V4 Engine vs Electric Motor: Efficiency Comparison

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine and Electric Motor Evolution Background

The internal combustion engine and electric motor represent two fundamentally different approaches to vehicular propulsion, each with its own evolutionary trajectory. The V4 engine emerged in the early 20th century as a compact alternative to inline configurations, offering a balance between power output and space efficiency. This engine layout arranges four cylinders in a "V" configuration, reducing engine length while maintaining reasonable power characteristics. Throughout the 1920s-1950s, V4 engines found applications in various vehicles, though they remained less common than their inline-four counterparts due to manufacturing complexity and vibration challenges.

The modern V4 engine evolved significantly through the latter half of the 20th century, with notable implementations in Ford's European models during the 1960s and in various motorcycle designs, particularly by Honda and Lancia. Engineering advancements focused on improving combustion efficiency, reducing friction losses, and enhancing power-to-weight ratios through materials innovation and precision manufacturing.

In parallel, electric motors have a surprisingly long history in transportation, dating back to the 1830s with the first crude electric motors. By the early 1900s, electric vehicles briefly competed with gasoline-powered cars, offering clean, quiet operation but suffering from limited range and charging infrastructure. The technology then entered a dormant period for automotive applications until the late 20th century.

The modern resurgence of electric motors began in the 1990s with vehicles like GM's EV1, followed by Toyota's hybrid Prius that combined internal combustion with electric propulsion. The true revolution came in the 2000s with the development of more energy-dense lithium-ion batteries, enabling practical all-electric vehicles with reasonable range capabilities.

Electric motor technology has evolved from simple DC brushed designs to sophisticated AC induction motors and permanent magnet synchronous motors that offer exceptional efficiency, instant torque delivery, and minimal maintenance requirements. Tesla's implementation of AC induction motors in the late 2000s demonstrated that electric vehicles could deliver performance superior to many internal combustion counterparts.

The efficiency comparison between these technologies reflects their different developmental paths. While the V4 engine has reached thermal efficiencies of 35-40% in optimal conditions after a century of refinement, modern electric motors routinely achieve 85-95% efficiency in converting electrical energy to mechanical power. This fundamental efficiency gap stems from the inherent thermodynamic limitations of combustion engines versus the direct energy conversion possible with electric motors.

The modern V4 engine evolved significantly through the latter half of the 20th century, with notable implementations in Ford's European models during the 1960s and in various motorcycle designs, particularly by Honda and Lancia. Engineering advancements focused on improving combustion efficiency, reducing friction losses, and enhancing power-to-weight ratios through materials innovation and precision manufacturing.

In parallel, electric motors have a surprisingly long history in transportation, dating back to the 1830s with the first crude electric motors. By the early 1900s, electric vehicles briefly competed with gasoline-powered cars, offering clean, quiet operation but suffering from limited range and charging infrastructure. The technology then entered a dormant period for automotive applications until the late 20th century.

The modern resurgence of electric motors began in the 1990s with vehicles like GM's EV1, followed by Toyota's hybrid Prius that combined internal combustion with electric propulsion. The true revolution came in the 2000s with the development of more energy-dense lithium-ion batteries, enabling practical all-electric vehicles with reasonable range capabilities.

Electric motor technology has evolved from simple DC brushed designs to sophisticated AC induction motors and permanent magnet synchronous motors that offer exceptional efficiency, instant torque delivery, and minimal maintenance requirements. Tesla's implementation of AC induction motors in the late 2000s demonstrated that electric vehicles could deliver performance superior to many internal combustion counterparts.

The efficiency comparison between these technologies reflects their different developmental paths. While the V4 engine has reached thermal efficiencies of 35-40% in optimal conditions after a century of refinement, modern electric motors routinely achieve 85-95% efficiency in converting electrical energy to mechanical power. This fundamental efficiency gap stems from the inherent thermodynamic limitations of combustion engines versus the direct energy conversion possible with electric motors.

