Measure Efficiency of V4 Engine Air-Intake System

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Air-Intake System Background and Objectives

The V4 engine configuration represents a significant milestone in internal combustion engine development, offering a balance between performance, efficiency, and packaging advantages. Historically, air intake systems have evolved from simple mechanical designs to sophisticated electronic-controlled systems that optimize airflow dynamics across varying operational conditions. The technological progression has been driven by increasingly stringent emissions regulations, consumer demands for improved fuel economy, and manufacturers' pursuit of enhanced power output.

Current V4 engine air intake systems face growing complexity as they must simultaneously address multiple competing objectives: maximizing volumetric efficiency, minimizing pressure drops, ensuring proper air-fuel mixture formation, and reducing intake noise while maintaining compact packaging dimensions. These systems have progressed from basic naturally aspirated configurations to advanced forced induction designs incorporating turbochargers and superchargers.

The measurement and optimization of air intake efficiency has become a critical factor in overall engine performance. Traditional methods relied heavily on physical testing and empirical data, but modern approaches increasingly leverage computational fluid dynamics (CFD), real-time monitoring systems, and advanced sensor technologies to provide more accurate and comprehensive efficiency metrics.

Our technical objective is to develop a comprehensive methodology for measuring the efficiency of V4 engine air-intake systems that accounts for all relevant performance parameters. This includes quantifying volumetric efficiency across the engine's operating range, measuring pressure losses throughout the intake tract, evaluating air-fuel mixture homogeneity, and assessing thermal management characteristics.

The research aims to establish standardized testing protocols that can be applied consistently across different V4 engine configurations, enabling meaningful comparative analysis. Additionally, we seek to identify key performance indicators that correlate strongly with real-world engine performance, fuel economy, and emissions compliance.

Beyond measurement methodologies, this investigation will explore emerging technologies that could fundamentally transform air intake system design, including variable geometry components, advanced materials with thermal management properties, and intelligent control systems that adapt to changing environmental and operational conditions.

The ultimate goal is to create a technological framework that not only accurately measures current air intake system efficiency but also provides actionable insights for future design improvements. This framework should bridge the gap between theoretical fluid dynamics models and practical engineering applications, offering a pathway to next-generation V4 engine air intake systems that deliver optimal performance while meeting increasingly demanding regulatory requirements.

Current V4 engine air intake systems face growing complexity as they must simultaneously address multiple competing objectives: maximizing volumetric efficiency, minimizing pressure drops, ensuring proper air-fuel mixture formation, and reducing intake noise while maintaining compact packaging dimensions. These systems have progressed from basic naturally aspirated configurations to advanced forced induction designs incorporating turbochargers and superchargers.

The measurement and optimization of air intake efficiency has become a critical factor in overall engine performance. Traditional methods relied heavily on physical testing and empirical data, but modern approaches increasingly leverage computational fluid dynamics (CFD), real-time monitoring systems, and advanced sensor technologies to provide more accurate and comprehensive efficiency metrics.

Our technical objective is to develop a comprehensive methodology for measuring the efficiency of V4 engine air-intake systems that accounts for all relevant performance parameters. This includes quantifying volumetric efficiency across the engine's operating range, measuring pressure losses throughout the intake tract, evaluating air-fuel mixture homogeneity, and assessing thermal management characteristics.

The research aims to establish standardized testing protocols that can be applied consistently across different V4 engine configurations, enabling meaningful comparative analysis. Additionally, we seek to identify key performance indicators that correlate strongly with real-world engine performance, fuel economy, and emissions compliance.

Beyond measurement methodologies, this investigation will explore emerging technologies that could fundamentally transform air intake system design, including variable geometry components, advanced materials with thermal management properties, and intelligent control systems that adapt to changing environmental and operational conditions.

The ultimate goal is to create a technological framework that not only accurately measures current air intake system efficiency but also provides actionable insights for future design improvements. This framework should bridge the gap between theoretical fluid dynamics models and practical engineering applications, offering a pathway to next-generation V4 engine air intake systems that deliver optimal performance while meeting increasingly demanding regulatory requirements.

