How to Protect V4 Engine from Pre-Ignition Issues

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Pre-Ignition Background and Objectives

Pre-ignition in V4 engines represents a significant challenge in modern internal combustion engine technology. This phenomenon, characterized by the uncontrolled combustion of the air-fuel mixture before the spark plug ignites, has been a persistent issue since the early development of high-compression engines. The evolution of V4 engine technology has seen remarkable advancements in power output, fuel efficiency, and emissions reduction; however, these improvements have often come at the cost of increased susceptibility to pre-ignition events.

Historically, pre-ignition was primarily associated with low-quality fuels and basic engine designs. As engine technology progressed through the 1980s and 1990s, the introduction of higher compression ratios, turbocharging, and direct injection systems created new pathways for pre-ignition to occur. The trend toward engine downsizing in the 2000s further exacerbated these issues, as smaller engines were required to deliver greater power density, placing additional thermal stress on components.

The technical evolution trajectory shows a clear correlation between increasing specific output (power per liter) and the frequency of pre-ignition events. Modern V4 engines, particularly those employing direct injection and turbocharging, commonly achieve specific outputs exceeding 100 hp/liter, creating operating conditions where cylinder temperatures and pressures reach critical thresholds for spontaneous ignition.

Current research indicates that pre-ignition mechanisms in V4 engines are multifaceted, involving interactions between fuel properties, combustion chamber deposits, oil droplets, and hot spots on components such as valves and pistons. The complexity of these interactions has made pre-ignition particularly challenging to predict and control through conventional engineering approaches.

The primary objective of this technical investigation is to develop comprehensive protection strategies for V4 engines against pre-ignition events. This includes identifying the fundamental mechanisms triggering pre-ignition, evaluating existing countermeasures, and exploring innovative solutions that can be implemented across various V4 engine applications. The goal extends beyond merely reducing the frequency of pre-ignition events to establishing robust prevention systems that maintain optimal engine performance without compromising efficiency or emissions compliance.

Secondary objectives include quantifying the relationship between engine operating parameters and pre-ignition susceptibility, developing advanced detection methodologies, and creating predictive models that can inform both engine design and control strategies. These objectives align with the broader industry trend toward more reliable, efficient, and environmentally sustainable internal combustion engines in an increasingly electrified automotive landscape.

Historically, pre-ignition was primarily associated with low-quality fuels and basic engine designs. As engine technology progressed through the 1980s and 1990s, the introduction of higher compression ratios, turbocharging, and direct injection systems created new pathways for pre-ignition to occur. The trend toward engine downsizing in the 2000s further exacerbated these issues, as smaller engines were required to deliver greater power density, placing additional thermal stress on components.

The technical evolution trajectory shows a clear correlation between increasing specific output (power per liter) and the frequency of pre-ignition events. Modern V4 engines, particularly those employing direct injection and turbocharging, commonly achieve specific outputs exceeding 100 hp/liter, creating operating conditions where cylinder temperatures and pressures reach critical thresholds for spontaneous ignition.

Current research indicates that pre-ignition mechanisms in V4 engines are multifaceted, involving interactions between fuel properties, combustion chamber deposits, oil droplets, and hot spots on components such as valves and pistons. The complexity of these interactions has made pre-ignition particularly challenging to predict and control through conventional engineering approaches.

The primary objective of this technical investigation is to develop comprehensive protection strategies for V4 engines against pre-ignition events. This includes identifying the fundamental mechanisms triggering pre-ignition, evaluating existing countermeasures, and exploring innovative solutions that can be implemented across various V4 engine applications. The goal extends beyond merely reducing the frequency of pre-ignition events to establishing robust prevention systems that maintain optimal engine performance without compromising efficiency or emissions compliance.

Secondary objectives include quantifying the relationship between engine operating parameters and pre-ignition susceptibility, developing advanced detection methodologies, and creating predictive models that can inform both engine design and control strategies. These objectives align with the broader industry trend toward more reliable, efficient, and environmentally sustainable internal combustion engines in an increasingly electrified automotive landscape.

