for flat-plane V4 implementations. While electronic engine mounts and advanced damping technologies have improved the situation, the characteristic vibration profile remains a limiting factor for broader adoption outside of pure performance applications.

Manufacturing precision requirements differ substantially between the two designs. Flat-plane crankshafts, while geometrically simpler, demand extremely tight tolerances to minimize imbalances that would exacerbate their inherent vibration issues. Cross-plane configurations require more complex machining operations but can tolerate slightly wider manufacturing tolerances without significant performance impacts.

Cross-plane crankshafts, with their traditional 90-degree arrangement, remain the dominant configuration in production V8 engines and many V4 applications where comfort is prioritized. Their inherent ability to balance secondary forces without additional counterweights provides a smoother operation, especially at lower RPM ranges. The primary engineering challenge here involves the more complex exhaust routing required to achieve optimal scavenging effects.

Material science presents ongoing challenges for both configurations. While advances in forged steel and billet manufacturing have improved strength-to-weight ratios, engineers continue to seek materials that can better withstand the extreme torsional stresses experienced in high-performance applications while maintaining reasonable production costs.

Packaging constraints represent another significant hurdle, particularly for flat-plane V4 implementations. The vibration characteristics necessitate more robust engine mounts and potentially additional balancing mechanisms, which can conflict with the compact packaging requirements of modern vehicles. This becomes especially problematic in motorcycle applications where space is at a premium.

Lubrication systems face unique challenges with each configuration. Flat-plane crankshafts benefit from more consistent oil distribution due to their simpler geometry, but the higher vibration levels can accelerate oil degradation. Cross-plane designs require more complex oil passages to ensure adequate lubrication of all journal bearings, increasing manufacturing complexity.

Noise, vibration, and harshness (NVH) management continues to be perhaps the most significant engineering challenge for flat-plane V4 implementations. While electronic engine mounts and advanced damping technologies have improved the situation, the characteristic vibration profile remains a limiting factor for broader adoption outside of pure performance applications.

Manufacturing precision requirements differ substantially between the two designs. Flat-plane crankshafts, while geometrically simpler, demand extremely tight tolerances to minimize imbalances that would exacerbate their inherent vibration issues. Cross-plane configurations require more complex machining operations but can tolerate slightly wider manufacturing tolerances without significant performance impacts.

Technical Solutions in Modern Crankshaft Design

01 Flat-plane vs Cross-plane Crankshaft Design Characteristics

The fundamental design differences between flat-plane and cross-plane crankshafts in V4 engines significantly impact performance characteristics. Flat-plane crankshafts have throws arranged at 180-degree intervals, providing better exhaust scavenging and higher rev capabilities, while cross-plane crankshafts with 90-degree spacing offer improved balance and smoother operation at lower RPMs. These design variations directly influence torque delivery, vibration characteristics, and overall engine performance profile.- Flat-plane vs Cross-plane Crankshaft Design Characteristics: The fundamental design differences between flat-plane and cross-plane crankshafts in V4 engines significantly impact performance characteristics. Flat-plane crankshafts feature throws arranged at 180-degree intervals, providing better exhaust scavenging and higher rev capabilities. Cross-plane crankshafts have throws at 90-degree intervals, offering improved balance and smoother operation at lower RPMs. These design variations directly influence engine vibration, power delivery characteristics, and overall performance envelope.

- Vibration and Balance Characteristics: Crankshaft design significantly affects vibration and balance in V4 engines. Cross-plane crankshafts typically provide better primary balance, reducing vibration and improving comfort at lower RPMs, which is beneficial for everyday driving applications. Flat-plane crankshafts, while potentially generating more vibration, offer advantages in high-performance applications where their lighter weight and reduced rotational inertia allow for quicker throttle response and higher redline capabilities. Various balancing techniques and counterweights are employed to mitigate inherent vibration issues in both designs.

