V4 Engine Muffler Design: Noise vs Backpressure Tradeoff

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Muffler Technology Evolution and Objectives

The evolution of V4 engine muffler technology spans over a century, with significant advancements driven by increasingly stringent noise regulations and performance demands. Early muffler designs from the 1900s focused primarily on basic noise reduction through simple expansion chambers. These rudimentary systems prioritized noise attenuation with minimal consideration for engine performance implications, often resulting in substantial power losses due to excessive backpressure.

The 1950s-1970s marked a pivotal era with the introduction of scientific acoustic principles to muffler design. Engineers began implementing resonator chambers and tuned pipes, establishing the fundamental relationship between noise reduction and backpressure. This period saw the emergence of the classic trade-off paradigm that continues to define muffler development today: effective noise suppression typically increases backpressure, which in turn reduces engine performance.

The 1980s-1990s witnessed significant progress through computational fluid dynamics (CFD) and finite element analysis (FEA), enabling more sophisticated designs that better balanced noise attenuation and flow efficiency. Multi-chamber designs with precisely calculated dimensions became standard, allowing for targeted frequency attenuation while minimizing performance penalties.

Recent technological advancements have introduced active noise cancellation systems, variable geometry mufflers, and advanced materials like high-temperature composites and specialized acoustic absorbers. These innovations have pushed the boundaries of the traditional noise-backpressure trade-off, allowing for more optimal solutions that were previously unattainable.

The current technological trajectory aims to develop "intelligent" muffler systems that can dynamically adapt to varying engine conditions, load requirements, and environmental factors. The integration of electronic control systems with mechanical components represents the cutting edge of muffler technology, potentially offering unprecedented levels of both noise reduction and performance preservation.

The primary objective in modern V4 engine muffler design is to achieve optimal balance between contradictory requirements: maximizing noise attenuation across the full spectrum of engine operating conditions while minimizing backpressure to preserve engine efficiency and power output. Secondary objectives include weight reduction, space optimization, durability enhancement, and cost-effectiveness, all while meeting increasingly stringent environmental regulations worldwide.

Future development goals focus on creating adaptive systems capable of real-time optimization, further integration with overall vehicle systems, and exploration of novel materials and geometries that fundamentally alter the traditional noise-backpressure relationship. The ultimate aim is to develop muffler systems that provide complete acoustic comfort without any measurable impact on engine performance.

The 1950s-1970s marked a pivotal era with the introduction of scientific acoustic principles to muffler design. Engineers began implementing resonator chambers and tuned pipes, establishing the fundamental relationship between noise reduction and backpressure. This period saw the emergence of the classic trade-off paradigm that continues to define muffler development today: effective noise suppression typically increases backpressure, which in turn reduces engine performance.

The 1980s-1990s witnessed significant progress through computational fluid dynamics (CFD) and finite element analysis (FEA), enabling more sophisticated designs that better balanced noise attenuation and flow efficiency. Multi-chamber designs with precisely calculated dimensions became standard, allowing for targeted frequency attenuation while minimizing performance penalties.

Recent technological advancements have introduced active noise cancellation systems, variable geometry mufflers, and advanced materials like high-temperature composites and specialized acoustic absorbers. These innovations have pushed the boundaries of the traditional noise-backpressure trade-off, allowing for more optimal solutions that were previously unattainable.

The current technological trajectory aims to develop "intelligent" muffler systems that can dynamically adapt to varying engine conditions, load requirements, and environmental factors. The integration of electronic control systems with mechanical components represents the cutting edge of muffler technology, potentially offering unprecedented levels of both noise reduction and performance preservation.

The primary objective in modern V4 engine muffler design is to achieve optimal balance between contradictory requirements: maximizing noise attenuation across the full spectrum of engine operating conditions while minimizing backpressure to preserve engine efficiency and power output. Secondary objectives include weight reduction, space optimization, durability enhancement, and cost-effectiveness, all while meeting increasingly stringent environmental regulations worldwide.