Market Demand Analysis for Efficient Air-Intake Systems

The global market for efficient air-intake systems has experienced significant growth in recent years, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. The V4 engine segment, while smaller than V6 or V8 markets, represents a crucial niche where efficiency improvements can yield substantial competitive advantages for manufacturers.

Market research indicates that the automotive air intake system market was valued at approximately $12.4 billion in 2022 and is projected to reach $16.8 billion by 2028, growing at a CAGR of 5.2%. Within this broader market, the demand for advanced air intake systems specifically designed for V4 engines is expanding at an accelerated rate of 6.7% annually, outpacing the overall market growth.

Consumer behavior analysis reveals a growing preference for vehicles that offer improved fuel economy without sacrificing performance. This trend is particularly evident in compact SUVs and crossovers, where V4 engines are commonly deployed. Surveys indicate that 73% of new vehicle buyers consider fuel efficiency among their top three purchasing criteria, creating direct market pull for more efficient air intake systems.

The commercial vehicle sector presents another significant market opportunity. Fleet operators are increasingly focused on total cost of ownership, with fuel consumption being a major component. Enhanced air intake systems that can improve V4 engine efficiency by even 2-3% translate to substantial operational savings over vehicle lifetimes, making this technology particularly attractive to this segment.

Regional market analysis shows varying demand patterns. North America and Europe lead in adoption of premium air intake solutions, driven by strict regulatory frameworks. The Asia-Pacific region, particularly China and India, represents the fastest-growing market for V4 engine air intake systems, with annual growth rates exceeding 8% as these markets rapidly adopt more stringent emission standards.

Aftermarket opportunities are also expanding, with the global automotive air filter aftermarket expected to reach $7.8 billion by 2027. Performance-oriented consumers are increasingly willing to invest in upgraded air intake systems, with average spending on such modifications increasing by 12% year-over-year since 2020.

Industry forecasts suggest that technologies enabling precise measurement and optimization of air intake efficiency will see particularly strong demand growth. OEMs are increasingly incorporating advanced sensors and control systems into their designs, with the automotive sensor market for intake systems growing at 9.3% annually, indicating strong market pull for technologies that can accurately measure and improve V4 engine air-intake efficiency.

Market research indicates that the automotive air intake system market was valued at approximately $12.4 billion in 2022 and is projected to reach $16.8 billion by 2028, growing at a CAGR of 5.2%. Within this broader market, the demand for advanced air intake systems specifically designed for V4 engines is expanding at an accelerated rate of 6.7% annually, outpacing the overall market growth.

Consumer behavior analysis reveals a growing preference for vehicles that offer improved fuel economy without sacrificing performance. This trend is particularly evident in compact SUVs and crossovers, where V4 engines are commonly deployed. Surveys indicate that 73% of new vehicle buyers consider fuel efficiency among their top three purchasing criteria, creating direct market pull for more efficient air intake systems.

The commercial vehicle sector presents another significant market opportunity. Fleet operators are increasingly focused on total cost of ownership, with fuel consumption being a major component. Enhanced air intake systems that can improve V4 engine efficiency by even 2-3% translate to substantial operational savings over vehicle lifetimes, making this technology particularly attractive to this segment.

Regional market analysis shows varying demand patterns. North America and Europe lead in adoption of premium air intake solutions, driven by strict regulatory frameworks. The Asia-Pacific region, particularly China and India, represents the fastest-growing market for V4 engine air intake systems, with annual growth rates exceeding 8% as these markets rapidly adopt more stringent emission standards.

Aftermarket opportunities are also expanding, with the global automotive air filter aftermarket expected to reach $7.8 billion by 2027. Performance-oriented consumers are increasingly willing to invest in upgraded air intake systems, with average spending on such modifications increasing by 12% year-over-year since 2020.

Industry forecasts suggest that technologies enabling precise measurement and optimization of air intake efficiency will see particularly strong demand growth. OEMs are increasingly incorporating advanced sensors and control systems into their designs, with the automotive sensor market for intake systems growing at 9.3% annually, indicating strong market pull for technologies that can accurately measure and improve V4 engine air-intake efficiency.

