How to Quantify V4 Engine Friction Using Tribology

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Friction Analysis Background and Objectives

Engine friction represents a significant challenge in automotive engineering, accounting for approximately 15-20% of total energy losses in internal combustion engines. The V4 engine configuration, with its unique arrangement of cylinders in a V-shape at 60-90 degree angles, presents specific tribological considerations that differ from inline or flat engine designs. Understanding and quantifying friction in these systems has evolved considerably since the early 20th century, with major advancements occurring in the 1970s through the introduction of computerized measurement systems.

The evolution of tribology as a discipline has provided increasingly sophisticated tools for analyzing surface interactions within engine components. Early friction studies relied primarily on mechanical dynamometers and basic thermal measurements, while contemporary approaches incorporate advanced sensors, real-time monitoring systems, and computational modeling. This progression has enabled more precise quantification of friction losses across different engine operating conditions.

Current technical objectives in V4 engine friction analysis focus on several key areas. Primary among these is the development of standardized measurement protocols that can accurately quantify friction across the piston assembly, valve train, crankshaft bearings, and auxiliary systems under various operating conditions. These protocols must account for temperature variations, lubricant properties, surface finishes, and material characteristics specific to V4 configurations.

Another critical objective involves establishing correlations between laboratory tribometer tests and actual engine performance. This translation between controlled experimental conditions and real-world operation remains challenging due to the complex interplay of variables in functioning engines. Researchers aim to develop scaling factors and transfer functions that can reliably bridge this gap.

The quantification of friction in V4 engines also seeks to separate and identify the contribution of different friction mechanisms, including boundary, mixed, and hydrodynamic lubrication regimes. Understanding the transition points between these regimes under varying engine speeds, loads, and temperatures is essential for developing targeted friction reduction strategies.

From an industry perspective, the ultimate goal extends beyond mere quantification to practical application. Engineers seek to leverage tribological insights to design components with optimized surface textures, coatings, and geometries that minimize friction while maintaining durability. Additionally, the development of next-generation lubricants specifically formulated for V4 engine characteristics represents a parallel objective in this technical domain.

The evolution of tribology as a discipline has provided increasingly sophisticated tools for analyzing surface interactions within engine components. Early friction studies relied primarily on mechanical dynamometers and basic thermal measurements, while contemporary approaches incorporate advanced sensors, real-time monitoring systems, and computational modeling. This progression has enabled more precise quantification of friction losses across different engine operating conditions.

Current technical objectives in V4 engine friction analysis focus on several key areas. Primary among these is the development of standardized measurement protocols that can accurately quantify friction across the piston assembly, valve train, crankshaft bearings, and auxiliary systems under various operating conditions. These protocols must account for temperature variations, lubricant properties, surface finishes, and material characteristics specific to V4 configurations.

Another critical objective involves establishing correlations between laboratory tribometer tests and actual engine performance. This translation between controlled experimental conditions and real-world operation remains challenging due to the complex interplay of variables in functioning engines. Researchers aim to develop scaling factors and transfer functions that can reliably bridge this gap.

The quantification of friction in V4 engines also seeks to separate and identify the contribution of different friction mechanisms, including boundary, mixed, and hydrodynamic lubrication regimes. Understanding the transition points between these regimes under varying engine speeds, loads, and temperatures is essential for developing targeted friction reduction strategies.

From an industry perspective, the ultimate goal extends beyond mere quantification to practical application. Engineers seek to leverage tribological insights to design components with optimized surface textures, coatings, and geometries that minimize friction while maintaining durability. Additionally, the development of next-generation lubricants specifically formulated for V4 engine characteristics represents a parallel objective in this technical domain.

Market Demand for Engine Friction Reduction

The global automotive industry is experiencing a significant shift towards more efficient and environmentally friendly vehicles, driving substantial market demand for engine friction reduction technologies. This demand is primarily fueled by increasingly stringent emissions regulations worldwide, with the European Union's Euro 7 standards, the United States' Corporate Average Fuel Economy (CAFE) standards, and China's China 6 emissions regulations all pushing manufacturers to reduce fuel consumption and emissions.

Engine friction accounts for approximately 15-20% of the total energy loss in internal combustion engines, making it a critical target for efficiency improvements. The V4 engine configuration, while less common than inline-four designs, presents unique tribological challenges and opportunities for friction reduction that have attracted growing interest from both manufacturers and researchers.

Market analysis indicates that the global automotive friction reduction technologies market is projected to grow at a compound annual growth rate of 8.2% through 2028, reaching a value of over $14 billion. This growth is particularly pronounced in regions with mature automotive industries such as North America, Europe, and parts of Asia, where manufacturers are investing heavily in research and development of advanced tribological solutions.

Consumer demand is also driving this market trend, with vehicle buyers increasingly prioritizing fuel efficiency as fuel prices continue to fluctuate globally. A recent industry survey revealed that 67% of new vehicle purchasers consider fuel economy as a "very important" factor in their buying decision, up from 48% just five years ago.