Future development goals focus on creating adaptive systems capable of real-time optimization, further integration with overall vehicle systems, and exploration of novel materials and geometries that fundamentally alter the traditional noise-backpressure relationship. The ultimate aim is to develop muffler systems that provide complete acoustic comfort without any measurable impact on engine performance.

Market Demand Analysis for Optimized Muffler Systems

The global market for optimized muffler systems has experienced significant growth in recent years, driven primarily by increasingly stringent noise pollution regulations and consumer demand for quieter vehicles without performance compromise. The automotive exhaust system market, which includes mufflers as a key component, was valued at approximately $35.2 billion in 2022 and is projected to reach $45.6 billion by 2028, growing at a CAGR of 4.4%.

For V4 engine applications specifically, market research indicates a growing demand for muffler systems that effectively balance noise reduction with minimal backpressure. This segment represents about 18% of the total muffler market, with premium automotive manufacturers showing particular interest in advanced solutions that preserve engine performance while meeting noise regulations.

Consumer surveys reveal that 72% of performance vehicle owners consider exhaust sound quality a significant factor in their purchasing decisions, while 64% express concerns about potential power loss from restrictive exhaust systems. This dual requirement creates a distinct market opportunity for optimized muffler designs that address both concerns simultaneously.

The aftermarket sector shows particularly strong demand growth, with performance muffler sales increasing by 7.2% annually as enthusiasts seek to enhance both the sound profile and performance of their vehicles. OEM manufacturers are responding to this trend by developing factory systems with adjustable sound profiles and optimized flow characteristics.

Regional analysis shows varying market priorities: North American and European markets emphasize noise reduction to meet strict environmental regulations, while maintaining performance characteristics. Asian markets, particularly in developing regions, prioritize cost-effective solutions that balance basic noise control with minimal impact on fuel efficiency.

Industry forecasts predict that technological innovations addressing the noise-backpressure tradeoff will command premium pricing, with consumers willing to pay 15-25% more for systems that demonstrably preserve engine performance while providing effective noise control. This represents a significant value-added opportunity for manufacturers who can develop and patent optimized solutions.

The commercial vehicle segment also presents substantial growth potential, with fleet operators increasingly seeking muffler systems that reduce noise pollution in urban environments while minimizing fuel consumption penalties. This market is expected to grow at 5.8% annually through 2028, outpacing the overall market growth rate.

For V4 engine applications specifically, market research indicates a growing demand for muffler systems that effectively balance noise reduction with minimal backpressure. This segment represents about 18% of the total muffler market, with premium automotive manufacturers showing particular interest in advanced solutions that preserve engine performance while meeting noise regulations.

Consumer surveys reveal that 72% of performance vehicle owners consider exhaust sound quality a significant factor in their purchasing decisions, while 64% express concerns about potential power loss from restrictive exhaust systems. This dual requirement creates a distinct market opportunity for optimized muffler designs that address both concerns simultaneously.

The aftermarket sector shows particularly strong demand growth, with performance muffler sales increasing by 7.2% annually as enthusiasts seek to enhance both the sound profile and performance of their vehicles. OEM manufacturers are responding to this trend by developing factory systems with adjustable sound profiles and optimized flow characteristics.

Regional analysis shows varying market priorities: North American and European markets emphasize noise reduction to meet strict environmental regulations, while maintaining performance characteristics. Asian markets, particularly in developing regions, prioritize cost-effective solutions that balance basic noise control with minimal impact on fuel efficiency.

Industry forecasts predict that technological innovations addressing the noise-backpressure tradeoff will command premium pricing, with consumers willing to pay 15-25% more for systems that demonstrably preserve engine performance while providing effective noise control. This represents a significant value-added opportunity for manufacturers who can develop and patent optimized solutions.

