Measuring Impact of E85 Fuel on V4 Engine Efficiency

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

E85 Fuel and V4 Engine Technology Background

E85 fuel represents a significant development in alternative fuel technology, consisting of a blend of 85% ethanol and 15% gasoline. This high-ethanol fuel emerged in the early 2000s as part of global efforts to reduce dependency on fossil fuels and decrease greenhouse gas emissions. The evolution of E85 has been closely tied to agricultural policies, particularly in regions with substantial corn production, as corn remains the primary feedstock for ethanol production in many countries.

The V4 engine configuration, characterized by four cylinders arranged in a "V" formation, has evolved considerably since its introduction in the early 20th century. Modern V4 engines are valued for their compact design, balanced operation, and versatility across various vehicle classes. The technology has seen significant advancements in materials science, combustion efficiency, and electronic control systems over the past decades.

The intersection of E85 fuel and V4 engine technology represents a complex technical domain with unique characteristics and challenges. E85's higher octane rating (typically 100-105 compared to 87-93 for regular gasoline) offers potential performance benefits, particularly in terms of resistance to engine knock and potential for higher compression ratios. However, its lower energy density (approximately 27% less than gasoline) presents efficiency challenges that require specific engine optimizations.

Historical development of V4 engines compatible with E85 has followed several technological waves. Early adaptations focused primarily on material compatibility issues, addressing ethanol's corrosive properties. The second wave centered on fuel delivery systems, with innovations in fuel injectors designed to handle the different flow characteristics of ethanol-rich fuels. The most recent developments have concentrated on advanced engine control units (ECUs) capable of real-time adjustments to ignition timing, air-fuel ratios, and other parameters based on fuel composition.

Current technical trends indicate growing interest in specifically optimizing V4 engines for E85 operation rather than simply making them "flex-fuel compatible." This includes research into variable compression ratio systems, advanced thermal management, and cold-start optimization technologies to address E85's unique properties. Additionally, the integration of direct injection technology with E85 fuels in V4 configurations has shown promising results in maximizing the benefits of ethanol's cooling effect and high octane rating.

The measurement of E85's impact on V4 engine efficiency represents a critical research area, as it directly influences the practical viability of this fuel alternative in various applications and markets. Understanding this relationship requires sophisticated testing methodologies that account for the complex interplay between fuel properties and engine design characteristics.

The V4 engine configuration, characterized by four cylinders arranged in a "V" formation, has evolved considerably since its introduction in the early 20th century. Modern V4 engines are valued for their compact design, balanced operation, and versatility across various vehicle classes. The technology has seen significant advancements in materials science, combustion efficiency, and electronic control systems over the past decades.

The intersection of E85 fuel and V4 engine technology represents a complex technical domain with unique characteristics and challenges. E85's higher octane rating (typically 100-105 compared to 87-93 for regular gasoline) offers potential performance benefits, particularly in terms of resistance to engine knock and potential for higher compression ratios. However, its lower energy density (approximately 27% less than gasoline) presents efficiency challenges that require specific engine optimizations.

Historical development of V4 engines compatible with E85 has followed several technological waves. Early adaptations focused primarily on material compatibility issues, addressing ethanol's corrosive properties. The second wave centered on fuel delivery systems, with innovations in fuel injectors designed to handle the different flow characteristics of ethanol-rich fuels. The most recent developments have concentrated on advanced engine control units (ECUs) capable of real-time adjustments to ignition timing, air-fuel ratios, and other parameters based on fuel composition.

Current technical trends indicate growing interest in specifically optimizing V4 engines for E85 operation rather than simply making them "flex-fuel compatible." This includes research into variable compression ratio systems, advanced thermal management, and cold-start optimization technologies to address E85's unique properties. Additionally, the integration of direct injection technology with E85 fuels in V4 configurations has shown promising results in maximizing the benefits of ethanol's cooling effect and high octane rating.

The measurement of E85's impact on V4 engine efficiency represents a critical research area, as it directly influences the practical viability of this fuel alternative in various applications and markets. Understanding this relationship requires sophisticated testing methodologies that account for the complex interplay between fuel properties and engine design characteristics.

Market Analysis for E85 Fuel Adoption

The E85 fuel market has experienced significant growth over the past decade, driven primarily by environmental concerns and the push for renewable energy sources. Current market data indicates that E85 consumption in the United States reached approximately 700 million gallons in 2022, representing about 0.5% of the total gasoline market. While this percentage remains relatively small, the compound annual growth rate of 8.3% since 2015 demonstrates increasing consumer interest and market potential.

Regional adoption patterns show considerable variation, with Midwestern states leading consumption due to proximity to corn production facilities. Minnesota, Illinois, and Iowa account for nearly 40% of all E85 fuel stations nationwide. This geographic concentration presents both challenges and opportunities for market expansion strategies.

Consumer demographics reveal that early adopters of E85 fuel tend to be environmentally conscious individuals with higher education levels and above-average income. Fleet operators, particularly government agencies and environmentally focused corporations, constitute another significant market segment, representing approximately 35% of total E85 consumption.

