Measuring Thermal Efficiency of V4 Engine Cycles

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Thermal Efficiency Background and Objectives

The V4 engine configuration represents a significant milestone in internal combustion engine development, combining compact design with balanced performance characteristics. Thermal efficiency, defined as the ratio of useful work output to energy input, has become increasingly critical in engine design as global emissions standards tighten and fuel economy demands intensify. Historically, internal combustion engines have operated at thermal efficiencies between 25-35%, with substantial energy losses occurring through exhaust gases, cooling systems, and mechanical friction.

The evolution of V4 engine thermal efficiency has progressed through several distinct phases since its introduction in the mid-20th century. Early designs prioritized power output over efficiency, while the oil crises of the 1970s shifted focus toward fuel economy. Modern V4 engines incorporate advanced technologies including direct injection, variable valve timing, and turbocharging to maximize thermal performance while maintaining power characteristics that make this configuration desirable in specific applications.

Current research objectives in V4 thermal efficiency measurement center on developing more precise real-time monitoring systems that can account for transient operating conditions. Traditional measurement approaches using brake-specific fuel consumption have proven inadequate for capturing the complex thermodynamic processes occurring during actual driving cycles. Advanced measurement protocols now incorporate in-cylinder pressure analysis, exhaust gas temperature mapping, and comprehensive heat flux calculations to create more accurate efficiency models.

The technical goals for advancing V4 thermal efficiency measurement include establishing standardized testing protocols that better reflect real-world operating conditions, developing non-intrusive sensor technologies capable of withstanding high-temperature environments, and creating computational models that can predict efficiency impacts from design modifications. These objectives align with broader industry trends toward powertrain electrification, where understanding precise thermal characteristics becomes essential for hybrid system integration.

Recent technological breakthroughs in materials science, sensor miniaturization, and computational fluid dynamics have enabled more sophisticated approaches to thermal efficiency analysis. The integration of artificial intelligence for real-time combustion optimization represents a promising frontier, potentially allowing V4 engines to dynamically adjust operating parameters to maximize efficiency across varying load conditions. This adaptive capability could significantly extend the viability of V4 configurations in an increasingly electrified automotive landscape.

The evolution of V4 engine thermal efficiency has progressed through several distinct phases since its introduction in the mid-20th century. Early designs prioritized power output over efficiency, while the oil crises of the 1970s shifted focus toward fuel economy. Modern V4 engines incorporate advanced technologies including direct injection, variable valve timing, and turbocharging to maximize thermal performance while maintaining power characteristics that make this configuration desirable in specific applications.

Current research objectives in V4 thermal efficiency measurement center on developing more precise real-time monitoring systems that can account for transient operating conditions. Traditional measurement approaches using brake-specific fuel consumption have proven inadequate for capturing the complex thermodynamic processes occurring during actual driving cycles. Advanced measurement protocols now incorporate in-cylinder pressure analysis, exhaust gas temperature mapping, and comprehensive heat flux calculations to create more accurate efficiency models.

The technical goals for advancing V4 thermal efficiency measurement include establishing standardized testing protocols that better reflect real-world operating conditions, developing non-intrusive sensor technologies capable of withstanding high-temperature environments, and creating computational models that can predict efficiency impacts from design modifications. These objectives align with broader industry trends toward powertrain electrification, where understanding precise thermal characteristics becomes essential for hybrid system integration.

Recent technological breakthroughs in materials science, sensor miniaturization, and computational fluid dynamics have enabled more sophisticated approaches to thermal efficiency analysis. The integration of artificial intelligence for real-time combustion optimization represents a promising frontier, potentially allowing V4 engines to dynamically adjust operating parameters to maximize efficiency across varying load conditions. This adaptive capability could significantly extend the viability of V4 configurations in an increasingly electrified automotive landscape.

