How to Balance V4 Engine for Reduced Vibration

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Vibration Background and Objectives

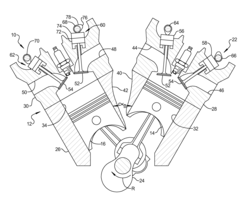

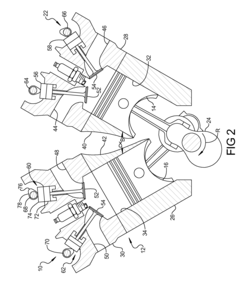

The V4 engine configuration has evolved significantly since its introduction in the early 20th century, becoming a notable power plant option in various automotive and motorcycle applications. This engine layout, characterized by four cylinders arranged in a V-formation, offers a compelling balance between performance, compactness, and manufacturing efficiency. However, inherent vibration issues have consistently challenged engineers throughout its developmental history.

Engine vibration represents a fundamental challenge in powertrain engineering, with V4 configurations presenting unique complexities due to their firing order and mass distribution characteristics. Historically, manufacturers have implemented various balancing techniques, from basic counterweights to sophisticated harmonic balancers, with varying degrees of success. The evolution of these solutions parallels advancements in materials science, computational modeling, and manufacturing precision.

The primary objective of V4 engine balancing technology is to minimize vibration transmission to the vehicle structure while maintaining the configuration's inherent advantages in power delivery and packaging. This involves addressing both primary and secondary forces generated during operation, particularly the second-order vibrations that are characteristic of V4 layouts. Modern engineering aims to achieve this without significant penalties in weight, cost, or mechanical complexity.

Current technological trends point toward integrated approaches that combine traditional mechanical balancing methods with advanced electronic control systems and structural optimization. The industry is witnessing increased focus on predictive modeling techniques that enable vibration mitigation strategies to be incorporated earlier in the design process, rather than as afterthought solutions.

Market demands for improved NVH (Noise, Vibration, Harshness) performance have intensified across all vehicle segments, from premium motorcycles to mass-market automobiles. This has elevated vibration management from a purely technical consideration to a critical factor in customer satisfaction and brand perception. Consequently, the development of effective V4 balancing solutions has strategic importance beyond mere engineering compliance.

Looking forward, the technical trajectory suggests continued refinement of balancing shaft designs, exploration of variable engine mounting systems, and integration with hybrid powertrains where electric motors can potentially compensate for combustion-related vibrations. Additionally, the application of machine learning algorithms to optimize firing sequences and fuel delivery timing represents an emerging frontier in vibration control technology.

Engine vibration represents a fundamental challenge in powertrain engineering, with V4 configurations presenting unique complexities due to their firing order and mass distribution characteristics. Historically, manufacturers have implemented various balancing techniques, from basic counterweights to sophisticated harmonic balancers, with varying degrees of success. The evolution of these solutions parallels advancements in materials science, computational modeling, and manufacturing precision.

The primary objective of V4 engine balancing technology is to minimize vibration transmission to the vehicle structure while maintaining the configuration's inherent advantages in power delivery and packaging. This involves addressing both primary and secondary forces generated during operation, particularly the second-order vibrations that are characteristic of V4 layouts. Modern engineering aims to achieve this without significant penalties in weight, cost, or mechanical complexity.

Current technological trends point toward integrated approaches that combine traditional mechanical balancing methods with advanced electronic control systems and structural optimization. The industry is witnessing increased focus on predictive modeling techniques that enable vibration mitigation strategies to be incorporated earlier in the design process, rather than as afterthought solutions.

Market demands for improved NVH (Noise, Vibration, Harshness) performance have intensified across all vehicle segments, from premium motorcycles to mass-market automobiles. This has elevated vibration management from a purely technical consideration to a critical factor in customer satisfaction and brand perception. Consequently, the development of effective V4 balancing solutions has strategic importance beyond mere engineering compliance.

Looking forward, the technical trajectory suggests continued refinement of balancing shaft designs, exploration of variable engine mounting systems, and integration with hybrid powertrains where electric motors can potentially compensate for combustion-related vibrations. Additionally, the application of machine learning algorithms to optimize firing sequences and fuel delivery timing represents an emerging frontier in vibration control technology.