Market Demand Analysis for Pre-Ignition Solutions

The global market for pre-ignition solutions in V4 engines has experienced significant growth over the past decade, driven by increasing consumer demand for high-performance, fuel-efficient vehicles. Pre-ignition issues, particularly Low-Speed Pre-Ignition (LSPI), have become more prevalent as manufacturers adopt downsized, turbocharged engines to meet stringent emissions regulations while maintaining performance standards.

Market research indicates that the automotive engine protection segment, specifically targeting pre-ignition solutions, is currently valued at approximately 3.2 billion USD globally, with a projected annual growth rate of 5.7% through 2028. This growth is primarily fueled by the expanding production of direct-injection turbocharged engines, which are particularly susceptible to pre-ignition problems.

Consumer awareness regarding engine longevity and maintenance costs has created substantial demand for effective pre-ignition prevention technologies. A recent industry survey revealed that 78% of vehicle owners expressed willingness to pay premium prices for technologies that extend engine life and prevent catastrophic failures associated with pre-ignition events.

The aftermarket segment for pre-ignition solutions has shown remarkable resilience, with specialized lubricants formulated to mitigate LSPI risks gaining significant market share. Premium engine oils with advanced additive packages designed specifically to address pre-ignition have seen sales increase by 23% year-over-year in major automotive markets.

Original Equipment Manufacturers (OEMs) are increasingly incorporating pre-ignition detection and prevention systems into new vehicle designs, responding to warranty claim data that attributes 14% of major engine failures to pre-ignition events. This has created a substantial market for sensor technologies and engine management systems capable of detecting and mitigating pre-ignition conditions in real-time.

Regional analysis reveals that North America and Europe currently dominate the market for pre-ignition solutions, accounting for 62% of global demand. However, the Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with annual growth rates exceeding 8.5%, driven by rapid motorization and increasing consumer preference for turbocharged engines.

The commercial vehicle sector has emerged as a particularly lucrative market for pre-ignition solutions, with fleet operators increasingly recognizing the substantial cost benefits of preventing engine damage. Industry data suggests that implementing effective pre-ignition prevention measures can reduce fleet maintenance costs by up to 17% and extend engine service life by approximately 30%, creating compelling economic incentives for adoption.

Market research indicates that the automotive engine protection segment, specifically targeting pre-ignition solutions, is currently valued at approximately 3.2 billion USD globally, with a projected annual growth rate of 5.7% through 2028. This growth is primarily fueled by the expanding production of direct-injection turbocharged engines, which are particularly susceptible to pre-ignition problems.

Consumer awareness regarding engine longevity and maintenance costs has created substantial demand for effective pre-ignition prevention technologies. A recent industry survey revealed that 78% of vehicle owners expressed willingness to pay premium prices for technologies that extend engine life and prevent catastrophic failures associated with pre-ignition events.

The aftermarket segment for pre-ignition solutions has shown remarkable resilience, with specialized lubricants formulated to mitigate LSPI risks gaining significant market share. Premium engine oils with advanced additive packages designed specifically to address pre-ignition have seen sales increase by 23% year-over-year in major automotive markets.

Original Equipment Manufacturers (OEMs) are increasingly incorporating pre-ignition detection and prevention systems into new vehicle designs, responding to warranty claim data that attributes 14% of major engine failures to pre-ignition events. This has created a substantial market for sensor technologies and engine management systems capable of detecting and mitigating pre-ignition conditions in real-time.

Regional analysis reveals that North America and Europe currently dominate the market for pre-ignition solutions, accounting for 62% of global demand. However, the Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with annual growth rates exceeding 8.5%, driven by rapid motorization and increasing consumer preference for turbocharged engines.

