V4 Engine Crankcase Ventilation: Enhancing Oil Separation

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Crankcase Ventilation Background and Objectives

Crankcase ventilation systems have been an integral part of internal combustion engines since the early 20th century, evolving significantly from simple open systems to sophisticated closed-loop designs. The V4 engine configuration, while less common than inline-four or V6 layouts, presents unique challenges and opportunities for crankcase ventilation due to its compact design and specific firing sequence characteristics. Initially, crankcase ventilation was implemented primarily to prevent pressure buildup inside the engine, but modern systems serve multiple critical functions including emissions control and engine longevity.

The evolution of crankcase ventilation technology has been largely driven by increasingly stringent environmental regulations, particularly those targeting hydrocarbon emissions. The 1960s marked a significant turning point with the introduction of Positive Crankcase Ventilation (PCV) systems, which redirected blow-by gases back into the intake manifold rather than venting them to atmosphere. This fundamental shift transformed crankcase ventilation from a simple pressure relief mechanism to an essential emissions control system.

In V4 engines, the crankcase ventilation system must address specific challenges related to the engine's compact V-configuration. The angular arrangement of cylinders creates unique flow dynamics for blow-by gases, requiring specialized routing and separation techniques. Additionally, the firing sequence and balance characteristics of V4 engines generate distinctive pressure fluctuation patterns in the crankcase that must be effectively managed to optimize oil separation efficiency.

The primary technical objective for enhancing oil separation in V4 engine crankcase ventilation systems is to achieve near-complete separation of oil particles from blow-by gases before they are recirculated into the intake system. This objective serves multiple purposes: preventing oil contamination of intake components, reducing hydrocarbon emissions, minimizing oil consumption, and maintaining optimal combustion conditions. Secondary objectives include minimizing system complexity, ensuring reliability across all operating conditions, and maintaining performance throughout the service life of the engine.

Current industry benchmarks for oil separation efficiency in premium automotive applications typically range from 95-98%, with emerging technologies pushing toward 99% efficiency. However, achieving these targets in the compact packaging constraints of V4 engines presents significant engineering challenges that require innovative approaches to separator design and integration.

The technological trajectory for crankcase ventilation systems is moving toward multi-stage separation techniques, advanced materials with specialized surface properties, and intelligent pressure management systems that adapt to varying engine operating conditions. These developments align with broader industry trends toward higher-efficiency engines with lower emissions and extended service intervals, making enhanced oil separation a critical enabling technology for next-generation powertrain systems.

The evolution of crankcase ventilation technology has been largely driven by increasingly stringent environmental regulations, particularly those targeting hydrocarbon emissions. The 1960s marked a significant turning point with the introduction of Positive Crankcase Ventilation (PCV) systems, which redirected blow-by gases back into the intake manifold rather than venting them to atmosphere. This fundamental shift transformed crankcase ventilation from a simple pressure relief mechanism to an essential emissions control system.

In V4 engines, the crankcase ventilation system must address specific challenges related to the engine's compact V-configuration. The angular arrangement of cylinders creates unique flow dynamics for blow-by gases, requiring specialized routing and separation techniques. Additionally, the firing sequence and balance characteristics of V4 engines generate distinctive pressure fluctuation patterns in the crankcase that must be effectively managed to optimize oil separation efficiency.

The primary technical objective for enhancing oil separation in V4 engine crankcase ventilation systems is to achieve near-complete separation of oil particles from blow-by gases before they are recirculated into the intake system. This objective serves multiple purposes: preventing oil contamination of intake components, reducing hydrocarbon emissions, minimizing oil consumption, and maintaining optimal combustion conditions. Secondary objectives include minimizing system complexity, ensuring reliability across all operating conditions, and maintaining performance throughout the service life of the engine.

Current industry benchmarks for oil separation efficiency in premium automotive applications typically range from 95-98%, with emerging technologies pushing toward 99% efficiency. However, achieving these targets in the compact packaging constraints of V4 engines presents significant engineering challenges that require innovative approaches to separator design and integration.