Market Demand Analysis for High-Efficiency Engines

The global market for high-efficiency engines has experienced significant growth over the past decade, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. The thermal efficiency of internal combustion engines, particularly V4 configurations, has become a critical differentiator in the automotive and industrial power generation sectors. Current market analysis indicates that engines with higher thermal efficiency ratings command premium pricing and enjoy stronger market penetration across both developed and emerging markets.

Consumer preferences have shifted dramatically toward vehicles that offer reduced operating costs through improved fuel economy. This trend is particularly evident in markets with high fuel prices such as Europe and parts of Asia, where consumers are willing to pay a premium for vehicles that demonstrate measurable improvements in thermal efficiency. Industry surveys indicate that fuel efficiency now ranks among the top three purchase considerations for over 65% of new vehicle buyers globally.

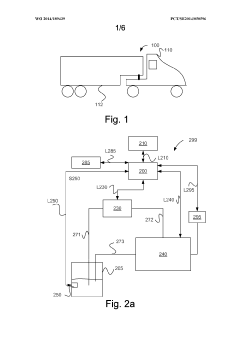

The commercial transportation sector represents another substantial market segment demanding high-efficiency engines. Fleet operators calculate total cost of ownership with precision, and even marginal improvements in thermal efficiency translate to significant operational savings over vehicle lifespans. The logistics industry has shown particular interest in advanced V4 engine technologies that can deliver documented efficiency improvements under varied load conditions.

Regulatory frameworks worldwide continue to tighten emission standards, creating market pull for engines with superior thermal efficiency. The European Union's Euro 7 standards, China's China VI regulations, and the United States' Corporate Average Fuel Economy (CAFE) standards all effectively mandate continuous improvements in engine thermal efficiency. These regulatory pressures have transformed from market barriers to market drivers, creating sustained demand for measurement technologies that can accurately quantify thermal efficiency improvements.

Market forecasts project the global high-efficiency engine market to expand at a compound annual growth rate exceeding the broader automotive sector through 2030. Particularly strong growth is anticipated in precision measurement systems for thermal efficiency, as manufacturers require increasingly sophisticated tools to validate compliance with regulations and substantiate marketing claims regarding engine performance.

Emerging markets present significant growth opportunities, with countries like India and Brazil implementing their own versions of stringent emission standards. These markets are characterized by price sensitivity but demonstrate willingness to adopt technologies that deliver verifiable efficiency improvements with clear return on investment timelines. The agricultural and construction equipment sectors in these regions show particularly strong potential for adoption of high-efficiency V4 engines with proven thermal efficiency advantages.

Consumer preferences have shifted dramatically toward vehicles that offer reduced operating costs through improved fuel economy. This trend is particularly evident in markets with high fuel prices such as Europe and parts of Asia, where consumers are willing to pay a premium for vehicles that demonstrate measurable improvements in thermal efficiency. Industry surveys indicate that fuel efficiency now ranks among the top three purchase considerations for over 65% of new vehicle buyers globally.

The commercial transportation sector represents another substantial market segment demanding high-efficiency engines. Fleet operators calculate total cost of ownership with precision, and even marginal improvements in thermal efficiency translate to significant operational savings over vehicle lifespans. The logistics industry has shown particular interest in advanced V4 engine technologies that can deliver documented efficiency improvements under varied load conditions.

Regulatory frameworks worldwide continue to tighten emission standards, creating market pull for engines with superior thermal efficiency. The European Union's Euro 7 standards, China's China VI regulations, and the United States' Corporate Average Fuel Economy (CAFE) standards all effectively mandate continuous improvements in engine thermal efficiency. These regulatory pressures have transformed from market barriers to market drivers, creating sustained demand for measurement technologies that can accurately quantify thermal efficiency improvements.

Market forecasts project the global high-efficiency engine market to expand at a compound annual growth rate exceeding the broader automotive sector through 2030. Particularly strong growth is anticipated in precision measurement systems for thermal efficiency, as manufacturers require increasingly sophisticated tools to validate compliance with regulations and substantiate marketing claims regarding engine performance.