The commercial vehicle sector has emerged as a particularly lucrative market for pre-ignition solutions, with fleet operators increasingly recognizing the substantial cost benefits of preventing engine damage. Industry data suggests that implementing effective pre-ignition prevention measures can reduce fleet maintenance costs by up to 17% and extend engine service life by approximately 30%, creating compelling economic incentives for adoption.

Current Pre-Ignition Challenges in V4 Engines

Pre-ignition in V4 engines represents one of the most significant challenges facing modern engine design and operation. This phenomenon, characterized by the uncontrolled combustion of the air-fuel mixture before the spark plug fires, has become increasingly prevalent as manufacturers pursue higher compression ratios and more efficient combustion processes. The primary manifestation of pre-ignition occurs as Low-Speed Pre-Ignition (LSPI), particularly affecting direct-injection turbocharged engines operating at low speeds and high loads.

Current research indicates that pre-ignition events in V4 engines are triggered by multiple factors working in concert. Oil droplets entering the combustion chamber, often from the positive crankcase ventilation system, can act as ignition sources when combined with carbon deposits. These deposits, forming on intake valves and cylinder walls, create hot spots that initiate combustion prematurely. Additionally, the compact design of modern V4 engines, while beneficial for weight and packaging, creates thermal management challenges that exacerbate pre-ignition tendencies.

Material limitations present another significant hurdle. Contemporary pistons and cylinder heads, despite advances in metallurgy and thermal coatings, struggle to dissipate heat effectively under extreme operating conditions. This inadequate heat management creates localized hot spots that can trigger pre-ignition events, particularly during transient operating conditions when thermal equilibrium is disrupted.

Fuel quality variations compound these challenges. Modern V4 engines are designed to operate with specific fuel octane ratings, but market variations in fuel quality introduce unpredictability in combustion behavior. Lower-than-specified octane ratings significantly increase pre-ignition susceptibility, especially in engines optimized for maximum efficiency and power density.

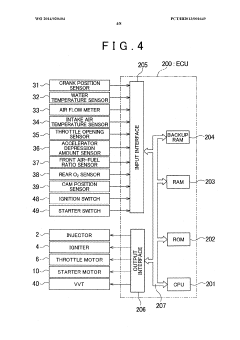

Control system limitations further complicate pre-ignition management. While modern engine control units (ECUs) employ sophisticated algorithms to detect and mitigate pre-ignition, their response capabilities remain constrained by sensor technology limitations and processing speeds. The millisecond timeframe in which pre-ignition develops often outpaces the system's ability to respond effectively.

The economic impact of these challenges is substantial. Pre-ignition events can cause catastrophic engine damage, leading to warranty claims estimated at hundreds of millions of dollars annually across the automotive industry. Furthermore, manufacturers must implement conservative calibration strategies that sacrifice performance and efficiency to ensure reliability, directly impacting competitive positioning and regulatory compliance.

Addressing these challenges requires a multidisciplinary approach spanning materials science, combustion engineering, control systems, and lubricant chemistry. The industry currently lacks a comprehensive solution that simultaneously addresses all contributing factors without compromising engine performance or increasing production costs prohibitively.

Current research indicates that pre-ignition events in V4 engines are triggered by multiple factors working in concert. Oil droplets entering the combustion chamber, often from the positive crankcase ventilation system, can act as ignition sources when combined with carbon deposits. These deposits, forming on intake valves and cylinder walls, create hot spots that initiate combustion prematurely. Additionally, the compact design of modern V4 engines, while beneficial for weight and packaging, creates thermal management challenges that exacerbate pre-ignition tendencies.

Material limitations present another significant hurdle. Contemporary pistons and cylinder heads, despite advances in metallurgy and thermal coatings, struggle to dissipate heat effectively under extreme operating conditions. This inadequate heat management creates localized hot spots that can trigger pre-ignition events, particularly during transient operating conditions when thermal equilibrium is disrupted.

