How to Optimize V4 Engine Performance for Fuel Efficiency

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Evolution and Efficiency Targets

The V4 engine configuration has evolved significantly since its introduction in the early 20th century. Initially developed as a space-saving alternative to inline engines, V4 designs have undergone numerous refinements aimed at improving performance while reducing fuel consumption. The earliest commercial V4 engines appeared in the 1920s, but gained prominence in the 1960s and 1970s when Ford and Lancia implemented them in various vehicle models. These early iterations prioritized compactness over efficiency, with fuel economy being a secondary consideration.

The oil crises of the 1970s marked a pivotal shift in engine development priorities, catalyzing research into more fuel-efficient designs. This period saw the first significant attempts to optimize V4 engines specifically for reduced fuel consumption, including improvements in combustion chamber design and the introduction of early fuel injection systems. By the 1980s, electronic engine management systems began to replace mechanical solutions, allowing for more precise control over the air-fuel mixture and ignition timing.

The 1990s and early 2000s witnessed the integration of variable valve timing and lift technologies into V4 configurations, enabling engines to adjust their breathing characteristics based on operating conditions. These innovations represented a major leap forward in balancing performance with efficiency. Concurrently, materials science advancements allowed for lighter components and tighter manufacturing tolerances, further enhancing efficiency through reduced friction and weight.

Current efficiency targets for V4 engines are increasingly ambitious, driven by stringent global emissions regulations and consumer demand for fuel economy. Modern V4 engines aim to achieve thermal efficiencies exceeding 40%, compared to the 25-30% typical of earlier generations. This represents a significant engineering challenge that requires holistic optimization across multiple parameters. Specific targets include reducing pumping losses by 15-20%, decreasing friction losses by 10-15%, and improving combustion efficiency by implementing advanced direct injection and ignition systems.

Looking forward, the trajectory of V4 engine development is increasingly influenced by hybridization strategies. Engineers are now designing V4 engines specifically to work in conjunction with electric motors, creating systems that leverage the strengths of both power sources. These hybrid-optimized V4 engines typically target lower displacement with higher specific output, operating in their most efficient ranges while electric systems handle transient loads and low-speed operation.

The ultimate efficiency target for modern V4 engines involves achieving near-zero waste energy, with comprehensive heat recovery systems, minimized friction through advanced coatings and lubricants, and combustion processes that approach theoretical limits of efficiency. These ambitious goals are driving innovation in areas such as homogeneous charge compression ignition (HCCI), variable compression ratio technologies, and intelligent thermal management systems.

The oil crises of the 1970s marked a pivotal shift in engine development priorities, catalyzing research into more fuel-efficient designs. This period saw the first significant attempts to optimize V4 engines specifically for reduced fuel consumption, including improvements in combustion chamber design and the introduction of early fuel injection systems. By the 1980s, electronic engine management systems began to replace mechanical solutions, allowing for more precise control over the air-fuel mixture and ignition timing.

The 1990s and early 2000s witnessed the integration of variable valve timing and lift technologies into V4 configurations, enabling engines to adjust their breathing characteristics based on operating conditions. These innovations represented a major leap forward in balancing performance with efficiency. Concurrently, materials science advancements allowed for lighter components and tighter manufacturing tolerances, further enhancing efficiency through reduced friction and weight.

Current efficiency targets for V4 engines are increasingly ambitious, driven by stringent global emissions regulations and consumer demand for fuel economy. Modern V4 engines aim to achieve thermal efficiencies exceeding 40%, compared to the 25-30% typical of earlier generations. This represents a significant engineering challenge that requires holistic optimization across multiple parameters. Specific targets include reducing pumping losses by 15-20%, decreasing friction losses by 10-15%, and improving combustion efficiency by implementing advanced direct injection and ignition systems.

Looking forward, the trajectory of V4 engine development is increasingly influenced by hybridization strategies. Engineers are now designing V4 engines specifically to work in conjunction with electric motors, creating systems that leverage the strengths of both power sources. These hybrid-optimized V4 engines typically target lower displacement with higher specific output, operating in their most efficient ranges while electric systems handle transient loads and low-speed operation.

The ultimate efficiency target for modern V4 engines involves achieving near-zero waste energy, with comprehensive heat recovery systems, minimized friction through advanced coatings and lubricants, and combustion processes that approach theoretical limits of efficiency. These ambitious goals are driving innovation in areas such as homogeneous charge compression ignition (HCCI), variable compression ratio technologies, and intelligent thermal management systems.