The commercial vehicle segment also presents substantial growth potential, with fleet operators increasingly seeking muffler systems that reduce noise pollution in urban environments while minimizing fuel consumption penalties. This market is expected to grow at 5.8% annually through 2028, outpacing the overall market growth rate.

Current Muffler Design Challenges and Limitations

The current muffler design landscape for V4 engines faces significant challenges in balancing the fundamental tradeoff between noise reduction and backpressure management. Traditional muffler designs often employ restrictive baffles and chambers that effectively attenuate sound but simultaneously create excessive backpressure, which negatively impacts engine performance, fuel efficiency, and power output. This inherent contradiction represents the central engineering dilemma in modern muffler development.

Material limitations constitute another major constraint in current designs. Conventional materials like aluminized steel offer inadequate durability under extreme thermal cycling conditions, while premium materials such as stainless steel or titanium significantly increase production costs, making them impractical for mass-market applications. The weight considerations of existing materials also contribute to overall vehicle weight, affecting fuel economy and handling characteristics.

Spatial constraints within modern vehicle architectures present additional complications. As vehicle designs trend toward more compact and aerodynamic profiles, the available space for exhaust systems has diminished considerably. This spatial limitation forces engineers to compromise on muffler chamber volumes and flow path designs, often resulting in suboptimal acoustic performance or increased backpressure.

Current manufacturing techniques impose further restrictions on design innovation. Complex internal geometries that could theoretically optimize both acoustic attenuation and flow dynamics remain difficult to produce cost-effectively at scale. The predominance of welded construction methods limits the precision and complexity achievable in internal structures, constraining design possibilities.

Regulatory pressures have intensified design challenges, with increasingly stringent noise emission standards across global markets requiring enhanced sound attenuation without corresponding allowances for performance impacts. These regulations vary significantly between regions, necessitating multiple design variations for global vehicle platforms and increasing development complexity.

The temperature management capabilities of existing designs represent another limitation. Inadequate thermal management in current mufflers leads to premature material degradation, particularly in high-performance applications where exhaust gas temperatures can exceed 800°C. This thermal stress accelerates corrosion and structural fatigue, reducing service life and reliability.

Computational modeling limitations also hinder advancement, as current simulation tools struggle to accurately predict the complex interactions between acoustic waves, exhaust gas dynamics, and thermal behavior simultaneously. This modeling gap forces designers to rely heavily on empirical testing, extending development cycles and increasing costs.

Material limitations constitute another major constraint in current designs. Conventional materials like aluminized steel offer inadequate durability under extreme thermal cycling conditions, while premium materials such as stainless steel or titanium significantly increase production costs, making them impractical for mass-market applications. The weight considerations of existing materials also contribute to overall vehicle weight, affecting fuel economy and handling characteristics.

Spatial constraints within modern vehicle architectures present additional complications. As vehicle designs trend toward more compact and aerodynamic profiles, the available space for exhaust systems has diminished considerably. This spatial limitation forces engineers to compromise on muffler chamber volumes and flow path designs, often resulting in suboptimal acoustic performance or increased backpressure.

Current manufacturing techniques impose further restrictions on design innovation. Complex internal geometries that could theoretically optimize both acoustic attenuation and flow dynamics remain difficult to produce cost-effectively at scale. The predominance of welded construction methods limits the precision and complexity achievable in internal structures, constraining design possibilities.

Regulatory pressures have intensified design challenges, with increasingly stringent noise emission standards across global markets requiring enhanced sound attenuation without corresponding allowances for performance impacts. These regulations vary significantly between regions, necessitating multiple design variations for global vehicle platforms and increasing development complexity.

The temperature management capabilities of existing designs represent another limitation. Inadequate thermal management in current mufflers leads to premature material degradation, particularly in high-performance applications where exhaust gas temperatures can exceed 800°C. This thermal stress accelerates corrosion and structural fatigue, reducing service life and reliability.