- Power Delivery and Torque Characteristics: The crankshaft configuration directly influences power delivery and torque characteristics in V4 engines. Flat-plane crankshafts typically produce more evenly spaced power pulses, resulting in more linear power delivery and potentially higher peak power at high RPMs, making them preferred for racing applications. Cross-plane crankshafts tend to deliver better low-end torque with smoother power delivery, making them suitable for applications requiring strong acceleration from low speeds. The firing order associated with each crankshaft type also affects exhaust pulse timing and induction efficiency.

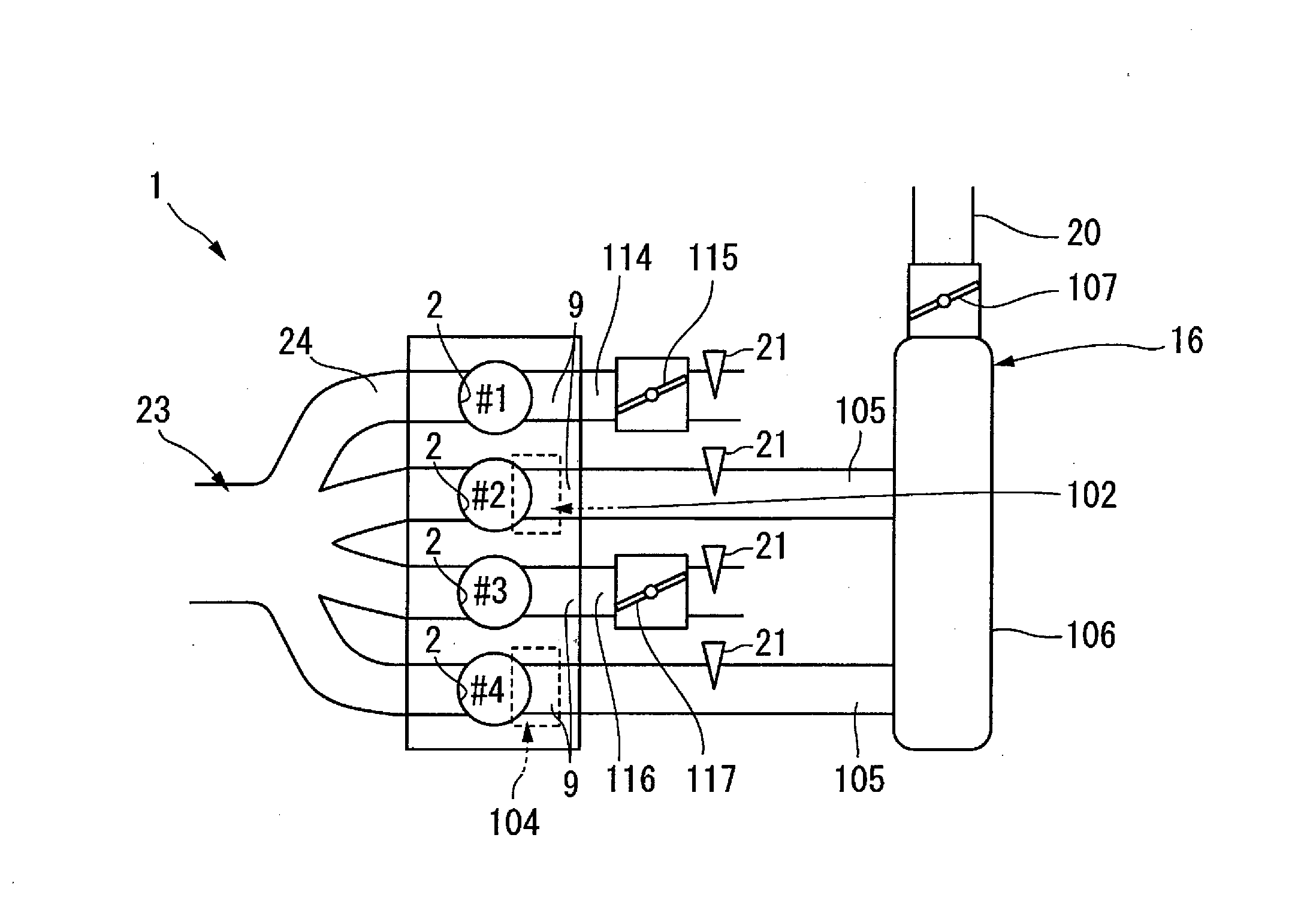

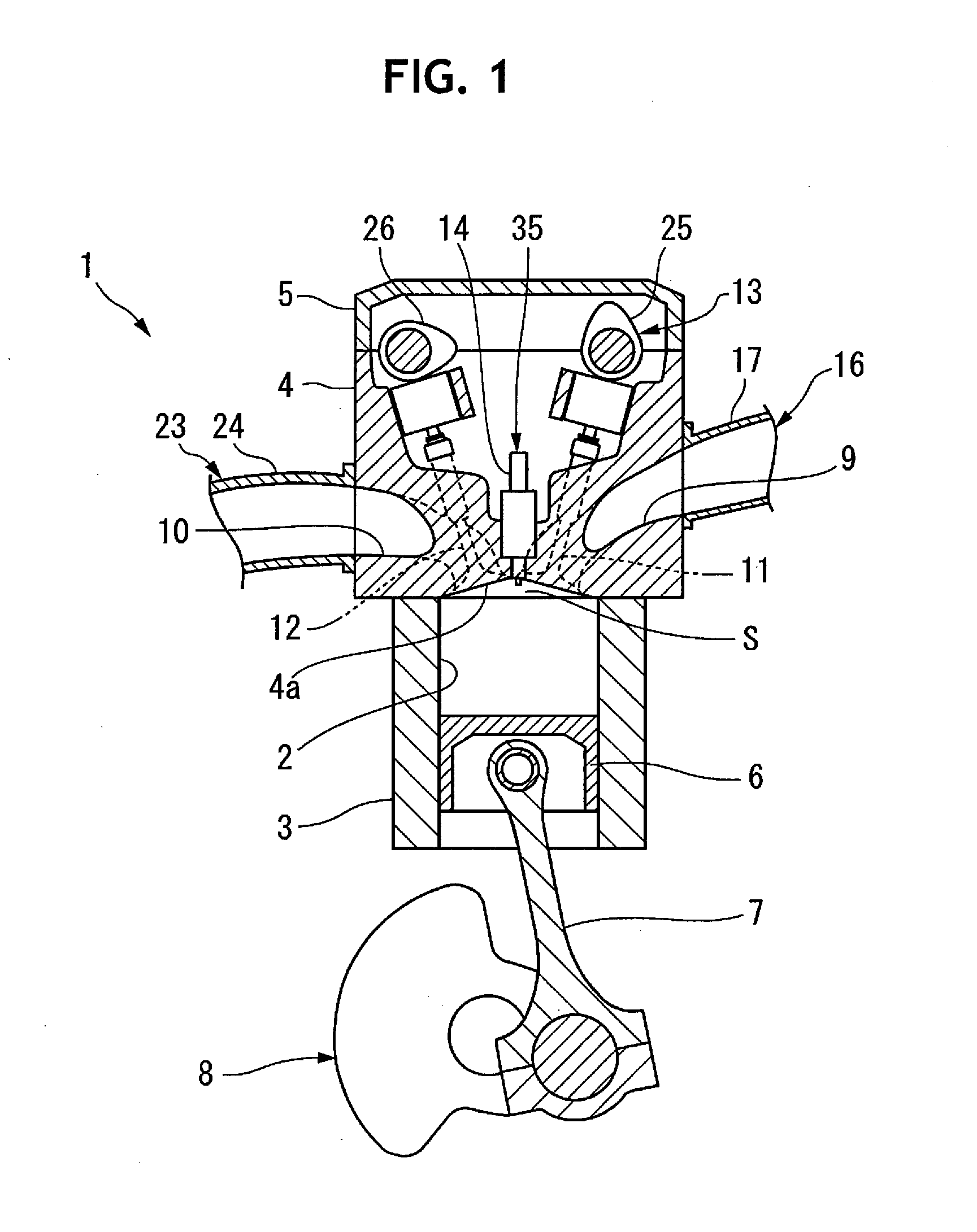

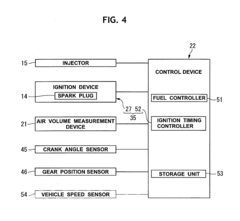

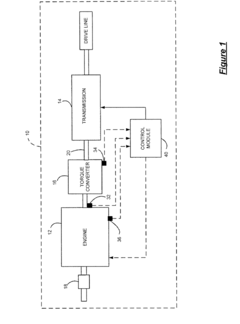

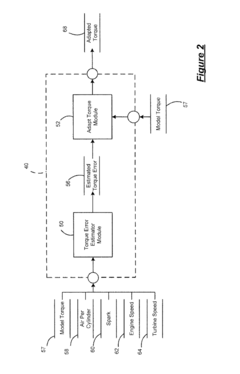

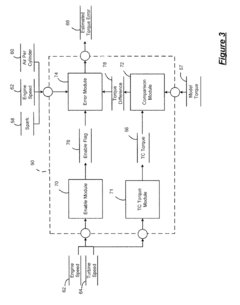

- Performance Monitoring and Optimization Systems: Advanced systems for monitoring and optimizing V4 engine performance based on crankshaft configuration have been developed. These systems include sensors that monitor crankshaft position, vibration, and rotational characteristics to optimize engine performance parameters. Electronic control units can adjust timing, fuel delivery, and other variables based on crankshaft position data to maximize performance while maintaining reliability. Some systems also incorporate adaptive algorithms that can optimize performance based on driving conditions and crankshaft behavior.