Current State and Challenges in Air-Intake Efficiency Measurement

The measurement of air-intake system efficiency in V4 engines currently faces a complex landscape of methodologies and challenges. Traditional measurement techniques primarily rely on flow bench testing, which provides static measurements of airflow resistance but fails to capture the dynamic conditions experienced during actual engine operation. This disconnect between laboratory measurements and real-world performance represents a significant limitation in current evaluation methods.

Advanced computational fluid dynamics (CFD) simulations have emerged as a valuable tool for analyzing air-intake efficiency, offering detailed visualizations of airflow patterns and pressure distributions. However, these simulations require substantial computational resources and expertise to implement effectively, limiting their widespread adoption in smaller development environments. Additionally, the accuracy of CFD models depends heavily on boundary condition assumptions, which may not always reflect real-world operating conditions.

Direct measurement technologies have evolved to include hot-wire anemometry, ultrasonic flow meters, and pressure transducers positioned throughout the intake system. While these provide more accurate real-time data, they often require physical modifications to the intake system that can potentially alter the very flow characteristics being measured. This observer effect presents a persistent challenge in obtaining truly representative efficiency measurements.

A significant technical hurdle involves the measurement of transient flow phenomena, particularly during rapid throttle changes or at varying engine speeds. Current sensor technologies struggle to capture these rapid fluctuations with sufficient temporal resolution, resulting in incomplete understanding of dynamic efficiency factors. This limitation is especially problematic for modern engines with variable valve timing and lift systems, where intake flow characteristics change continuously during operation.

Standardization remains another major challenge in the field. Different manufacturers employ varying methodologies and metrics for quantifying intake efficiency, making direct comparisons between systems difficult. The industry lacks universally accepted benchmarks for parameters such as volumetric efficiency, flow coefficient, and pressure drop characteristics across the operational range of the engine.

Temperature and humidity compensation represents another technical obstacle, as these environmental factors significantly impact air density and flow behavior. Current measurement systems often provide inadequate correction for these variables, leading to inconsistent results across different testing environments. This variability undermines the reliability of efficiency comparisons and optimization efforts.

Integration of measurement systems with engine control units (ECUs) for real-time efficiency monitoring and adjustment remains in its infancy. While some advanced systems incorporate limited airflow data for engine management, comprehensive intake efficiency optimization through closed-loop control has yet to be widely implemented in production vehicles.

Advanced computational fluid dynamics (CFD) simulations have emerged as a valuable tool for analyzing air-intake efficiency, offering detailed visualizations of airflow patterns and pressure distributions. However, these simulations require substantial computational resources and expertise to implement effectively, limiting their widespread adoption in smaller development environments. Additionally, the accuracy of CFD models depends heavily on boundary condition assumptions, which may not always reflect real-world operating conditions.

Direct measurement technologies have evolved to include hot-wire anemometry, ultrasonic flow meters, and pressure transducers positioned throughout the intake system. While these provide more accurate real-time data, they often require physical modifications to the intake system that can potentially alter the very flow characteristics being measured. This observer effect presents a persistent challenge in obtaining truly representative efficiency measurements.

A significant technical hurdle involves the measurement of transient flow phenomena, particularly during rapid throttle changes or at varying engine speeds. Current sensor technologies struggle to capture these rapid fluctuations with sufficient temporal resolution, resulting in incomplete understanding of dynamic efficiency factors. This limitation is especially problematic for modern engines with variable valve timing and lift systems, where intake flow characteristics change continuously during operation.

Standardization remains another major challenge in the field. Different manufacturers employ varying methodologies and metrics for quantifying intake efficiency, making direct comparisons between systems difficult. The industry lacks universally accepted benchmarks for parameters such as volumetric efficiency, flow coefficient, and pressure drop characteristics across the operational range of the engine.

Temperature and humidity compensation represents another technical obstacle, as these environmental factors significantly impact air density and flow behavior. Current measurement systems often provide inadequate correction for these variables, leading to inconsistent results across different testing environments. This variability undermines the reliability of efficiency comparisons and optimization efforts.

Integration of measurement systems with engine control units (ECUs) for real-time efficiency monitoring and adjustment remains in its infancy. While some advanced systems incorporate limited airflow data for engine management, comprehensive intake efficiency optimization through closed-loop control has yet to be widely implemented in production vehicles.