Emerging markets present significant growth opportunities, with countries like India and Brazil implementing their own versions of stringent emission standards. These markets are characterized by price sensitivity but demonstrate willingness to adopt technologies that deliver verifiable efficiency improvements with clear return on investment timelines. The agricultural and construction equipment sectors in these regions show particularly strong potential for adoption of high-efficiency V4 engines with proven thermal efficiency advantages.

Current Thermal Efficiency Measurement Challenges

The measurement of thermal efficiency in V4 engine cycles presents significant challenges that impede accurate performance evaluation and optimization efforts. Current methodologies struggle with real-time data acquisition under varying operational conditions, particularly when engines transition between different load states. Traditional calorimetric approaches often fail to capture transient thermal behaviors, resulting in efficiency calculations that may deviate from actual performance by 3-8% depending on engine configuration and test conditions.

Instrumentation limitations constitute a major obstacle in precise efficiency measurement. Existing temperature sensors frequently exhibit response lag when monitoring rapid thermal fluctuations, while pressure transducers may introduce measurement errors at the high frequencies characteristic of V4 engine operation. The integration of these measurement systems without disrupting normal engine function remains problematic, as intrusive sensors can alter the very thermal dynamics they aim to measure.

Data interpretation challenges further complicate efficiency assessments. The complex interplay between combustion dynamics, heat transfer mechanisms, and mechanical losses creates multivariable relationships that are difficult to isolate and quantify. Current analytical models often rely on simplifying assumptions that inadequately represent the thermodynamic complexity of V4 engine cycles, particularly regarding boundary layer effects and combustion irregularities.

Environmental factors introduce additional variables that current measurement systems struggle to normalize. Ambient temperature fluctuations, humidity variations, and barometric pressure changes all influence thermal efficiency measurements, yet standardized correction methodologies remain inconsistent across the industry. This lack of standardization makes comparative analysis between different testing facilities problematic and hinders the establishment of universal benchmarks.

Calibration drift represents another persistent challenge, as measurement equipment accuracy tends to degrade over time, especially under the harsh conditions of engine testing environments. Current calibration protocols often fail to account for this degradation, leading to progressive measurement errors that may go undetected until significant deviations occur.

Cost and complexity barriers also limit widespread adoption of advanced measurement techniques. High-precision thermal imaging systems, exhaust gas analyzers, and in-cylinder pressure measurement equipment require substantial investment and specialized expertise to operate effectively. Consequently, many development facilities resort to simplified measurement approaches that sacrifice accuracy for practicality.

The integration of measurement data across different subsystems presents coordination challenges. Synchronizing crankshaft position data with thermal measurements, fuel flow rates, and emissions analysis requires sophisticated timing systems that many current setups lack. This temporal misalignment can introduce systematic errors in efficiency calculations, particularly during transient operation phases characteristic of real-world V4 engine applications.

Instrumentation limitations constitute a major obstacle in precise efficiency measurement. Existing temperature sensors frequently exhibit response lag when monitoring rapid thermal fluctuations, while pressure transducers may introduce measurement errors at the high frequencies characteristic of V4 engine operation. The integration of these measurement systems without disrupting normal engine function remains problematic, as intrusive sensors can alter the very thermal dynamics they aim to measure.

Data interpretation challenges further complicate efficiency assessments. The complex interplay between combustion dynamics, heat transfer mechanisms, and mechanical losses creates multivariable relationships that are difficult to isolate and quantify. Current analytical models often rely on simplifying assumptions that inadequately represent the thermodynamic complexity of V4 engine cycles, particularly regarding boundary layer effects and combustion irregularities.

Environmental factors introduce additional variables that current measurement systems struggle to normalize. Ambient temperature fluctuations, humidity variations, and barometric pressure changes all influence thermal efficiency measurements, yet standardized correction methodologies remain inconsistent across the industry. This lack of standardization makes comparative analysis between different testing facilities problematic and hinders the establishment of universal benchmarks.