Market Demand for Fuel-Efficient V4 Engines

The global automotive market has witnessed a significant shift towards fuel efficiency in recent years, driven primarily by stringent environmental regulations, rising fuel costs, and increasing consumer awareness about carbon footprints. This trend has created a substantial demand for fuel-efficient V4 engines across various vehicle segments, particularly in compact cars, small SUVs, and hybrid vehicles.

Market research indicates that the fuel-efficient engine market is projected to grow at a compound annual growth rate of 5.7% between 2023 and 2028. Within this broader market, V4 engines are gaining particular attention due to their balanced combination of power, compactness, and efficiency potential. Consumer surveys reveal that fuel economy now ranks among the top three purchasing considerations for over 68% of new car buyers globally.

Regional analysis shows varying degrees of demand intensity. European markets demonstrate the strongest preference for fuel-efficient V4 engines, influenced by strict EU emission standards and high fuel taxation policies. The Asia-Pacific region follows closely, with rapidly growing economies like China and India showing increased consumer interest in fuel-efficient vehicles as urban air quality concerns mount and middle-class purchasing power expands.

The commercial vehicle sector also presents a significant market opportunity. Fleet operators increasingly prioritize total cost of ownership calculations where fuel consumption represents a major operational expense. This has created a growing demand for fuel-efficient V4 engines in light commercial vehicles and delivery vans, particularly in urban logistics applications.

Market segmentation analysis reveals distinct consumer groups driving demand. Urban commuters seek compact, efficient engines for daily city driving. Weekend adventurers desire adequate power combined with extended range for occasional longer trips. Fleet managers require proven reliability alongside operational cost savings. Each segment presents unique optimization priorities that manufacturers must address.

Competitive analysis indicates that manufacturers who successfully optimize V4 engines for fuel efficiency while maintaining acceptable performance characteristics can expect to capture premium market positioning. Consumers have demonstrated willingness to pay 8-12% price premiums for vehicles offering 15-20% better fuel economy than segment averages, creating strong economic incentives for technological advancement in this area.

Future market projections suggest continued growth in demand for fuel-efficient V4 engines, even as electrification progresses. Industry analysts predict a substantial transitional period where optimized internal combustion engines will remain dominant in many market segments, particularly in regions with underdeveloped charging infrastructure or where price sensitivity limits electric vehicle adoption.

Market research indicates that the fuel-efficient engine market is projected to grow at a compound annual growth rate of 5.7% between 2023 and 2028. Within this broader market, V4 engines are gaining particular attention due to their balanced combination of power, compactness, and efficiency potential. Consumer surveys reveal that fuel economy now ranks among the top three purchasing considerations for over 68% of new car buyers globally.

Regional analysis shows varying degrees of demand intensity. European markets demonstrate the strongest preference for fuel-efficient V4 engines, influenced by strict EU emission standards and high fuel taxation policies. The Asia-Pacific region follows closely, with rapidly growing economies like China and India showing increased consumer interest in fuel-efficient vehicles as urban air quality concerns mount and middle-class purchasing power expands.

The commercial vehicle sector also presents a significant market opportunity. Fleet operators increasingly prioritize total cost of ownership calculations where fuel consumption represents a major operational expense. This has created a growing demand for fuel-efficient V4 engines in light commercial vehicles and delivery vans, particularly in urban logistics applications.

Market segmentation analysis reveals distinct consumer groups driving demand. Urban commuters seek compact, efficient engines for daily city driving. Weekend adventurers desire adequate power combined with extended range for occasional longer trips. Fleet managers require proven reliability alongside operational cost savings. Each segment presents unique optimization priorities that manufacturers must address.

Competitive analysis indicates that manufacturers who successfully optimize V4 engines for fuel efficiency while maintaining acceptable performance characteristics can expect to capture premium market positioning. Consumers have demonstrated willingness to pay 8-12% price premiums for vehicles offering 15-20% better fuel economy than segment averages, creating strong economic incentives for technological advancement in this area.

Future market projections suggest continued growth in demand for fuel-efficient V4 engines, even as electrification progresses. Industry analysts predict a substantial transitional period where optimized internal combustion engines will remain dominant in many market segments, particularly in regions with underdeveloped charging infrastructure or where price sensitivity limits electric vehicle adoption.