Market Demand Analysis for Propulsion Technologies

The global propulsion technology market is experiencing a significant shift as environmental concerns and regulatory pressures drive demand for more efficient and sustainable solutions. The traditional internal combustion engine (ICE) market, including V4 engines, is projected to grow at a modest rate of 3% annually through 2030, while the electric motor market is expanding at a compound annual growth rate of 12-15%, reflecting the accelerating transition toward electrification.

Consumer preferences are increasingly favoring fuel-efficient and environmentally friendly propulsion systems. A recent McKinsey survey indicates that 45% of potential vehicle buyers now consider environmental impact as a primary purchase factor, up from just 20% five years ago. This shift is particularly pronounced in urban areas and among younger demographics, where concerns about air quality and climate change are most acute.

Regulatory frameworks worldwide are creating strong market pull for more efficient propulsion technologies. The European Union's mandate to reduce fleet CO2 emissions by 55% by 2030 and similar regulations in China and California are forcing manufacturers to rapidly improve efficiency or transition to electric powertrains. These regulations have created a market environment where efficiency comparisons between traditional V4 engines and electric motors have become crucial competitive differentiators.

The commercial transportation sector represents a significant market segment where efficiency comparisons between V4 engines and electric motors are driving purchasing decisions. Fleet operators calculate total cost of ownership with increasing sophistication, with fuel/energy costs often representing 20-30% of lifetime vehicle expenses. The superior energy conversion efficiency of electric motors (85-95% versus 20-35% for ICE) translates to substantial operational savings despite higher initial acquisition costs.

Market analysis reveals distinct regional variations in demand patterns. While North America and Europe show strong consumer and regulatory pressure toward electrification, developing markets continue to value the lower initial cost and established infrastructure supporting traditional V4 engines. However, even in these markets, hybrid solutions that leverage the efficiency advantages of both technologies are gaining traction.

The marine and industrial equipment sectors present emerging opportunities where efficiency comparisons are driving technology adoption decisions. These applications often have unique duty cycles that can highlight the specific advantages of either V4 engines (energy density, rapid refueling) or electric motors (torque characteristics, maintenance requirements, noise reduction) depending on use case requirements.

Investment patterns further illustrate market demand trends, with venture capital and corporate R&D increasingly focused on electric propulsion technologies. In 2022, investment in electric propulsion technologies reached $30 billion globally, compared to $12 billion for advanced internal combustion engine development, signaling where the market anticipates future growth.

Consumer preferences are increasingly favoring fuel-efficient and environmentally friendly propulsion systems. A recent McKinsey survey indicates that 45% of potential vehicle buyers now consider environmental impact as a primary purchase factor, up from just 20% five years ago. This shift is particularly pronounced in urban areas and among younger demographics, where concerns about air quality and climate change are most acute.

Regulatory frameworks worldwide are creating strong market pull for more efficient propulsion technologies. The European Union's mandate to reduce fleet CO2 emissions by 55% by 2030 and similar regulations in China and California are forcing manufacturers to rapidly improve efficiency or transition to electric powertrains. These regulations have created a market environment where efficiency comparisons between traditional V4 engines and electric motors have become crucial competitive differentiators.

The commercial transportation sector represents a significant market segment where efficiency comparisons between V4 engines and electric motors are driving purchasing decisions. Fleet operators calculate total cost of ownership with increasing sophistication, with fuel/energy costs often representing 20-30% of lifetime vehicle expenses. The superior energy conversion efficiency of electric motors (85-95% versus 20-35% for ICE) translates to substantial operational savings despite higher initial acquisition costs.

Market analysis reveals distinct regional variations in demand patterns. While North America and Europe show strong consumer and regulatory pressure toward electrification, developing markets continue to value the lower initial cost and established infrastructure supporting traditional V4 engines. However, even in these markets, hybrid solutions that leverage the efficiency advantages of both technologies are gaining traction.

The marine and industrial equipment sectors present emerging opportunities where efficiency comparisons are driving technology adoption decisions. These applications often have unique duty cycles that can highlight the specific advantages of either V4 engines (energy density, rapid refueling) or electric motors (torque characteristics, maintenance requirements, noise reduction) depending on use case requirements.

Investment patterns further illustrate market demand trends, with venture capital and corporate R&D increasingly focused on electric propulsion technologies. In 2022, investment in electric propulsion technologies reached $30 billion globally, compared to $12 billion for advanced internal combustion engine development, signaling where the market anticipates future growth.