Calibration drift represents another persistent challenge, as measurement equipment accuracy tends to degrade over time, especially under the harsh conditions of engine testing environments. Current calibration protocols often fail to account for this degradation, leading to progressive measurement errors that may go undetected until significant deviations occur.

Cost and complexity barriers also limit widespread adoption of advanced measurement techniques. High-precision thermal imaging systems, exhaust gas analyzers, and in-cylinder pressure measurement equipment require substantial investment and specialized expertise to operate effectively. Consequently, many development facilities resort to simplified measurement approaches that sacrifice accuracy for practicality.

The integration of measurement data across different subsystems presents coordination challenges. Synchronizing crankshaft position data with thermal measurements, fuel flow rates, and emissions analysis requires sophisticated timing systems that many current setups lack. This temporal misalignment can introduce systematic errors in efficiency calculations, particularly during transient operation phases characteristic of real-world V4 engine applications.

Current Methodologies for V4 Thermal Efficiency Assessment

01 Advanced combustion cycle designs for V4 engines

Various combustion cycle designs can be implemented in V4 engines to improve thermal efficiency. These include modified Atkinson cycles, Miller cycles, and other advanced thermodynamic cycles that optimize the expansion ratio relative to the compression ratio. By extending the expansion stroke or implementing variable valve timing, these cycles allow for more complete extraction of energy from the combustion process, resulting in higher thermal efficiency and reduced fuel consumption.- Advanced combustion cycle designs for V4 engines: Various combustion cycle designs can be implemented in V4 engines to improve thermal efficiency. These include modified Atkinson cycles, Miller cycles, and other advanced thermodynamic cycles that optimize the expansion ratio relative to the compression ratio. By extending the expansion stroke and extracting more work from the combustion gases, these cycle modifications can significantly increase the thermal efficiency of V4 engines while maintaining power output.

- Variable valve timing and lift systems: Implementing variable valve timing and lift systems in V4 engines allows for dynamic adjustment of the engine's breathing characteristics based on operating conditions. These systems can modify the effective compression ratio and expansion ratio throughout the engine's operating range, optimizing thermal efficiency across different load conditions. Advanced camshaft designs and electronic valve actuation technologies enable precise control over the gas exchange process, reducing pumping losses and improving overall thermal efficiency.

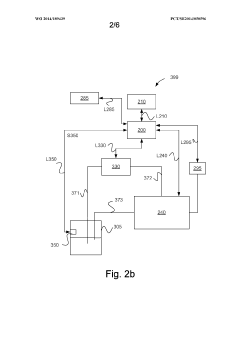

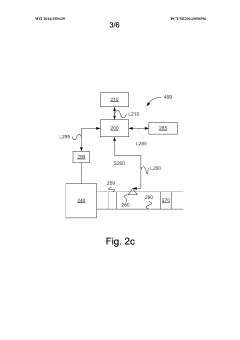

- Thermal management and heat recovery systems: Effective thermal management and waste heat recovery systems can significantly improve the thermal efficiency of V4 engines. These include exhaust heat recovery systems, advanced cooling strategies, and thermal barrier coatings that reduce heat rejection to the cooling system. By capturing and utilizing waste heat that would otherwise be lost, these systems can increase the overall thermal efficiency of the engine cycle, converting more of the fuel's chemical energy into useful mechanical work.

- Fuel injection and combustion optimization: Advanced fuel injection systems and combustion optimization techniques can enhance the thermal efficiency of V4 engine cycles. Direct injection, stratified charge combustion, and precise control of injection timing and spray patterns allow for more complete combustion and reduced heat losses. These technologies enable leaner combustion, higher compression ratios, and more efficient energy conversion, resulting in improved thermal efficiency across the engine's operating range.