Current V4 Technology Limitations and Challenges

V4 engines, while offering a balance between power and compactness, face significant limitations in achieving optimal fuel efficiency. The primary challenge stems from inherent design constraints, particularly the firing order and balance characteristics. Unlike inline-four engines, V4 configurations experience more complex vibration patterns that necessitate additional balancing mechanisms, adding weight and reducing overall efficiency.

Thermal management represents another critical challenge. The compact V-configuration creates concentrated heat zones that can lead to uneven temperature distribution across cylinders. This thermal imbalance often results in inconsistent combustion processes, with some cylinders operating at sub-optimal temperatures, directly impacting fuel consumption and emissions performance.

Valve train inefficiencies constitute a substantial limitation in current V4 designs. Many existing systems employ traditional camshaft arrangements that cannot adequately adjust to varying engine loads and speeds. This inability to optimize valve timing across different operating conditions leads to significant efficiency losses, particularly during partial load operations which represent the majority of real-world driving scenarios.

Friction losses within V4 engines remain disproportionately high compared to other configurations. The compact design necessitates tighter packaging of components, often resulting in more complex oil circulation pathways and increased parasitic losses. Studies indicate that up to 15% of fuel energy is lost to friction in current V4 designs, representing a substantial opportunity for efficiency improvements.

Intake and exhaust flow dynamics present particular challenges in V4 configurations. The compact design often requires compromised intake runner lengths and exhaust manifold geometries, leading to sub-optimal volumetric efficiency across the RPM range. This limitation directly impacts the engine's breathing capability and consequently its fuel efficiency potential.

Modern emission control requirements have further complicated V4 optimization efforts. The integration of increasingly complex after-treatment systems creates packaging challenges and often necessitates compromises in combustion chamber design. These constraints frequently result in combustion strategies that prioritize emissions compliance over maximum efficiency.

Manufacturing precision also remains a significant challenge. The complex geometry of V4 engines requires extremely tight tolerances, particularly in the valve train and cylinder head interfaces. Production variations, even within acceptable manufacturing tolerances, can lead to performance inconsistencies between individual engines, making systematic optimization more difficult.

The integration of advanced technologies such as direct injection and variable valve timing has been slower in V4 platforms compared to other configurations, primarily due to the engineering complexity and cost considerations. This technology gap represents a significant limitation in achieving competitive fuel efficiency metrics in current V4 engine offerings.

Thermal management represents another critical challenge. The compact V-configuration creates concentrated heat zones that can lead to uneven temperature distribution across cylinders. This thermal imbalance often results in inconsistent combustion processes, with some cylinders operating at sub-optimal temperatures, directly impacting fuel consumption and emissions performance.

Valve train inefficiencies constitute a substantial limitation in current V4 designs. Many existing systems employ traditional camshaft arrangements that cannot adequately adjust to varying engine loads and speeds. This inability to optimize valve timing across different operating conditions leads to significant efficiency losses, particularly during partial load operations which represent the majority of real-world driving scenarios.

Friction losses within V4 engines remain disproportionately high compared to other configurations. The compact design necessitates tighter packaging of components, often resulting in more complex oil circulation pathways and increased parasitic losses. Studies indicate that up to 15% of fuel energy is lost to friction in current V4 designs, representing a substantial opportunity for efficiency improvements.

Intake and exhaust flow dynamics present particular challenges in V4 configurations. The compact design often requires compromised intake runner lengths and exhaust manifold geometries, leading to sub-optimal volumetric efficiency across the RPM range. This limitation directly impacts the engine's breathing capability and consequently its fuel efficiency potential.

Modern emission control requirements have further complicated V4 optimization efforts. The integration of increasingly complex after-treatment systems creates packaging challenges and often necessitates compromises in combustion chamber design. These constraints frequently result in combustion strategies that prioritize emissions compliance over maximum efficiency.

Manufacturing precision also remains a significant challenge. The complex geometry of V4 engines requires extremely tight tolerances, particularly in the valve train and cylinder head interfaces. Production variations, even within acceptable manufacturing tolerances, can lead to performance inconsistencies between individual engines, making systematic optimization more difficult.

The integration of advanced technologies such as direct injection and variable valve timing has been slower in V4 platforms compared to other configurations, primarily due to the engineering complexity and cost considerations. This technology gap represents a significant limitation in achieving competitive fuel efficiency metrics in current V4 engine offerings.