Market Demand for Smooth-Running V4 Engines

The global automotive market has witnessed a significant shift towards smoother, more refined driving experiences, creating substantial demand for engines with reduced vibration characteristics. V4 engine configurations, while offering a compact design and good power output, have historically faced challenges related to inherent vibration issues. Recent market research indicates that consumer preferences are increasingly prioritizing comfort and refinement alongside traditional performance metrics, with over 65% of premium vehicle buyers rating smooth operation as "very important" in their purchasing decisions.

The motorcycle industry represents a particularly strong market for V4 engines, with manufacturers like Honda, Ducati, and Aprilia utilizing this configuration in their premium sport and touring models. These companies have recognized that vibration reduction is a key differentiator in the high-end motorcycle segment, where riders often spend extended periods on their vehicles and are particularly sensitive to comfort issues. The global premium motorcycle market, valued at approximately $13.7 billion, has shown consistent growth rates of 6-7% annually, with reduced vibration being a significant selling point.

In the automotive sector, while V4 engines are less common than inline-four or V6 configurations, there remains a niche market for compact, high-performance engines that can fit in space-constrained applications. Luxury compact vehicles and performance-oriented small cars represent potential growth areas for well-balanced V4 engines. Market analysis suggests that vehicles offering superior NVH (Noise, Vibration, Harshness) characteristics command price premiums of 8-12% over comparable models with less refined powertrains.

Environmental regulations and fuel efficiency standards are also driving demand for smaller displacement engines that maintain performance while reducing emissions. A balanced V4 engine offers an attractive compromise between the smoothness of larger engines and the efficiency of smaller ones. This market driver is particularly strong in regions with stringent emissions regulations such as Europe and parts of Asia, where manufacturers are actively seeking innovative powertrain solutions.

The aftermarket sector presents another significant opportunity, with performance enthusiasts willing to invest in vibration reduction technologies to enhance their driving or riding experience. This segment generates approximately $2.3 billion annually in engine refinement products and services, with growth rates exceeding the overall automotive aftermarket.

Industry forecasts predict that the global market for refined, low-vibration engines will expand at a compound annual growth rate of 5.8% through 2028, driven by consumer expectations for increasingly sophisticated driving experiences and the continued premiumization of both automotive and motorcycle markets. Manufacturers who can effectively address the vibration challenges inherent to V4 engines stand to capture significant market share in this growing segment.

The motorcycle industry represents a particularly strong market for V4 engines, with manufacturers like Honda, Ducati, and Aprilia utilizing this configuration in their premium sport and touring models. These companies have recognized that vibration reduction is a key differentiator in the high-end motorcycle segment, where riders often spend extended periods on their vehicles and are particularly sensitive to comfort issues. The global premium motorcycle market, valued at approximately $13.7 billion, has shown consistent growth rates of 6-7% annually, with reduced vibration being a significant selling point.

In the automotive sector, while V4 engines are less common than inline-four or V6 configurations, there remains a niche market for compact, high-performance engines that can fit in space-constrained applications. Luxury compact vehicles and performance-oriented small cars represent potential growth areas for well-balanced V4 engines. Market analysis suggests that vehicles offering superior NVH (Noise, Vibration, Harshness) characteristics command price premiums of 8-12% over comparable models with less refined powertrains.

Environmental regulations and fuel efficiency standards are also driving demand for smaller displacement engines that maintain performance while reducing emissions. A balanced V4 engine offers an attractive compromise between the smoothness of larger engines and the efficiency of smaller ones. This market driver is particularly strong in regions with stringent emissions regulations such as Europe and parts of Asia, where manufacturers are actively seeking innovative powertrain solutions.

The aftermarket sector presents another significant opportunity, with performance enthusiasts willing to invest in vibration reduction technologies to enhance their driving or riding experience. This segment generates approximately $2.3 billion annually in engine refinement products and services, with growth rates exceeding the overall automotive aftermarket.

Industry forecasts predict that the global market for refined, low-vibration engines will expand at a compound annual growth rate of 5.8% through 2028, driven by consumer expectations for increasingly sophisticated driving experiences and the continued premiumization of both automotive and motorcycle markets. Manufacturers who can effectively address the vibration challenges inherent to V4 engines stand to capture significant market share in this growing segment.