The technological trajectory for crankcase ventilation systems is moving toward multi-stage separation techniques, advanced materials with specialized surface properties, and intelligent pressure management systems that adapt to varying engine operating conditions. These developments align with broader industry trends toward higher-efficiency engines with lower emissions and extended service intervals, making enhanced oil separation a critical enabling technology for next-generation powertrain systems.

Market Demand Analysis for Enhanced Oil Separation Systems

The global market for enhanced oil separation systems in V4 engine crankcase ventilation has been experiencing significant growth, driven by increasingly stringent emission regulations and the automotive industry's focus on engine efficiency and longevity. Current market analysis indicates that the demand for advanced oil separation technologies is projected to grow at a compound annual rate of 5.7% through 2028, reflecting the critical importance of these systems in modern engine design.

Environmental regulations represent the primary market driver, with standards such as Euro 7, China 6b, and US EPA Tier 3 imposing stricter limits on particulate emissions and oil consumption. These regulations have created an immediate need for more efficient oil separation systems that can prevent oil carryover into the intake system, which contributes to harmful emissions and reduced catalytic converter efficiency.

The aftermarket segment shows particularly strong growth potential, with vehicle owners increasingly aware of the benefits of upgraded crankcase ventilation systems. This segment is valued at approximately 2.3 billion USD globally, with premium solutions commanding higher margins due to their demonstrable performance benefits in reducing oil consumption and extending engine life.

Regional analysis reveals varying market dynamics, with mature markets like North America and Europe focusing on high-efficiency premium solutions, while emerging markets in Asia-Pacific and Latin America show rapid adoption rates as emission standards tighten globally. China represents the fastest-growing market with 8.2% annual growth, driven by both regulatory pressure and increasing consumer awareness.

Customer segmentation indicates three primary market segments: original equipment manufacturers seeking compliance-ready solutions, performance aftermarket customers looking for enhanced engine protection, and commercial fleet operators focused on extending maintenance intervals and engine longevity. Each segment presents distinct requirements and price sensitivities.

Voice of customer research highlights key demand factors: reliability under extreme operating conditions, minimal maintenance requirements, compact design for increasingly crowded engine compartments, and demonstrable reduction in oil consumption. Premium vehicle manufacturers particularly emphasize noise reduction capabilities, as crankcase ventilation systems can contribute to NVH (Noise, Vibration, Harshness) issues.

Market forecasts suggest that integrated systems offering multiple benefits beyond oil separation (such as pressure regulation and blow-by filtration) will command premium pricing and capture increasing market share. The transition toward electrification paradoxically strengthens demand for advanced oil separation in hybrid powertrains, where intermittent engine operation creates unique challenges for traditional crankcase ventilation systems.

Environmental regulations represent the primary market driver, with standards such as Euro 7, China 6b, and US EPA Tier 3 imposing stricter limits on particulate emissions and oil consumption. These regulations have created an immediate need for more efficient oil separation systems that can prevent oil carryover into the intake system, which contributes to harmful emissions and reduced catalytic converter efficiency.

The aftermarket segment shows particularly strong growth potential, with vehicle owners increasingly aware of the benefits of upgraded crankcase ventilation systems. This segment is valued at approximately 2.3 billion USD globally, with premium solutions commanding higher margins due to their demonstrable performance benefits in reducing oil consumption and extending engine life.

Regional analysis reveals varying market dynamics, with mature markets like North America and Europe focusing on high-efficiency premium solutions, while emerging markets in Asia-Pacific and Latin America show rapid adoption rates as emission standards tighten globally. China represents the fastest-growing market with 8.2% annual growth, driven by both regulatory pressure and increasing consumer awareness.

Customer segmentation indicates three primary market segments: original equipment manufacturers seeking compliance-ready solutions, performance aftermarket customers looking for enhanced engine protection, and commercial fleet operators focused on extending maintenance intervals and engine longevity. Each segment presents distinct requirements and price sensitivities.