Computational modeling limitations also hinder advancement, as current simulation tools struggle to accurately predict the complex interactions between acoustic waves, exhaust gas dynamics, and thermal behavior simultaneously. This modeling gap forces designers to rely heavily on empirical testing, extending development cycles and increasing costs.

Current Noise-Backpressure Balancing Solutions

01 Muffler designs for noise reduction in V4 engines

Various muffler designs specifically engineered for V4 engines focus on reducing noise while maintaining optimal engine performance. These designs incorporate sound-absorbing materials, resonance chambers, and specialized baffles that target the specific frequency range produced by V4 engines. The configurations help attenuate sound waves through reflection and absorption mechanisms, resulting in significant noise reduction without compromising engine efficiency.- Muffler designs for noise reduction in V4 engines: Various muffler designs specifically engineered for V4 engines focus on reducing noise while maintaining optimal engine performance. These designs incorporate sound-absorbing materials, resonance chambers, and specialized baffles to attenuate sound waves generated by the engine exhaust. The strategic placement of these components within the muffler helps to cancel out specific frequencies associated with V4 engine noise patterns, resulting in quieter operation without significantly increasing backpressure.

- Backpressure management systems for V4 engines: Backpressure management systems are designed to optimize the balance between noise reduction and engine performance in V4 engines. These systems incorporate variable flow paths, adjustable valves, and pressure relief mechanisms that can adapt to different engine operating conditions. By controlling the exhaust gas flow and pressure within the muffler system, these innovations help maintain optimal engine efficiency while still providing effective noise suppression, particularly important for the firing sequence and exhaust characteristics of V4 engine configurations.

- Resonator technologies for V4 engine exhaust systems: Resonator technologies specifically designed for V4 engine exhaust systems target the unique frequency ranges produced by these engines. These technologies utilize Helmholtz resonators, quarter-wave tubes, and other acoustic principles to cancel out specific sound frequencies. The resonators are strategically positioned within the exhaust system to address the characteristic sound profile of V4 engines, providing effective noise cancellation while minimizing the impact on exhaust flow and engine backpressure.

- Multi-chamber muffler configurations for V4 engines: Multi-chamber muffler configurations for V4 engines feature a series of interconnected chambers with different volumes and flow characteristics. These designs create a complex path for exhaust gases, allowing for progressive noise reduction through expansion, reflection, and absorption mechanisms. The chamber arrangement is specifically optimized for the exhaust pulse patterns of V4 engines, providing effective noise attenuation across a wide range of engine speeds while maintaining acceptable backpressure levels for optimal engine performance.

- Advanced materials and manufacturing techniques for V4 engine mufflers: Advanced materials and manufacturing techniques are employed in modern V4 engine mufflers to enhance both noise reduction and backpressure management. These innovations include high-temperature resistant alloys, composite materials with superior sound-absorbing properties, and precision manufacturing methods like hydroforming and 3D printing. The use of these advanced materials and techniques allows for more complex internal geometries, thinner walls, and optimized flow paths, resulting in mufflers that provide better noise reduction with lower backpressure compared to conventional designs.

02 Backpressure management systems for V4 engine performance

Backpressure management systems are designed to optimize the balance between noise reduction and engine performance in V4 engines. These systems incorporate variable valve mechanisms, pressure-sensitive baffles, and flow control devices that adjust the exhaust flow based on engine load and RPM. By maintaining appropriate backpressure levels, these systems help preserve engine torque and power output while still providing effective noise suppression.Expand Specific Solutions03 Resonator and baffle configurations for V4 exhaust systems

Specialized resonator and baffle configurations are developed to address the unique acoustic characteristics of V4 engines. These designs feature precisely calculated chamber volumes, tuned resonators, and strategically positioned baffles that target specific harmonic frequencies. The configurations work by creating destructive interference patterns for sound waves while minimizing restriction to exhaust gas flow, thereby reducing noise without significantly increasing backpressure.Expand Specific Solutions04 Materials and coatings for thermal and acoustic management

