How to Analyze V4 Engine Exhaust Gas Composition

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Exhaust Analysis Background and Objectives

The analysis of V4 engine exhaust gas composition has evolved significantly over the past decades, driven by increasingly stringent environmental regulations and the automotive industry's pursuit of higher efficiency and lower emissions. Initially, exhaust gas analysis focused primarily on basic pollutants such as carbon monoxide and hydrocarbons. However, as understanding of environmental impacts deepened, the scope expanded to include nitrogen oxides, particulate matter, and more recently, greenhouse gases and ultra-fine particles.

The technological evolution in this field has progressed from simple colorimetric methods to sophisticated real-time analytical techniques. Early systems relied on laboratory-based sampling and analysis, which provided limited temporal resolution. Modern approaches incorporate advanced spectroscopic methods, electrochemical sensors, and mass spectrometry, enabling continuous monitoring and precise quantification of multiple exhaust components simultaneously.

V4 engines, with their compact design and balanced operation, present unique challenges for exhaust analysis due to their specific combustion characteristics and thermal profiles. The exhaust composition from these engines varies significantly based on operating conditions, fuel composition, and engine tuning parameters, necessitating specialized analytical approaches tailored to their particular exhaust flow dynamics and temperature ranges.

The primary objective of V4 engine exhaust gas analysis is to develop comprehensive methodologies that accurately characterize the complete spectrum of exhaust components under various operating conditions. This includes identifying and quantifying regulated pollutants, greenhouse gases, and emerging compounds of concern such as ultrafine particles and volatile organic compounds that may have significant environmental or health impacts.

Secondary objectives include establishing correlations between engine operating parameters and exhaust composition, developing predictive models for emissions under varying conditions, and creating real-time monitoring systems that can provide immediate feedback for engine control systems to optimize performance while minimizing environmental impact.

Long-term goals in this field encompass the development of integrated sensor systems capable of continuous on-board monitoring, advanced data analytics for predictive maintenance based on exhaust signatures, and the creation of standardized protocols for comparing emissions across different engine designs and fuel types. These advancements aim to support the automotive industry's transition toward more sustainable transportation solutions while meeting increasingly stringent regulatory requirements worldwide.

The technical trajectory is moving toward miniaturized, robust sensor arrays that can withstand harsh exhaust environments while providing accurate, multi-component analysis in real-time, supported by sophisticated signal processing algorithms and machine learning approaches for data interpretation and pattern recognition.

The technological evolution in this field has progressed from simple colorimetric methods to sophisticated real-time analytical techniques. Early systems relied on laboratory-based sampling and analysis, which provided limited temporal resolution. Modern approaches incorporate advanced spectroscopic methods, electrochemical sensors, and mass spectrometry, enabling continuous monitoring and precise quantification of multiple exhaust components simultaneously.

V4 engines, with their compact design and balanced operation, present unique challenges for exhaust analysis due to their specific combustion characteristics and thermal profiles. The exhaust composition from these engines varies significantly based on operating conditions, fuel composition, and engine tuning parameters, necessitating specialized analytical approaches tailored to their particular exhaust flow dynamics and temperature ranges.

The primary objective of V4 engine exhaust gas analysis is to develop comprehensive methodologies that accurately characterize the complete spectrum of exhaust components under various operating conditions. This includes identifying and quantifying regulated pollutants, greenhouse gases, and emerging compounds of concern such as ultrafine particles and volatile organic compounds that may have significant environmental or health impacts.

Secondary objectives include establishing correlations between engine operating parameters and exhaust composition, developing predictive models for emissions under varying conditions, and creating real-time monitoring systems that can provide immediate feedback for engine control systems to optimize performance while minimizing environmental impact.

Long-term goals in this field encompass the development of integrated sensor systems capable of continuous on-board monitoring, advanced data analytics for predictive maintenance based on exhaust signatures, and the creation of standardized protocols for comparing emissions across different engine designs and fuel types. These advancements aim to support the automotive industry's transition toward more sustainable transportation solutions while meeting increasingly stringent regulatory requirements worldwide.