Voice of customer research highlights key demand factors: reliability under extreme operating conditions, minimal maintenance requirements, compact design for increasingly crowded engine compartments, and demonstrable reduction in oil consumption. Premium vehicle manufacturers particularly emphasize noise reduction capabilities, as crankcase ventilation systems can contribute to NVH (Noise, Vibration, Harshness) issues.

Market forecasts suggest that integrated systems offering multiple benefits beyond oil separation (such as pressure regulation and blow-by filtration) will command premium pricing and capture increasing market share. The transition toward electrification paradoxically strengthens demand for advanced oil separation in hybrid powertrains, where intermittent engine operation creates unique challenges for traditional crankcase ventilation systems.

Current Challenges in Crankcase Ventilation Technology

The crankcase ventilation system in V4 engines faces several significant challenges that impact overall engine performance and longevity. Primary among these is the insufficient oil separation efficiency in conventional systems, which allows oil particles to enter the intake manifold and combustion chambers. This oil carryover leads to carbon deposits on intake valves, combustion chambers, and piston crowns, ultimately reducing engine efficiency and increasing emissions.

Blow-by gases, containing unburned fuel, water vapor, and combustion byproducts, present another major challenge. These gases increase with engine wear and under high-load conditions, overwhelming standard ventilation systems. The variable nature of blow-by gas production across different operating conditions makes designing a universally effective system particularly difficult.

Space constraints within modern V4 engine compartments severely limit the implementation of more sophisticated oil separation technologies. Engineers must balance separation efficiency with compact design requirements, often leading to compromises in system performance. This spatial limitation becomes even more pronounced in downsized engines where every cubic centimeter is valuable.

Temperature fluctuations across different operating conditions significantly impact oil viscosity and separation characteristics. Cold-start conditions are especially problematic as higher oil viscosity reduces separation efficiency, while high-temperature operation can cause oil to become more volatile, increasing the likelihood of oil vapor carryover.

Current filtration materials and technologies show limitations in capturing ultra-fine oil particles and aerosols. Conventional mesh filters and baffles effectively capture larger droplets but struggle with sub-micron particles. These fine particles are particularly problematic as they can bypass traditional separation mechanisms and enter the intake system.

Pressure differential management across the crankcase ventilation system presents another technical hurdle. Excessive vacuum can increase oil carryover, while insufficient vacuum may lead to pressure buildup in the crankcase. Maintaining optimal pressure balance across varying engine speeds and loads requires sophisticated control mechanisms that many current systems lack.

Regulatory pressures further complicate the landscape, with increasingly stringent emissions standards demanding more effective crankcase ventilation systems. The need to reduce hydrocarbon emissions from the crankcase while maintaining engine performance creates additional design constraints for engineers working on next-generation systems.

Blow-by gases, containing unburned fuel, water vapor, and combustion byproducts, present another major challenge. These gases increase with engine wear and under high-load conditions, overwhelming standard ventilation systems. The variable nature of blow-by gas production across different operating conditions makes designing a universally effective system particularly difficult.

Space constraints within modern V4 engine compartments severely limit the implementation of more sophisticated oil separation technologies. Engineers must balance separation efficiency with compact design requirements, often leading to compromises in system performance. This spatial limitation becomes even more pronounced in downsized engines where every cubic centimeter is valuable.

Temperature fluctuations across different operating conditions significantly impact oil viscosity and separation characteristics. Cold-start conditions are especially problematic as higher oil viscosity reduces separation efficiency, while high-temperature operation can cause oil to become more volatile, increasing the likelihood of oil vapor carryover.

Current filtration materials and technologies show limitations in capturing ultra-fine oil particles and aerosols. Conventional mesh filters and baffles effectively capture larger droplets but struggle with sub-micron particles. These fine particles are particularly problematic as they can bypass traditional separation mechanisms and enter the intake system.