The commercial vehicle sector represents another significant market segment for engine friction reduction technologies. Fleet operators are particularly sensitive to operational costs, with fuel representing 30-40% of total ownership costs. Even marginal improvements in fuel efficiency through reduced engine friction can translate to substantial savings across large fleets, creating strong economic incentives for adoption.

Emerging markets present additional growth opportunities, as regions like India, Brazil, and Southeast Asia experience increasing vehicle ownership rates coupled with the implementation of more stringent emissions standards. These markets are expected to contribute significantly to the global demand for friction reduction technologies in the coming decade.

The aftermarket segment also shows promising growth potential, with retrofit solutions for friction reduction gaining popularity among cost-conscious consumers seeking to improve the efficiency of existing vehicles rather than purchasing new ones. This trend is particularly evident in markets with aging vehicle fleets.

Engine friction accounts for approximately 15-20% of the total energy loss in internal combustion engines, making it a critical target for efficiency improvements. The V4 engine configuration, while less common than inline-four designs, presents unique tribological challenges and opportunities for friction reduction that have attracted growing interest from both manufacturers and researchers.

Market analysis indicates that the global automotive friction reduction technologies market is projected to grow at a compound annual growth rate of 8.2% through 2028, reaching a value of over $14 billion. This growth is particularly pronounced in regions with mature automotive industries such as North America, Europe, and parts of Asia, where manufacturers are investing heavily in research and development of advanced tribological solutions.

Consumer demand is also driving this market trend, with vehicle buyers increasingly prioritizing fuel efficiency as fuel prices continue to fluctuate globally. A recent industry survey revealed that 67% of new vehicle purchasers consider fuel economy as a "very important" factor in their buying decision, up from 48% just five years ago.

The commercial vehicle sector represents another significant market segment for engine friction reduction technologies. Fleet operators are particularly sensitive to operational costs, with fuel representing 30-40% of total ownership costs. Even marginal improvements in fuel efficiency through reduced engine friction can translate to substantial savings across large fleets, creating strong economic incentives for adoption.

Emerging markets present additional growth opportunities, as regions like India, Brazil, and Southeast Asia experience increasing vehicle ownership rates coupled with the implementation of more stringent emissions standards. These markets are expected to contribute significantly to the global demand for friction reduction technologies in the coming decade.

The aftermarket segment also shows promising growth potential, with retrofit solutions for friction reduction gaining popularity among cost-conscious consumers seeking to improve the efficiency of existing vehicles rather than purchasing new ones. This trend is particularly evident in markets with aging vehicle fleets.

Current Tribological Measurement Challenges

The quantification of V4 engine friction using tribological methods faces several significant measurement challenges that impede accurate data collection and analysis. Current tribometers and measurement systems struggle with replicating the complex operating conditions found in actual V4 engines, including varying temperatures, pressures, and speeds that occur simultaneously during engine operation. This environmental complexity creates a substantial gap between laboratory measurements and real-world engine performance.

Traditional pin-on-disk and ball-on-disk tribometers provide valuable friction coefficient data but fail to simulate the dynamic loading conditions and lubricant behavior characteristic of engine environments. The reciprocating motion, combined with combustion-induced pressure variations in V4 engines, creates transient friction states that are difficult to capture with static measurement approaches.

Lubricant film thickness measurement presents another critical challenge. Current optical interferometry techniques work well for transparent materials but struggle with the metallic surfaces found in engine components. Alternative methods such as capacitance and ultrasonic techniques offer potential solutions but suffer from resolution limitations when measuring the nanometer-scale films that form between engine components during operation.

Temperature control and measurement during tribological testing represent persistent obstacles. Engine components experience significant temperature gradients and thermal cycling that affect material properties and lubricant behavior. Current testing apparatus often cannot accurately replicate these thermal conditions, leading to discrepancies between measured friction values and actual engine performance.

Real-time data acquisition poses additional challenges, particularly in capturing transient friction events that occur during combustion cycles. Most measurement systems operate at sampling rates insufficient to detect microsecond-level friction variations, resulting in averaged data that masks important friction phenomena. This limitation is particularly problematic for V4 engines where firing order creates complex friction patterns.

Surface topography characterization before and after tribological testing remains problematic. While advanced techniques like atomic force microscopy and white light interferometry provide nanometer-scale resolution, they typically require component removal and cannot measure wear progression during operation. This creates a disconnect between measured surface changes and the dynamic friction processes that caused them.

Standardization of measurement protocols represents perhaps the most significant challenge in the field. Different research groups and manufacturers employ varied testing conditions, making direct comparison of friction data difficult. The lack of universally accepted testing standards for engine friction measurement hampers technology transfer and slows industry-wide improvements in friction reduction strategies.