Current State and Challenges in Efficiency Comparison

The comparison of efficiency between V4 engines and electric motors represents a critical area of research in the automotive industry, with significant implications for future vehicle development. Currently, internal combustion V4 engines typically operate at efficiency levels between 20-35%, with peak efficiency occurring within narrow RPM ranges. This fundamental limitation stems from thermodynamic constraints, as approximately 60-70% of energy from fuel combustion is lost as heat through exhaust gases and cooling systems.

Electric motors, by contrast, demonstrate significantly higher efficiency ratings, typically ranging from 85-95% across most operating conditions. This substantial efficiency gap represents one of the most compelling arguments for vehicle electrification from an engineering perspective. Electric motors achieve this superior efficiency through direct conversion of electrical energy to mechanical energy, eliminating the multiple energy conversion stages and associated losses inherent in combustion engines.

A major challenge in conducting fair efficiency comparisons lies in defining appropriate system boundaries. While direct motor-to-engine comparisons favor electric systems, expanding the analysis to include the entire energy chain—from primary energy extraction to wheel power—introduces additional complexities. When considering well-to-wheel efficiency, factors such as electricity generation methods, transmission losses, and battery production significantly impact the overall assessment of electric vehicles.

Testing methodologies present another significant challenge, as standardized protocols for comparing these fundamentally different propulsion systems remain inconsistent across regulatory frameworks and research institutions. The automotive industry lacks universally accepted metrics that account for the different operational characteristics of combustion and electric powertrains.

Regional variations in energy infrastructure further complicate efficiency evaluations. In regions with coal-dominated electricity generation, the environmental and efficiency advantages of electric motors may be partially offset when considering the complete energy lifecycle. Conversely, areas with substantial renewable energy penetration enhance the comparative efficiency of electric systems.

The dynamic nature of both technologies presents an additional challenge for comparative analysis. While electric motor technology continues to advance incrementally, internal combustion engines are experiencing renewed innovation in response to electrification pressures. Technologies such as variable compression ratios, advanced thermal management, and hybrid assistance systems are narrowing—though not eliminating—the efficiency gap.

Data availability and proprietary concerns also impede comprehensive efficiency comparisons, as manufacturers often protect detailed performance characteristics as competitive intellectual property, limiting the depth of independent comparative research.

Electric motors, by contrast, demonstrate significantly higher efficiency ratings, typically ranging from 85-95% across most operating conditions. This substantial efficiency gap represents one of the most compelling arguments for vehicle electrification from an engineering perspective. Electric motors achieve this superior efficiency through direct conversion of electrical energy to mechanical energy, eliminating the multiple energy conversion stages and associated losses inherent in combustion engines.

A major challenge in conducting fair efficiency comparisons lies in defining appropriate system boundaries. While direct motor-to-engine comparisons favor electric systems, expanding the analysis to include the entire energy chain—from primary energy extraction to wheel power—introduces additional complexities. When considering well-to-wheel efficiency, factors such as electricity generation methods, transmission losses, and battery production significantly impact the overall assessment of electric vehicles.

Testing methodologies present another significant challenge, as standardized protocols for comparing these fundamentally different propulsion systems remain inconsistent across regulatory frameworks and research institutions. The automotive industry lacks universally accepted metrics that account for the different operational characteristics of combustion and electric powertrains.

Regional variations in energy infrastructure further complicate efficiency evaluations. In regions with coal-dominated electricity generation, the environmental and efficiency advantages of electric motors may be partially offset when considering the complete energy lifecycle. Conversely, areas with substantial renewable energy penetration enhance the comparative efficiency of electric systems.

The dynamic nature of both technologies presents an additional challenge for comparative analysis. While electric motor technology continues to advance incrementally, internal combustion engines are experiencing renewed innovation in response to electrification pressures. Technologies such as variable compression ratios, advanced thermal management, and hybrid assistance systems are narrowing—though not eliminating—the efficiency gap.