Pressure differential management across the crankcase ventilation system presents another technical hurdle. Excessive vacuum can increase oil carryover, while insufficient vacuum may lead to pressure buildup in the crankcase. Maintaining optimal pressure balance across varying engine speeds and loads requires sophisticated control mechanisms that many current systems lack.

Regulatory pressures further complicate the landscape, with increasingly stringent emissions standards demanding more effective crankcase ventilation systems. The need to reduce hydrocarbon emissions from the crankcase while maintaining engine performance creates additional design constraints for engineers working on next-generation systems.

Current Oil Separation Solutions for V4 Engines

01 Cyclonic oil separation systems for crankcase ventilation

Cyclonic oil separation systems utilize centrifugal force to separate oil particles from crankcase gases in V4 engines. These systems typically include a cyclonic chamber where the gas-oil mixture enters tangentially, creating a spinning motion that forces oil droplets to the outer walls while allowing cleaner gases to exit through the center. This design improves separation efficiency while maintaining compact dimensions suitable for V4 engine configurations.- Cyclonic oil separation systems for crankcase ventilation: Cyclonic oil separation systems utilize centrifugal force to separate oil particles from crankcase gases in V4 engines. These systems create a swirling motion that forces heavier oil droplets to the outer walls of the separator while allowing cleaner gases to flow through the center. This design improves separation efficiency and reduces oil consumption while maintaining proper engine ventilation. The cyclonic separators can be integrated directly into the engine design or installed as separate components in the ventilation system.

- Baffle and labyrinth separation mechanisms: Baffle and labyrinth systems create complex pathways for crankcase gases to travel through, causing oil droplets to impact surfaces and separate from the airflow. These systems use multiple chambers, plates, or mesh structures to create changes in flow direction and velocity. As gases navigate through these obstacles, oil particles collide with surfaces and drain back to the crankcase. This passive separation method is effective for V4 engines as it requires no moving parts, improving reliability while maintaining separation efficiency under various operating conditions.

- Integrated PCV valve and oil separation systems: Integrated systems combine the positive crankcase ventilation (PCV) valve functionality with oil separation for V4 engines. These designs incorporate flow control mechanisms that regulate crankcase pressure while simultaneously separating oil from blow-by gases. The integration reduces system complexity, saves space in the engine compartment, and ensures optimal pressure regulation. These systems often include temperature compensation features to maintain separation efficiency across different engine operating temperatures and conditions.

- Filtration media and coalescing elements: Advanced filtration media and coalescing elements are used in V4 engine crankcase ventilation systems to capture oil particles from blow-by gases. These systems employ specialized materials such as fibrous filters, mesh screens, or porous membranes that trap oil droplets while allowing gases to pass through. The coalescing action causes small oil droplets to combine into larger ones that can more easily drain back to the crankcase. These filtration systems are designed to maintain efficiency over extended periods while minimizing flow restriction and pressure drop.

- Electronic monitoring and control of oil separation: Electronic monitoring and control systems enhance oil separation in V4 engine crankcase ventilation by actively adjusting separation parameters based on real-time engine conditions. These systems use sensors to monitor pressure, temperature, and flow rates, then optimize separation efficiency through electronically controlled valves or heating elements. Some advanced designs incorporate diagnostic capabilities that alert drivers to separation system issues or maintenance requirements. This approach ensures consistent oil separation performance across varying engine loads, speeds, and environmental conditions.