Price sensitivity analysis indicates that E85 adoption rates increase substantially when the price differential between conventional gasoline and E85 exceeds 20%. This price elasticity suggests that government subsidies and tax incentives play crucial roles in market development. Currently, federal tax credits provide $0.54 per gallon for ethanol blenders, significantly influencing market dynamics.

Infrastructure limitations remain a primary barrier to widespread adoption. With approximately 4,500 E85 fueling stations nationwide compared to over 150,000 conventional gasoline stations, accessibility concerns deter potential consumers. Investment in fueling infrastructure has been growing at 12% annually, but regional disparities persist.

Vehicle compatibility represents another market constraint. While flex-fuel vehicles (FFVs) capable of using E85 have been produced since the late 1990s, they constitute only about 8% of the current U.S. vehicle fleet. Major automotive manufacturers have reduced FFV model offerings in recent years, potentially limiting future market growth.

Competitive analysis reveals that E85 faces increasing competition from other alternative fuels and technologies, particularly electric vehicles. Market forecasts suggest that E85 will maintain its niche position, with projected market share reaching 2.3% of the transportation fuel market by 2030, contingent upon continued policy support and infrastructure development.

Regional adoption patterns show considerable variation, with Midwestern states leading consumption due to proximity to corn production facilities. Minnesota, Illinois, and Iowa account for nearly 40% of all E85 fuel stations nationwide. This geographic concentration presents both challenges and opportunities for market expansion strategies.

Consumer demographics reveal that early adopters of E85 fuel tend to be environmentally conscious individuals with higher education levels and above-average income. Fleet operators, particularly government agencies and environmentally focused corporations, constitute another significant market segment, representing approximately 35% of total E85 consumption.

Price sensitivity analysis indicates that E85 adoption rates increase substantially when the price differential between conventional gasoline and E85 exceeds 20%. This price elasticity suggests that government subsidies and tax incentives play crucial roles in market development. Currently, federal tax credits provide $0.54 per gallon for ethanol blenders, significantly influencing market dynamics.

Infrastructure limitations remain a primary barrier to widespread adoption. With approximately 4,500 E85 fueling stations nationwide compared to over 150,000 conventional gasoline stations, accessibility concerns deter potential consumers. Investment in fueling infrastructure has been growing at 12% annually, but regional disparities persist.

Vehicle compatibility represents another market constraint. While flex-fuel vehicles (FFVs) capable of using E85 have been produced since the late 1990s, they constitute only about 8% of the current U.S. vehicle fleet. Major automotive manufacturers have reduced FFV model offerings in recent years, potentially limiting future market growth.

Competitive analysis reveals that E85 faces increasing competition from other alternative fuels and technologies, particularly electric vehicles. Market forecasts suggest that E85 will maintain its niche position, with projected market share reaching 2.3% of the transportation fuel market by 2030, contingent upon continued policy support and infrastructure development.

Current Challenges in E85-V4 Engine Integration

The integration of E85 fuel with V4 engines presents several significant technical challenges that require comprehensive analysis and innovative solutions. One primary obstacle is the fuel system compatibility issue. E85's higher ethanol content (up to 85%) creates corrosion concerns for traditional fuel system components designed for gasoline. Materials such as certain rubbers, plastics, and metals used in fuel lines, injectors, and pumps may degrade prematurely when exposed to E85's more aggressive chemical properties, necessitating specialized materials engineering solutions.

Cold-start performance represents another major challenge, particularly in regions with colder climates. E85 has lower vapor pressure and higher latent heat of vaporization compared to conventional gasoline, making engine ignition difficult at low temperatures. This often requires V4 engines to incorporate sophisticated cold-start strategies, including modified ignition timing, increased fuel enrichment, or auxiliary heating systems to ensure reliable operation in sub-optimal conditions.

Fuel economy degradation is a persistent concern when adapting V4 engines to E85 fuel. The lower energy density of ethanol (approximately 33% less energy per volume than gasoline) necessitates increased fuel consumption to maintain equivalent power output. This creates a technical challenge in optimizing the engine's efficiency to minimize this performance gap while maintaining acceptable driving range between refueling.

Calibration complexity presents significant engineering hurdles. V4 engines require extensive recalibration of fuel injection parameters, ignition timing, and air-fuel ratios to accommodate E85's different combustion characteristics. The challenge is compounded by the variable ethanol content in commercial E85 (which can range from 51% to 83% ethanol), requiring sophisticated fuel composition sensing and adaptive control strategies to maintain optimal performance across varying fuel blends.

Emissions control systems face unique challenges with E85 implementation. While E85 generally produces lower carbon monoxide and hydrocarbon emissions, it can generate increased aldehyde emissions and potentially higher nitrogen oxide levels under certain operating conditions. Catalytic converter systems designed for gasoline-powered V4 engines may require modification to effectively manage these different emission profiles.

Infrastructure limitations further complicate E85-V4 engine integration. The limited availability of E85 fueling stations in many regions creates practical challenges for widespread adoption, influencing both consumer acceptance and manufacturer investment in E85-optimized V4 engine technologies. This market reality often necessitates flexible-fuel approaches rather than dedicated E85 optimization, creating additional technical compromises.