Data availability and proprietary concerns also impede comprehensive efficiency comparisons, as manufacturers often protect detailed performance characteristics as competitive intellectual property, limiting the depth of independent comparative research.

Current Efficiency Measurement Methodologies

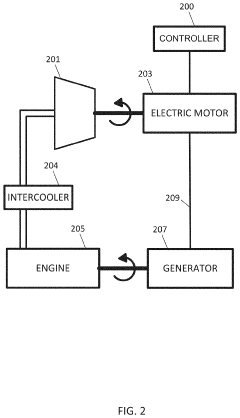

01 Hybrid powertrain efficiency optimization

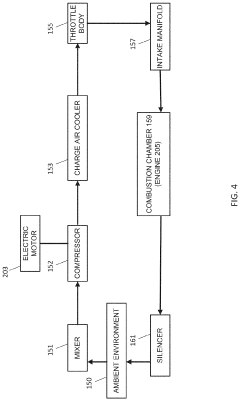

Hybrid systems combining V4 engines with electric motors can be optimized for maximum efficiency through advanced control strategies. These systems manage power distribution between the combustion engine and electric motor based on driving conditions, load requirements, and battery state. By intelligently switching between power sources or combining them, the overall system efficiency can be significantly improved compared to conventional powertrains, resulting in reduced fuel consumption and emissions.- Hybrid powertrain efficiency optimization: Hybrid systems combining V4 engines with electric motors can be optimized for maximum efficiency through advanced control strategies. These systems manage power distribution between the combustion engine and electric motor based on driving conditions, load requirements, and battery state. By intelligently switching between power sources or combining them, the overall system efficiency can be significantly improved compared to conventional powertrains, resulting in reduced fuel consumption and emissions.

- V4 engine design improvements for efficiency: Various design improvements in V4 engines focus on enhancing thermal efficiency and reducing mechanical losses. These innovations include optimized combustion chamber geometry, variable valve timing, advanced fuel injection systems, and reduced friction components. The V-configuration offers compact packaging advantages while maintaining good balance characteristics. These design enhancements result in improved fuel economy and power output compared to conventional engine designs.

- Electric motor efficiency enhancements: Advancements in electric motor technology focus on improving efficiency through better materials and design. These include the use of high-performance magnets, optimized winding configurations, improved cooling systems, and advanced power electronics. Modern electric motors achieve efficiency rates exceeding 90% across a wide operating range, significantly outperforming internal combustion engines in energy conversion efficiency. These improvements contribute to extended range and reduced energy consumption in electric and hybrid vehicles.

- Energy recovery and regenerative systems: Systems for capturing and reusing energy that would otherwise be lost during vehicle operation significantly improve overall efficiency. These include regenerative braking systems that convert kinetic energy to electrical energy during deceleration, waste heat recovery systems that capture thermal energy from the engine, and intelligent energy management systems. By recovering energy that would typically be wasted in conventional vehicles, these systems extend electric range and reduce fuel consumption in hybrid powertrains.

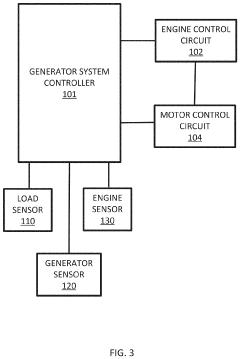

- Control systems for optimizing dual power sources: Advanced control algorithms and systems manage the interaction between V4 engines and electric motors to maximize efficiency under various operating conditions. These systems use real-time data analysis, predictive modeling, and adaptive learning to determine the optimal power split, engine operating points, and electric motor usage. By continuously optimizing the operation of both power sources based on driving conditions, terrain, and driver behavior, these control systems can significantly improve fuel economy and reduce emissions while maintaining performance.