02 Integrated oil separation and pressure regulation

Advanced crankcase ventilation systems for V4 engines incorporate both oil separation and pressure regulation functions in a single unit. These systems maintain optimal crankcase pressure while effectively removing oil mist from blow-by gases. The integration reduces system complexity, saves space in the engine compartment, and ensures consistent performance across varying engine operating conditions.Expand Specific Solutions03 Multi-stage filtration for enhanced oil separation

Multi-stage filtration systems provide progressive oil separation from crankcase gases in V4 engines. These systems typically include a primary separation stage using baffles or mesh elements to capture larger oil droplets, followed by secondary stages with finer filtration media to remove smaller oil particles. This approach significantly improves separation efficiency while extending service intervals and reducing oil consumption.Expand Specific Solutions04 Compact design solutions for V4 engine applications

Specialized compact oil separation systems are designed specifically for the space constraints of V4 engine layouts. These solutions feature innovative component arrangements, such as stacked separation chambers or integration with valve covers, to minimize the overall footprint. The compact designs maintain separation efficiency while accommodating the unique geometry of V4 engine configurations and allowing for easier installation and maintenance.Expand Specific Solutions05 Temperature-optimized crankcase ventilation systems

Temperature-optimized crankcase ventilation systems for V4 engines incorporate features to maintain effective oil separation across varying operating temperatures. These systems may include thermal insulation, heating elements, or strategic placement relative to heat sources to prevent condensation and freezing in cold conditions. Some designs also incorporate cooling provisions to maintain optimal separation efficiency during high-temperature operation, ensuring consistent performance in all operating environments.Expand Specific Solutions

Key Patents and Innovations in Crankcase Ventilation

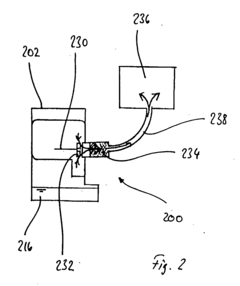

Crankcase ventilation device

PatentInactiveEP1544424A1

Innovation

- A multifunctional oil separation system comprising a pressure-controlled valve, a centrifugal wheel, and a fabric separator is used to reduce pressure pulsation, achieve initial and further oil separation, and ensure effective oil removal from crankcase gases, with the centrifugal wheel rotating against the flow and the fabric separator utilizing a diameter-enlarged area to collect and return oil droplets to the oil chamber.

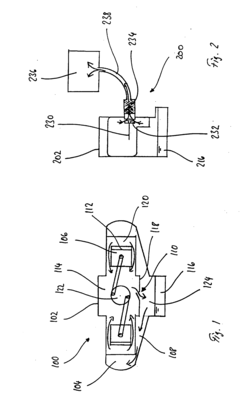

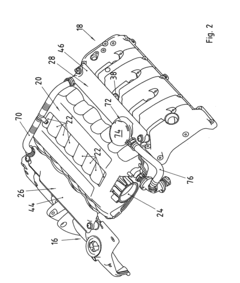

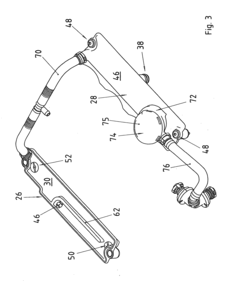

System for ventilation of an internal-combustion engine crankcase as well as a V-shaped internal combustion engine

PatentInactiveUS20060180131A1

Innovation

- A separate oil separation module with central blow-by gas intake openings and end-mounted oil return openings, featuring a labyrinthine path and mushroom-shaped valves for controlled oil return, is integrated between the cylinder head cover and air intake module, allowing for improved oil separation and ventilation path length, ensuring continuous operation by preventing oil return during uphill driving.

Environmental Regulations Impact on Crankcase Ventilation Design

Environmental regulations have become increasingly stringent worldwide, significantly influencing the design and performance requirements of crankcase ventilation systems in V4 engines. The primary regulatory frameworks governing these systems include the United States Environmental Protection Agency (EPA) standards, European Union's Euro emissions standards, and similar regulations in Asia-Pacific markets. These regulations specifically target the reduction of hydrocarbon emissions from all vehicle systems, including those from the crankcase.

The evolution of these regulations has created a clear trajectory toward near-zero emissions tolerance. For instance, the latest Euro 7 standards propose a significant reduction in allowable hydrocarbon emissions compared to previous iterations, directly impacting crankcase ventilation design parameters. Similarly, California Air Resources Board (CARB) regulations have established precedents that often become national standards in the United States, pushing manufacturers toward more effective oil separation technologies.