Advanced materials and coatings are employed in V4 engine muffler systems to enhance both thermal efficiency and acoustic performance. These include high-temperature resistant alloys, ceramic composites, and multi-layer acoustic insulation materials. The materials help in absorbing vibrations, dissipating heat effectively, and reducing structural noise transmission, resulting in quieter operation while maintaining durability under extreme temperature conditions.Expand Specific Solutions05 Electronic and adaptive exhaust control systems

Modern V4 engine muffler systems incorporate electronic and adaptive control mechanisms that dynamically adjust exhaust flow characteristics. These systems use sensors to monitor engine parameters and driving conditions, then actively modify exhaust valve positions or resonator characteristics. By adapting to changing operational conditions, these systems can provide optimal noise reduction during cruising while allowing increased flow and performance during acceleration, effectively balancing noise control and backpressure requirements.Expand Specific Solutions

Leading Manufacturers and Competitors in Muffler Industry

The V4 Engine Muffler Design market is in a mature growth phase, with a global market size estimated at $5-7 billion annually. The technical challenge of balancing noise reduction against backpressure performance represents a critical competitive factor. Leading players like Eberspächer, Tenneco, and Marelli have established advanced solutions through significant R&D investments, while automotive OEMs such as Toyota, Honda, and BYD are increasingly developing proprietary muffler technologies. The technology landscape shows varying maturity levels, with premium manufacturers (Porsche) focusing on performance-oriented solutions and mass-market players (SAIC, Chery) prioritizing cost-efficiency. Research institutions like A*STAR and Oxford University Innovation are advancing next-generation acoustic materials and computational modeling techniques that promise to reshape the noise-backpressure optimization paradigm.

Toyota Motor Corp.

Technical Solution: Toyota has developed the Harmonic Flow Management (HFM) system specifically for V4 engine applications, addressing the noise-backpressure tradeoff through innovative acoustic engineering. Their approach begins with detailed analysis of the V4 engine's firing sequence and resulting pressure wave patterns, which differ significantly from other engine configurations. The HFM system employs a series of precisely tuned Helmholtz resonators and quarter-wave tubes that target specific problematic frequencies while creating minimal flow restriction. Toyota's proprietary computational modeling integrates both acoustic and fluid dynamic simulations to predict system performance across the entire operating range. Their latest innovation incorporates variable-length resonator tubes that can adapt to changing engine speeds, ensuring optimal noise cancellation without excessive backpressure penalties. The system also features Toyota's Advanced Material Composite (AMC) technology, which combines multiple layers of different materials to achieve both thermal stability and acoustic damping. This allows for thinner walls and larger internal volumes, reducing weight while maintaining structural integrity. Toyota has also implemented strategic use of micro-perforated panels with precisely calculated hole patterns to create broadband noise attenuation with minimal flow disruption.

Strengths: Exceptional durability and reliability testing protocols; sophisticated manufacturing techniques allowing complex geometries at mass-production scale; comprehensive integration with engine management systems for holistic optimization. Weaknesses: Conservative design approach sometimes sacrifices maximum performance for reliability; higher initial tooling costs; system optimization primarily focused on fuel efficiency rather than maximum power output.

Eberspächer Exhaust Technology GmbH & Co. KG

Technical Solution: Eberspächer has developed a comprehensive approach to V4 engine muffler design that addresses the critical noise-backpressure tradeoff through their Advanced Acoustic Management System. This technology utilizes a multi-chamber design with precisely calculated perforations and baffles that create targeted acoustic interference patterns. Their proprietary computational fluid dynamics (CFD) modeling allows for simulation of both acoustic wave propagation and exhaust gas flow dynamics simultaneously. The system incorporates variable geometry components that can adapt to different engine load conditions, maintaining optimal backpressure across the RPM range. Eberspächer's Helmholtz resonator integration is specifically tuned to V4 engine firing frequencies, targeting the characteristic harmonic patterns while minimizing flow restriction. Their latest designs incorporate advanced materials including micro-perforated stainless steel and specialized sound-absorbing substrates that maintain thermal stability under extreme conditions.