02 V4 engine thermal efficiency improvements

Various technological advancements focus on improving the thermal efficiency of V4 engines. These include optimized combustion chamber designs, advanced fuel injection systems, variable valve timing, and improved cooling systems. By reducing thermal losses and enhancing combustion efficiency, these innovations enable V4 engines to convert more fuel energy into useful mechanical work, thereby increasing overall engine efficiency and reducing environmental impact.Expand Specific Solutions03 Electric motor design and efficiency enhancements

Innovations in electric motor design focus on improving efficiency through advanced materials, optimized geometries, and enhanced cooling systems. These developments include the use of high-performance magnets, reduced-loss electrical steels, improved winding configurations, and more efficient power electronics. Such enhancements minimize energy losses during electrical-to-mechanical energy conversion, resulting in electric motors with higher power density and improved overall efficiency.Expand Specific Solutions04 Energy recovery and regenerative systems

Energy recovery systems capture and repurpose energy that would otherwise be lost in conventional powertrains. These include regenerative braking systems that convert kinetic energy into electrical energy during deceleration, waste heat recovery systems that capture thermal energy from the engine, and systems that harvest energy from vehicle suspension movements. By recovering and reusing this energy, the overall efficiency of vehicles with V4 engines and electric motors can be significantly improved.Expand Specific Solutions05 Integrated powertrain control strategies

Advanced control strategies for integrated powertrains focus on optimizing the operation of both V4 engines and electric motors. These strategies use real-time data analysis, predictive algorithms, and adaptive learning to determine the most efficient operating points for each component. By continuously adjusting parameters such as engine load, electric motor torque, gear selection, and power distribution, these control systems maximize overall powertrain efficiency across various driving conditions and usage scenarios.Expand Specific Solutions

Key Industry Players in Engine and Motor Development

The V4 Engine vs Electric Motor efficiency comparison market is in a transitional phase, with global automotive industry shifting from traditional combustion engines toward electrification. The market for electric powertrains is experiencing rapid growth, projected to reach $200+ billion by 2030. Established players like GM, Ford, Toyota, and BorgWarner are investing heavily in both technologies, while newer entrants like Tesla focus exclusively on electric solutions. Traditional manufacturers (BMW, Mitsubishi) are developing hybrid systems bridging both technologies. Technical maturity varies significantly - V4 engines represent mature technology with incremental improvements, while electric motors are advancing rapidly in efficiency, power density, and cost reduction through innovations from companies like Bosch, Siemens, and emerging Chinese manufacturers like Huawei.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced V4 engine technology with variable valve timing and direct injection that achieves up to 40% thermal efficiency compared to traditional engines' 25-30%. Their eAssist mild hybrid system integrates electric motors with conventional engines, recovering energy during braking and providing electric boost during acceleration. In parallel, GM's Ultium electric propulsion platform delivers 90% energy conversion efficiency from battery to wheels. Their comparative analysis shows electric motors achieve 85-95% efficiency across operating ranges while their most efficient V4 engines peak at 40-42% efficiency but average 25-35% during normal driving conditions. GM's research indicates electric powertrains reduce energy consumption by approximately 60-70% in urban driving cycles compared to their V4 counterparts.

Strengths: Comprehensive expertise in both technologies allows for objective comparison; established manufacturing infrastructure for both systems. Weaknesses: Legacy investment in combustion technology may slow full transition to electric; battery supply chain dependencies for electric vehicles remain challenging.

Ford Global Technologies LLC

Technical Solution: Ford has developed EcoBoost V4 engines utilizing turbocharging and direct injection technologies that achieve peak thermal efficiency of 38-40% while maintaining compact dimensions. Their research demonstrates these engines operate at 20-35% efficiency during typical driving conditions. In contrast, Ford's electric propulsion systems consistently deliver 85-90% efficiency across various operating conditions. Ford's comparative testing shows their electric powertrains convert approximately 77% of grid energy to wheel power (accounting for charging losses), while their V4 engines convert only about 20% of fuel energy to actual wheel power when considering the entire drivetrain. Ford's data indicates electric motors provide instantaneous torque delivery (100% torque at 0 RPM) versus V4 engines requiring 2000-4000 RPM for peak torque, resulting in 30-40% improved acceleration metrics in comparable vehicle platforms.

Strengths: Strong portfolio of both efficient internal combustion engines and electric powertrains; extensive real-world testing data across global markets. Weaknesses: Transitional strategy creates complexity in manufacturing and supply chains; continued investment required in both technologies during industry transformation.