Cold-start performance represents another major challenge, particularly in regions with colder climates. E85 has lower vapor pressure and higher latent heat of vaporization compared to conventional gasoline, making engine ignition difficult at low temperatures. This often requires V4 engines to incorporate sophisticated cold-start strategies, including modified ignition timing, increased fuel enrichment, or auxiliary heating systems to ensure reliable operation in sub-optimal conditions.

Fuel economy degradation is a persistent concern when adapting V4 engines to E85 fuel. The lower energy density of ethanol (approximately 33% less energy per volume than gasoline) necessitates increased fuel consumption to maintain equivalent power output. This creates a technical challenge in optimizing the engine's efficiency to minimize this performance gap while maintaining acceptable driving range between refueling.

Calibration complexity presents significant engineering hurdles. V4 engines require extensive recalibration of fuel injection parameters, ignition timing, and air-fuel ratios to accommodate E85's different combustion characteristics. The challenge is compounded by the variable ethanol content in commercial E85 (which can range from 51% to 83% ethanol), requiring sophisticated fuel composition sensing and adaptive control strategies to maintain optimal performance across varying fuel blends.

Emissions control systems face unique challenges with E85 implementation. While E85 generally produces lower carbon monoxide and hydrocarbon emissions, it can generate increased aldehyde emissions and potentially higher nitrogen oxide levels under certain operating conditions. Catalytic converter systems designed for gasoline-powered V4 engines may require modification to effectively manage these different emission profiles.

Infrastructure limitations further complicate E85-V4 engine integration. The limited availability of E85 fueling stations in many regions creates practical challenges for widespread adoption, influencing both consumer acceptance and manufacturer investment in E85-optimized V4 engine technologies. This market reality often necessitates flexible-fuel approaches rather than dedicated E85 optimization, creating additional technical compromises.

Existing E85 Fuel System Solutions

01 Engine modifications for E85 fuel compatibility

Engines can be modified to optimize performance with E85 fuel, which has different combustion characteristics than traditional gasoline. These modifications include adjusting the compression ratio, modifying fuel injection systems, and redesigning combustion chambers to accommodate the higher oxygen content of ethanol. Such adaptations help maximize the efficiency of E85 fuel while minimizing emissions and maintaining engine durability.- Engine modifications for E85 compatibility: Engines require specific modifications to efficiently use E85 fuel due to its different properties compared to gasoline. These modifications include adjustments to fuel injection systems, changes to compression ratios, and alterations to ignition timing. By optimizing these components for E85's higher octane rating and different stoichiometric ratio, engines can achieve better combustion efficiency and performance while accommodating the fuel's unique characteristics.