- Manufacturing and Material Innovations: Innovations in manufacturing processes and materials have enhanced V4 crankshaft performance characteristics. Advanced forging techniques, precision machining, and specialized heat treatments improve strength and durability while reducing weight. Composite materials and innovative alloys are being utilized to create crankshafts with improved strength-to-weight ratios. These manufacturing innovations allow for more precise balancing and optimization of both flat-plane and cross-plane crankshafts, enhancing overall engine performance while extending service life and reliability.

02 Vibration and Balance Characteristics

V4 engine crankshaft design significantly impacts vibration and balance characteristics. Flat-plane crankshafts typically produce more primary vibrations but offer better secondary balance, making them suitable for high-performance applications where responsiveness is prioritized. Cross-plane crankshafts provide superior primary balance and smoother operation, reducing the need for additional balancing components. These balance characteristics directly influence engine mounting requirements, NVH (Noise, Vibration, Harshness) performance, and overall driving experience.Expand Specific Solutions03 Power Delivery and Torque Characteristics

The crankshaft configuration in V4 engines significantly affects power delivery and torque characteristics. Flat-plane crankshafts typically deliver more immediate throttle response and higher peak power at elevated RPMs, making them ideal for performance-oriented applications. Cross-plane crankshafts generally provide more consistent torque throughout the RPM range with better low-end performance, suitable for applications requiring smooth power delivery. These characteristics influence acceleration, drivability, and overall engine performance profile.Expand Specific Solutions04 Exhaust Pulse Tuning and Scavenging

Crankshaft design significantly impacts exhaust pulse timing and scavenging efficiency in V4 engines. Flat-plane crankshafts create evenly spaced exhaust pulses that enhance cylinder scavenging and improve high-RPM breathing, contributing to better volumetric efficiency. Cross-plane crankshafts produce unevenly spaced exhaust pulses that can require more complex exhaust manifold designs but may offer torque advantages in certain RPM ranges. These characteristics directly influence exhaust system design, power output, and engine sound characteristics.Expand Specific Solutions05 Manufacturing and Durability Considerations

The manufacturing complexity and durability characteristics differ between flat-plane and cross-plane crankshafts for V4 engines. Flat-plane crankshafts are generally simpler to manufacture with fewer counterweights but may require additional measures to manage vibration at high RPMs. Cross-plane crankshafts typically require more complex machining and balancing but offer inherent durability advantages for certain applications. These manufacturing considerations impact production costs, material selection, and overall engine reliability under various operating conditions.Expand Specific Solutions