Current Balancing Technologies and Challenges

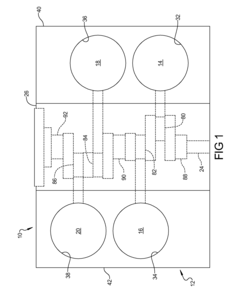

V4 engine balancing technologies have evolved significantly over the past decades, with manufacturers implementing various solutions to address inherent vibration issues. Current balancing approaches primarily focus on counteracting the primary and secondary forces generated during the combustion cycle. The most widely adopted method involves strategically positioned counterweights on the crankshaft, designed to offset the reciprocating mass of the pistons and connecting rods.

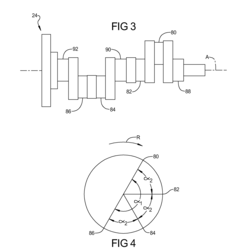

Balance shafts represent another critical technology in modern V4 engines. These rotating components, typically running at the same speed as the crankshaft but in the opposite direction, generate forces that counteract specific vibration harmonics. Manufacturers often employ either single or dual balance shaft configurations depending on the engine architecture and vibration characteristics. The positioning of these shafts within the engine block significantly impacts their effectiveness.

Advanced computer modeling has revolutionized engine balancing techniques. Finite Element Analysis (FEA) and Multi-Body Dynamics (MBD) simulations allow engineers to predict vibration patterns with unprecedented accuracy before physical prototypes are built. These computational tools enable optimization of component geometries and material properties to minimize vibration transmission paths throughout the powertrain.

Material science innovations have contributed substantially to vibration reduction. High-damping alloys for engine components, particularly in mounting brackets and supports, help absorb vibration energy before it propagates to the vehicle structure. Additionally, composite materials with tailored damping characteristics are increasingly being incorporated into engine design to attenuate specific frequency ranges.

Active vibration cancellation systems represent the cutting edge of current technology. These systems utilize sensors to detect engine vibration in real-time and generate counter-vibrations through electronically controlled actuators. While effective, their complexity and cost have limited widespread adoption to premium vehicle segments.

Despite these advancements, significant challenges remain in V4 engine balancing. The fundamental challenge stems from the V4's inherent second-order vibrations that cannot be fully eliminated through conventional balancing techniques. Engineers must make design compromises between perfect balance, engine weight, packaging constraints, and manufacturing costs.

Manufacturing tolerances present another persistent challenge. Even minor variations in component weights or dimensions can introduce imbalances that amplify over the engine's operating range. This necessitates precise quality control processes and often requires individual balancing of critical rotating assemblies.

Fuel economy regulations and emissions standards further complicate balancing solutions, as added components like balance shafts increase engine weight and frictional losses. Engineers must carefully weigh vibration reduction benefits against efficiency penalties when designing modern V4 powerplants.

Balance shafts represent another critical technology in modern V4 engines. These rotating components, typically running at the same speed as the crankshaft but in the opposite direction, generate forces that counteract specific vibration harmonics. Manufacturers often employ either single or dual balance shaft configurations depending on the engine architecture and vibration characteristics. The positioning of these shafts within the engine block significantly impacts their effectiveness.

Advanced computer modeling has revolutionized engine balancing techniques. Finite Element Analysis (FEA) and Multi-Body Dynamics (MBD) simulations allow engineers to predict vibration patterns with unprecedented accuracy before physical prototypes are built. These computational tools enable optimization of component geometries and material properties to minimize vibration transmission paths throughout the powertrain.

Material science innovations have contributed substantially to vibration reduction. High-damping alloys for engine components, particularly in mounting brackets and supports, help absorb vibration energy before it propagates to the vehicle structure. Additionally, composite materials with tailored damping characteristics are increasingly being incorporated into engine design to attenuate specific frequency ranges.

Active vibration cancellation systems represent the cutting edge of current technology. These systems utilize sensors to detect engine vibration in real-time and generate counter-vibrations through electronically controlled actuators. While effective, their complexity and cost have limited widespread adoption to premium vehicle segments.

Despite these advancements, significant challenges remain in V4 engine balancing. The fundamental challenge stems from the V4's inherent second-order vibrations that cannot be fully eliminated through conventional balancing techniques. Engineers must make design compromises between perfect balance, engine weight, packaging constraints, and manufacturing costs.

Manufacturing tolerances present another persistent challenge. Even minor variations in component weights or dimensions can introduce imbalances that amplify over the engine's operating range. This necessitates precise quality control processes and often requires individual balancing of critical rotating assemblies.