Traditional pin-on-disk and ball-on-disk tribometers provide valuable friction coefficient data but fail to simulate the dynamic loading conditions and lubricant behavior characteristic of engine environments. The reciprocating motion, combined with combustion-induced pressure variations in V4 engines, creates transient friction states that are difficult to capture with static measurement approaches.

Lubricant film thickness measurement presents another critical challenge. Current optical interferometry techniques work well for transparent materials but struggle with the metallic surfaces found in engine components. Alternative methods such as capacitance and ultrasonic techniques offer potential solutions but suffer from resolution limitations when measuring the nanometer-scale films that form between engine components during operation.

Temperature control and measurement during tribological testing represent persistent obstacles. Engine components experience significant temperature gradients and thermal cycling that affect material properties and lubricant behavior. Current testing apparatus often cannot accurately replicate these thermal conditions, leading to discrepancies between measured friction values and actual engine performance.

Real-time data acquisition poses additional challenges, particularly in capturing transient friction events that occur during combustion cycles. Most measurement systems operate at sampling rates insufficient to detect microsecond-level friction variations, resulting in averaged data that masks important friction phenomena. This limitation is particularly problematic for V4 engines where firing order creates complex friction patterns.

Surface topography characterization before and after tribological testing remains problematic. While advanced techniques like atomic force microscopy and white light interferometry provide nanometer-scale resolution, they typically require component removal and cannot measure wear progression during operation. This creates a disconnect between measured surface changes and the dynamic friction processes that caused them.

Standardization of measurement protocols represents perhaps the most significant challenge in the field. Different research groups and manufacturers employ varied testing conditions, making direct comparison of friction data difficult. The lack of universally accepted testing standards for engine friction measurement hampers technology transfer and slows industry-wide improvements in friction reduction strategies.

Current Methodologies for V4 Engine Friction Measurement

01 Friction reduction coatings for V4 engine components

Various coating technologies can be applied to V4 engine components to reduce friction between moving parts. These coatings include diamond-like carbon (DLC) films, molybdenum disulfide, and other low-friction materials that create a smooth surface on engine components. By applying these specialized coatings to critical engine parts such as pistons, cylinder walls, and valve train components, the overall friction within the V4 engine can be significantly reduced, leading to improved fuel efficiency and extended engine life.- Friction reduction coatings for V4 engine components: Various coating technologies can be applied to V4 engine components to reduce friction between moving parts. These coatings include specialized materials such as diamond-like carbon (DLC), molybdenum disulfide, and other low-friction materials that create a barrier between metal surfaces. These coatings can be applied to pistons, cylinder walls, valve components, and other critical engine parts to minimize friction, reduce wear, and improve overall engine efficiency and performance.

- Lubricant formulations for V4 engine friction reduction: Advanced lubricant formulations specifically designed for V4 engines can significantly reduce friction between moving components. These lubricants contain friction modifiers, anti-wear additives, and viscosity improvers that create a more effective oil film between metal surfaces. The specialized formulations help maintain optimal oil pressure and viscosity across various operating temperatures and conditions, resulting in reduced mechanical losses, improved fuel efficiency, and extended engine life.

- Engine component design optimization for friction reduction: Innovative design modifications to V4 engine components can minimize friction and improve efficiency. These design optimizations include changes to piston ring geometry, crankshaft bearing surfaces, valve train components, and cylinder wall texturing. By reducing contact areas, optimizing surface finishes, and improving oil retention characteristics, these design enhancements decrease friction between moving parts, resulting in improved power output, reduced fuel consumption, and lower emissions.

- Electronic control systems for friction management: Advanced electronic control systems can actively manage and reduce friction in V4 engines. These systems utilize sensors to monitor engine operating conditions and adjust parameters such as valve timing, fuel injection, and oil pressure to minimize friction losses. By optimizing engine operation based on real-time data, these control systems can reduce friction during cold starts, high-load conditions, and other operating scenarios, resulting in improved efficiency and reduced wear across the engine's operating range.

- Thermal management solutions for friction reduction: Effective thermal management systems can significantly reduce friction in V4 engines by maintaining optimal operating temperatures. These solutions include advanced cooling systems, strategic oil cooling pathways, and temperature-responsive components that help regulate heat distribution throughout the engine. By preventing localized overheating and maintaining consistent operating temperatures, these thermal management approaches minimize oil viscosity variations and thermal expansion issues that can increase friction between engine components.