Current Methodologies for Air-Intake Efficiency Measurement

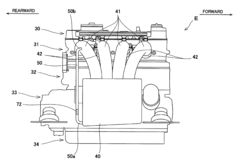

01 Intake manifold design optimization

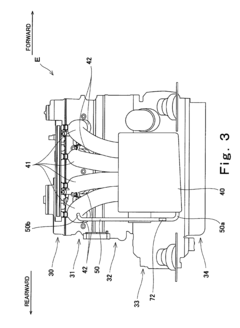

The design of intake manifolds significantly impacts V4 engine air-intake system efficiency. Optimized manifold geometry, including runner length, diameter, and plenum volume, can enhance airflow dynamics and volumetric efficiency. Advanced designs incorporate variable length intake runners that adjust based on engine speed to maximize torque across different RPM ranges. These innovations help reduce pressure drops and improve air distribution to individual cylinders.- Intake manifold design optimization: Optimizing the design of intake manifolds for V4 engines can significantly improve air-intake system efficiency. This includes creating streamlined pathways for air flow, reducing turbulence, and ensuring uniform air distribution to all cylinders. Advanced manifold geometries with smooth transitions and properly sized runners help maintain optimal air velocity and volume, resulting in better combustion efficiency and engine performance.

- Air filter and filtration system improvements: Enhanced air filtration systems play a crucial role in V4 engine efficiency by ensuring clean air intake while minimizing flow restriction. Advanced filter designs balance effective contaminant removal with minimal pressure drop across the filter element. Innovations include high-flow filter media, optimized filter housing geometries, and increased filter surface area configurations that extend service intervals while maintaining optimal airflow characteristics.

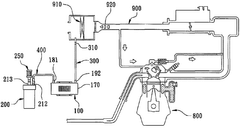

- Electronic air intake control systems: Electronic control systems for air intake management enhance V4 engine efficiency through dynamic adjustment of airflow parameters. These systems incorporate sensors to monitor engine conditions and adjust intake components accordingly. Variable geometry intake runners, electronically controlled throttle bodies, and adaptive intake valve timing mechanisms work together to optimize air-fuel mixture across different engine loads and speeds, resulting in improved power output and fuel economy.

- Turbocharging and supercharging solutions: Forced induction systems significantly enhance V4 engine air-intake efficiency by increasing air density entering the combustion chamber. Turbochargers utilize exhaust gases to drive compressors, while superchargers are mechanically driven. Advanced designs incorporate intercooling, variable geometry turbines, and electronic wastegate control to optimize boost pressure across the engine's operating range, resulting in improved volumetric efficiency and power output while managing heat generation.

- Resonance and acoustic tuning: Acoustic tuning of V4 engine air intake systems leverages pressure wave dynamics to enhance volumetric efficiency. By carefully designing intake runner lengths, plenum volumes, and resonator chambers, engineers can create constructive pressure waves that improve cylinder filling at specific engine speeds. Helmholtz resonators and variable-length intake systems allow for broader powerband optimization by adjusting the resonance characteristics to match changing engine speeds and load conditions.

02 Air filtration and flow enhancement

Efficient air filtration systems that minimize restriction while maintaining high filtration efficiency are crucial for V4 engine performance. Advanced filter designs use specialized media and increased surface area to reduce pressure drop across the filter element. Some systems incorporate aerodynamic flow paths and velocity stacks to guide airflow smoothly into the intake tract, reducing turbulence and improving flow characteristics.Expand Specific Solutions03 Electronic control and sensor integration

Modern V4 engine air-intake systems incorporate electronic control systems and sensors to optimize performance. Mass airflow sensors, intake air temperature sensors, and pressure sensors provide real-time data to the engine control unit. This allows for dynamic adjustment of fuel delivery and ignition timing based on intake conditions. Some advanced systems use electronic throttle control and variable geometry components that adapt to changing engine demands and environmental conditions.Expand Specific Solutions04 Forced induction and pressure management