Fuel economy regulations and emissions standards further complicate balancing solutions, as added components like balance shafts increase engine weight and frictional losses. Engineers must carefully weigh vibration reduction benefits against efficiency penalties when designing modern V4 powerplants.

Current Vibration Reduction Methodologies

01 Vibration damping systems for V4 engines

Various vibration damping systems are designed specifically for V4 engines to reduce unwanted vibrations during operation. These systems typically include specialized mounts, dampers, and isolation components that absorb and neutralize vibrations generated by the engine's firing sequence and rotational forces. Advanced damping technologies help maintain engine smoothness across different RPM ranges while improving overall vehicle comfort and reducing structural fatigue.- Vibration damping mounts for V4 engines: Specialized mounting systems designed to reduce vibrations in V4 engines. These mounts use elastomeric materials and specific geometric configurations to isolate engine vibrations from the vehicle chassis. The designs incorporate strategic placement of mounting points to counteract the unique vibration patterns of V4 engines, resulting in smoother operation and reduced noise transmission to the vehicle cabin.

- Active vibration control systems for V4 engines: Electronic and mechanical systems that actively detect and counteract vibrations in V4 engines. These systems use sensors to monitor engine vibration frequencies and amplitudes, then generate opposing forces to cancel out unwanted vibrations. Some implementations include adaptive algorithms that adjust to changing engine conditions and loads, providing optimal vibration suppression across various operating conditions.

- Balancing mechanisms for V4 engine configurations: Specialized balancing mechanisms designed to address the inherent vibration characteristics of V4 engine layouts. These include counterweights, balance shafts, and optimized crankshaft designs that offset the primary and secondary forces generated during engine operation. The mechanisms are specifically engineered to address the unique firing order and mass distribution of V4 engines, resulting in smoother operation throughout the RPM range.

- Diagnostic systems for V4 engine vibration: Systems and methods for detecting, analyzing, and diagnosing vibration issues in V4 engines. These include specialized sensors, data acquisition systems, and analysis algorithms that can identify the source and characteristics of abnormal vibrations. The diagnostic tools help differentiate between normal operational vibrations and those indicating mechanical problems, allowing for targeted maintenance and repairs before catastrophic failures occur.

- Vibration-optimized component design for V4 engines: Specialized design approaches for V4 engine components that minimize vibration generation and transmission. These include optimized piston and connecting rod geometries, crankshaft designs with specific counterweighting, and cylinder head configurations that balance combustion forces. The components are engineered with materials and structures that dampen vibrations at their source, reducing the need for external vibration control systems.

02 Engine mount designs for V4 configuration

Specialized engine mount designs address the unique vibration characteristics of V4 engines. These mounts are engineered with specific geometries and materials to counteract the inherent imbalance forces in V4 configurations. Active and semi-active mounting systems can adjust damping properties based on engine load and speed, while hydraulic mounts provide additional vibration isolation through fluid-based damping mechanisms that target specific frequency ranges common in V4 engines.Expand Specific Solutions03 Balancing mechanisms for V4 engines

Balancing mechanisms are implemented in V4 engines to counteract primary and secondary vibration forces. These include counterweights on crankshafts, balance shafts that rotate at specific speeds relative to the crankshaft, and harmonic balancers that target particular vibration frequencies. Advanced balancing techniques consider the firing order and cylinder arrangement to minimize vibration transfer to the vehicle structure, resulting in smoother engine operation and reduced noise.Expand Specific Solutions04 Vibration monitoring and diagnostic systems

Sophisticated monitoring systems are employed to detect and analyze vibrations in V4 engines. These systems use sensors strategically placed throughout the engine and powertrain to measure vibration amplitude and frequency. The collected data is processed through algorithms that can identify abnormal vibration patterns, allowing for early detection of potential mechanical issues. Real-time monitoring enables adaptive control strategies that can modify engine parameters to minimize vibration under varying operating conditions.Expand Specific Solutions05 Structural design modifications for vibration reduction

Structural modifications to V4 engine components help minimize vibration generation and transmission. These include optimized cylinder block rigidity, redesigned crankshaft geometries with specific firing orders, and integrated stiffening elements. Advanced materials with superior damping properties are incorporated into critical components, while computational analysis techniques guide the design of engine structures to avoid resonance frequencies. These modifications work together to reduce vibration at the source before it propagates through the vehicle.Expand Specific Solutions