Fuel quality variations compound these challenges. Modern V4 engines are designed to operate with specific fuel octane ratings, but market variations in fuel quality introduce unpredictability in combustion behavior. Lower-than-specified octane ratings significantly increase pre-ignition susceptibility, especially in engines optimized for maximum efficiency and power density.

Control system limitations further complicate pre-ignition management. While modern engine control units (ECUs) employ sophisticated algorithms to detect and mitigate pre-ignition, their response capabilities remain constrained by sensor technology limitations and processing speeds. The millisecond timeframe in which pre-ignition develops often outpaces the system's ability to respond effectively.

The economic impact of these challenges is substantial. Pre-ignition events can cause catastrophic engine damage, leading to warranty claims estimated at hundreds of millions of dollars annually across the automotive industry. Furthermore, manufacturers must implement conservative calibration strategies that sacrifice performance and efficiency to ensure reliability, directly impacting competitive positioning and regulatory compliance.

Addressing these challenges requires a multidisciplinary approach spanning materials science, combustion engineering, control systems, and lubricant chemistry. The industry currently lacks a comprehensive solution that simultaneously addresses all contributing factors without compromising engine performance or increasing production costs prohibitively.

Existing Pre-Ignition Mitigation Strategies

01 Fuel composition modifications to prevent pre-ignition

Specific fuel compositions can be formulated to reduce the occurrence of pre-ignition in V4 engines. These compositions may include additives that improve combustion stability, reduce deposit formation, and minimize the risk of early ignition events. By modifying fuel properties such as octane rating, volatility, and detergency characteristics, the tendency for pre-ignition can be significantly reduced, leading to improved engine performance and longevity.- Fuel composition modifications to prevent pre-ignition: Specific fuel compositions can be formulated to reduce pre-ignition in V4 engines. These compositions may include additives that modify combustion characteristics, reduce deposit formation, or alter fuel properties. By optimizing fuel composition, the likelihood of pre-ignition events can be significantly decreased, improving engine performance and longevity.

- Engine design modifications to mitigate pre-ignition: Structural modifications to V4 engine components can help prevent pre-ignition. These include redesigned combustion chambers, modified piston geometries, improved cooling systems, and optimized valve timing mechanisms. Such design changes can reduce hot spots and control combustion temperatures, thereby minimizing conditions that lead to pre-ignition events.

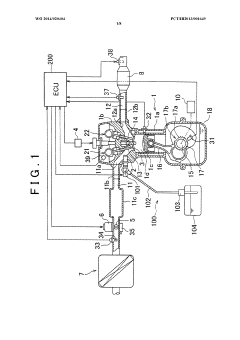

- Engine control strategies for pre-ignition prevention: Advanced control strategies can be implemented to detect and prevent pre-ignition in V4 engines. These include modified ignition timing, adaptive fuel injection patterns, cylinder pressure monitoring, and knock detection algorithms. By continuously monitoring engine parameters and making real-time adjustments, these control systems can effectively reduce pre-ignition occurrences.

- Lubricant formulations to reduce pre-ignition: Specialized lubricant formulations can significantly reduce the risk of pre-ignition in V4 engines. These lubricants may contain additives that minimize deposit formation, improve heat transfer, and reduce oil consumption. The chemical composition of these lubricants is designed to maintain stability under high-temperature conditions, thereby reducing the likelihood of oil-induced pre-ignition events.

- Diagnostic and detection systems for pre-ignition: Advanced diagnostic systems can be employed to detect pre-ignition events in V4 engines. These systems utilize sensors to monitor parameters such as cylinder pressure, temperature, vibration patterns, and exhaust gas composition. Early detection allows for immediate corrective actions, preventing engine damage and optimizing performance through adaptive control strategies based on real-time data analysis.