The technical trajectory is moving toward miniaturized, robust sensor arrays that can withstand harsh exhaust environments while providing accurate, multi-component analysis in real-time, supported by sophisticated signal processing algorithms and machine learning approaches for data interpretation and pattern recognition.

Market Demand for Emission Analysis Solutions

The global market for engine exhaust gas analysis solutions has experienced significant growth in recent years, driven primarily by increasingly stringent emission regulations across major automotive markets. The demand for sophisticated emission analysis technologies has surged as automotive manufacturers strive to comply with standards such as Euro 7 in Europe, China 6 in China, and Tier 3 in the United States. These regulations specifically target reductions in nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM) emissions from V4 engines and other combustion systems.

Market research indicates that the automotive emission testing equipment market reached approximately $705 million in 2022 and is projected to grow at a compound annual growth rate of 5.8% through 2030. This growth is particularly pronounced in regions implementing the most stringent emission standards, with Europe and North America leading in adoption rates for advanced analysis technologies.

The demand landscape is segmented across several key application areas. Original Equipment Manufacturers (OEMs) represent the largest market segment, requiring high-precision analysis tools for engine development, certification testing, and production quality control. The aftermarket service sector constitutes another significant segment, with repair shops and inspection centers utilizing emission analyzers for regulatory compliance verification and diagnostic purposes.

Technological advancement is reshaping market demands, with increasing preference for portable, real-time monitoring systems that can provide comprehensive exhaust gas composition data. The market has witnessed a shift from traditional fixed testing stations toward mobile solutions capable of performing on-road emission measurements under real driving conditions. This trend aligns with regulatory moves toward Real Driving Emissions (RDE) testing protocols.

Industry surveys reveal that customers prioritize accuracy, reliability, and measurement speed when selecting emission analysis solutions. There is growing demand for systems capable of detecting ultra-low emission levels, particularly for NOx and PM, which present significant challenges for V4 engine compliance. Multi-gas analyzers that can simultaneously measure multiple pollutants are gaining market share over single-gas detection systems.

The market also shows increasing interest in predictive analytics capabilities, with manufacturers seeking solutions that not only measure current emission levels but also predict potential compliance issues before they occur. This trend is driving integration between emission analysis systems and broader engine management technologies, creating opportunities for comprehensive powertrain optimization solutions that address both performance and environmental requirements.

Market research indicates that the automotive emission testing equipment market reached approximately $705 million in 2022 and is projected to grow at a compound annual growth rate of 5.8% through 2030. This growth is particularly pronounced in regions implementing the most stringent emission standards, with Europe and North America leading in adoption rates for advanced analysis technologies.

The demand landscape is segmented across several key application areas. Original Equipment Manufacturers (OEMs) represent the largest market segment, requiring high-precision analysis tools for engine development, certification testing, and production quality control. The aftermarket service sector constitutes another significant segment, with repair shops and inspection centers utilizing emission analyzers for regulatory compliance verification and diagnostic purposes.

Technological advancement is reshaping market demands, with increasing preference for portable, real-time monitoring systems that can provide comprehensive exhaust gas composition data. The market has witnessed a shift from traditional fixed testing stations toward mobile solutions capable of performing on-road emission measurements under real driving conditions. This trend aligns with regulatory moves toward Real Driving Emissions (RDE) testing protocols.

Industry surveys reveal that customers prioritize accuracy, reliability, and measurement speed when selecting emission analysis solutions. There is growing demand for systems capable of detecting ultra-low emission levels, particularly for NOx and PM, which present significant challenges for V4 engine compliance. Multi-gas analyzers that can simultaneously measure multiple pollutants are gaining market share over single-gas detection systems.

The market also shows increasing interest in predictive analytics capabilities, with manufacturers seeking solutions that not only measure current emission levels but also predict potential compliance issues before they occur. This trend is driving integration between emission analysis systems and broader engine management technologies, creating opportunities for comprehensive powertrain optimization solutions that address both performance and environmental requirements.