02 Lubricant formulations for V4 engine friction reduction

Advanced lubricant formulations specifically designed for V4 engines can substantially reduce internal friction. These lubricants contain friction modifiers, anti-wear additives, and viscosity improvers that maintain optimal performance across various operating temperatures and conditions. The specialized formulations create a more effective oil film between moving parts, reducing metal-to-metal contact and minimizing energy losses due to friction, which ultimately improves engine efficiency and reduces wear on critical components.Expand Specific Solutions03 Engine component design optimization for friction reduction

Innovative design modifications to V4 engine components can significantly reduce friction. These design optimizations include lightweight pistons with reduced skirt area, roller bearings for camshafts, reduced contact area on bearing surfaces, and optimized valve train geometries. By redesigning critical components to minimize contact areas and incorporate rolling elements instead of sliding surfaces where possible, the overall friction within the V4 engine can be substantially reduced, leading to improved performance and fuel economy.Expand Specific Solutions04 Electronic control systems for friction management

Advanced electronic control systems can actively manage and reduce friction in V4 engines. These systems utilize sensors to monitor engine conditions and adjust parameters such as valve timing, cylinder deactivation, and oil pressure to minimize friction losses under various operating conditions. By implementing intelligent control algorithms that optimize engine operation in real-time, these systems can significantly reduce friction-related energy losses, particularly during cold starts and partial load conditions, resulting in improved fuel efficiency and reduced emissions.Expand Specific Solutions05 Thermal management techniques for friction reduction

Effective thermal management systems can help reduce friction in V4 engines by maintaining optimal operating temperatures. These techniques include precision cooling systems that target specific engine components, advanced thermostat designs, and thermal barrier coatings. By ensuring that engine components reach their optimal operating temperatures quickly and maintaining consistent temperatures throughout the engine, these systems help reduce oil viscosity variations and thermal expansion issues that can increase friction, particularly during cold starts and varying load conditions.Expand Specific Solutions

Leading Players in Engine Tribology Research

The V4 engine friction quantification market is in a growth phase, with increasing demand for fuel-efficient engines driving research in tribology applications. The market is characterized by a mix of established automotive manufacturers (Ford, GM, Bosch, Dongfeng, Geely) and specialized research entities (Southwest Research Institute, Anton Paar). Technical maturity varies significantly across players, with traditional OEMs like Bosch and Ford demonstrating advanced capabilities through extensive patent portfolios, while academic institutions (National Taiwan University, University of Minho) contribute fundamental research. Specialized companies such as ExxonMobil and Solvay are advancing lubricant technologies to reduce friction, while tier-one suppliers like JTEKT and Brembo focus on component-level optimization. The competitive landscape reflects a collaborative ecosystem where automotive manufacturers partner with research institutions and specialty chemical companies to achieve incremental improvements in engine efficiency.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced tribological measurement systems specifically for V4 engine friction quantification. Their approach combines high-precision sensors with real-time data acquisition to measure friction coefficients at critical engine interfaces. The company utilizes specialized tribometers that simulate actual engine operating conditions, including temperature variations (20-150°C), different lubricant formulations, and varying loads (50-500N). Their methodology incorporates surface texture analysis with 3D profilometry to correlate surface finish parameters with friction performance. Bosch's system can detect friction changes as small as 0.01N·m across the entire engine operating range, enabling engineers to identify specific components contributing to energy losses. The data is processed through proprietary algorithms that separate different friction mechanisms (boundary, mixed, and hydrodynamic lubrication regimes).

Strengths: Exceptional measurement precision with industry-leading sensor technology; comprehensive testing capabilities across all engine operating conditions; integrated with manufacturing quality control systems. Weaknesses: High implementation costs; requires specialized training for operators; system calibration is time-intensive.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered a comprehensive tribological approach to quantify V4 engine friction through their Powertrain Friction Reduction (PFR) system. This technology employs floating liner techniques that directly measure friction forces between piston rings and cylinder walls during actual engine operation. Their method incorporates piezoelectric force transducers strategically positioned around the cylinder liner to capture instantaneous friction forces with crank angle resolution of 0.1 degrees. Ford's system simultaneously monitors oil film thickness using capacitance probes with nanometer-level precision, correlating lubrication conditions with friction events. The company has developed specialized test protocols that simulate various driving cycles, enabling engineers to identify friction hotspots under real-world conditions. Their data analysis platform integrates machine learning algorithms to distinguish between different friction mechanisms and predict long-term wear patterns based on short-duration tests.

Strengths: Direct measurement of friction forces during actual engine operation; excellent correlation with real-world driving conditions; integrated with Ford's broader powertrain development ecosystem. Weaknesses: System installation requires significant engine modification; sensitive to thermal expansion effects; higher measurement uncertainty at extreme operating conditions.

Key Tribological Innovations for Friction Quantification

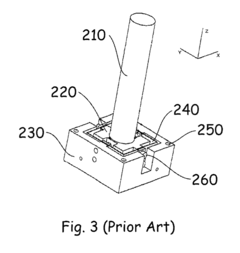

Tribological test rig by using IC engine

PatentUndeterminedIN202221024096A

Innovation

- A system utilizing an IC engine driven by a speed-controlled DC/AC electric motor with force and speed sensors, data acquisition, and microcontroller processing to measure coefficient of friction and wear between piston cylinders under variable speed conditions, allowing observation of lubricant effects with different materials and blends.