02 Engine control strategies to mitigate pre-ignition

Advanced control strategies can be implemented to detect and mitigate pre-ignition events in V4 engines. These strategies may involve adjusting ignition timing, fuel injection parameters, and air-fuel ratios based on real-time monitoring of combustion conditions. By implementing sophisticated algorithms that can predict potential pre-ignition conditions, the engine management system can take preventive actions to avoid damaging combustion events and maintain optimal performance.Expand Specific Solutions03 Cooling system enhancements to reduce pre-ignition risk

Improved cooling systems can help manage cylinder temperatures more effectively, reducing the risk of pre-ignition in V4 engines. These enhancements may include optimized coolant flow paths, advanced thermal management strategies, and targeted cooling of critical components. By maintaining more uniform and controlled temperature distributions within the combustion chamber, hot spots that could trigger pre-ignition can be minimized.Expand Specific Solutions04 Combustion chamber design modifications

Specific design modifications to the combustion chamber geometry can help prevent pre-ignition in V4 engines. These modifications may include optimized piston crown shapes, revised valve positioning, and improved flame propagation paths. By enhancing the combustion process through better mixture formation and more controlled flame front development, the likelihood of abnormal combustion events like pre-ignition can be significantly reduced.Expand Specific Solutions05 Lubricant formulations to minimize pre-ignition

Specialized lubricant formulations can be developed to reduce the contribution of oil to pre-ignition events in V4 engines. These formulations may include additives that improve thermal stability, reduce volatility, and minimize deposit formation. By optimizing the chemical properties of the engine oil, the risk of oil droplets or oil vapor causing pre-ignition can be significantly decreased, leading to more reliable engine operation under high-load conditions.Expand Specific Solutions

Key Manufacturers and Suppliers in Engine Protection

Pre-ignition issues in V4 engines represent a critical challenge in the automotive industry, currently in a mature development phase with established solutions. The market for pre-ignition prevention technologies is substantial, estimated at several billion dollars annually as manufacturers prioritize engine reliability and performance. Leading companies like Ford Global Technologies, Toyota Motor Corp., and Volkswagen AG have developed advanced solutions including improved combustion chamber designs, enhanced fuel injection systems, and specialized engine control algorithms. ExxonMobil and Lubrizol have focused on lubricant formulations that minimize low-speed pre-ignition, while Robert Bosch GmbH and Schaeffler Technologies offer sophisticated knock detection systems. BMW, Mercedes-Benz, and GM Global Technology Operations have implemented multi-faceted approaches combining hardware modifications with software-based prevention strategies, demonstrating the industry's commitment to resolving this technical challenge.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive approach to mitigate pre-ignition in V4 engines through their EcoBoost technology. Their solution incorporates direct fuel injection with precise timing control that cools the combustion chamber, reducing hot spots that can cause pre-ignition. Ford's system includes advanced knock sensors that can detect pre-ignition events within milliseconds and immediately adjust spark timing and fuel delivery. They've also implemented a dual cooling system that maintains optimal cylinder head temperatures while separately managing block temperature. Ford's proprietary cylinder coating technology reduces friction and heat buildup, while their ECU programming includes adaptive learning algorithms that adjust engine parameters based on driving conditions and fuel quality to prevent pre-ignition events before they occur.

Strengths: Integrated approach combining hardware and software solutions; real-time detection and prevention capabilities; adaptive learning for different conditions. Weaknesses: System complexity increases manufacturing costs; requires premium fuel for optimal performance; potential reliability concerns with multiple electronic sensors.

Toyota Motor Corp.