Regulatory compliance has necessitated substantial improvements in oil separation efficiency within crankcase ventilation systems. Traditional systems achieving 60-70% separation efficiency are no longer sufficient to meet current standards, which often require efficiencies exceeding 95% for ultra-fine oil particles. This regulatory pressure has accelerated innovation in separation technologies, particularly for particles in the 1-5 micron range that previously escaped capture.

The regulatory landscape has also expanded to include lifecycle environmental impact considerations. Modern regulations increasingly address the environmental footprint of components throughout their operational life, including maintenance requirements and end-of-life disposal. This has prompted the development of more durable separation media and systems that maintain high efficiency over extended service intervals, reducing waste and resource consumption.

Temperature range compliance represents another regulatory-driven challenge. Crankcase ventilation systems must now demonstrate consistent performance across extreme operating conditions, from cold-start scenarios to high-load, high-temperature operations. This has led to the development of adaptive systems that can maintain separation efficiency across varying thermal conditions, often incorporating smart materials or multi-stage separation processes.

Furthermore, on-board diagnostic (OBD) requirements have expanded to include monitoring of crankcase ventilation system performance. Modern systems must incorporate sensors and diagnostic capabilities to detect degradation in separation efficiency, ensuring emissions compliance throughout the vehicle's operational life. This integration of monitoring technology represents a significant shift from purely mechanical systems to mechatronic solutions with feedback capabilities.

The evolution of these regulations has created a clear trajectory toward near-zero emissions tolerance. For instance, the latest Euro 7 standards propose a significant reduction in allowable hydrocarbon emissions compared to previous iterations, directly impacting crankcase ventilation design parameters. Similarly, California Air Resources Board (CARB) regulations have established precedents that often become national standards in the United States, pushing manufacturers toward more effective oil separation technologies.

Regulatory compliance has necessitated substantial improvements in oil separation efficiency within crankcase ventilation systems. Traditional systems achieving 60-70% separation efficiency are no longer sufficient to meet current standards, which often require efficiencies exceeding 95% for ultra-fine oil particles. This regulatory pressure has accelerated innovation in separation technologies, particularly for particles in the 1-5 micron range that previously escaped capture.

The regulatory landscape has also expanded to include lifecycle environmental impact considerations. Modern regulations increasingly address the environmental footprint of components throughout their operational life, including maintenance requirements and end-of-life disposal. This has prompted the development of more durable separation media and systems that maintain high efficiency over extended service intervals, reducing waste and resource consumption.

Temperature range compliance represents another regulatory-driven challenge. Crankcase ventilation systems must now demonstrate consistent performance across extreme operating conditions, from cold-start scenarios to high-load, high-temperature operations. This has led to the development of adaptive systems that can maintain separation efficiency across varying thermal conditions, often incorporating smart materials or multi-stage separation processes.

Furthermore, on-board diagnostic (OBD) requirements have expanded to include monitoring of crankcase ventilation system performance. Modern systems must incorporate sensors and diagnostic capabilities to detect degradation in separation efficiency, ensuring emissions compliance throughout the vehicle's operational life. This integration of monitoring technology represents a significant shift from purely mechanical systems to mechatronic solutions with feedback capabilities.

Performance Testing and Validation Methodologies

Effective performance testing and validation methodologies are crucial for evaluating crankcase ventilation systems in V4 engines, particularly when focusing on oil separation efficiency. The testing protocols must be comprehensive, reproducible, and aligned with industry standards to ensure reliable data collection and analysis.

Laboratory bench testing represents the initial validation phase, where controlled conditions allow for precise measurement of oil separation efficiency. These tests typically involve simulating various engine operating conditions while measuring oil carryover rates using gravimetric analysis and particle size distribution measurements. High-precision instruments such as laser particle counters and optical emission spectrometers are employed to quantify separation performance across different particle size ranges, from sub-micron oil mist to larger droplets.