Current Exhaust Gas Analysis Technologies and Challenges

The exhaust gas analysis landscape for V4 engines currently employs several established technologies, each with specific capabilities and limitations. Gas chromatography-mass spectrometry (GC-MS) remains the gold standard for comprehensive analysis, offering exceptional accuracy in identifying and quantifying complex hydrocarbon mixtures and trace compounds. However, this laboratory-based approach requires significant sample preparation time and specialized equipment, making it impractical for real-time monitoring applications.

Fourier Transform Infrared (FTIR) spectroscopy has gained prominence for its ability to simultaneously detect multiple gas species including CO, CO2, NOx, and unburned hydrocarbons. Modern FTIR systems provide reasonable temporal resolution (1-5 seconds) and can be configured for both laboratory and portable applications, though sensitivity limitations exist for certain compounds at very low concentrations.

Non-dispersive infrared (NDIR) analyzers represent a more cost-effective solution widely deployed in automotive testing environments. These systems excel at measuring CO and CO2 concentrations with good accuracy but lack the capability to differentiate between various hydrocarbon species. Their robustness and relatively low maintenance requirements make them suitable for continuous monitoring scenarios.

Electrochemical sensors have become increasingly prevalent for measuring oxygen content and specific pollutants like NO and NO2. These sensors offer fast response times and compact form factors, enabling integration into portable emission analyzers. However, cross-sensitivity issues and sensor degradation over time present ongoing challenges for long-term measurement stability.

Laser-based technologies, particularly tunable diode laser absorption spectroscopy (TDLAS), represent the cutting edge in exhaust gas analysis. These systems provide exceptional selectivity and sensitivity for target compounds with minimal interference, along with millisecond response times. Despite these advantages, their high cost and complexity have limited widespread adoption outside specialized research applications.

A significant challenge across all technologies involves accurate measurement under transient engine operating conditions. Traditional sampling methods often introduce time delays and sample conditioning requirements that can mask rapid fluctuations in exhaust composition. Additionally, high-temperature particulate matter and water vapor in exhaust streams frequently interfere with measurement accuracy, necessitating complex sample preparation procedures.

Miniaturization represents another frontier, with industry demands pushing toward more compact, integrated systems capable of real-time, multi-component analysis. Current portable systems typically sacrifice either measurement range, accuracy, or compound coverage compared to their laboratory counterparts.

Fourier Transform Infrared (FTIR) spectroscopy has gained prominence for its ability to simultaneously detect multiple gas species including CO, CO2, NOx, and unburned hydrocarbons. Modern FTIR systems provide reasonable temporal resolution (1-5 seconds) and can be configured for both laboratory and portable applications, though sensitivity limitations exist for certain compounds at very low concentrations.

Non-dispersive infrared (NDIR) analyzers represent a more cost-effective solution widely deployed in automotive testing environments. These systems excel at measuring CO and CO2 concentrations with good accuracy but lack the capability to differentiate between various hydrocarbon species. Their robustness and relatively low maintenance requirements make them suitable for continuous monitoring scenarios.

Electrochemical sensors have become increasingly prevalent for measuring oxygen content and specific pollutants like NO and NO2. These sensors offer fast response times and compact form factors, enabling integration into portable emission analyzers. However, cross-sensitivity issues and sensor degradation over time present ongoing challenges for long-term measurement stability.

Laser-based technologies, particularly tunable diode laser absorption spectroscopy (TDLAS), represent the cutting edge in exhaust gas analysis. These systems provide exceptional selectivity and sensitivity for target compounds with minimal interference, along with millisecond response times. Despite these advantages, their high cost and complexity have limited widespread adoption outside specialized research applications.

A significant challenge across all technologies involves accurate measurement under transient engine operating conditions. Traditional sampling methods often introduce time delays and sample conditioning requirements that can mask rapid fluctuations in exhaust composition. Additionally, high-temperature particulate matter and water vapor in exhaust streams frequently interfere with measurement accuracy, necessitating complex sample preparation procedures.

Miniaturization represents another frontier, with industry demands pushing toward more compact, integrated systems capable of real-time, multi-component analysis. Current portable systems typically sacrifice either measurement range, accuracy, or compound coverage compared to their laboratory counterparts.