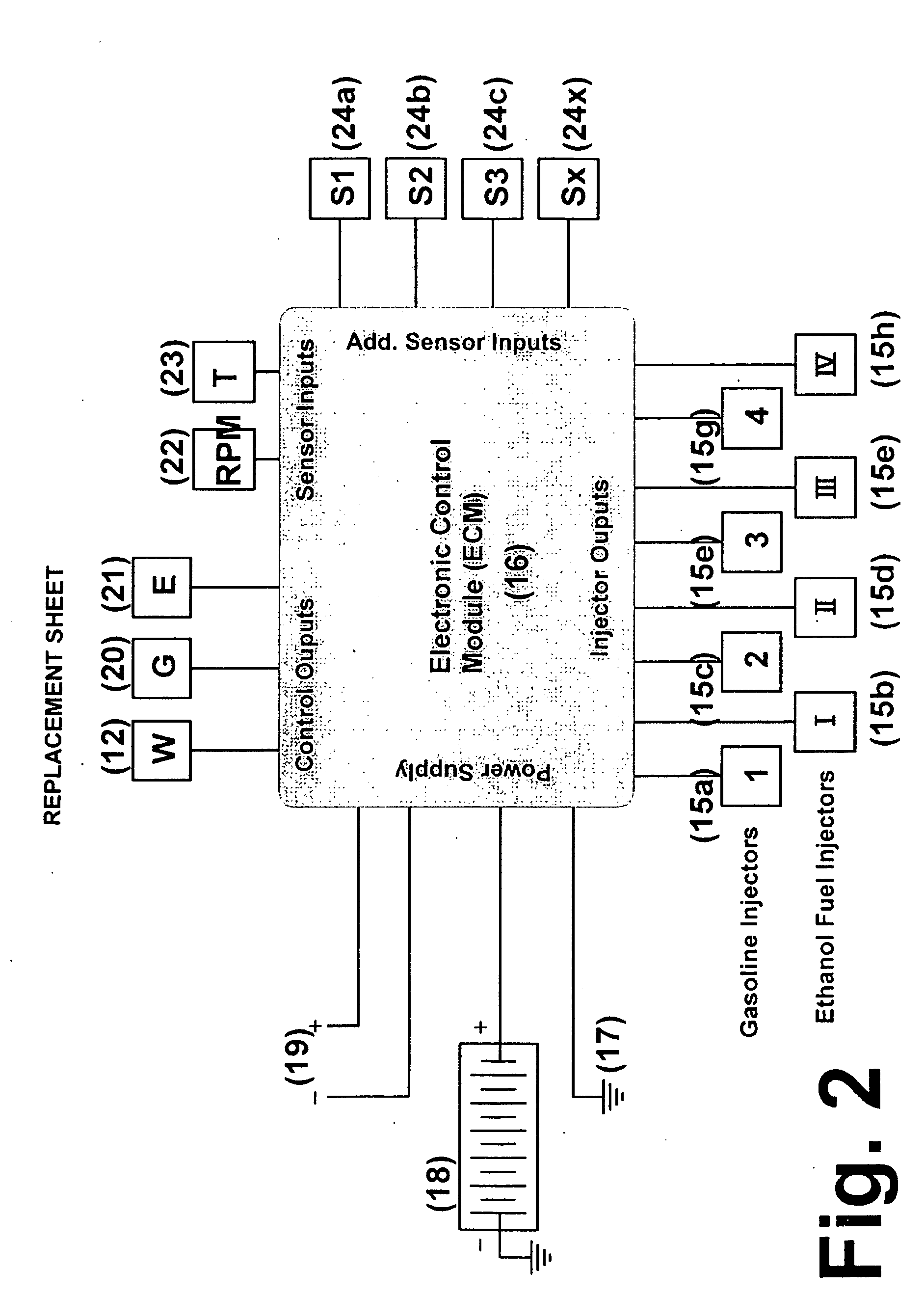

- Fuel management systems for E85: Advanced fuel management systems are essential for maximizing E85 engine efficiency. These systems include specialized sensors that detect ethanol content, electronic control units that adjust fuel delivery parameters, and adaptive algorithms that optimize air-fuel ratios. By precisely controlling the fuel mixture based on real-time operating conditions, these management systems can compensate for E85's lower energy density while taking advantage of its higher octane rating to improve overall engine performance.

- Cold start improvements for E85 engines: E85 fuel presents challenges for cold starting due to ethanol's lower vapor pressure at low temperatures. Innovations to address this issue include auxiliary heating systems, modified starting sequences, and specialized injector designs. These technologies ensure reliable ignition in cold conditions by enhancing fuel vaporization and providing richer fuel mixtures during startup, thereby improving the overall usability and efficiency of E85-powered engines across various climate conditions.