Engine dynamometer testing provides a more realistic evaluation environment, allowing for assessment under actual operating conditions. During these tests, the crankcase ventilation system is subjected to varying engine speeds, loads, and temperatures to evaluate performance across the entire operating envelope. Key parameters monitored include blow-by gas flow rates, pressure differentials across the system, oil carryover quantities, and the impact on engine performance metrics such as power output and fuel consumption.

Durability testing constitutes a critical component of validation methodologies, typically involving extended operation cycles designed to simulate the system's entire service life. Accelerated aging protocols expose the ventilation system to extreme conditions, including high-temperature cycling, contamination challenges, and vibration profiles that replicate real-world usage scenarios. Post-test analysis includes visual inspection, flow testing, and microscopic examination of separator media to assess degradation patterns.

Field testing in actual vehicles complements laboratory data by exposing the system to real-world variables that may not be fully replicable in controlled environments. Instrumented test vehicles equipped with data acquisition systems collect performance metrics across diverse driving conditions, geographic locations, and climate zones. This phase often includes cold-start performance evaluation, altitude testing, and operation under varying humidity levels.

Computational Fluid Dynamics (CFD) modeling has emerged as a valuable complement to physical testing, allowing engineers to visualize flow patterns, predict separation efficiency, and optimize designs before prototype fabrication. Advanced simulation techniques incorporating multiphase flow models can predict oil droplet trajectories and separation mechanisms with increasing accuracy, reducing development cycles and testing costs.

Standardized reporting protocols ensure consistency across testing programs, with results typically presented as separation efficiency percentages across different particle size ranges and operating conditions. Statistical analysis methods such as Design of Experiments (DOE) help identify key performance factors and their interactions, guiding further optimization efforts.

Laboratory bench testing represents the initial validation phase, where controlled conditions allow for precise measurement of oil separation efficiency. These tests typically involve simulating various engine operating conditions while measuring oil carryover rates using gravimetric analysis and particle size distribution measurements. High-precision instruments such as laser particle counters and optical emission spectrometers are employed to quantify separation performance across different particle size ranges, from sub-micron oil mist to larger droplets.

Engine dynamometer testing provides a more realistic evaluation environment, allowing for assessment under actual operating conditions. During these tests, the crankcase ventilation system is subjected to varying engine speeds, loads, and temperatures to evaluate performance across the entire operating envelope. Key parameters monitored include blow-by gas flow rates, pressure differentials across the system, oil carryover quantities, and the impact on engine performance metrics such as power output and fuel consumption.

Durability testing constitutes a critical component of validation methodologies, typically involving extended operation cycles designed to simulate the system's entire service life. Accelerated aging protocols expose the ventilation system to extreme conditions, including high-temperature cycling, contamination challenges, and vibration profiles that replicate real-world usage scenarios. Post-test analysis includes visual inspection, flow testing, and microscopic examination of separator media to assess degradation patterns.

Field testing in actual vehicles complements laboratory data by exposing the system to real-world variables that may not be fully replicable in controlled environments. Instrumented test vehicles equipped with data acquisition systems collect performance metrics across diverse driving conditions, geographic locations, and climate zones. This phase often includes cold-start performance evaluation, altitude testing, and operation under varying humidity levels.

Computational Fluid Dynamics (CFD) modeling has emerged as a valuable complement to physical testing, allowing engineers to visualize flow patterns, predict separation efficiency, and optimize designs before prototype fabrication. Advanced simulation techniques incorporating multiphase flow models can predict oil droplet trajectories and separation mechanisms with increasing accuracy, reducing development cycles and testing costs.

Standardized reporting protocols ensure consistency across testing programs, with results typically presented as separation efficiency percentages across different particle size ranges and operating conditions. Statistical analysis methods such as Design of Experiments (DOE) help identify key performance factors and their interactions, guiding further optimization efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!