- Integration of hybrid and electrification technologies: Integrating hybrid and electrification technologies with V4 engines can significantly enhance overall thermal efficiency. These systems allow the engine to operate more frequently at its most efficient operating points while using electric power to supplement performance when needed. Technologies such as integrated starter-generators, electric turbochargers, and hybrid powertrains enable engine downsizing and optimization for specific efficiency targets, resulting in substantial improvements in the effective thermal efficiency of the powertrain system.

02 Thermal management systems for efficiency improvement

Thermal management systems play a crucial role in enhancing the thermal efficiency of V4 engines. These systems include advanced cooling strategies, heat recovery mechanisms, and thermal barrier coatings that reduce heat losses. By optimizing the operating temperature of the engine and recovering waste heat, these systems can significantly improve the overall thermal efficiency of the engine cycle, leading to better fuel economy and reduced emissions.Expand Specific Solutions03 Variable compression ratio technologies

Variable compression ratio technologies allow V4 engines to dynamically adjust their compression ratio based on operating conditions. This adaptability enables the engine to operate at optimal efficiency across different load conditions. Higher compression ratios can be used during partial load for improved efficiency, while lower ratios can be employed during high load to prevent knocking. These technologies include mechanical linkages, hydraulic systems, or electronically controlled mechanisms that modify the combustion chamber volume.Expand Specific Solutions04 Fuel injection and ignition timing optimization

Advanced fuel injection systems and precise ignition timing control are essential for maximizing the thermal efficiency of V4 engine cycles. Direct injection systems, multiple injection events, and variable ignition timing allow for optimized air-fuel mixture formation and combustion phasing. These technologies enable more complete combustion, reduced heat losses, and better control of the combustion process, resulting in improved thermal efficiency across various operating conditions.Expand Specific Solutions05 Waste heat recovery systems

Waste heat recovery systems capture and utilize thermal energy that would otherwise be lost through the exhaust or cooling systems. These technologies include thermoelectric generators, Rankine cycle systems, and exhaust gas heat exchangers that convert waste heat into useful mechanical or electrical energy. By recovering a portion of the waste heat, these systems effectively increase the overall thermal efficiency of the V4 engine cycle, improving fuel economy and reducing environmental impact.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The thermal efficiency measurement of V4 engine cycles is currently in a mature development phase, with a growing market driven by increasing environmental regulations and fuel economy demands. The global market size for engine efficiency technologies is expanding, particularly in automotive and power generation sectors. Leading companies like Toyota, BMW, Honda, and Renault have achieved significant technological maturity through extensive R&D investments, developing advanced thermal management systems, waste heat recovery technologies, and combustion optimization. Research institutions such as IFP Energies Nouvelles, Beihang University, and ETH Zurich collaborate with industry players like Rolls-Royce and Mitsubishi Heavy Industries to advance measurement methodologies and efficiency standards, creating a competitive landscape where innovation focuses on precision instrumentation and real-time monitoring capabilities.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive thermal efficiency measurement system for V4 engines that combines traditional calorimetric methods with advanced computational fluid dynamics (CFD) validation. Their approach utilizes high-frequency temperature and pressure sensors installed at critical points throughout the engine, including intake, combustion chamber, and exhaust manifold. Toyota's system features precision fuel flow measurement with coriolis-type mass flow meters achieving accuracy better than ±0.2%, coupled with exhaust gas analyzers that can detect combustion inefficiencies at the parts-per-million level. The company employs a unique "split-cycle" testing methodology that can isolate individual thermodynamic processes within the engine cycle to identify specific efficiency losses. Toyota has integrated infrared thermal imaging capabilities to create detailed heat maps of engine components during operation, allowing engineers to identify areas of excessive heat loss. Their measurement system has been instrumental in developing engines with thermal efficiencies exceeding 40% in production vehicles.