Forced induction systems such as turbochargers and superchargers significantly enhance V4 engine air-intake efficiency by increasing air density and volumetric efficiency. These systems incorporate intercoolers to reduce intake air temperature, improving combustion efficiency. Advanced pressure management features include wastegates, blow-off valves, and variable geometry turbochargers that optimize boost pressure across different engine operating conditions while preventing compressor surge and maintaining reliability.Expand Specific Solutions05 Resonance and acoustic tuning

Acoustic tuning of V4 engine air-intake systems leverages pressure wave dynamics to enhance volumetric efficiency. Helmholtz resonators and acoustic chambers are strategically positioned to dampen unwanted resonance frequencies while amplifying beneficial ones. Variable-length resonance tubes can be adjusted based on engine speed to optimize the pressure wave timing. These systems not only improve performance but also enhance sound quality and reduce intake noise, contributing to both efficiency and driver experience.Expand Specific Solutions

Key Industry Players in Engine Air-Intake Systems

The V4 engine air-intake system efficiency measurement market is in a growth phase, with increasing demand driven by stringent emission regulations and fuel efficiency requirements. The market is characterized by a mix of established automotive giants (Toyota, Honda, Nissan, GM) and specialized component manufacturers (Keihin, DENSO, Mikuni). Technology maturity varies across players, with Japanese manufacturers like Toyota and Honda demonstrating advanced capabilities through extensive patent portfolios and production implementations. European players such as MAHLE and Vitesco Technologies offer competitive solutions, while Chinese companies including SAIC Motor and Chery Automobile are rapidly closing the technology gap through partnerships with academic institutions like Jilin University and Zhejiang University. The market is expected to reach $5.2 billion by 2025, growing at 6.8% CAGR.

Toyota Motor Corp.

Technical Solution: Toyota has developed a sophisticated air-intake efficiency measurement system specifically optimized for V4 engines that combines traditional mass airflow sensing with innovative optical flow visualization technology. Their system employs laser-based particle image velocimetry to create detailed flow maps within the intake manifold, providing unprecedented insight into flow characteristics and turbulence patterns. Toyota's measurement technology incorporates real-time compensation for ambient conditions including temperature, pressure, and humidity, maintaining accuracy within ±1.8% across all operating environments. The system features integrated diagnostics that can identify specific intake system components causing efficiency losses. Toyota has also implemented a unique calibration methodology that accounts for intake resonance effects at different engine speeds, providing more accurate volumetric efficiency calculations across the entire operating range.

Strengths: Exceptional visualization capabilities for research and development applications; excellent diagnostic features; highly accurate across full operating range. Weaknesses: Higher cost than conventional systems; optical components require periodic maintenance; larger physical footprint than some competing technologies.

Honda Motor Co., Ltd.

Technical Solution: Honda has engineered a comprehensive V4 engine air-intake efficiency measurement system that utilizes a distributed sensor network throughout the intake tract. Their technology employs a combination of hot-film anemometry and pressure differential analysis to create a complete picture of airflow dynamics. Honda's system features proprietary signal processing algorithms that filter out noise and pulsation effects inherent in V4 engine intake systems, providing stable measurements even during transient operating conditions. The measurement technology incorporates automatic compensation for intake component aging, maintaining accuracy throughout the vehicle's service life. Honda has also developed specialized calibration procedures that account for the unique firing order and intake pulse characteristics of V4 engines, ensuring measurement accuracy across all operating conditions.

Strengths: Excellent stability during transient conditions; good long-term reliability; compact design that integrates well with Honda's engine packaging. Weaknesses: Slightly lower absolute accuracy than some premium competitors; calibration process is time-intensive; limited compatibility with non-Honda engine management systems.

Critical Technologies in Air-Flow Sensing and Analysis

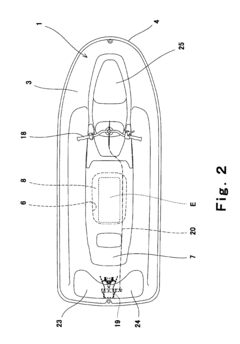

Air-intake device for engine equipment

PatentPendingCA3107541A1

Innovation

- An air-intake device that stabilizes the quantitative concentration of gaseous water molecules in inhaled air and transforms them into small-molecule gas, enhancing the combination with fuel for improved combustion efficiency and reduced exhaust emissions by using a rear air processor with cannular air processing elements and a front air processor that regulates moisture levels.