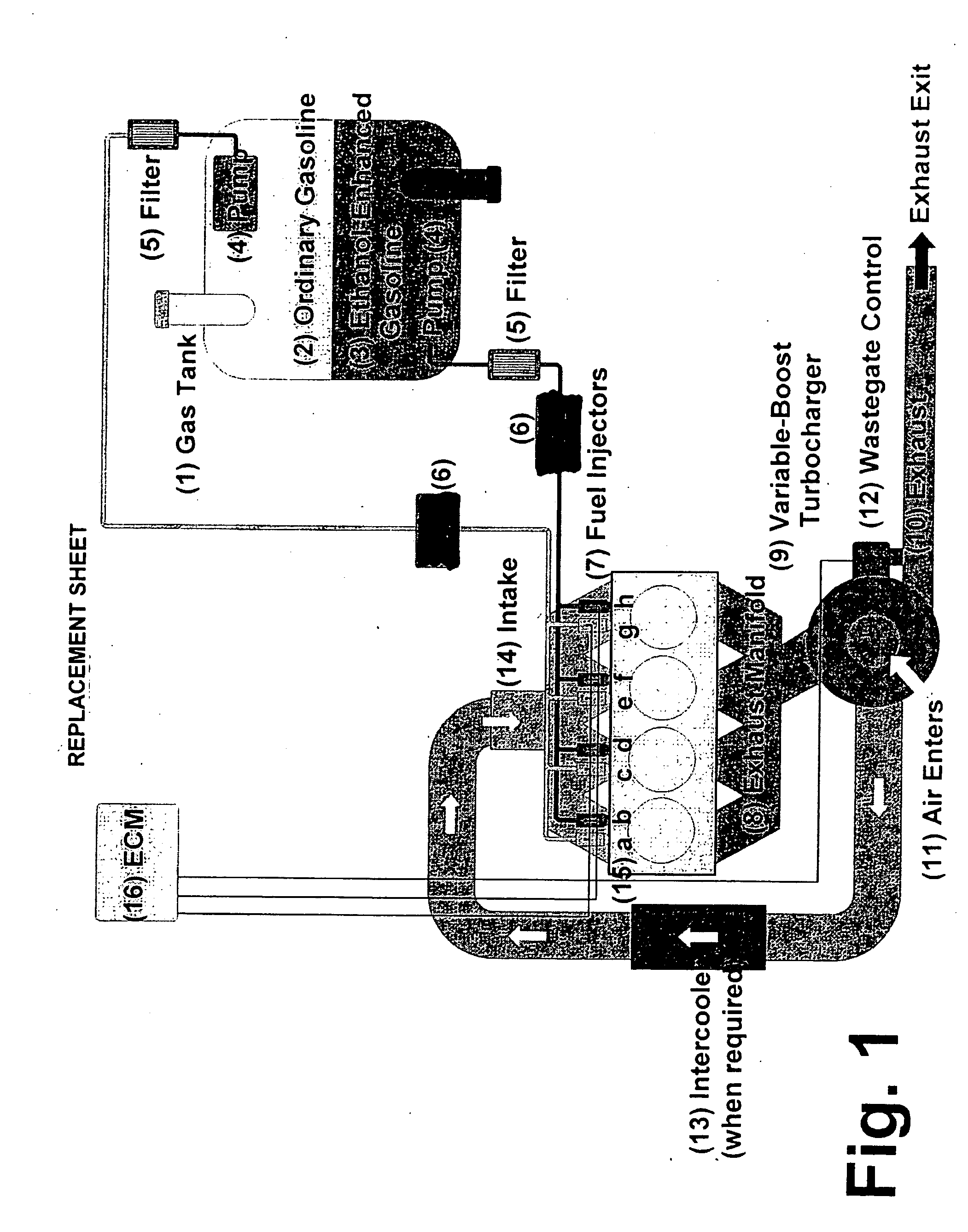

- Dual-fuel systems for optimized efficiency: Dual-fuel systems allow engines to operate on both conventional gasoline and E85, optimizing efficiency across different operating conditions. These systems incorporate flexible fuel sensors, switchable fuel maps, and adaptive control strategies that can seamlessly transition between fuel types. By leveraging the advantages of each fuel under appropriate conditions, dual-fuel systems maximize performance while minimizing emissions, offering a practical solution for varying fuel availability and driving requirements.

- Thermal management for E85 combustion: Effective thermal management is crucial for E85 engines due to ethanol's higher heat of vaporization and different combustion characteristics. Innovations in this area include redesigned cooling systems, heat recovery mechanisms, and temperature-optimized combustion chambers. These technologies help maintain ideal operating temperatures, prevent overheating, and improve combustion efficiency, resulting in better fuel economy and reduced emissions when using E85 fuel.

02 Fuel management systems for E85 efficiency

Advanced fuel management systems can be implemented to optimize E85 fuel consumption and engine performance. These systems include electronic control units that adjust fuel-air mixtures, ignition timing, and other parameters based on real-time data. By precisely controlling the combustion process, these management systems can compensate for the lower energy density of E85 fuel and improve overall engine efficiency.Expand Specific Solutions03 Dual-fuel systems for optimized E85 usage

Dual-fuel systems allow engines to operate on both conventional gasoline and E85 fuel, either separately or in blended ratios. These systems incorporate sensors to detect ethanol content and automatically adjust engine parameters accordingly. This flexibility enables optimal efficiency across various fuel compositions and driving conditions, maximizing the benefits of E85 while mitigating its limitations.Expand Specific Solutions04 Cold-start improvements for E85 engines

E85 fuel presents challenges for engine cold-starts due to ethanol's higher vaporization temperature. Innovations to address this issue include specialized heating elements for fuel systems, modified starter motors, and advanced ignition systems. These technologies ensure reliable cold-weather performance and maintain efficiency during the critical warm-up phase, which is particularly important for maximizing the overall efficiency of E85-powered engines.Expand Specific Solutions05 Turbocharging and supercharging for E85 applications

Forced induction systems like turbochargers and superchargers can be specially designed to leverage E85's higher octane rating and cooling properties. These systems compress intake air, allowing for increased power output and efficiency when using E85 fuel. The cooling effect of ethanol's higher heat of vaporization also reduces the risk of engine knock, enabling more aggressive boost pressures and ignition timing for improved performance and efficiency.Expand Specific Solutions

Key Manufacturers in E85 Compatible Engines

The E85 fuel impact on V4 engine efficiency market is in a growth phase, driven by increasing environmental regulations and alternative fuel adoption. The market size is expanding as automotive manufacturers invest in biofuel compatibility, with projected significant growth in the next decade. Major automotive players like GM, Ford, Toyota, and Nissan are leading technical innovation, while specialized companies such as Afton Chemical and Lubrizol focus on fuel additives to enhance E85 performance. Research institutions including Shanghai Dianji University and Beihang University contribute to technical advancements. The technology is approaching maturity with ongoing refinements in engine design, fuel systems, and emissions control to optimize V4 engine performance with E85 fuel.