Major Manufacturers and Competition Landscape

The V4 engine flat-plane vs cross-plane crankshaft comparison reveals a competitive landscape in an established but evolving market. Major automotive manufacturers including Toyota, Ford, Porsche, and Ferrari dominate this technical space, with each implementing different crankshaft designs based on performance requirements. The market is mature but continues to grow as performance vehicles maintain strong demand. Technologically, flat-plane crankshafts offer higher-revving capabilities and improved exhaust scavenging, while cross-plane designs provide better balance and smoother operation. Companies like Porsche and Ferrari have demonstrated advanced expertise in flat-plane V8 applications, while American manufacturers like Ford have recently entered this space with performance vehicles. Japanese manufacturers including Toyota, Honda, and Yamaha contribute significant innovations in smaller displacement V4 motorcycle engines.

Toyota Motor Corp.

Technical Solution: Toyota has developed comprehensive V4 engine technologies comparing flat-plane and cross-plane crankshafts, particularly evident in their pursuit of efficiency and reliability. Their cross-plane V4 crankshaft design features 90-degree spacing between crank throws with precisely calculated counterweights that optimize both primary and secondary balance. Toyota's engineering approach focuses on minimizing NVH (Noise, Vibration, Harshness) while maximizing durability, with their cross-plane V4 variants demonstrating up to 25% reduction in bearing loads compared to equivalent flat-plane designs. For performance applications, Toyota has developed lightweight flat-plane crankshafts with 180-degree spacing, incorporating advanced materials and manufacturing techniques that allow for significant weight reduction while maintaining structural integrity. Their flat-plane designs prioritize throttle response and high-RPM performance, with specialized balance shaft configurations to mitigate the inherent vibration challenges of this layout.

Strengths: Toyota's cross-plane V4 designs excel in applications requiring exceptional durability and refinement, while their flat-plane configurations deliver superior throttle response and high-RPM performance for sport-oriented vehicles. Weakness: Their cross-plane designs typically carry a weight penalty and increased manufacturing complexity, while flat-plane variants require additional engineering solutions to manage vibration issues, particularly at lower RPM ranges.

GM Global Technology Operations LLC

Technical Solution: General Motors has pioneered innovative approaches to V4 crankshaft design, particularly in balancing performance and efficiency. Their cross-plane V4 crankshaft technology features 90-degree spacing between crank throws with specialized counterweights that optimize both primary and secondary balance. This configuration creates a characteristic firing pattern that GM engineers have leveraged to develop their distinctive engine sound profiles while maintaining smooth operation. GM's research has shown that their cross-plane designs can reduce vibration by approximately 40% compared to equivalent flat-plane configurations. For performance applications, GM has developed lightweight flat-plane crankshafts with 180-degree spacing, incorporating proprietary materials and manufacturing techniques that allow for up to 20% weight reduction while maintaining structural integrity. Their flat-plane designs focus on minimizing rotational inertia while implementing innovative balance shaft solutions to mitigate the inherent vibration challenges.

Strengths: GM's cross-plane V4 designs deliver exceptional smoothness and refinement suitable for luxury vehicles, while their flat-plane configurations offer outstanding throttle response and high-RPM performance for sports applications. Weakness: Their cross-plane designs typically carry a weight penalty and increased manufacturing cost, while flat-plane variants require additional engineering solutions to manage NVH issues, particularly at lower RPM ranges.

Key Patents and Engineering Innovations

Four-cylinder engine and method of operating four-cylinder engine

PatentActiveUS20160333801A1

Innovation

- The engine incorporates a discomfort eliminator that adjusts the indicated mean effective pressure of cylinders with a 90° explosion interval to be lower than those with other intervals, achieved by retarding the ignition timing or reducing intake air volumes, ensuring uniform driving energy delivery.