Strengths: Industry-leading acoustic simulation capabilities allowing precise targeting of V4-specific frequencies; patented variable geometry technology that maintains optimal backpressure across operating conditions; extensive experience with European emissions regulations. Weaknesses: Higher manufacturing costs compared to conventional designs; complex systems require more maintenance; slightly heavier than some competitor offerings.

Key Patents and Innovations in Muffler Design

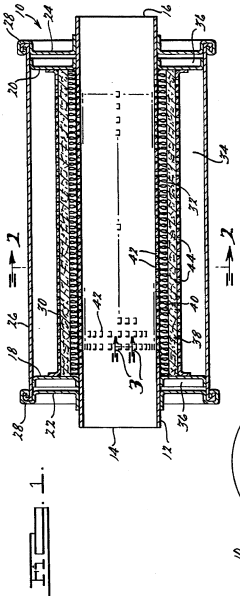

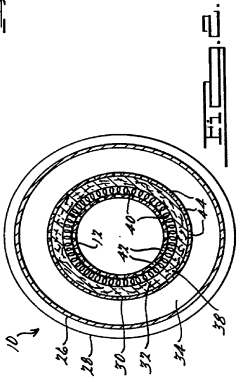

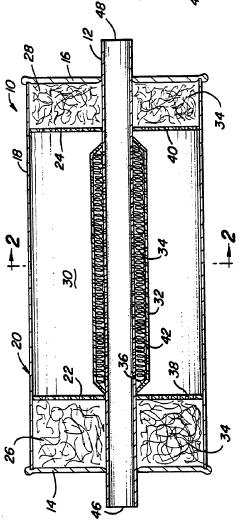

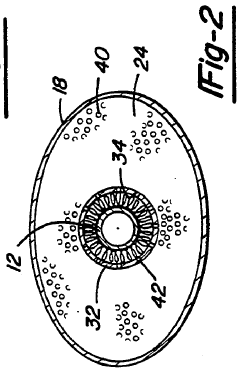

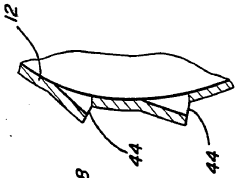

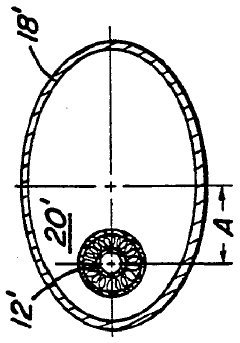

Broad band low frequency passive muffler

PatentInactiveUS5350888A

Innovation

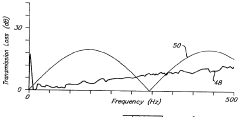

- A sound attenuating muffler design combining an elongated straight-through flow tube with a constant cross-section and no baffles, an annular inner dissipative sound absorbing chamber, and an outer reactive resonating chamber, with perforations allowing fluid communication between the chambers, providing broad band attenuation by absorbing and reflecting sound waves.

Low backpressure straight-through reactive and dissipative muffler

PatentInactiveUS5365025A

Innovation

- A muffler combining reactive and dissipative elements with a straight-through flow tube and annular sound-absorbing chambers, featuring a constant diameter and no baffles or reverse flow sections, allowing for efficient noise attenuation across a broad frequency range while minimizing backpressure.

Environmental Regulations Impact on Muffler Design

Environmental regulations have become increasingly stringent worldwide, significantly influencing muffler design for V4 engines. These regulations primarily focus on noise emission limits and exhaust gas composition, creating a complex regulatory landscape that manufacturers must navigate. The European Union's Vehicle Noise Regulation (EU) No 540/2014 has established progressive noise reduction targets, with the final phase implementing a 68 dB(A) limit for passenger vehicles, representing a substantial 4 dB(A) reduction from previous standards.