Current Fuel Efficiency Solutions for V4 Engines

01 Cylinder deactivation systems for V4 engines

Cylinder deactivation technology allows V4 engines to operate on fewer cylinders during light load conditions, significantly improving fuel efficiency. By selectively deactivating cylinders when full power is not required, the active cylinders operate at higher efficiency points. This technology reduces pumping losses and improves thermal efficiency, resulting in reduced fuel consumption during highway cruising and light-load city driving conditions.- Cylinder deactivation systems for V4 engines: Cylinder deactivation technology allows V4 engines to operate on fewer cylinders during light load conditions, significantly improving fuel efficiency. By selectively shutting down cylinders when full power isn't needed, these systems reduce pumping losses and improve thermal efficiency. The technology includes sophisticated valve control mechanisms and engine management systems that seamlessly transition between full and partial cylinder operation based on driving conditions and power demands.

- Advanced fuel injection and combustion optimization: Innovative fuel injection systems specifically designed for V4 engines enhance combustion efficiency through precise fuel delivery and atomization. These systems incorporate direct injection technology, variable injection timing, and optimized spray patterns to ensure complete fuel combustion. Advanced combustion chamber designs with improved air-fuel mixing capabilities further enhance the thermal efficiency of V4 engines, resulting in better fuel economy and reduced emissions.

- Variable valve timing and lift systems: Variable valve timing and lift systems allow V4 engines to optimize air intake and exhaust flow across different operating conditions. By dynamically adjusting valve timing, duration, and lift height based on engine speed and load, these systems improve volumetric efficiency and reduce pumping losses. This technology enables better torque characteristics at low RPM while maintaining power at higher RPM, contributing to overall improved fuel efficiency in V4 engine configurations.

- Thermal management and friction reduction: Advanced thermal management systems for V4 engines control operating temperatures more precisely, allowing engines to reach optimal operating temperature faster and maintain it more consistently. These systems include variable coolant flow, strategic cooling passages, and thermal barrier coatings. Additionally, friction reduction technologies such as specialized coatings, improved bearing designs, and optimized piston ring configurations minimize mechanical losses, contributing to better fuel efficiency in V4 engine applications.

- Electronic control systems and engine mapping: Sophisticated electronic control units (ECUs) with advanced algorithms optimize V4 engine operation in real-time. These systems continuously adjust multiple parameters including ignition timing, air-fuel ratio, and throttle response based on driving conditions and environmental factors. Machine learning and adaptive control strategies enable the engine to operate in its most efficient zone more consistently. Integration with vehicle systems like transmission control further enhances overall powertrain efficiency.

02 Advanced fuel injection and combustion control

Innovative fuel injection systems and combustion control strategies enhance the fuel efficiency of V4 engines. These include direct injection technologies, variable injection timing, and precise fuel delivery systems that optimize the air-fuel mixture. Advanced electronic control units continuously adjust injection parameters based on operating conditions, ensuring optimal combustion efficiency across various engine loads and speeds, thereby reducing fuel consumption.Expand Specific Solutions03 Variable valve timing and lift mechanisms

Variable valve timing and lift mechanisms allow V4 engines to optimize airflow at different engine speeds and loads. By adjusting valve opening duration, timing, and lift height, these systems can reduce pumping losses and improve volumetric efficiency. This technology enables engines to operate more efficiently across a broader range of conditions, resulting in improved fuel economy while maintaining performance capabilities.Expand Specific Solutions04 Thermal management and friction reduction

Enhanced thermal management systems and friction reduction technologies significantly improve V4 engine fuel efficiency. These include advanced cooling systems, low-friction coatings on engine components, optimized piston designs, and improved lubricants. By reducing mechanical losses and maintaining optimal operating temperatures, these technologies decrease the energy wasted as heat and friction, allowing more of the fuel's energy to be converted into useful work.Expand Specific Solutions05 Integrated hybrid and electrification systems

Integration of hybrid and electrification technologies with V4 engines creates significant fuel efficiency improvements. These systems include start-stop functionality, regenerative braking, electric motor assist during acceleration, and battery-powered operation during low-load conditions. By allowing the engine to operate at its most efficient points and recovering energy that would otherwise be lost, these integrated systems can substantially reduce overall fuel consumption while maintaining or enhancing performance.Expand Specific Solutions