GM Global Technology Operations LLC

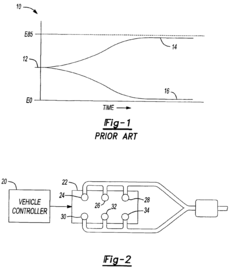

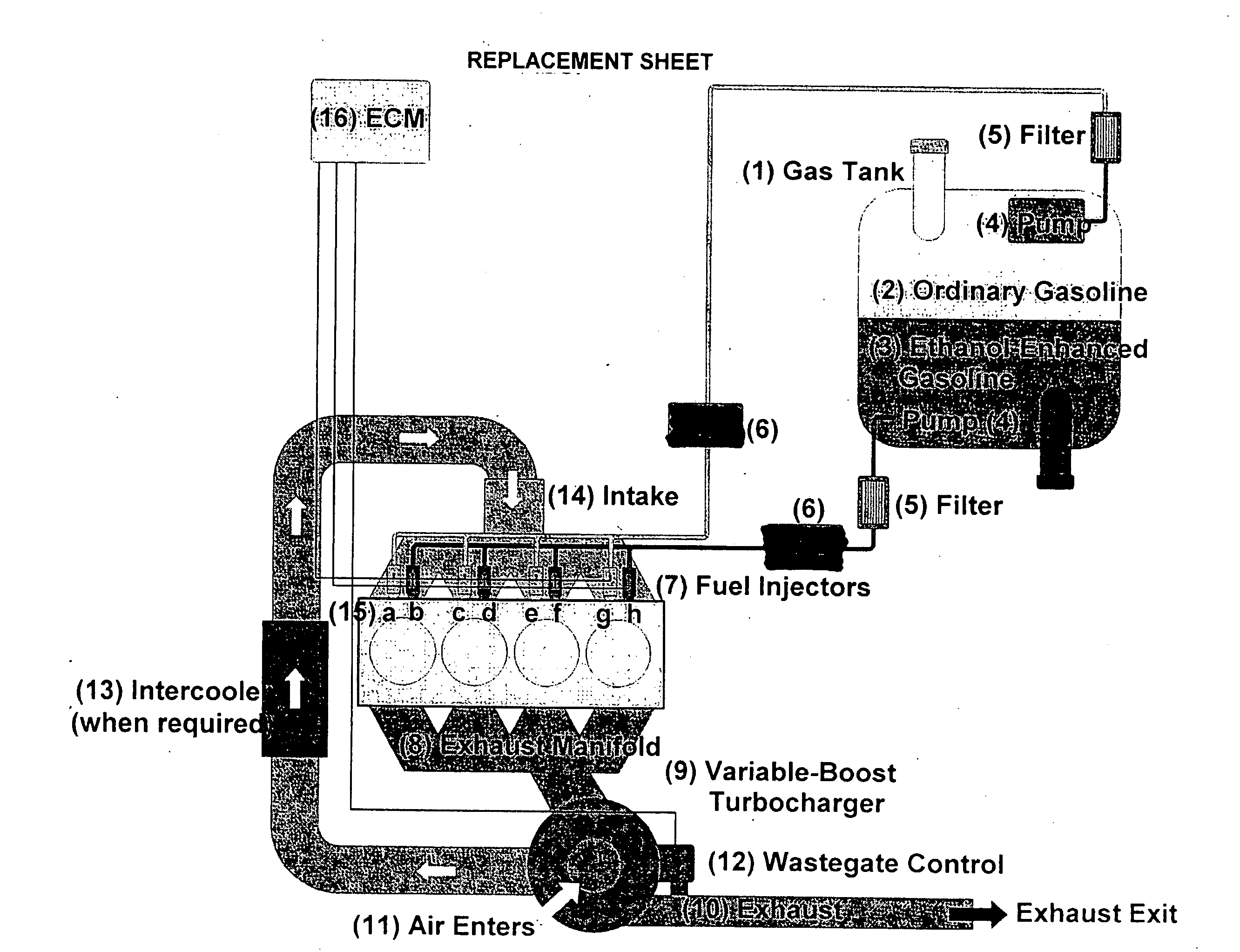

Technical Solution: GM has developed a comprehensive approach to measuring E85 impact on V4 engine efficiency through their FlexFuel technology. Their system employs advanced oxygen sensors and adaptive fuel mapping to optimize combustion parameters specifically for ethanol blends. GM's proprietary Engine Control Module (ECM) algorithms continuously adjust ignition timing, fuel injection duration, and air-fuel ratios based on real-time ethanol content detection. Their research has demonstrated that properly calibrated V4 engines can leverage E85's higher octane rating (typically 100-105 compared to gasoline's 87-93) to achieve improved thermal efficiency under certain operating conditions. GM has implemented specialized cold-start strategies to address E85's lower energy density and volatility challenges, including modified injection patterns and heating elements for cold climate operation. Their testing protocols incorporate both laboratory dynamometer measurements and real-world driving cycles to capture comprehensive efficiency metrics across various temperature ranges and load conditions.