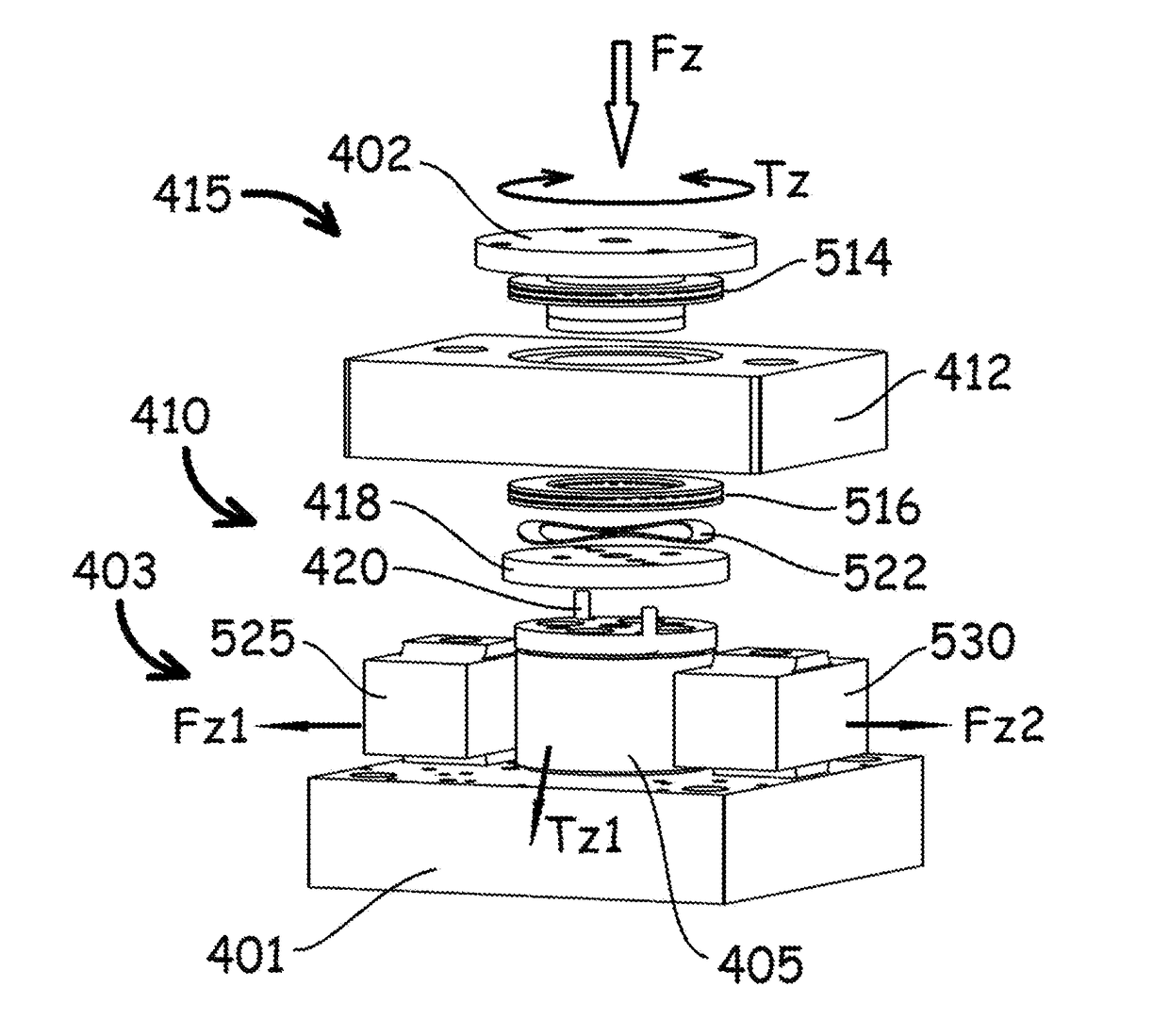

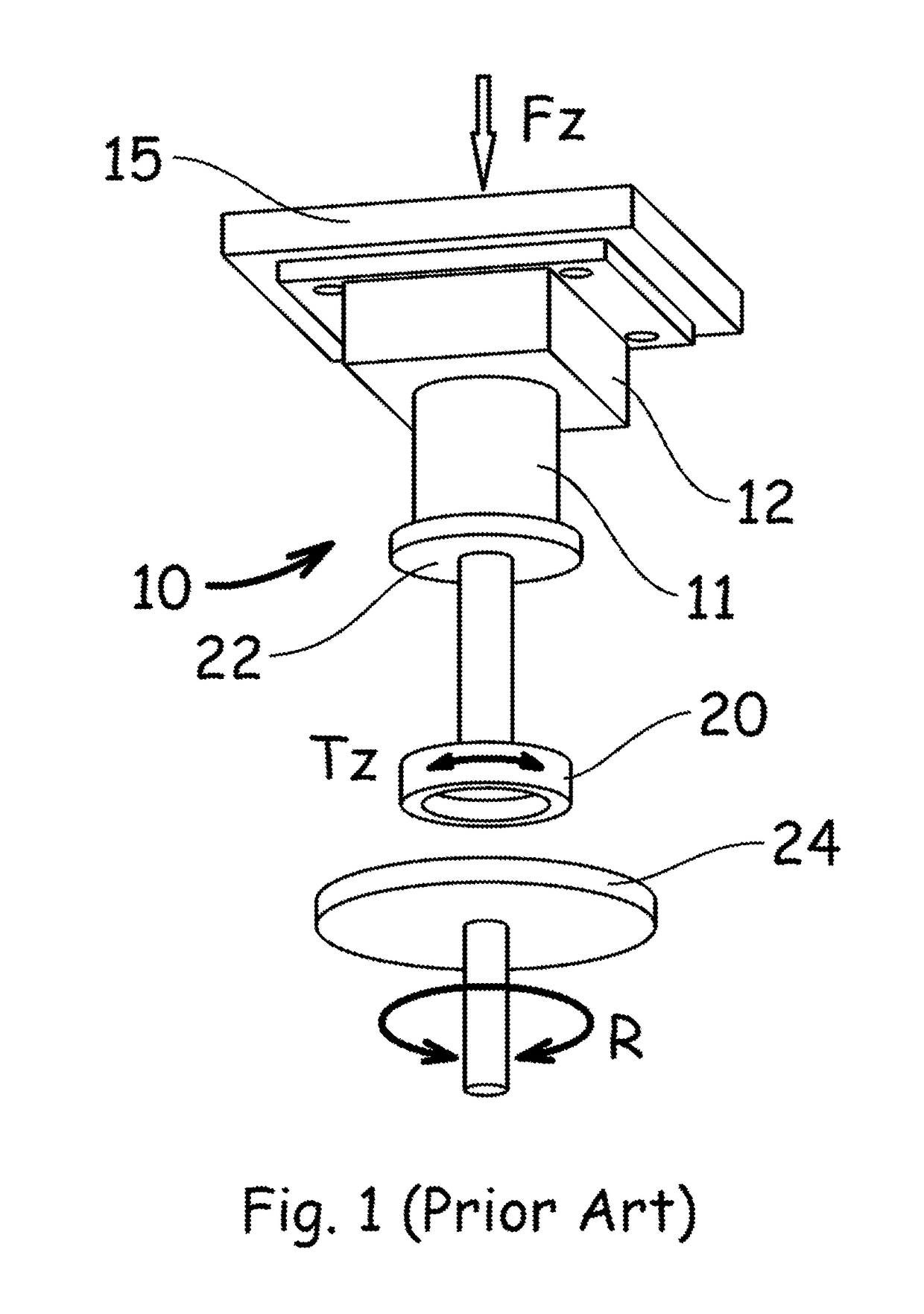

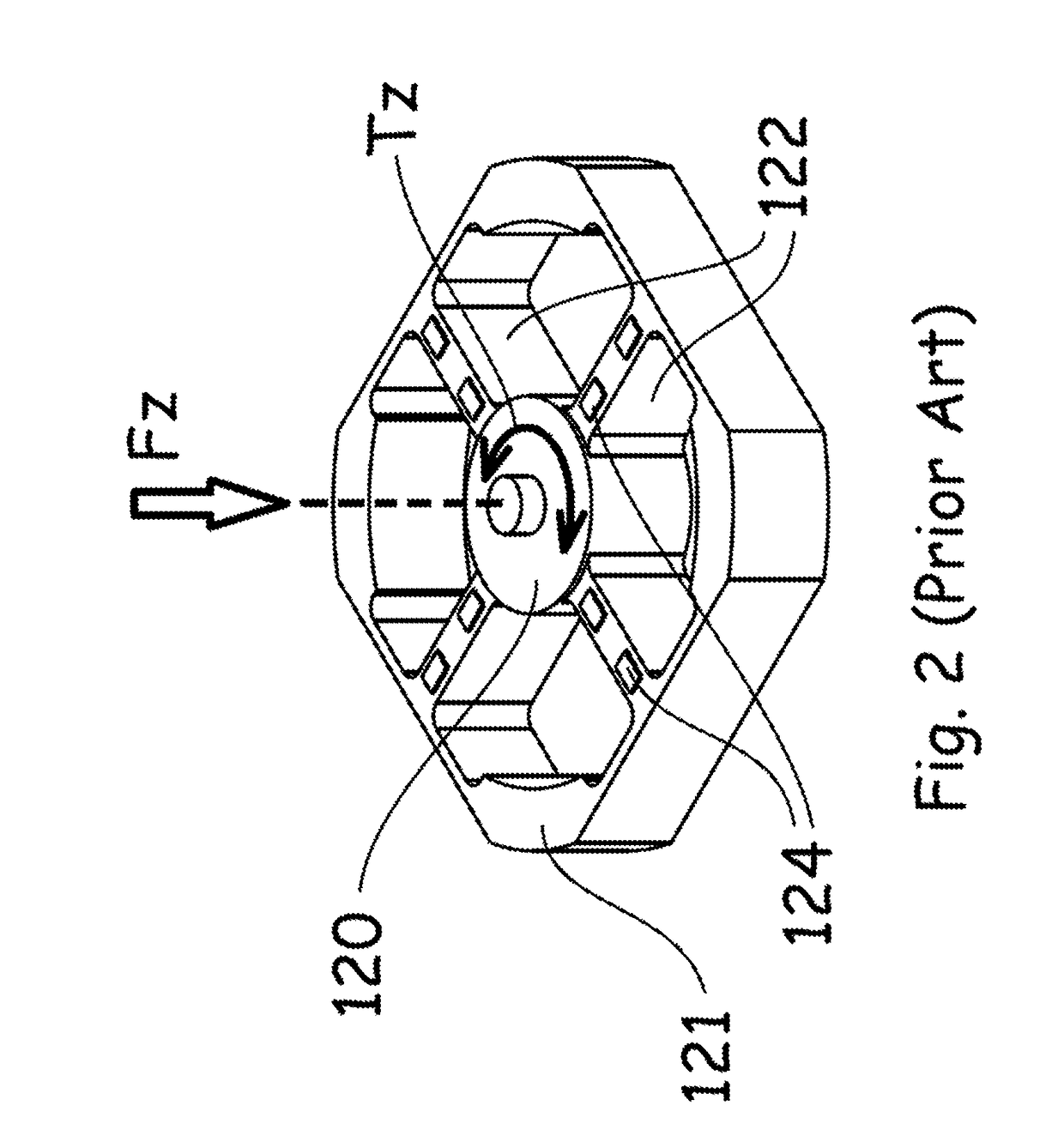

Multi-component force-torque sensing device with reduced cross-talk for twist-compression testing machine

PatentActiveUS20170191888A1

Innovation

- A multi-component force-torque sensing device with a mounting base supporting a force sensitive unit and a torque sensitive unit, interconnected by a sensor cross-talk reducing member via adapters, allowing for independent translation of forces and torques without interference, enhancing mechanical stability and accuracy.

Environmental Impact of Reduced Engine Friction

The reduction of engine friction in V4 engines represents a significant opportunity for environmental improvement across multiple dimensions. When friction is reduced through tribological advancements, there is a direct correlation with decreased fuel consumption, typically ranging from 2-5% depending on the specific friction reduction technologies implemented. This translates to a proportional reduction in carbon dioxide emissions, which constitutes a substantial environmental benefit considering the global scale of internal combustion engine usage.

Beyond carbon dioxide, reduced engine friction also contributes to lower emissions of other harmful pollutants including nitrogen oxides (NOx), particulate matter, and unburned hydrocarbons. This occurs because engines operating with lower friction can maintain more optimal combustion conditions, reducing the formation of these secondary pollutants that contribute to urban air pollution and respiratory health issues.