Leading Manufacturers in V4 Engine Optimization

The V4 engine fuel efficiency optimization market is currently in a growth phase, with increasing demand driven by stringent emissions regulations and consumer preference for fuel-efficient vehicles. The market size is expanding significantly as automotive manufacturers prioritize fuel economy across their product lines. Leading players include established OEMs like Ford, GM, Hyundai, and Volkswagen, who are investing heavily in advanced combustion technologies. Oil companies such as ExxonMobil and Shell are developing specialized lubricants to reduce friction losses. Component suppliers like Bosch and Visteon are focusing on precision fuel injection systems and electronic control units. The technology landscape shows varying maturity levels, with traditional optimization techniques being well-established, while newer approaches involving AI-driven combustion control, variable compression, and cylinder deactivation represent emerging frontiers where companies are actively competing for technological leadership.

Ford Global Technologies LLC

Technical Solution: Ford has developed EcoBoost technology for V4 engines that combines direct fuel injection, turbocharging, and variable valve timing to optimize performance while improving fuel efficiency. Their system precisely controls fuel delivery directly into the combustion chamber, allowing for more complete combustion. The turbocharging technology enables smaller displacement engines to deliver power equivalent to larger engines while consuming less fuel. Ford's cylinder deactivation system selectively shuts down cylinders during light load conditions, reducing fuel consumption by up to 20% during highway cruising[1]. Additionally, Ford has implemented advanced thermal management systems that reduce warm-up time and friction losses, contributing to a 3-5% improvement in fuel economy[3]. Their integrated exhaust gas recirculation (EGR) system further reduces pumping losses and NOx emissions while improving fuel efficiency.

Strengths: Comprehensive integration of multiple technologies (direct injection, turbocharging, variable valve timing) creates synergistic efficiency gains. The cylinder deactivation system provides significant real-world fuel savings without compromising performance when needed. Weaknesses: The complex systems require more sophisticated electronic controls and can increase manufacturing costs. Turbocharging technology may lead to increased thermal stress on engine components, potentially affecting long-term durability.

GM Global Technology Operations LLC

Technical Solution: GM has developed Dynamic Fuel Management (DFM) technology for V4 engines that uses sophisticated algorithms to continuously evaluate driving conditions and determine the optimal number of active cylinders needed. This system can switch between 17 different cylinder patterns to maximize efficiency. GM's Active Fuel Management (AFM) technology can deactivate cylinders during light load conditions, reducing fuel consumption by up to 15%[2]. Their V4 engines incorporate variable valve timing with dual independent cam phasing that optimizes valve operation across the entire RPM range. GM has also implemented direct injection technology with precision fuel delivery control that improves combustion efficiency by up to 3%[4]. Additionally, their engines feature low-friction components, including specialized piston coatings and roller-finger followers for the valvetrain, reducing parasitic losses. GM's integrated thermal management system uses electronic thermostats and split cooling to reduce warm-up time and maintain optimal operating temperatures.

Strengths: Dynamic Fuel Management offers more flexible cylinder deactivation patterns than competitors, providing smoother operation and better fuel economy across various driving conditions. The comprehensive approach to friction reduction addresses multiple sources of efficiency loss. Weaknesses: The complex cylinder management systems require sophisticated electronic controls and sensors that can increase maintenance costs. The technology may have diminished benefits in extreme cold weather conditions when engines require more consistent operation.

Key Patents in V4 Engine Efficiency Technology

Method for improving engine fuel efficiency

PatentInactiveUS20130165354A1

Innovation

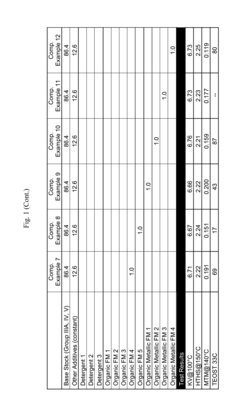

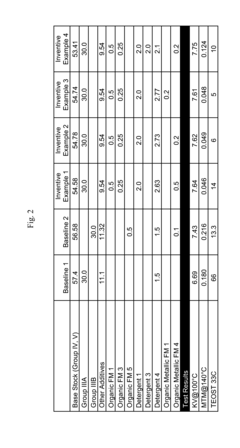

- A formulated lubricating oil composition comprising a lubricating oil base stock, a propylene-based polymer viscosity index improver with specific molecular weight and molecular weight distribution, and optional dispersants and pour point depressants, which improves fuel efficiency by reducing temperature dependency of viscosity.