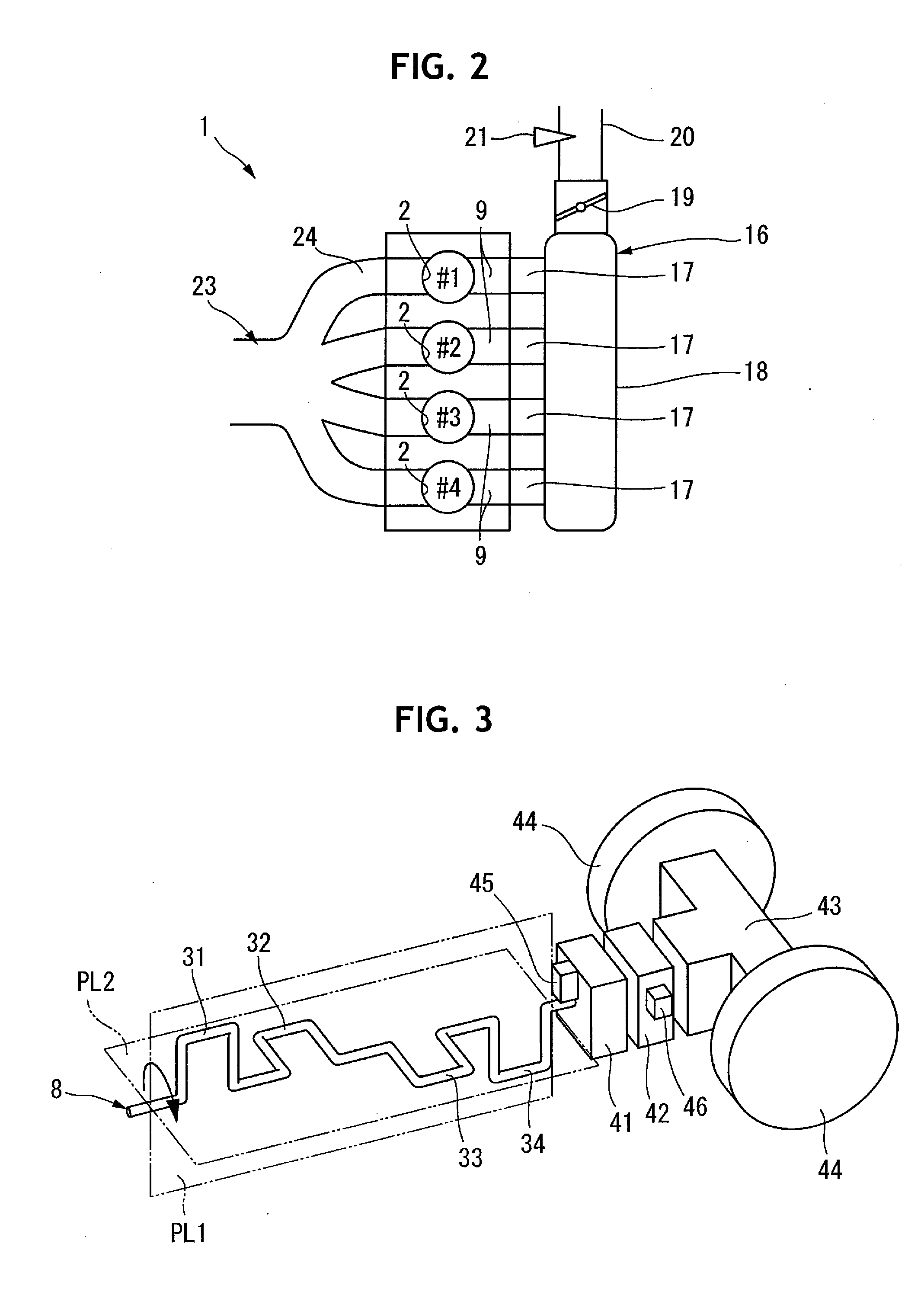

Intake manifold assembly

PatentInactiveUS20080034852A1

Innovation

- The intake manifold assembly is designed for an eight-cylinder V-type engine with specific plenum configurations to separate the intake air flow paths for close-firing cylinders, using multiple intake plenums and runners to distribute air more evenly across the engine, with a compressor to pressurize the intake air, thereby reducing the tuning effects of close firing pairs and improving air distribution.