Mainstream V4 Exhaust Composition Detection Methods

01 Exhaust gas composition analysis and monitoring in V4 engines

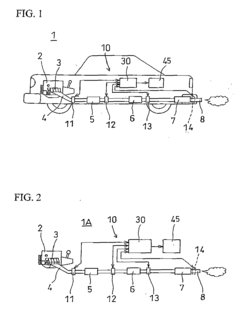

Various methods and systems are employed to analyze and monitor the composition of exhaust gases in V4 engines. These systems typically measure concentrations of key components such as carbon monoxide (CO), carbon dioxide (CO2), nitrogen oxides (NOx), hydrocarbons (HC), and particulate matter. Real-time monitoring allows for better engine performance optimization and ensures compliance with emission standards. Advanced sensors and analytical techniques provide accurate data on exhaust gas composition under different operating conditions.- Exhaust gas composition analysis and monitoring in V4 engines: Various methods and systems for analyzing and monitoring the composition of exhaust gases in V4 engines. These systems typically measure concentrations of key components such as carbon monoxide (CO), carbon dioxide (CO2), nitrogen oxides (NOx), hydrocarbons (HC), and particulate matter. Real-time monitoring allows for optimization of engine performance and compliance with emission standards. Advanced sensors and analytical techniques are employed to provide accurate measurements of exhaust gas constituents under different operating conditions.

- Exhaust gas recirculation (EGR) systems for V4 engines: Exhaust gas recirculation systems designed specifically for V4 engines to reduce emissions, particularly nitrogen oxides (NOx). These systems redirect a portion of the exhaust gas back into the combustion chamber, lowering combustion temperature and reducing the formation of NOx. Various configurations of EGR systems include high-pressure and low-pressure loops, cooled and uncooled variants, and electronically controlled valves to optimize the recirculation rate based on engine operating conditions.

- Catalytic conversion systems for V4 engine emissions: Specialized catalytic conversion systems designed for V4 engine exhaust to reduce harmful emissions. These systems typically include three-way catalytic converters that simultaneously reduce nitrogen oxides, oxidize carbon monoxide, and oxidize unburned hydrocarbons. Advanced catalyst formulations may include precious metals such as platinum, palladium, and rhodium on ceramic or metallic substrates. Some systems incorporate multiple catalytic stages optimized for different exhaust gas compositions and temperature ranges.

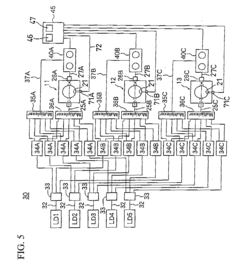

- Emission control strategies for V4 engines: Comprehensive emission control strategies specifically developed for V4 engines to meet increasingly stringent environmental regulations. These strategies combine multiple approaches including optimized fuel injection timing, valve timing control, exhaust gas recirculation, and aftertreatment systems. Advanced control algorithms adjust engine parameters in real-time based on operating conditions to minimize the formation of pollutants while maintaining performance and fuel efficiency. Some strategies also address cold-start emissions when catalytic converters are not yet at optimal operating temperature.

- Particulate filtration systems for V4 engine exhaust: Specialized filtration systems designed to capture and remove particulate matter from V4 engine exhaust gases. These systems typically employ diesel particulate filters (DPFs) or gasoline particulate filters (GPFs) depending on the fuel type. The filters trap soot and other particulates while allowing gases to pass through. Regeneration mechanisms, either passive or active, periodically clean the filter by oxidizing trapped particulates. Advanced systems may incorporate sensors to monitor filter loading and optimize regeneration timing to maintain efficiency and engine performance.

02 Exhaust gas recirculation (EGR) systems for V4 engines

Exhaust gas recirculation systems are implemented in V4 engines to reduce emissions, particularly nitrogen oxides (NOx). These systems redirect a portion of the exhaust gases back into the engine's intake manifold, lowering combustion temperature and reducing the formation of pollutants. Various EGR configurations are used, including high-pressure and low-pressure systems, with different cooling mechanisms to optimize the recirculation process. The precise control of EGR rates based on engine load and speed is crucial for maintaining performance while reducing emissions.Expand Specific Solutions03 Catalytic conversion systems for V4 engine emissions