Strengths: GM's adaptive control systems allow for optimized performance regardless of ethanol content, providing seamless operation across fuel blends. Their extensive real-world testing provides robust validation of laboratory findings. Weaknesses: The system complexity adds cost to vehicle manufacturing, and cold-start performance remains challenging in extreme cold conditions despite mitigation strategies.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered a multi-faceted approach to measuring and optimizing E85 impact on V4 engine efficiency through their EcoBoost platform. Their methodology incorporates direct injection technology specifically calibrated for ethanol blends, with spray pattern optimization to leverage E85's cooling effect during injection. Ford's research has focused on developing specialized combustion chamber designs that maximize E85's higher octane potential while minimizing the efficiency losses typically associated with ethanol's lower energy content. Their measurement system employs high-precision in-cylinder pressure transducers coupled with exhaust gas analysis to quantify combustion efficiency across various operating conditions. Ford has developed a patented ethanol content sensing system that provides real-time feedback to their powertrain control module, enabling dynamic adjustments to valve timing, compression ratios (in applicable engines), and boost pressure in turbocharged applications. Their testing protocol includes specialized cold-start evaluation procedures that account for E85's unique vaporization characteristics at low temperatures, with performance metrics tracked across multiple climate conditions.

Strengths: Ford's direct injection technology is particularly well-suited to capitalize on E85's cooling properties, allowing for higher compression ratios and improved thermal efficiency. Their real-time ethanol sensing provides precise control adaptations. Weaknesses: The system shows diminished fuel economy benefits in short-trip urban driving cycles, and the specialized injector designs require more frequent maintenance due to ethanol's different solvent properties.

Critical Innovations in Biofuel Combustion

Engine operation on an unknown ethanol fuel blend

PatentInactiveUS6851416B1

Innovation

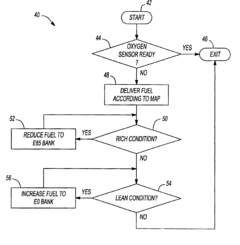

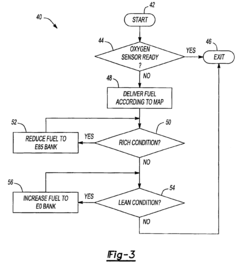

- The method involves controlling fuel delivery to two sets of engine cylinders using pre-defined fueling schemes based on E85 and E0 fuel curves, allowing the engine to operate until the oxygen sensor is functional, and adjusting fuel rates to correct abnormal oxygen levels detected by one or two oxygen sensors.

Power modulated, dual fuel, small displacement engine control system

PatentInactiveUS20090076705A1

Innovation

- A power-modulated dual-fuel engine control system that uses separate fuel injectors for primary gasoline and secondary ethanol or E-85 fuels, dynamically controlling intake boost pressures and fuel mixture ratios to optimize engine performance across varying load conditions, ensuring efficient power delivery and improved fuel economy.

Environmental Impact Assessment

The environmental implications of E85 fuel adoption in V4 engines represent a critical dimension of sustainable transportation development. When comparing E85 (a blend of 85% ethanol and 15% gasoline) with conventional petroleum fuels, significant differences emerge in greenhouse gas (GHG) emissions profiles. Research indicates that E85 can reduce lifecycle carbon dioxide emissions by approximately 20-30% compared to conventional gasoline, primarily due to the carbon sequestration that occurs during the growth phase of feedstock crops.

Air quality assessments demonstrate that E85 combustion in V4 engines produces substantially lower levels of carbon monoxide (CO) and particulate matter (PM). Studies conducted by the Environmental Protection Agency reveal CO reductions of up to 40% in properly calibrated V4 engines running on E85. However, nitrogen oxide (NOx) emissions present a more complex picture, with some testing scenarios showing marginal increases depending on engine calibration parameters and operating conditions.

The water footprint associated with E85 production represents a significant environmental consideration. Ethanol production from corn requires approximately 470-860 gallons of water per gallon of ethanol produced, creating potential stress on water resources in agricultural regions. This water-intensity factor must be weighed against the reduced water pollution risks from petroleum extraction and transportation incidents.

Land use change implications of expanded E85 adoption warrant careful analysis. The conversion of natural habitats to cropland for biofuel feedstock production can potentially offset carbon benefits through release of stored carbon and reduction of carbon sequestration capacity. Advanced lifecycle assessment models suggest that these indirect land use changes could reduce the net environmental benefits of E85 by 10-15% depending on production pathways and agricultural practices.

Soil health considerations reveal both positive and negative impacts. While corn rotation systems for ethanol production can contribute to soil erosion in certain regions, the implementation of sustainable agricultural practices such as cover cropping and conservation tillage can mitigate these effects. Research from agricultural extension services demonstrates that properly managed biofuel feedstock production can maintain or even enhance soil organic carbon levels.

Biodiversity impacts vary significantly based on production methods and locations. Studies from ecological research institutions highlight that large-scale monoculture production of corn for ethanol can reduce habitat diversity, while perennial feedstocks like switchgrass offer improved habitat value for native species. These biodiversity considerations must be integrated into comprehensive environmental impact assessments of E85 fuel systems for V4 engines.

Air quality assessments demonstrate that E85 combustion in V4 engines produces substantially lower levels of carbon monoxide (CO) and particulate matter (PM). Studies conducted by the Environmental Protection Agency reveal CO reductions of up to 40% in properly calibrated V4 engines running on E85. However, nitrogen oxide (NOx) emissions present a more complex picture, with some testing scenarios showing marginal increases depending on engine calibration parameters and operating conditions.