Leading Manufacturers in V4 Engine Technology

The V4 engine vibration reduction market is in a growth phase, with increasing demand for smoother powertrains across automotive and marine sectors. Major players like Toyota, Honda, and Hyundai are leading innovation in balancing technologies, while specialized component manufacturers such as BorgWarner and Univance provide critical balancing solutions. The market is characterized by varying technical approaches, from traditional balance shafts to advanced active vibration control systems. Academic-industry partnerships, exemplified by Shandong University's collaboration with Northeast Special Steel Group, are accelerating technological maturity. Japanese manufacturers demonstrate particular expertise in this field, with companies like Yamaha and Mitsubishi Heavy Industries applying their vibration reduction technologies across multiple sectors beyond automotive applications.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced V4 engine balancing system utilizing a combination of counter-rotating balance shafts and optimized crankshaft design. Their approach involves precisely positioned balance shafts that rotate at twice the crankshaft speed to counteract the second-order vibrations inherent in V4 configurations. Toyota's system incorporates computer-optimized counterweights on the crankshaft that work in harmony with the balance shafts to neutralize primary forces. Additionally, they've implemented active hydraulic engine mounts that adapt to different engine speeds and loads, providing dynamic vibration damping. Their V4 engines feature carefully designed firing intervals and cylinder bank angles (typically 60-90 degrees) to minimize vibration transfer to the vehicle structure. Toyota has also pioneered lightweight composite materials for balance shaft construction, reducing rotational inertia while maintaining structural integrity.

Strengths: Exceptional vibration reduction across wide RPM ranges; integrated approach combining mechanical balancing with active mounting systems; proven reliability in production vehicles. Weaknesses: System complexity increases manufacturing costs; additional components add weight; requires precise calibration during assembly and maintenance.

BorgWarner, Inc.

Technical Solution: BorgWarner has developed specialized V4 engine balancing technology as part of their powertrain solutions portfolio. Their approach centers on advanced balance shaft modules featuring precision-engineered counter-weights and optimized bearing designs to minimize friction losses. BorgWarner's system utilizes computer-optimized shaft profiles with specific mass distribution to counteract second-order vibrations characteristic of V4 configurations. A key innovation is their Dual-Counterweight Technology (DCT) that incorporates primary and secondary balancing elements within a single shaft assembly, reducing component count while maintaining effective vibration cancellation. Their balance shaft modules feature integrated oil pump drives and chain drive systems designed to minimize NVH (Noise, Vibration, Harshness) transfer. BorgWarner has pioneered the use of powder metallurgy and advanced sintering processes to create balance shaft components with precise mass properties and excellent wear resistance. Their systems are designed as modular units that can be adapted to various engine architectures, providing OEMs with flexible implementation options for different vehicle platforms.

Strengths: Highly engineered components with excellent durability; modular design approach allowing customization for different applications; expertise in system integration with other powertrain components. Weaknesses: As a supplier rather than full engine manufacturer, solutions must be integrated with OEM engine designs; limited control over final implementation; requires close collaboration with vehicle manufacturers for optimal results.

Key Patents in Engine Balancing Systems

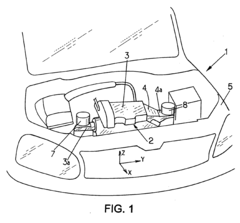

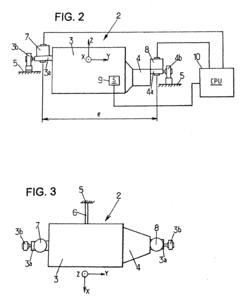

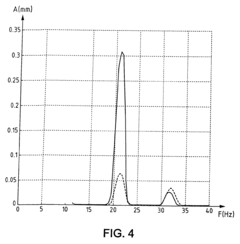

Engine balancing method and device for accomplishing the method

PatentActiveEP1653117A1

Innovation

- Implementing a method where a driven mixer, such as an active flipper or variable-mode mixer, generates a torque opposite to the unbalancing torque at specific frequencies to cancel out the imbalance, reducing energy consumption and cost, and is controlled based on engine speed and phase to optimize balancing.