From a lifecycle perspective, engines with optimized tribological properties demonstrate extended service intervals and overall longevity. This reduced maintenance frequency decreases the environmental footprint associated with manufacturing replacement parts, disposal of worn components, and the consumption of lubricants and other maintenance materials. Studies indicate that advanced tribological solutions can extend engine life by 15-25%, representing significant resource conservation.

The environmental benefits extend to manufacturing processes as well. Modern tribological coatings and surface treatments that reduce friction often employ more environmentally friendly production methods compared to traditional approaches. Technologies such as diamond-like carbon coatings and laser surface texturing typically require fewer hazardous chemicals and generate less waste during application compared to conventional hardening or plating processes.

Additionally, the reduced thermal load resulting from lower friction contributes to more efficient thermal management systems. This can lead to smaller cooling system requirements, further reducing the material footprint of engines and potentially decreasing the use of coolants containing environmentally problematic glycols and corrosion inhibitors.

When quantifying these environmental benefits, lifecycle assessment methodologies reveal that the cumulative environmental advantage of friction-optimized engines extends well beyond the direct operational emissions reductions. The comprehensive environmental return on investment for implementing advanced tribological solutions in V4 engines typically shows positive results within the first 30-40% of the engine's operational lifetime.

Beyond carbon dioxide, reduced engine friction also contributes to lower emissions of other harmful pollutants including nitrogen oxides (NOx), particulate matter, and unburned hydrocarbons. This occurs because engines operating with lower friction can maintain more optimal combustion conditions, reducing the formation of these secondary pollutants that contribute to urban air pollution and respiratory health issues.

From a lifecycle perspective, engines with optimized tribological properties demonstrate extended service intervals and overall longevity. This reduced maintenance frequency decreases the environmental footprint associated with manufacturing replacement parts, disposal of worn components, and the consumption of lubricants and other maintenance materials. Studies indicate that advanced tribological solutions can extend engine life by 15-25%, representing significant resource conservation.