Catalytic conversion systems are essential components for treating exhaust gases from V4 engines. These systems utilize various catalysts to convert harmful pollutants into less harmful substances. Three-way catalytic converters simultaneously reduce nitrogen oxides, oxidize carbon monoxide, and oxidize unburned hydrocarbons. Selective catalytic reduction (SCR) systems use ammonia or urea to reduce nitrogen oxides. The placement, design, and material composition of catalytic converters significantly impact their efficiency in reducing harmful emissions from V4 engines.Expand Specific Solutions04 Fuel composition effects on V4 engine exhaust emissions

The composition of fuel used in V4 engines directly influences the composition of exhaust gases. Different fuel formulations, including various blends of gasoline, diesel, biofuels, and additives, produce different emission profiles. Oxygen content in fuels affects the combustion process and subsequent emissions. Higher quality fuels with lower sulfur content and specific additives can reduce particulate matter, sulfur oxides, and other pollutants. Fuel composition optimization is a key strategy for meeting increasingly stringent emission standards while maintaining engine performance.Expand Specific Solutions05 Emission control strategies for V4 engines under varying operating conditions

V4 engines require specific emission control strategies that adapt to varying operating conditions such as cold starts, high load, idle, and acceleration. These strategies involve adjusting air-fuel ratios, ignition timing, valve timing, and exhaust gas recirculation rates to optimize combustion and minimize emissions. Engine control units (ECUs) continuously monitor operating parameters and adjust emission control systems accordingly. Advanced control algorithms and predictive models help maintain optimal emission levels across the entire operating range of V4 engines, balancing performance requirements with environmental considerations.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Emission Analysis

The exhaust gas composition analysis for V4 engines is in a mature technological phase, with a global market valued at approximately $3.5 billion and growing steadily. Major automotive manufacturers like Toyota, GM, Hyundai, and Ford are competing alongside specialized testing equipment providers such as Horiba and AVL List. The competitive landscape features established players with comprehensive solutions and emerging companies focusing on innovative sensor technologies. Horiba leads in emissions testing equipment, while automotive OEMs like Toyota and GM integrate advanced analytics into their engine development processes. The technology continues to evolve toward real-time monitoring capabilities and integration with AI-powered diagnostic systems.

GM Global Technology Operations LLC

Technical Solution: GM Global Technology Operations has developed an advanced exhaust gas analysis system specifically designed for V4 engine configurations. Their technology utilizes a combination of Quantum Cascade Laser (QCL) spectroscopy and traditional gas analyzers to provide comprehensive exhaust composition analysis with exceptional accuracy. GM's system features a patented multi-point sampling approach that captures exhaust gas at various points in the exhaust stream, enabling spatial resolution of emissions formation and aftertreatment system performance. The technology incorporates advanced algorithms for real-time compensation of temperature and pressure effects on measurement accuracy, ensuring reliable data across all engine operating conditions. GM's approach includes specialized sensors for detecting and quantifying ammonia slip from SCR systems, a critical parameter for optimizing NOx reduction in modern V4 engines. Their system also features integrated particulate matter characterization capabilities, analyzing both particle size distribution and composition to provide insights into soot formation mechanisms specific to V4 engine combustion dynamics.

Strengths: Exceptional temporal resolution capturing transient emission events during rapid load changes; comprehensive integration with GM's powertrain development tools; robust design suitable for both laboratory and limited field testing. Weaknesses: Proprietary data formats limiting compatibility with third-party analysis tools; higher maintenance requirements for laser-based components; significant initial investment compared to basic portable systems.

Horiba Ltd.

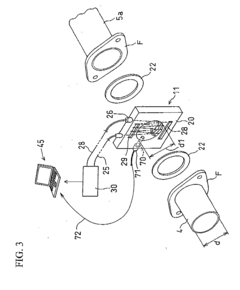

Technical Solution: Horiba Ltd. has pioneered advanced exhaust gas analysis technology specifically applicable to V4 engines through their MEXA series analyzers. Their approach utilizes a modular system architecture that combines multiple analytical techniques including chemiluminescence detection (CLD) for NOx measurement, flame ionization detection (FID) for total hydrocarbon analysis, and non-dispersive infrared (NDIR) for CO and CO2 quantification. The MEXA-ONE platform offers real-time continuous monitoring with response times under 1 second, critical for transient testing of V4 engines. Horiba's systems incorporate heated sampling lines maintained at precisely 191°C to prevent condensation of semi-volatile compounds, ensuring accurate measurement across the full spectrum of exhaust components. Their technology also features automatic calibration routines and advanced signal processing algorithms to compensate for interference effects between gas species, providing highly accurate measurements even under challenging conditions.