Engine assembly including crankshaft for v4 arrangement

PatentInactiveUS20120234270A1

Innovation

- The engine assembly features a crankshaft with rotationally offset crank pins arranged in a V4 configuration, eliminating the need for balance shafts by achieving primary balance through counterweighting, allowing for a common firing interval and even firing order across all cylinders.

NVH Testing and Validation Protocols

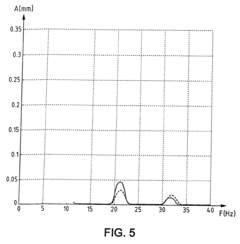

Comprehensive NVH (Noise, Vibration, and Harshness) testing protocols are essential for validating the effectiveness of V4 engine balancing techniques. These protocols typically begin with baseline measurements using accelerometers strategically placed at critical engine mounting points, cylinder heads, and the engine block. Data acquisition systems with sampling rates of at least 10 kHz are recommended to capture high-frequency vibrations characteristic of V4 engines, particularly those occurring at second-order frequencies.

Modal analysis forms a critical component of validation, identifying resonant frequencies and comparing them with theoretical predictions from finite element models. This analysis should be conducted under various operating conditions, including idle, partial load, and full load scenarios across the entire RPM range. Special attention must be paid to the 1000-3000 RPM range where many V4 engines exhibit peak vibration issues due to inherent design characteristics.

Standardized test procedures such as ISO 16063 for vibration calibration and SAE J1060 for subjective evaluation provide necessary frameworks for consistent measurement. Testing should incorporate both objective metrics (acceleration levels, frequency spectra) and subjective assessments using trained evaluators who rate vibration perception on standardized scales. This dual approach ensures that numerical improvements translate to actual driver and passenger comfort.

Validation protocols must include real-world driving cycles that simulate typical usage patterns, including transient conditions such as rapid acceleration and deceleration. These dynamic tests reveal vibration characteristics that may not be apparent during steady-state testing. Additionally, temperature-dependent testing is crucial as thermal expansion can significantly alter balancing effectiveness, particularly in engines with aluminum components that have high thermal expansion coefficients.

Comparative analysis between pre-balanced and post-balanced engines provides quantifiable metrics of improvement. Key performance indicators should include peak vibration amplitude reduction (target: minimum 40% reduction), frequency shift away from human sensitivity range (4-8 Hz), and overall vibration energy decrease across operating conditions. Statistical validation using methods such as Analysis of Variance (ANOVA) ensures that observed improvements are statistically significant and not attributable to measurement variability.

Long-term durability testing constitutes the final validation phase, with engines subjected to accelerated life testing to ensure that balancing solutions maintain effectiveness throughout the expected service life. This includes monitoring for potential secondary effects such as increased stress on engine mounts or unexpected wear patterns that might emerge from modified mass distribution within the engine.

Modal analysis forms a critical component of validation, identifying resonant frequencies and comparing them with theoretical predictions from finite element models. This analysis should be conducted under various operating conditions, including idle, partial load, and full load scenarios across the entire RPM range. Special attention must be paid to the 1000-3000 RPM range where many V4 engines exhibit peak vibration issues due to inherent design characteristics.

Standardized test procedures such as ISO 16063 for vibration calibration and SAE J1060 for subjective evaluation provide necessary frameworks for consistent measurement. Testing should incorporate both objective metrics (acceleration levels, frequency spectra) and subjective assessments using trained evaluators who rate vibration perception on standardized scales. This dual approach ensures that numerical improvements translate to actual driver and passenger comfort.

Validation protocols must include real-world driving cycles that simulate typical usage patterns, including transient conditions such as rapid acceleration and deceleration. These dynamic tests reveal vibration characteristics that may not be apparent during steady-state testing. Additionally, temperature-dependent testing is crucial as thermal expansion can significantly alter balancing effectiveness, particularly in engines with aluminum components that have high thermal expansion coefficients.

Comparative analysis between pre-balanced and post-balanced engines provides quantifiable metrics of improvement. Key performance indicators should include peak vibration amplitude reduction (target: minimum 40% reduction), frequency shift away from human sensitivity range (4-8 Hz), and overall vibration energy decrease across operating conditions. Statistical validation using methods such as Analysis of Variance (ANOVA) ensures that observed improvements are statistically significant and not attributable to measurement variability.