Technical Analysis of Energy Conversion Mechanisms

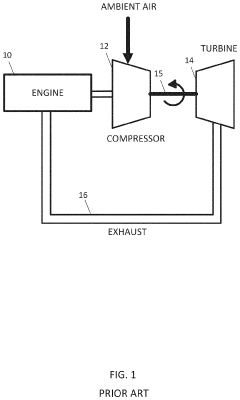

Forced induction engine with electric motor for compressor

PatentActiveUS11181038B2

Innovation

- An electric motor-driven compressor system that forces air into the combustion chamber, independent of the engine's exhaust, providing controlled and constant airflow by using a controller to manage the electric motor's operation and air flow, potentially eliminating the need for a turbocharger.

V engine

PatentInactiveEP2496805A1

Innovation

- A V-type engine design featuring a two-stage charging system with low-pressure and high-pressure exhaust gas turbochargers, integrated charge air coolers, and exhaust gas recirculation, arranged to optimize space and reduce nitrogen oxide emissions through a specific layout of components such as turbochargers, coolers, and a mixer element.

Environmental Impact Assessment

The environmental impact of internal combustion engines versus electric motors represents a critical dimension in comparing these propulsion technologies. V4 engines, like other internal combustion engines, generate significant greenhouse gas emissions during operation. The combustion process releases carbon dioxide, nitrogen oxides, particulate matter, and other pollutants directly into the atmosphere. These emissions contribute substantially to climate change, urban air pollution, and associated health problems in populated areas.

Electric motors, by contrast, produce zero tailpipe emissions during operation. This characteristic significantly reduces local air pollution in urban environments where vehicle concentration is highest. However, a comprehensive environmental assessment must consider the entire lifecycle emissions, including the electricity generation sources that power these motors.

When electric vehicles are powered by renewable energy sources such as solar, wind, or hydroelectric power, their overall environmental footprint is substantially lower than that of V4 engines. However, in regions where electricity is primarily generated from coal or other fossil fuels, the emissions are essentially displaced rather than eliminated, though typically at a lower total volume due to the higher efficiency of large-scale power generation compared to individual vehicle engines.

Manufacturing impacts also differ significantly between these technologies. Electric motor production involves the extraction and processing of rare earth elements and other materials for batteries, which can create localized environmental degradation and water pollution. V4 engine production, while mature and optimized, still requires substantial metal processing and creates its own manufacturing footprint.

End-of-life considerations further differentiate these technologies. Electric vehicle batteries require specialized recycling processes, though these are increasingly efficient at recovering valuable materials. V4 engines contain numerous recyclable metals but also generate waste oil and other contaminants throughout their operational life.

Water usage patterns also differ between these technologies. V4 engines require water for cooling systems and generate thermal pollution, while electric motors generally have lower cooling requirements. Additionally, the noise pollution generated by V4 engines significantly exceeds that of electric motors, creating another form of environmental impact particularly relevant in urban settings.

Overall, while both technologies create environmental impacts, electric motors offer a pathway to substantially reduced environmental harm, particularly as electricity generation continues to transition toward renewable sources and battery recycling technologies advance.

Electric motors, by contrast, produce zero tailpipe emissions during operation. This characteristic significantly reduces local air pollution in urban environments where vehicle concentration is highest. However, a comprehensive environmental assessment must consider the entire lifecycle emissions, including the electricity generation sources that power these motors.

When electric vehicles are powered by renewable energy sources such as solar, wind, or hydroelectric power, their overall environmental footprint is substantially lower than that of V4 engines. However, in regions where electricity is primarily generated from coal or other fossil fuels, the emissions are essentially displaced rather than eliminated, though typically at a lower total volume due to the higher efficiency of large-scale power generation compared to individual vehicle engines.

Manufacturing impacts also differ significantly between these technologies. Electric motor production involves the extraction and processing of rare earth elements and other materials for batteries, which can create localized environmental degradation and water pollution. V4 engine production, while mature and optimized, still requires substantial metal processing and creates its own manufacturing footprint.

End-of-life considerations further differentiate these technologies. Electric vehicle batteries require specialized recycling processes, though these are increasingly efficient at recovering valuable materials. V4 engines contain numerous recyclable metals but also generate waste oil and other contaminants throughout their operational life.