Method for improving engine fuel efficiency

PatentInactiveUS9506008B2

Innovation

- A lubricating oil formulation combining a friction modifier mixture comprising alkoxylated fatty acid ester, alkanolamide, polyol fatty acid ester, borated glycerol fatty acid ester, and fatty alcohol ether, along with a petroleum-derived calcium sulfonate detergent, to enhance fuel efficiency and reduce friction while maintaining or improving deposit control.

Emissions Regulations Impact on V4 Development

Emissions regulations have become a primary driver in the evolution of V4 engine technology, creating both challenges and opportunities for performance optimization. Since the early 2000s, increasingly stringent standards from regulatory bodies like the EPA, CARB, and European Commission have fundamentally altered engine design priorities. The introduction of Euro 6 and Tier 3 standards has specifically targeted nitrogen oxides (NOx) and particulate matter emissions, forcing manufacturers to implement sophisticated exhaust after-treatment systems that often compromise fuel efficiency.

These regulations have accelerated the development of advanced combustion strategies for V4 engines. Direct injection systems, variable valve timing, and exhaust gas recirculation (EGR) technologies have been refined specifically to meet emissions targets while maintaining performance. The regulatory landscape has effectively created a technological arms race, with manufacturers investing heavily in compliance solutions that simultaneously address efficiency concerns.

The regional variation in emissions standards presents a particular challenge for global V4 engine platforms. European regulations emphasize CO2 reduction, while North American standards focus more on NOx and hydrocarbon emissions. This divergence has led to market-specific engine calibrations and technology packages, increasing development costs and complexity. Manufacturers must now design flexible engine architectures capable of adaptation to various regulatory environments without complete redesigns.

Recent regulatory trends indicate a continued tightening of emissions limits, with particular emphasis on real-world driving emissions (RDE) testing protocols. These protocols have exposed the gap between laboratory certification results and actual on-road performance, necessitating more robust emissions control strategies that function effectively across all driving conditions. This shift has prompted increased integration of sensors and adaptive control systems in V4 engines to continuously optimize combustion parameters.

The financial implications of emissions compliance have become a significant factor in V4 engine development economics. The cost of after-treatment systems, advanced materials, and control technologies can represent up to 30% of total engine production costs. This economic pressure has accelerated research into alternative approaches to emissions reduction that simultaneously enhance fuel efficiency, such as low-temperature combustion modes and advanced thermal management systems.

Looking forward, upcoming regulations like Euro 7 and post-2025 CAFE standards will likely push V4 engines toward hybridization as a compliance strategy. The integration of electric components with V4 engines offers a pathway to meet increasingly stringent emissions targets while potentially improving overall system efficiency. This regulatory-driven evolution may ultimately determine whether V4 engines remain viable in the long term or serve as transitional technology in the broader shift toward electrification.

These regulations have accelerated the development of advanced combustion strategies for V4 engines. Direct injection systems, variable valve timing, and exhaust gas recirculation (EGR) technologies have been refined specifically to meet emissions targets while maintaining performance. The regulatory landscape has effectively created a technological arms race, with manufacturers investing heavily in compliance solutions that simultaneously address efficiency concerns.

The regional variation in emissions standards presents a particular challenge for global V4 engine platforms. European regulations emphasize CO2 reduction, while North American standards focus more on NOx and hydrocarbon emissions. This divergence has led to market-specific engine calibrations and technology packages, increasing development costs and complexity. Manufacturers must now design flexible engine architectures capable of adaptation to various regulatory environments without complete redesigns.

Recent regulatory trends indicate a continued tightening of emissions limits, with particular emphasis on real-world driving emissions (RDE) testing protocols. These protocols have exposed the gap between laboratory certification results and actual on-road performance, necessitating more robust emissions control strategies that function effectively across all driving conditions. This shift has prompted increased integration of sensors and adaptive control systems in V4 engines to continuously optimize combustion parameters.

The financial implications of emissions compliance have become a significant factor in V4 engine development economics. The cost of after-treatment systems, advanced materials, and control technologies can represent up to 30% of total engine production costs. This economic pressure has accelerated research into alternative approaches to emissions reduction that simultaneously enhance fuel efficiency, such as low-temperature combustion modes and advanced thermal management systems.