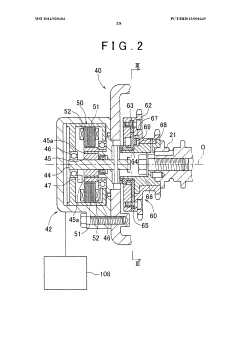

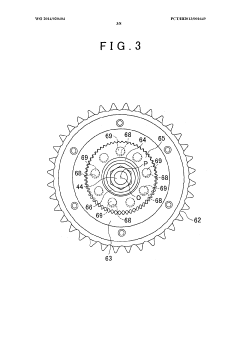

Technical Solution: Toyota's pre-ignition protection system for V4 engines centers around their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology. This dual injection system combines direct and port fuel injection, allowing the ECU to dynamically switch between or combine both methods depending on engine load and conditions. For pre-ignition prevention, Toyota employs water-cooled exhaust gas recirculation (EGR) that significantly reduces combustion temperatures. Their engines feature variable valve timing with intelligence (VVT-i) that optimizes valve timing to prevent cylinder conditions conducive to pre-ignition. Toyota has also developed specialized piston designs with cooling channels and thermal barrier coatings that manage heat distribution. Their system includes multi-point temperature sensors throughout the engine that feed data to predictive algorithms, allowing the ECU to anticipate and prevent pre-ignition events before they occur.

Strengths: Dual injection system provides flexibility across various operating conditions; excellent thermal management; proven reliability in production vehicles. Weaknesses: System adds weight and complexity; higher initial manufacturing cost; requires more sophisticated maintenance procedures.

Critical Patents and Research on Pre-Ignition Control

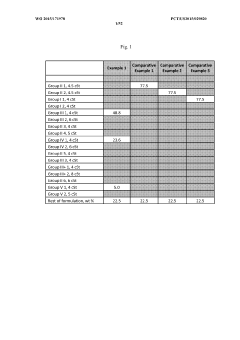

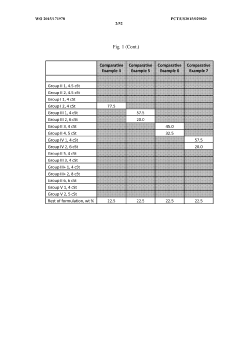

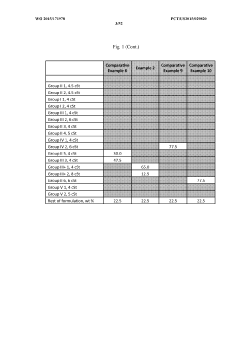

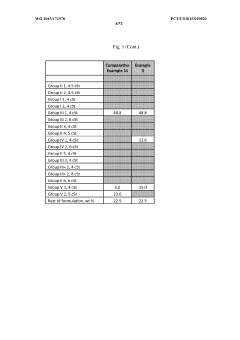

Method for preventing or reducing low speed pre-ignition

PatentWO2015171978A1

Innovation

- A lubricating oil formulation containing a detergent with at least one alkaline earth metal salt of an organic acid, preferably magnesium salt, along with zinc-containing compounds and boron-containing compounds, is used to reduce LSPI by forming a stable film that prevents hot spots and auto-ignition in the combustion chamber.

Apparatus for controlling a variable valve timing at engine start of an internal combustion engine

PatentWO2014020404A1

Innovation

- A startup control apparatus that determines the temperature condition of the engine at startup and adjusts the closing timing of the intake valve using a variable valve timing mechanism, retarding the valve timing before cranking if high temperatures are detected to reduce the effective compression ratio and prevent pre-ignition, while ensuring favorable startability.

Environmental Impact of Pre-Ignition Solutions

The environmental implications of pre-ignition solutions in V4 engines represent a critical dimension of automotive engineering that extends beyond performance considerations. As regulatory frameworks worldwide increasingly emphasize reduced emissions and sustainable transportation solutions, the environmental impact of technologies addressing pre-ignition becomes paramount in research and development strategies.

Fuel additives commonly employed to mitigate pre-ignition issues present complex environmental trade-offs. While metal-based additives like manganese and iron compounds effectively suppress pre-ignition, they contribute to particulate emissions that can degrade air quality and potentially harm respiratory health in urban environments. Conversely, newer organic additives demonstrate promising reduction in harmful emissions but may introduce other environmental challenges through their production processes.