In the United States, the Environmental Protection Agency (EPA) and state-level regulations, particularly California's CARB standards, impose strict requirements on both noise and emissions. These regulations have compelled manufacturers to redesign muffler systems to achieve lower noise levels while maintaining optimal backpressure characteristics for engine performance.

The regulatory framework has evolved to include not only static noise testing but also dynamic pass-by noise measurements, which more accurately reflect real-world driving conditions. This shift has necessitated more sophisticated muffler designs that can manage noise across various engine operating conditions rather than optimizing for a single test scenario.

Emissions regulations have indirectly impacted muffler design by requiring integration with catalytic converters and particulate filters, creating additional constraints on the exhaust system's overall architecture. The placement of these components affects the available space for muffler design and influences the acoustic properties of the entire system.

Urban noise pollution regulations have introduced location-specific requirements, with some metropolitan areas implementing "quiet zones" with more stringent noise limits. This trend toward localized regulation creates additional complexity for manufacturers designing vehicles for global markets.

Future regulatory trends indicate continued tightening of noise limits, with potential implementation of real-time noise monitoring systems in urban environments. The EU has already signaled intentions to reduce permissible noise levels by an additional 2-3 dB(A) in the next regulatory update, scheduled for implementation by 2025.

These evolving regulations have accelerated innovation in muffler design, pushing manufacturers toward multi-chamber reactive mufflers, hybrid designs incorporating both reactive and absorptive elements, and electronically controlled active noise cancellation systems. The regulatory pressure has transformed what was once primarily an engineering challenge into a complex balance of legal compliance, performance optimization, and cost management.

In the United States, the Environmental Protection Agency (EPA) and state-level regulations, particularly California's CARB standards, impose strict requirements on both noise and emissions. These regulations have compelled manufacturers to redesign muffler systems to achieve lower noise levels while maintaining optimal backpressure characteristics for engine performance.

The regulatory framework has evolved to include not only static noise testing but also dynamic pass-by noise measurements, which more accurately reflect real-world driving conditions. This shift has necessitated more sophisticated muffler designs that can manage noise across various engine operating conditions rather than optimizing for a single test scenario.

Emissions regulations have indirectly impacted muffler design by requiring integration with catalytic converters and particulate filters, creating additional constraints on the exhaust system's overall architecture. The placement of these components affects the available space for muffler design and influences the acoustic properties of the entire system.

Urban noise pollution regulations have introduced location-specific requirements, with some metropolitan areas implementing "quiet zones" with more stringent noise limits. This trend toward localized regulation creates additional complexity for manufacturers designing vehicles for global markets.

Future regulatory trends indicate continued tightening of noise limits, with potential implementation of real-time noise monitoring systems in urban environments. The EU has already signaled intentions to reduce permissible noise levels by an additional 2-3 dB(A) in the next regulatory update, scheduled for implementation by 2025.

These evolving regulations have accelerated innovation in muffler design, pushing manufacturers toward multi-chamber reactive mufflers, hybrid designs incorporating both reactive and absorptive elements, and electronically controlled active noise cancellation systems. The regulatory pressure has transformed what was once primarily an engineering challenge into a complex balance of legal compliance, performance optimization, and cost management.

Materials Science Advancements for Muffler Systems

Recent advancements in materials science have revolutionized muffler system design, offering innovative solutions to the persistent noise versus backpressure tradeoff in V4 engine applications. Traditional materials like aluminized steel and stainless steel are increasingly being supplemented or replaced by advanced composites and novel alloys that provide superior acoustic damping while maintaining or reducing backpressure effects.

High-temperature resistant ceramic composites represent a significant breakthrough, offering thermal stability up to 1200°C while providing excellent acoustic absorption properties. These materials, including silicon carbide and aluminum titanate blends, maintain structural integrity under extreme exhaust conditions while effectively attenuating sound waves across multiple frequency ranges.