Looking forward, upcoming regulations like Euro 7 and post-2025 CAFE standards will likely push V4 engines toward hybridization as a compliance strategy. The integration of electric components with V4 engines offers a pathway to meet increasingly stringent emissions targets while potentially improving overall system efficiency. This regulatory-driven evolution may ultimately determine whether V4 engines remain viable in the long term or serve as transitional technology in the broader shift toward electrification.

Materials Science Advancements for V4 Engines

Recent advancements in materials science have significantly contributed to enhancing V4 engine performance and fuel efficiency. Lightweight alloys, particularly aluminum-silicon and magnesium alloys, have revolutionized engine block and component design, reducing overall engine weight by up to 30% compared to traditional cast iron constructions. This weight reduction directly translates to improved power-to-weight ratios and decreased fuel consumption under various driving conditions.

Thermal management materials represent another critical advancement area. Newly developed ceramic coatings with enhanced thermal barrier properties allow engines to operate at higher temperatures while maintaining structural integrity. These coatings, typically applied to combustion chambers and exhaust components, reduce heat loss by 15-20%, improving thermal efficiency and consequently fuel economy.

Friction reduction technologies have evolved substantially through the development of diamond-like carbon (DLC) coatings and nano-composite materials. When applied to critical engine components such as piston rings, valve train components, and bearings, these materials can reduce friction coefficients by up to 40% compared to conventional materials. Lower friction directly correlates with decreased mechanical losses and improved fuel efficiency, particularly during cold starts and variable load conditions.

Advanced polymer composites are increasingly replacing traditional materials in peripheral engine components. These composites offer superior vibration damping, thermal insulation, and weight reduction benefits. Intake manifolds, valve covers, and oil pans manufactured from these materials contribute to overall engine efficiency while providing additional benefits such as noise reduction and improved durability in extreme operating conditions.

Smart materials with adaptive properties represent the cutting edge of materials science applications in V4 engines. Shape memory alloys and piezoelectric materials enable the development of adaptive components that can optimize their geometry or characteristics based on operating conditions. Variable geometry turbochargers utilizing these materials can adjust their performance parameters in real-time, optimizing air delivery across the entire engine operating range.

Catalytic materials have also undergone significant development, with nano-structured catalysts improving exhaust gas treatment efficiency. These advanced materials enable more complete combustion and reduced emissions while minimizing back pressure, contributing to overall engine efficiency without compromising environmental performance.

Surface engineering techniques, including laser texturing and micro-patterning, have enabled the creation of optimized surface topographies on engine components. These engineered surfaces can control oil film thickness, reduce boundary friction, and enhance heat transfer characteristics, all contributing to improved fuel efficiency across various engine operating regimes.

Thermal management materials represent another critical advancement area. Newly developed ceramic coatings with enhanced thermal barrier properties allow engines to operate at higher temperatures while maintaining structural integrity. These coatings, typically applied to combustion chambers and exhaust components, reduce heat loss by 15-20%, improving thermal efficiency and consequently fuel economy.

Friction reduction technologies have evolved substantially through the development of diamond-like carbon (DLC) coatings and nano-composite materials. When applied to critical engine components such as piston rings, valve train components, and bearings, these materials can reduce friction coefficients by up to 40% compared to conventional materials. Lower friction directly correlates with decreased mechanical losses and improved fuel efficiency, particularly during cold starts and variable load conditions.

Advanced polymer composites are increasingly replacing traditional materials in peripheral engine components. These composites offer superior vibration damping, thermal insulation, and weight reduction benefits. Intake manifolds, valve covers, and oil pans manufactured from these materials contribute to overall engine efficiency while providing additional benefits such as noise reduction and improved durability in extreme operating conditions.

Smart materials with adaptive properties represent the cutting edge of materials science applications in V4 engines. Shape memory alloys and piezoelectric materials enable the development of adaptive components that can optimize their geometry or characteristics based on operating conditions. Variable geometry turbochargers utilizing these materials can adjust their performance parameters in real-time, optimizing air delivery across the entire engine operating range.

Catalytic materials have also undergone significant development, with nano-structured catalysts improving exhaust gas treatment efficiency. These advanced materials enable more complete combustion and reduced emissions while minimizing back pressure, contributing to overall engine efficiency without compromising environmental performance.

Surface engineering techniques, including laser texturing and micro-patterning, have enabled the creation of optimized surface topographies on engine components. These engineered surfaces can control oil film thickness, reduce boundary friction, and enhance heat transfer characteristics, all contributing to improved fuel efficiency across various engine operating regimes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!