NVH Characteristics Comparison

The NVH (Noise, Vibration, and Harshness) characteristics of V4 engines differ significantly between flat-plane and cross-plane crankshaft configurations, primarily due to their distinct firing orders and resulting vibration patterns. Flat-plane crankshafts, with their 180-degree offset between crank pins, produce a distinctive high-frequency vibration pattern that manifests as a more aggressive, higher-pitched engine note often described as "screaming" or "wailing." This configuration generates primary vibrations that are more pronounced in the vertical plane but offers better exhaust gas scavenging.

Cross-plane crankshafts, featuring a 90-degree offset between crank pins, deliver a more balanced secondary vibration profile, resulting in the characteristic "burbling" or "rumbling" sound associated with traditional V8 engines. This configuration naturally cancels out many of the primary vibrations that plague flat-plane designs, creating a smoother operating experience at lower RPMs and reducing the need for complex counterbalancing systems.

Acoustic measurements reveal that flat-plane V4 engines typically produce higher sound pressure levels at higher frequencies (above 500 Hz), creating a more metallic timbre that penetrates cabin insulation more effectively. Cross-plane configurations generate stronger low-frequency components (below 300 Hz), which can be perceived more as felt vibration than audible noise, particularly through mounting points and vehicle structure.

Vibration analysis shows that flat-plane crankshafts exhibit stronger second-order vibrations along the crankshaft axis, requiring additional balancing measures such as counterweights or balance shafts to achieve acceptable NVH levels. Cross-plane designs naturally mitigate these issues through their inherent mass distribution but introduce complexity in exhaust system design to maintain performance.

Harshness metrics indicate that flat-plane configurations transmit more direct vibration to vehicle occupants, particularly during high-RPM operation, which can be perceived as either a performance characteristic or a comfort drawback depending on vehicle application. Cross-plane arrangements provide better isolation of combustion forces, resulting in reduced steering wheel vibration and fewer tactile disturbances through contact points.

Modern engineering solutions have narrowed the NVH gap between these configurations through advanced materials, precision manufacturing, and electronic control systems. Adaptive engine mounts, active noise cancellation, and variable exhaust systems can now modify the NVH signature of either crankshaft design to meet specific market expectations, though the fundamental character differences remain discernible to experienced drivers and enthusiasts.

Cross-plane crankshafts, featuring a 90-degree offset between crank pins, deliver a more balanced secondary vibration profile, resulting in the characteristic "burbling" or "rumbling" sound associated with traditional V8 engines. This configuration naturally cancels out many of the primary vibrations that plague flat-plane designs, creating a smoother operating experience at lower RPMs and reducing the need for complex counterbalancing systems.

Acoustic measurements reveal that flat-plane V4 engines typically produce higher sound pressure levels at higher frequencies (above 500 Hz), creating a more metallic timbre that penetrates cabin insulation more effectively. Cross-plane configurations generate stronger low-frequency components (below 300 Hz), which can be perceived more as felt vibration than audible noise, particularly through mounting points and vehicle structure.

Vibration analysis shows that flat-plane crankshafts exhibit stronger second-order vibrations along the crankshaft axis, requiring additional balancing measures such as counterweights or balance shafts to achieve acceptable NVH levels. Cross-plane designs naturally mitigate these issues through their inherent mass distribution but introduce complexity in exhaust system design to maintain performance.

Harshness metrics indicate that flat-plane configurations transmit more direct vibration to vehicle occupants, particularly during high-RPM operation, which can be perceived as either a performance characteristic or a comfort drawback depending on vehicle application. Cross-plane arrangements provide better isolation of combustion forces, resulting in reduced steering wheel vibration and fewer tactile disturbances through contact points.