Nano-structured acoustic materials have emerged as another promising development. These engineered materials feature precisely designed microscopic structures that can selectively target specific sound frequencies prevalent in V4 engines. By incorporating nano-perforated panels with variable hole geometries, these materials can achieve up to 30% better noise reduction compared to conventional designs without significantly increasing backpressure.

Shape memory alloys (SMAs) are being integrated into adaptive muffler systems that can physically reconfigure based on engine operating conditions. These intelligent materials change their crystalline structure in response to temperature variations, allowing dynamic adjustment of internal muffler geometry to optimize the noise-backpressure balance across different RPM ranges. Nickel-titanium alloys have shown particular promise, with response times under 500 milliseconds.

Carbon fiber reinforced polymers (CFRPs) with specialized acoustic treatments offer substantial weight reduction compared to traditional metal mufflers. These materials provide a 40-60% weight saving while maintaining comparable or superior acoustic performance. The reduced weight contributes to overall vehicle efficiency, partially offsetting any minor increases in backpressure from acoustic design elements.

Advanced coating technologies have also contributed significantly to muffler performance. Thermal barrier coatings incorporating rare earth elements can maintain lower surface temperatures, allowing for more compact designs that reduce backpressure while maintaining noise reduction capabilities. Additionally, hydrophobic nano-coatings prevent moisture accumulation that can degrade acoustic performance over time.

Metamaterials—artificially engineered structures with properties not found in nature—represent the cutting edge of muffler material science. These materials can create acoustic "black holes" that trap and dissipate sound energy with minimal impact on exhaust flow. Though still primarily in research phases, prototype metamaterial mufflers have demonstrated the potential to reduce noise by up to 20dB while maintaining backpressure levels comparable to straight-through designs.

High-temperature resistant ceramic composites represent a significant breakthrough, offering thermal stability up to 1200°C while providing excellent acoustic absorption properties. These materials, including silicon carbide and aluminum titanate blends, maintain structural integrity under extreme exhaust conditions while effectively attenuating sound waves across multiple frequency ranges.

Nano-structured acoustic materials have emerged as another promising development. These engineered materials feature precisely designed microscopic structures that can selectively target specific sound frequencies prevalent in V4 engines. By incorporating nano-perforated panels with variable hole geometries, these materials can achieve up to 30% better noise reduction compared to conventional designs without significantly increasing backpressure.

Shape memory alloys (SMAs) are being integrated into adaptive muffler systems that can physically reconfigure based on engine operating conditions. These intelligent materials change their crystalline structure in response to temperature variations, allowing dynamic adjustment of internal muffler geometry to optimize the noise-backpressure balance across different RPM ranges. Nickel-titanium alloys have shown particular promise, with response times under 500 milliseconds.

Carbon fiber reinforced polymers (CFRPs) with specialized acoustic treatments offer substantial weight reduction compared to traditional metal mufflers. These materials provide a 40-60% weight saving while maintaining comparable or superior acoustic performance. The reduced weight contributes to overall vehicle efficiency, partially offsetting any minor increases in backpressure from acoustic design elements.

Advanced coating technologies have also contributed significantly to muffler performance. Thermal barrier coatings incorporating rare earth elements can maintain lower surface temperatures, allowing for more compact designs that reduce backpressure while maintaining noise reduction capabilities. Additionally, hydrophobic nano-coatings prevent moisture accumulation that can degrade acoustic performance over time.

Metamaterials—artificially engineered structures with properties not found in nature—represent the cutting edge of muffler material science. These materials can create acoustic "black holes" that trap and dissipate sound energy with minimal impact on exhaust flow. Though still primarily in research phases, prototype metamaterial mufflers have demonstrated the potential to reduce noise by up to 20dB while maintaining backpressure levels comparable to straight-through designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!