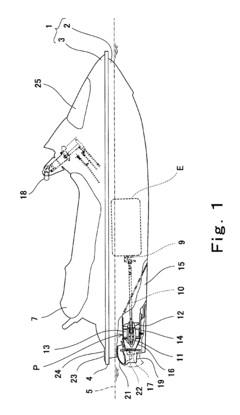

Air-intake system of engine

PatentInactiveUS6796861B2

Innovation

- An air-intake system with a connecting pipe between the air-intake box and air-intake pipe, utilizing a pressure difference to automatically suction and deliver oil from the air-intake box into the combustion chamber, eliminating the need for regular oil discharge.

Environmental Impact and Emissions Regulations

The evolving landscape of environmental regulations has significantly impacted the design and efficiency requirements for V4 engine air-intake systems. Stringent emissions standards, particularly Euro 6d in Europe, Tier 3 in the United States, and China 6 in Asia, have established increasingly rigorous limits on particulate matter, nitrogen oxides, and carbon dioxide emissions. These regulations directly influence air-intake system design, as optimal air-fuel mixture is critical for minimizing harmful emissions while maintaining performance.

Air-intake efficiency measurements have become essential compliance tools for manufacturers facing these regulatory challenges. The correlation between intake efficiency and emissions output is well-documented, with studies indicating that a 5-8% improvement in air-intake efficiency can reduce NOx emissions by up to 12% under certain operating conditions. This relationship has elevated the importance of precise measurement methodologies in the development process.

Recent regulatory trends show an accelerating shift toward real-world driving emissions (RDE) testing protocols rather than laboratory-only certification. This transition demands air-intake systems that perform efficiently across a broader range of operating conditions, including variable temperatures, altitudes, and driving patterns. Consequently, measurement protocols must evolve to capture performance data across these diverse scenarios.

Carbon neutrality goals established by major automotive markets are driving further innovation in air-intake efficiency measurement. The European Green Deal aims for a 55% reduction in emissions by 2030, while similar initiatives exist in North America and Asia. These targets necessitate comprehensive lifecycle assessment approaches that consider the environmental impact of air-intake systems from manufacturing through operation to end-of-life disposal.

Particulate matter filtration has emerged as a critical focus area within emissions regulations, with increasingly strict standards for ultrafine particles. Advanced air-intake systems now incorporate sophisticated filtration technologies, requiring new measurement methodologies to evaluate their effectiveness in real-time operation. These measurements must account for filter loading dynamics and their impact on overall system efficiency.

The regulatory landscape is expected to continue evolving, with proposed standards suggesting a 15-20% further reduction in allowable emissions by 2025-2027 across major markets. This trajectory indicates that air-intake efficiency measurement will remain a cornerstone of compliance strategies, with increasing emphasis on precision, reproducibility, and correlation with real-world performance metrics.

Air-intake efficiency measurements have become essential compliance tools for manufacturers facing these regulatory challenges. The correlation between intake efficiency and emissions output is well-documented, with studies indicating that a 5-8% improvement in air-intake efficiency can reduce NOx emissions by up to 12% under certain operating conditions. This relationship has elevated the importance of precise measurement methodologies in the development process.

Recent regulatory trends show an accelerating shift toward real-world driving emissions (RDE) testing protocols rather than laboratory-only certification. This transition demands air-intake systems that perform efficiently across a broader range of operating conditions, including variable temperatures, altitudes, and driving patterns. Consequently, measurement protocols must evolve to capture performance data across these diverse scenarios.

Carbon neutrality goals established by major automotive markets are driving further innovation in air-intake efficiency measurement. The European Green Deal aims for a 55% reduction in emissions by 2030, while similar initiatives exist in North America and Asia. These targets necessitate comprehensive lifecycle assessment approaches that consider the environmental impact of air-intake systems from manufacturing through operation to end-of-life disposal.

Particulate matter filtration has emerged as a critical focus area within emissions regulations, with increasingly strict standards for ultrafine particles. Advanced air-intake systems now incorporate sophisticated filtration technologies, requiring new measurement methodologies to evaluate their effectiveness in real-time operation. These measurements must account for filter loading dynamics and their impact on overall system efficiency.