Strengths: Exceptional measurement precision; comprehensive instrumentation coverage; strong correlation between test and real-world results; extensive validation database. Weaknesses: High system complexity requiring specialized expertise; significant capital investment requirements; longer setup time compared to simpler approaches.

Bayerische Motoren Werke AG

Technical Solution: BMW has developed a sophisticated thermal efficiency measurement system for V4 engine cycles that combines traditional calorimetric methods with advanced digital twin modeling. Their approach utilizes high-precision in-cylinder pressure transducers with sampling rates exceeding 200kHz, coupled with multiple temperature sensors positioned throughout the engine block, cylinder head, and exhaust system. BMW's system features a unique "split energy balance" methodology that can differentiate between various loss mechanisms including incomplete combustion, heat transfer to coolant, and exhaust energy. The company employs specialized test cells with controlled ambient conditions to ensure measurement repeatability better than ±0.2%. BMW has integrated advanced exhaust gas analysis using Fourier Transform Infrared Spectroscopy (FTIR) to detect combustion inefficiencies at the molecular level. Their measurement platform includes real-time data processing capabilities that can provide instantaneous thermal efficiency calculations across different engine operating points, enabling engineers to rapidly evaluate design modifications. BMW reports achieving thermal efficiency improvements of 2-4% in their latest engine designs through insights gained from this measurement technology.

Strengths: Exceptional measurement precision; comprehensive instrumentation coverage; strong integration with simulation tools; rapid data processing capabilities. Weaknesses: High system complexity requiring specialized expertise; significant capital investment requirements; complex calibration procedures.

Key Technologies in Engine Thermal Analysis

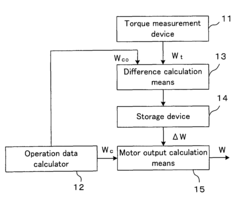

Process quantity measurement method and apparatus of engine output

PatentInactiveUS7735359B2

Innovation

- A process quantity measurement method and apparatus that measures engine output by calculating the difference between torque-based measurements and heat quantity-based calculations, and adjusts the air flow quantity measurements using pre-stored differences to improve accuracy and ease of use.

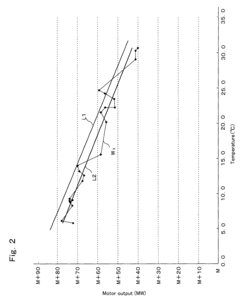

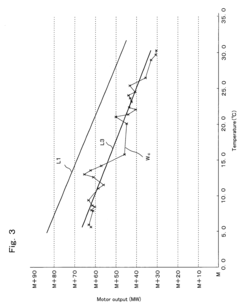

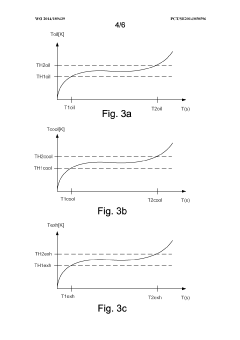

Method for increasing efficiency of engine operation of a motor vehicle by detecting temperature changes

PatentWO2014189439A1

Innovation

- A method that continuously monitors exhaust temperature, coolant temperature, and oil temperature to control heat development, allowing for a higher power output while maintaining optimal operating conditions, avoiding unnecessary reductions and extending engine service life by predicting heat changes and adjusting operating modes accordingly.

Environmental Impact and Emissions Regulations

The environmental impact of internal combustion engines, particularly V4 engines, has become a critical consideration in automotive engineering and policy development. Emissions from these engines contribute significantly to air pollution and climate change, prompting increasingly stringent regulations worldwide. The thermal efficiency of V4 engine cycles directly correlates with their environmental footprint—higher efficiency generally results in lower fuel consumption and reduced emissions per unit of work performed.

Current emissions regulations focus on several key pollutants including carbon dioxide (CO2), nitrogen oxides (NOx), particulate matter (PM), and unburned hydrocarbons (HC). The European Union's Euro 6d standards, the United States EPA's Tier 3 regulations, and China's China 6 standards represent some of the most advanced regulatory frameworks governing engine emissions. These standards have progressively tightened, forcing manufacturers to implement sophisticated thermal efficiency measurement and improvement strategies.