Advanced cooling systems designed to prevent pre-ignition typically require additional energy consumption, potentially increasing the overall carbon footprint of vehicles. However, this impact must be balanced against the environmental benefits of preventing incomplete combustion events that generate significantly higher levels of carbon monoxide and unburned hydrocarbons. Life cycle assessment studies indicate that the net environmental effect generally favors implementation of effective cooling solutions despite their energy requirements.

Sensor-based detection and prevention systems represent perhaps the most environmentally favorable approach. These technologies enable real-time combustion monitoring and adjustment, optimizing fuel efficiency while minimizing emissions across various operating conditions. The environmental advantage stems from their ability to maintain ideal combustion parameters without requiring chemical additives or excessive cooling energy.

Material science innovations in piston and cylinder design offer substantial environmental benefits through weight reduction and improved thermal management. Lightweight components reduce overall vehicle weight, improving fuel efficiency and reducing lifetime emissions. Additionally, advanced ceramic coatings and composite materials that resist pre-ignition can extend engine lifespan, reducing resource consumption associated with manufacturing replacement parts or entire engines.

From a lifecycle perspective, solutions that extend engine durability by preventing pre-ignition damage contribute significantly to environmental sustainability by reducing the resource-intensive processes of manufacturing replacement components. This aspect is particularly relevant as the automotive industry faces increasing pressure to minimize its environmental footprint across the entire product lifecycle, from manufacturing through operation to end-of-life disposal.

Fuel additives commonly employed to mitigate pre-ignition issues present complex environmental trade-offs. While metal-based additives like manganese and iron compounds effectively suppress pre-ignition, they contribute to particulate emissions that can degrade air quality and potentially harm respiratory health in urban environments. Conversely, newer organic additives demonstrate promising reduction in harmful emissions but may introduce other environmental challenges through their production processes.

Advanced cooling systems designed to prevent pre-ignition typically require additional energy consumption, potentially increasing the overall carbon footprint of vehicles. However, this impact must be balanced against the environmental benefits of preventing incomplete combustion events that generate significantly higher levels of carbon monoxide and unburned hydrocarbons. Life cycle assessment studies indicate that the net environmental effect generally favors implementation of effective cooling solutions despite their energy requirements.

Sensor-based detection and prevention systems represent perhaps the most environmentally favorable approach. These technologies enable real-time combustion monitoring and adjustment, optimizing fuel efficiency while minimizing emissions across various operating conditions. The environmental advantage stems from their ability to maintain ideal combustion parameters without requiring chemical additives or excessive cooling energy.

Material science innovations in piston and cylinder design offer substantial environmental benefits through weight reduction and improved thermal management. Lightweight components reduce overall vehicle weight, improving fuel efficiency and reducing lifetime emissions. Additionally, advanced ceramic coatings and composite materials that resist pre-ignition can extend engine lifespan, reducing resource consumption associated with manufacturing replacement parts or entire engines.

From a lifecycle perspective, solutions that extend engine durability by preventing pre-ignition damage contribute significantly to environmental sustainability by reducing the resource-intensive processes of manufacturing replacement components. This aspect is particularly relevant as the automotive industry faces increasing pressure to minimize its environmental footprint across the entire product lifecycle, from manufacturing through operation to end-of-life disposal.

Durability Testing and Validation Methods

Durability testing and validation methods for V4 engines require comprehensive approaches to identify and mitigate pre-ignition issues before they reach production. These methods typically involve a combination of laboratory testing, engine dynamometer evaluations, and real-world driving simulations designed to stress the engine under various operating conditions.

Laboratory testing begins with material analysis of critical components such as pistons, cylinder heads, and valves to ensure they can withstand the thermal stresses associated with pre-ignition events. Advanced metallurgical testing includes thermal cycling, high-temperature exposure tests, and microscopic analysis to detect potential failure points before they manifest in operational engines.