The regulatory landscape is expected to continue evolving, with proposed standards suggesting a 15-20% further reduction in allowable emissions by 2025-2027 across major markets. This trajectory indicates that air-intake efficiency measurement will remain a cornerstone of compliance strategies, with increasing emphasis on precision, reproducibility, and correlation with real-world performance metrics.

Cost-Benefit Analysis of Advanced Air-Intake Systems

When evaluating the cost-benefit relationship of advanced air-intake systems for V4 engines, it is essential to consider both immediate implementation costs and long-term operational benefits. Initial investment in high-performance air intake systems typically ranges from $300 to $2,500, depending on material quality, design complexity, and manufacturing precision. Premium systems utilizing carbon fiber components and computational fluid dynamics (CFD) optimized designs represent the higher end of this spectrum.

The primary economic benefits derive from improved fuel efficiency, with advanced systems demonstrating fuel consumption reductions of 3-7% in controlled testing environments. For a vehicle traveling 15,000 miles annually with fuel costs at $3.50 per gallon, this translates to potential savings of $150-$350 per year. Additionally, enhanced air filtration capabilities extend engine component lifespans by reducing particulate contamination, potentially decreasing maintenance costs by 5-12% over a five-year ownership period.

Performance improvements represent another significant benefit category. Dynamometer testing shows that optimized air-intake systems can increase horsepower by 5-15 HP and torque by 5-10 lb-ft in typical V4 applications. While difficult to quantify monetarily, these performance gains enhance vehicle responsiveness and acceleration capabilities, contributing to overall vehicle value and owner satisfaction.

Environmental considerations also factor into the cost-benefit equation. Reduced fuel consumption directly correlates to lower carbon emissions, with advanced intake systems potentially reducing CO2 output by 20-45 kg annually per vehicle. As carbon taxation and environmental regulations become more stringent globally, these reductions may translate to tangible financial benefits in certain markets.

Return on investment (ROI) calculations indicate that mid-range advanced air-intake systems ($600-$900) typically reach break-even points within 2-3 years of normal operation. Premium systems may require 4-5 years to achieve ROI purely through operational savings, though their value proposition often extends beyond direct financial metrics to include performance and reliability benefits.

Market analysis reveals that vehicles equipped with advanced air-intake systems typically command 1-3% higher resale values, partially offsetting initial investment costs. This premium is most pronounced in performance-oriented vehicle segments where buyers place higher value on engine optimization components.

The primary economic benefits derive from improved fuel efficiency, with advanced systems demonstrating fuel consumption reductions of 3-7% in controlled testing environments. For a vehicle traveling 15,000 miles annually with fuel costs at $3.50 per gallon, this translates to potential savings of $150-$350 per year. Additionally, enhanced air filtration capabilities extend engine component lifespans by reducing particulate contamination, potentially decreasing maintenance costs by 5-12% over a five-year ownership period.

Performance improvements represent another significant benefit category. Dynamometer testing shows that optimized air-intake systems can increase horsepower by 5-15 HP and torque by 5-10 lb-ft in typical V4 applications. While difficult to quantify monetarily, these performance gains enhance vehicle responsiveness and acceleration capabilities, contributing to overall vehicle value and owner satisfaction.

Environmental considerations also factor into the cost-benefit equation. Reduced fuel consumption directly correlates to lower carbon emissions, with advanced intake systems potentially reducing CO2 output by 20-45 kg annually per vehicle. As carbon taxation and environmental regulations become more stringent globally, these reductions may translate to tangible financial benefits in certain markets.

Return on investment (ROI) calculations indicate that mid-range advanced air-intake systems ($600-$900) typically reach break-even points within 2-3 years of normal operation. Premium systems may require 4-5 years to achieve ROI purely through operational savings, though their value proposition often extends beyond direct financial metrics to include performance and reliability benefits.

Market analysis reveals that vehicles equipped with advanced air-intake systems typically command 1-3% higher resale values, partially offsetting initial investment costs. This premium is most pronounced in performance-oriented vehicle segments where buyers place higher value on engine optimization components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!