Thermal efficiency measurements have become essential tools for regulatory compliance. Real Driving Emissions (RDE) tests now complement laboratory testing, requiring engines to maintain efficiency across a broader range of operating conditions. This shift has necessitated more comprehensive thermal efficiency measurement methodologies that account for transient operating states rather than just steady-state conditions.

The relationship between thermal efficiency and emissions is complex but direct. For every percentage point improvement in thermal efficiency, CO2 emissions typically decrease by a corresponding amount. However, optimization strategies that improve thermal efficiency may sometimes increase other emissions, particularly NOx in high-temperature combustion scenarios, creating engineering trade-offs that must be carefully managed.

Carbon pricing mechanisms and emissions trading schemes in various regions have created economic incentives for improving engine thermal efficiency. These market-based approaches complement regulatory standards by attaching financial consequences to emissions, further driving investment in efficiency measurement and enhancement technologies.

Looking forward, upcoming regulations are expected to further tighten emissions limits, with several jurisdictions announcing plans to phase out internal combustion engines entirely. This regulatory trajectory emphasizes the critical importance of advanced thermal efficiency measurement techniques as both compliance tools and development guides for the remaining lifecycle of V4 and other internal combustion engines.

The integration of thermal efficiency measurements with onboard diagnostics (OBD) systems represents another regulatory trend, enabling continuous monitoring of emissions performance throughout a vehicle's operational life rather than just during certification testing. This evolution requires more robust and durable measurement approaches that can maintain accuracy over extended periods.

Current emissions regulations focus on several key pollutants including carbon dioxide (CO2), nitrogen oxides (NOx), particulate matter (PM), and unburned hydrocarbons (HC). The European Union's Euro 6d standards, the United States EPA's Tier 3 regulations, and China's China 6 standards represent some of the most advanced regulatory frameworks governing engine emissions. These standards have progressively tightened, forcing manufacturers to implement sophisticated thermal efficiency measurement and improvement strategies.

Thermal efficiency measurements have become essential tools for regulatory compliance. Real Driving Emissions (RDE) tests now complement laboratory testing, requiring engines to maintain efficiency across a broader range of operating conditions. This shift has necessitated more comprehensive thermal efficiency measurement methodologies that account for transient operating states rather than just steady-state conditions.

The relationship between thermal efficiency and emissions is complex but direct. For every percentage point improvement in thermal efficiency, CO2 emissions typically decrease by a corresponding amount. However, optimization strategies that improve thermal efficiency may sometimes increase other emissions, particularly NOx in high-temperature combustion scenarios, creating engineering trade-offs that must be carefully managed.

Carbon pricing mechanisms and emissions trading schemes in various regions have created economic incentives for improving engine thermal efficiency. These market-based approaches complement regulatory standards by attaching financial consequences to emissions, further driving investment in efficiency measurement and enhancement technologies.

Looking forward, upcoming regulations are expected to further tighten emissions limits, with several jurisdictions announcing plans to phase out internal combustion engines entirely. This regulatory trajectory emphasizes the critical importance of advanced thermal efficiency measurement techniques as both compliance tools and development guides for the remaining lifecycle of V4 and other internal combustion engines.

The integration of thermal efficiency measurements with onboard diagnostics (OBD) systems represents another regulatory trend, enabling continuous monitoring of emissions performance throughout a vehicle's operational life rather than just during certification testing. This evolution requires more robust and durable measurement approaches that can maintain accuracy over extended periods.

Cost-Benefit Analysis of Efficiency Improvements

Improving the thermal efficiency of V4 engines represents a significant investment for manufacturers, necessitating a thorough cost-benefit analysis to determine the economic viability of various efficiency enhancement strategies. Initial implementation costs for advanced thermal efficiency improvements typically range from $500,000 to $3 million, depending on the complexity of the technology and scale of production.