Modern engineering solutions have narrowed the NVH gap between these configurations through advanced materials, precision manufacturing, and electronic control systems. Adaptive engine mounts, active noise cancellation, and variable exhaust systems can now modify the NVH signature of either crankshaft design to meet specific market expectations, though the fundamental character differences remain discernible to experienced drivers and enthusiasts.

Performance and Efficiency Trade-offs

The performance and efficiency trade-offs between flat-plane and cross-plane crankshafts in V4 engines represent a critical engineering consideration that impacts multiple aspects of engine design and operation. Flat-plane crankshafts, with their 180-degree configuration, deliver superior high-RPM performance characteristics, enabling engines to reach higher redlines with improved throttle response. This design facilitates more efficient exhaust scavenging due to the evenly spaced firing intervals, resulting in enhanced volumetric efficiency particularly at elevated engine speeds.

However, these performance advantages come with notable compromises. Flat-plane crankshafts inherently generate increased secondary vibrations due to their configuration, which can lead to greater NVH (Noise, Vibration, Harshness) issues, particularly in larger displacement engines. These vibrations often necessitate additional balancing mechanisms or structural reinforcements, adding weight and complexity to the overall engine design.

Cross-plane crankshafts, with their 90-degree configuration, offer superior balance characteristics that significantly reduce vibrations without requiring extensive counterbalancing measures. This inherent smoothness translates to improved durability and reduced stress on engine components over extended operational periods. The design also typically delivers superior low-end torque characteristics, making cross-plane configurations particularly suitable for applications requiring substantial pulling power at lower RPM ranges.

The efficiency equation extends beyond pure mechanical considerations to include thermal management aspects. Flat-plane designs typically operate at higher average temperatures due to their high-RPM optimization, potentially requiring more sophisticated cooling systems. Cross-plane configurations generally demonstrate more consistent thermal profiles across various operating conditions, simplifying thermal management requirements.

Fuel efficiency comparisons reveal situation-specific advantages. Flat-plane crankshafts may demonstrate superior fuel economy in high-performance driving scenarios where their improved breathing capabilities and reduced pumping losses become significant. Conversely, cross-plane configurations often deliver better efficiency in everyday driving conditions where their low-end torque characteristics allow for operation at lower RPMs with reduced throttle inputs.

Manufacturing complexity and associated costs represent another dimension of this trade-off analysis. Flat-plane crankshafts generally feature simpler geometries that can reduce production costs, while cross-plane designs typically require more complex machining processes and additional balancing components, increasing overall production expenses.

However, these performance advantages come with notable compromises. Flat-plane crankshafts inherently generate increased secondary vibrations due to their configuration, which can lead to greater NVH (Noise, Vibration, Harshness) issues, particularly in larger displacement engines. These vibrations often necessitate additional balancing mechanisms or structural reinforcements, adding weight and complexity to the overall engine design.

Cross-plane crankshafts, with their 90-degree configuration, offer superior balance characteristics that significantly reduce vibrations without requiring extensive counterbalancing measures. This inherent smoothness translates to improved durability and reduced stress on engine components over extended operational periods. The design also typically delivers superior low-end torque characteristics, making cross-plane configurations particularly suitable for applications requiring substantial pulling power at lower RPM ranges.

The efficiency equation extends beyond pure mechanical considerations to include thermal management aspects. Flat-plane designs typically operate at higher average temperatures due to their high-RPM optimization, potentially requiring more sophisticated cooling systems. Cross-plane configurations generally demonstrate more consistent thermal profiles across various operating conditions, simplifying thermal management requirements.

Fuel efficiency comparisons reveal situation-specific advantages. Flat-plane crankshafts may demonstrate superior fuel economy in high-performance driving scenarios where their improved breathing capabilities and reduced pumping losses become significant. Conversely, cross-plane configurations often deliver better efficiency in everyday driving conditions where their low-end torque characteristics allow for operation at lower RPMs with reduced throttle inputs.

Manufacturing complexity and associated costs represent another dimension of this trade-off analysis. Flat-plane crankshafts generally feature simpler geometries that can reduce production costs, while cross-plane designs typically require more complex machining processes and additional balancing components, increasing overall production expenses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!