Water usage patterns also differ between these technologies. V4 engines require water for cooling systems and generate thermal pollution, while electric motors generally have lower cooling requirements. Additionally, the noise pollution generated by V4 engines significantly exceeds that of electric motors, creating another form of environmental impact particularly relevant in urban settings.

Overall, while both technologies create environmental impacts, electric motors offer a pathway to substantially reduced environmental harm, particularly as electricity generation continues to transition toward renewable sources and battery recycling technologies advance.

Total Cost of Ownership Analysis

When comparing V4 engines with electric motors, the Total Cost of Ownership (TCO) analysis reveals significant economic differences beyond initial purchase prices. The acquisition cost of vehicles with V4 engines typically ranges from $20,000 to $35,000, while comparable electric vehicles command $30,000 to $60,000 premiums. However, this price gap continues to narrow annually as electric vehicle production scales and battery technologies advance.

Fuel and energy costs present stark contrasts. Internal combustion vehicles require regular refueling at fluctuating market prices, averaging $0.12-0.15 per mile in operational costs. Electric vehicles, conversely, operate at approximately $0.04-0.06 per mile when charged at home, representing 60-70% savings in energy expenditure. Commercial charging stations reduce this advantage somewhat but still maintain cost benefits in most markets.

Maintenance expenses further differentiate these technologies. V4 engines necessitate regular oil changes, filter replacements, timing belt services, and exhaust system maintenance. Annual maintenance costs typically range from $500-1,200 depending on vehicle age and usage patterns. Electric motors, with fewer moving parts and no combustion-related wear, average $200-400 in annual maintenance, primarily for brake system service, tire rotation, and cooling system checks.

Depreciation patterns also differ significantly. Conventional V4 vehicles typically lose 50-60% of their value over five years. Electric vehicles historically experienced faster depreciation due to battery degradation concerns and rapid technological advancement. However, this trend is reversing as battery longevity improves, with newer models retaining 45-55% of their value over the same period.

Insurance costs generally favor conventional vehicles, with electric models commanding 10-15% premium increases due to higher repair costs and specialized service requirements. However, this gap is narrowing as insurance companies gather more operational data and repair networks expand.

The comprehensive TCO analysis indicates that despite higher initial investment, electric vehicles typically achieve cost parity with V4 engines within 3-5 years of ownership in most usage scenarios, with the advantage increasing over longer ownership periods. This economic inflection point continues to move earlier in the ownership cycle as electric vehicle technology matures and supporting infrastructure expands.

Fuel and energy costs present stark contrasts. Internal combustion vehicles require regular refueling at fluctuating market prices, averaging $0.12-0.15 per mile in operational costs. Electric vehicles, conversely, operate at approximately $0.04-0.06 per mile when charged at home, representing 60-70% savings in energy expenditure. Commercial charging stations reduce this advantage somewhat but still maintain cost benefits in most markets.

Maintenance expenses further differentiate these technologies. V4 engines necessitate regular oil changes, filter replacements, timing belt services, and exhaust system maintenance. Annual maintenance costs typically range from $500-1,200 depending on vehicle age and usage patterns. Electric motors, with fewer moving parts and no combustion-related wear, average $200-400 in annual maintenance, primarily for brake system service, tire rotation, and cooling system checks.

Depreciation patterns also differ significantly. Conventional V4 vehicles typically lose 50-60% of their value over five years. Electric vehicles historically experienced faster depreciation due to battery degradation concerns and rapid technological advancement. However, this trend is reversing as battery longevity improves, with newer models retaining 45-55% of their value over the same period.

Insurance costs generally favor conventional vehicles, with electric models commanding 10-15% premium increases due to higher repair costs and specialized service requirements. However, this gap is narrowing as insurance companies gather more operational data and repair networks expand.

The comprehensive TCO analysis indicates that despite higher initial investment, electric vehicles typically achieve cost parity with V4 engines within 3-5 years of ownership in most usage scenarios, with the advantage increasing over longer ownership periods. This economic inflection point continues to move earlier in the ownership cycle as electric vehicle technology matures and supporting infrastructure expands.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!