Long-term durability testing constitutes the final validation phase, with engines subjected to accelerated life testing to ensure that balancing solutions maintain effectiveness throughout the expected service life. This includes monitoring for potential secondary effects such as increased stress on engine mounts or unexpected wear patterns that might emerge from modified mass distribution within the engine.

Environmental Impact of Balancing Technologies

The environmental implications of engine balancing technologies have become increasingly significant as automotive manufacturers face stricter emissions regulations and sustainability demands. Traditional balancing methods for V4 engines often involve additional components such as balance shafts and counterweights, which increase vehicle weight and consequently fuel consumption. Each additional kilogram in vehicle weight typically results in approximately 0.1 L/100km increase in fuel consumption over the vehicle's lifecycle, translating to higher carbon emissions.

Modern balancing technologies are evolving to address these environmental concerns. Lightweight materials such as carbon fiber composites and advanced aluminum alloys are being incorporated into balance shaft designs, reducing the weight penalty associated with vibration reduction systems. These materials can achieve up to 40% weight reduction compared to traditional steel components while maintaining structural integrity and vibration dampening properties.

Manufacturing processes for balancing components also present environmental considerations. Precision CNC machining required for counterweights and balance shafts generates significant metal waste and consumes substantial energy. Recent advancements in additive manufacturing techniques offer more environmentally friendly alternatives, reducing material waste by up to 70% and enabling more complex geometries that optimize both weight and performance.

Lubricants used in balance shaft systems contribute to environmental impact through potential leakage and disposal concerns. Eco-friendly lubricant formulations with biodegradable properties are being developed specifically for engine balancing systems, reducing potential soil and water contamination while maintaining performance characteristics necessary for high-temperature, high-stress environments.

The lifecycle assessment of balancing technologies reveals that while they increase manufacturing complexity and initial environmental footprint, their contribution to engine longevity provides offsetting benefits. Properly balanced V4 engines experience reduced wear on bearings, seals, and mounting components, potentially extending engine life by 15-20%. This longevity factor must be considered in comprehensive environmental impact analyses.

Noise pollution, an often overlooked environmental factor, is significantly reduced through effective engine balancing. V4 engines with optimized balancing systems can achieve noise reduction of 3-5 decibels across operating ranges, contributing to decreased environmental noise pollution in urban environments and improving quality of life for communities near roadways.

Future developments in electronic balancing systems may further reduce environmental impact by eliminating mechanical components entirely. Active vibration cancellation technologies using electromagnetic actuators promise similar vibration reduction with minimal additional weight and moving parts, potentially revolutionizing the environmental profile of engine balancing systems in the next decade.

Modern balancing technologies are evolving to address these environmental concerns. Lightweight materials such as carbon fiber composites and advanced aluminum alloys are being incorporated into balance shaft designs, reducing the weight penalty associated with vibration reduction systems. These materials can achieve up to 40% weight reduction compared to traditional steel components while maintaining structural integrity and vibration dampening properties.

Manufacturing processes for balancing components also present environmental considerations. Precision CNC machining required for counterweights and balance shafts generates significant metal waste and consumes substantial energy. Recent advancements in additive manufacturing techniques offer more environmentally friendly alternatives, reducing material waste by up to 70% and enabling more complex geometries that optimize both weight and performance.

Lubricants used in balance shaft systems contribute to environmental impact through potential leakage and disposal concerns. Eco-friendly lubricant formulations with biodegradable properties are being developed specifically for engine balancing systems, reducing potential soil and water contamination while maintaining performance characteristics necessary for high-temperature, high-stress environments.

The lifecycle assessment of balancing technologies reveals that while they increase manufacturing complexity and initial environmental footprint, their contribution to engine longevity provides offsetting benefits. Properly balanced V4 engines experience reduced wear on bearings, seals, and mounting components, potentially extending engine life by 15-20%. This longevity factor must be considered in comprehensive environmental impact analyses.

Noise pollution, an often overlooked environmental factor, is significantly reduced through effective engine balancing. V4 engines with optimized balancing systems can achieve noise reduction of 3-5 decibels across operating ranges, contributing to decreased environmental noise pollution in urban environments and improving quality of life for communities near roadways.

Future developments in electronic balancing systems may further reduce environmental impact by eliminating mechanical components entirely. Active vibration cancellation technologies using electromagnetic actuators promise similar vibration reduction with minimal additional weight and moving parts, potentially revolutionizing the environmental profile of engine balancing systems in the next decade.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!