Material upgrades, such as ceramic coatings for combustion chambers and high-temperature alloys for critical components, constitute approximately 15-20% of the total investment. These materials significantly reduce heat loss but add $80-150 per engine unit in production costs. Advanced electronic control systems for optimizing combustion timing and fuel delivery represent another 25-30% of implementation expenses, though these systems can improve efficiency by 3-7%.

Operational savings present the most compelling economic argument for efficiency improvements. A 5% increase in thermal efficiency can reduce fuel consumption by approximately 7-10%, translating to lifetime savings of $2,000-3,500 per vehicle for consumers. For fleet operators, this represents potential savings of $150,000-250,000 over a five-year period for every 100 vehicles.

Maintenance cost reductions also factor significantly into the benefit calculation. Enhanced thermal efficiency typically correlates with reduced engine wear, extending service intervals by 15-20% and engine lifespan by up to 30%. This translates to maintenance savings of approximately $1,200-1,800 over the vehicle's operational life.

Environmental compliance represents another critical economic consideration. As emissions regulations tighten globally, manufacturers face potential penalties ranging from $50-200 per gram of CO2/km exceeded. Improved thermal efficiency directly reduces emissions, potentially saving manufacturers millions in compliance costs and avoiding sales restrictions in regulated markets.

Return on investment timelines vary significantly based on technology type. Simple improvements like optimized valve timing may achieve ROI within 18-24 months, while complex technologies like integrated waste heat recovery systems typically require 3-5 years to reach profitability. Market analysis indicates that premium vehicle segments can absorb a 3-5% price increase for improved efficiency, while mass-market segments remain more price-sensitive, tolerating only 1-2% increases despite demonstrated long-term savings.

The most economically viable efficiency improvements currently include variable compression ratio systems, integrated thermal management, and advanced combustion control algorithms, all demonstrating ROI periods under three years when implemented at scale.

Material upgrades, such as ceramic coatings for combustion chambers and high-temperature alloys for critical components, constitute approximately 15-20% of the total investment. These materials significantly reduce heat loss but add $80-150 per engine unit in production costs. Advanced electronic control systems for optimizing combustion timing and fuel delivery represent another 25-30% of implementation expenses, though these systems can improve efficiency by 3-7%.

Operational savings present the most compelling economic argument for efficiency improvements. A 5% increase in thermal efficiency can reduce fuel consumption by approximately 7-10%, translating to lifetime savings of $2,000-3,500 per vehicle for consumers. For fleet operators, this represents potential savings of $150,000-250,000 over a five-year period for every 100 vehicles.

Maintenance cost reductions also factor significantly into the benefit calculation. Enhanced thermal efficiency typically correlates with reduced engine wear, extending service intervals by 15-20% and engine lifespan by up to 30%. This translates to maintenance savings of approximately $1,200-1,800 over the vehicle's operational life.

Environmental compliance represents another critical economic consideration. As emissions regulations tighten globally, manufacturers face potential penalties ranging from $50-200 per gram of CO2/km exceeded. Improved thermal efficiency directly reduces emissions, potentially saving manufacturers millions in compliance costs and avoiding sales restrictions in regulated markets.

Return on investment timelines vary significantly based on technology type. Simple improvements like optimized valve timing may achieve ROI within 18-24 months, while complex technologies like integrated waste heat recovery systems typically require 3-5 years to reach profitability. Market analysis indicates that premium vehicle segments can absorb a 3-5% price increase for improved efficiency, while mass-market segments remain more price-sensitive, tolerating only 1-2% increases despite demonstrated long-term savings.

The most economically viable efficiency improvements currently include variable compression ratio systems, integrated thermal management, and advanced combustion control algorithms, all demonstrating ROI periods under three years when implemented at scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!