The environmental benefits extend to manufacturing processes as well. Modern tribological coatings and surface treatments that reduce friction often employ more environmentally friendly production methods compared to traditional approaches. Technologies such as diamond-like carbon coatings and laser surface texturing typically require fewer hazardous chemicals and generate less waste during application compared to conventional hardening or plating processes.

Additionally, the reduced thermal load resulting from lower friction contributes to more efficient thermal management systems. This can lead to smaller cooling system requirements, further reducing the material footprint of engines and potentially decreasing the use of coolants containing environmentally problematic glycols and corrosion inhibitors.

When quantifying these environmental benefits, lifecycle assessment methodologies reveal that the cumulative environmental advantage of friction-optimized engines extends well beyond the direct operational emissions reductions. The comprehensive environmental return on investment for implementing advanced tribological solutions in V4 engines typically shows positive results within the first 30-40% of the engine's operational lifetime.

Cost-Benefit Analysis of Friction Reduction Solutions

When evaluating friction reduction solutions for V4 engines, a comprehensive cost-benefit analysis reveals significant economic implications across multiple dimensions. Initial implementation costs for advanced tribological solutions typically range from $5,000 to $25,000 depending on the technology sophistication, with surface coating technologies representing the higher end of this spectrum while lubricant optimizations fall at the lower end.

Operational savings present the most compelling economic argument for friction reduction. Studies indicate that effective friction reduction technologies can decrease fuel consumption by 2-5%, translating to approximately $500-1,200 annual savings per vehicle in commercial applications. For fleet operations, this represents substantial cumulative savings that can offset initial investments within 1-3 years.

Maintenance cost reductions constitute another significant benefit stream. Reduced friction correlates directly with decreased wear rates, extending component lifespans by 15-30% according to tribological field studies. This extension translates to fewer replacement parts and reduced maintenance labor, estimated at $800-1,500 in annual savings per engine.

Environmental compliance benefits, while more difficult to quantify directly, carry increasing financial weight as emissions regulations tighten globally. Friction reduction technologies that decrease CO2 emissions by reducing fuel consumption help manufacturers avoid non-compliance penalties, which can exceed $100 per gram of CO2/km over regulatory limits in some markets.

Performance improvements resulting from friction reduction include enhanced power output (typically 2-4% gains) and improved thermal efficiency. These improvements contribute to competitive advantage and potentially higher market valuation, though these benefits resist precise quantification.

Long-term reliability improvements represent perhaps the most undervalued benefit. Reduced friction correlates strongly with decreased catastrophic failure rates, with studies suggesting a 20-40% reduction in major engine failures over vehicle lifetime. When considering the average cost of major engine repairs ($3,000-7,000) and associated downtime costs, this benefit stream can exceed $2,000 in risk-adjusted value.

Return on investment calculations indicate that most friction reduction technologies achieve positive ROI within 12-36 months in commercial applications, with surface treatments and advanced lubricant formulations showing the most favorable cost-benefit ratios. For consumer applications, the payback period extends to 3-5 years, still within typical ownership cycles.

Operational savings present the most compelling economic argument for friction reduction. Studies indicate that effective friction reduction technologies can decrease fuel consumption by 2-5%, translating to approximately $500-1,200 annual savings per vehicle in commercial applications. For fleet operations, this represents substantial cumulative savings that can offset initial investments within 1-3 years.

Maintenance cost reductions constitute another significant benefit stream. Reduced friction correlates directly with decreased wear rates, extending component lifespans by 15-30% according to tribological field studies. This extension translates to fewer replacement parts and reduced maintenance labor, estimated at $800-1,500 in annual savings per engine.

Environmental compliance benefits, while more difficult to quantify directly, carry increasing financial weight as emissions regulations tighten globally. Friction reduction technologies that decrease CO2 emissions by reducing fuel consumption help manufacturers avoid non-compliance penalties, which can exceed $100 per gram of CO2/km over regulatory limits in some markets.

Performance improvements resulting from friction reduction include enhanced power output (typically 2-4% gains) and improved thermal efficiency. These improvements contribute to competitive advantage and potentially higher market valuation, though these benefits resist precise quantification.

Long-term reliability improvements represent perhaps the most undervalued benefit. Reduced friction correlates strongly with decreased catastrophic failure rates, with studies suggesting a 20-40% reduction in major engine failures over vehicle lifetime. When considering the average cost of major engine repairs ($3,000-7,000) and associated downtime costs, this benefit stream can exceed $2,000 in risk-adjusted value.

Return on investment calculations indicate that most friction reduction technologies achieve positive ROI within 12-36 months in commercial applications, with surface treatments and advanced lubricant formulations showing the most favorable cost-benefit ratios. For consumer applications, the payback period extends to 3-5 years, still within typical ownership cycles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!