The water footprint associated with E85 production represents a significant environmental consideration. Ethanol production from corn requires approximately 470-860 gallons of water per gallon of ethanol produced, creating potential stress on water resources in agricultural regions. This water-intensity factor must be weighed against the reduced water pollution risks from petroleum extraction and transportation incidents.

Land use change implications of expanded E85 adoption warrant careful analysis. The conversion of natural habitats to cropland for biofuel feedstock production can potentially offset carbon benefits through release of stored carbon and reduction of carbon sequestration capacity. Advanced lifecycle assessment models suggest that these indirect land use changes could reduce the net environmental benefits of E85 by 10-15% depending on production pathways and agricultural practices.

Soil health considerations reveal both positive and negative impacts. While corn rotation systems for ethanol production can contribute to soil erosion in certain regions, the implementation of sustainable agricultural practices such as cover cropping and conservation tillage can mitigate these effects. Research from agricultural extension services demonstrates that properly managed biofuel feedstock production can maintain or even enhance soil organic carbon levels.

Biodiversity impacts vary significantly based on production methods and locations. Studies from ecological research institutions highlight that large-scale monoculture production of corn for ethanol can reduce habitat diversity, while perennial feedstocks like switchgrass offer improved habitat value for native species. These biodiversity considerations must be integrated into comprehensive environmental impact assessments of E85 fuel systems for V4 engines.

Economic Viability Analysis

The economic viability of E85 fuel implementation in V4 engines presents a complex cost-benefit equation that requires thorough analysis. Initial conversion costs for manufacturers to adapt V4 engines for E85 compatibility typically range between $1,500-3,000 per engine design, with additional production costs of $200-400 per unit. These investments must be evaluated against the long-term operational economics of E85 fuel usage.

Current market dynamics show E85 fuel prices averaging 15-30% lower than conventional gasoline, though this advantage is partially offset by E85's lower energy density, resulting in 20-30% reduced fuel economy. This relationship creates a break-even threshold dependent on regional fuel pricing variations and driving patterns. In high corn-producing regions where E85 prices are most competitive, the economic advantage becomes more pronounced.

Fleet operators with high mileage vehicles represent the demographic most likely to achieve positive return on investment, with potential fuel cost savings of $800-1,200 annually per vehicle under optimal conditions. However, these savings are highly sensitive to fluctuations in both petroleum and agricultural commodity markets, introducing an element of economic volatility.

Infrastructure considerations further impact economic viability, with E85 fueling station installation costs ranging from $25,000 for tank conversion to $200,000 for new installation. The limited distribution network in many regions creates additional "fuel search costs" for consumers, estimated at $120-240 annually in time and extra travel expenses.

Government incentives significantly alter the economic equation, with federal tax credits of up to $0.45 per gallon for blenders and various state-level incentives for both producers and consumers. These policy instruments can shift the break-even point substantially, though their inconsistent implementation and potential for policy changes create planning uncertainties for stakeholders.

Maintenance economics present mixed results, with some studies indicating 5-10% lower maintenance costs due to E85's higher octane and cleaner combustion characteristics, while others highlight potential issues with fuel system components requiring more frequent replacement, particularly in older engine designs not optimized for ethanol blends.

The total cost of ownership analysis reveals that economic viability is highly dependent on usage patterns, geographic location, and policy environment, with positive returns most likely for high-mileage applications in regions with strong ethanol production infrastructure and supportive policy frameworks.

Current market dynamics show E85 fuel prices averaging 15-30% lower than conventional gasoline, though this advantage is partially offset by E85's lower energy density, resulting in 20-30% reduced fuel economy. This relationship creates a break-even threshold dependent on regional fuel pricing variations and driving patterns. In high corn-producing regions where E85 prices are most competitive, the economic advantage becomes more pronounced.

Fleet operators with high mileage vehicles represent the demographic most likely to achieve positive return on investment, with potential fuel cost savings of $800-1,200 annually per vehicle under optimal conditions. However, these savings are highly sensitive to fluctuations in both petroleum and agricultural commodity markets, introducing an element of economic volatility.

Infrastructure considerations further impact economic viability, with E85 fueling station installation costs ranging from $25,000 for tank conversion to $200,000 for new installation. The limited distribution network in many regions creates additional "fuel search costs" for consumers, estimated at $120-240 annually in time and extra travel expenses.

Government incentives significantly alter the economic equation, with federal tax credits of up to $0.45 per gallon for blenders and various state-level incentives for both producers and consumers. These policy instruments can shift the break-even point substantially, though their inconsistent implementation and potential for policy changes create planning uncertainties for stakeholders.

Maintenance economics present mixed results, with some studies indicating 5-10% lower maintenance costs due to E85's higher octane and cleaner combustion characteristics, while others highlight potential issues with fuel system components requiring more frequent replacement, particularly in older engine designs not optimized for ethanol blends.

The total cost of ownership analysis reveals that economic viability is highly dependent on usage patterns, geographic location, and policy environment, with positive returns most likely for high-mileage applications in regions with strong ethanol production infrastructure and supportive policy frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!