Engine dynamometer testing represents the cornerstone of durability validation, where engines undergo controlled testing cycles that simulate extreme operating conditions. These tests typically include high-load, high-temperature cycles specifically designed to induce pre-ignition events. Modern dynamometer facilities can precisely control parameters such as air-fuel ratios, ignition timing, coolant temperatures, and intake air temperatures to replicate conditions known to trigger pre-ignition.

Accelerated aging protocols have become increasingly sophisticated, with test cycles designed to compress years of normal operation into weeks of testing. These protocols often include rapid transitions between idle and full-load conditions, extended operation at high RPM, and thermal shock testing to evaluate how engine components respond to extreme temperature fluctuations that might lead to pre-ignition.

Real-world validation complements laboratory testing through instrumented fleet testing across diverse environments. Test vehicles equipped with data acquisition systems capture operational parameters during mountain driving, high-temperature desert conditions, and cold-weather operation. This data helps engineers understand how environmental factors influence pre-ignition tendencies and validate the effectiveness of protective measures.

Endurance testing typically extends beyond standard validation periods, with some manufacturers implementing 100,000+ kilometer equivalent testing protocols specifically focused on pre-ignition resistance. These extended tests often incorporate fuel quality variations to ensure engines remain protected even when operated with lower-quality fuels that may increase pre-ignition risk.

Advanced monitoring technologies have revolutionized durability testing by enabling real-time detection of pre-ignition events. High-speed in-cylinder pressure transducers, knock sensors with enhanced sensitivity, and thermal imaging systems allow engineers to identify even subtle pre-ignition events that might otherwise go undetected until component damage occurs.

Statistical validation methods ensure test results are representative of production engines. Multiple test units undergo identical test protocols, with data analyzed to establish confidence intervals for pre-ignition resistance. This approach helps manufacturers quantify the effectiveness of protective measures and predict real-world reliability with greater accuracy.

Laboratory testing begins with material analysis of critical components such as pistons, cylinder heads, and valves to ensure they can withstand the thermal stresses associated with pre-ignition events. Advanced metallurgical testing includes thermal cycling, high-temperature exposure tests, and microscopic analysis to detect potential failure points before they manifest in operational engines.

Engine dynamometer testing represents the cornerstone of durability validation, where engines undergo controlled testing cycles that simulate extreme operating conditions. These tests typically include high-load, high-temperature cycles specifically designed to induce pre-ignition events. Modern dynamometer facilities can precisely control parameters such as air-fuel ratios, ignition timing, coolant temperatures, and intake air temperatures to replicate conditions known to trigger pre-ignition.

Accelerated aging protocols have become increasingly sophisticated, with test cycles designed to compress years of normal operation into weeks of testing. These protocols often include rapid transitions between idle and full-load conditions, extended operation at high RPM, and thermal shock testing to evaluate how engine components respond to extreme temperature fluctuations that might lead to pre-ignition.

Real-world validation complements laboratory testing through instrumented fleet testing across diverse environments. Test vehicles equipped with data acquisition systems capture operational parameters during mountain driving, high-temperature desert conditions, and cold-weather operation. This data helps engineers understand how environmental factors influence pre-ignition tendencies and validate the effectiveness of protective measures.

Endurance testing typically extends beyond standard validation periods, with some manufacturers implementing 100,000+ kilometer equivalent testing protocols specifically focused on pre-ignition resistance. These extended tests often incorporate fuel quality variations to ensure engines remain protected even when operated with lower-quality fuels that may increase pre-ignition risk.

Advanced monitoring technologies have revolutionized durability testing by enabling real-time detection of pre-ignition events. High-speed in-cylinder pressure transducers, knock sensors with enhanced sensitivity, and thermal imaging systems allow engineers to identify even subtle pre-ignition events that might otherwise go undetected until component damage occurs.

Statistical validation methods ensure test results are representative of production engines. Multiple test units undergo identical test protocols, with data analyzed to establish confidence intervals for pre-ignition resistance. This approach helps manufacturers quantify the effectiveness of protective measures and predict real-world reliability with greater accuracy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!