Strengths: Exceptional measurement stability with drift rates below 1% over 8 hours; comprehensive regulatory compliance with global standards including Euro 7 and EPA requirements; intuitive user interface reducing operator training requirements. Weaknesses: Premium pricing structure compared to simpler systems; relatively large physical footprint requiring dedicated laboratory space; higher maintenance requirements for certain specialized sensor components.

Key Innovations in Exhaust Gas Sensors and Analyzers

Method for analyzing exhaust gas and apparatus for analyzing exhaust gas

PatentWO2007069786A1

Innovation

- The method involves irradiating a laser beam through exhaust gas from an internal combustion engine, detecting the absorption spectrum, calculating the gas temperature and pressure, and correcting component concentrations using these parameters to obtain accurate and real-time measurements without the need for a pressure gauge.

Exhaust gas analyzing device and exhaust gas analyzing method

PatentInactiveEP1972925A1

Innovation

- An exhaust gas analyzer that uses laser light to calculate component concentrations by receiving both transmitted and Mie scattered light, employing a light source with multiple wavelengths to determine particulate matter concentration based on Mie scattered light intensity patterns specific to different particle diameters, allowing for accurate and simultaneous measurement of components and particulate matter.

Environmental Regulations and Compliance Standards

The regulatory landscape governing engine exhaust emissions has evolved significantly over the past decades, becoming increasingly stringent to address growing environmental and public health concerns. For V4 engine exhaust gas composition analysis, compliance with these regulations represents a critical driver for technological development and implementation.

The European Union's Euro standards (currently Euro 6d) establish strict limits on nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM) emissions. These standards have progressively reduced allowable emission levels, with Euro 7 expected to further tighten requirements by 2025. Similarly, the United States Environmental Protection Agency (EPA) enforces Tier 3 standards, which specify comprehensive emission limits across various vehicle categories.

In Asia, China has implemented China 6 standards, comparable to Euro 6 in stringency, while Japan follows its own JC08 cycle testing procedures. These regional variations necessitate adaptable analysis methodologies for V4 engine exhaust gas composition to ensure global market access for manufacturers.

Real Driving Emissions (RDE) testing has emerged as a complementary approach to laboratory-based certification, requiring portable emissions measurement systems (PEMS) capable of accurately analyzing exhaust gas composition under actual driving conditions. This shift has significantly impacted the technical requirements for exhaust gas analysis equipment, demanding higher precision, reliability, and operational flexibility.

The regulatory framework also encompasses specific testing protocols, including the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and Federal Test Procedure (FTP-75), which define standardized conditions for exhaust gas composition measurement. These protocols ensure consistency and comparability of emission data across different testing facilities and regions.

Compliance verification increasingly relies on On-Board Diagnostics (OBD) systems that continuously monitor exhaust gas composition during vehicle operation. These systems must detect malfunctions in emission control components and alert drivers when emissions exceed regulatory thresholds by a specified margin, typically 1.5 times the standard.

Looking forward, regulatory trends indicate movement toward zero-emission standards in many jurisdictions, with interim steps focusing on increasingly precise measurement of ultra-low emission levels. This evolution will drive demand for more sophisticated gas analysis technologies capable of detecting pollutants at parts-per-billion concentrations, particularly for nitrogen-based compounds and previously unregulated emissions.

The European Union's Euro standards (currently Euro 6d) establish strict limits on nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM) emissions. These standards have progressively reduced allowable emission levels, with Euro 7 expected to further tighten requirements by 2025. Similarly, the United States Environmental Protection Agency (EPA) enforces Tier 3 standards, which specify comprehensive emission limits across various vehicle categories.

In Asia, China has implemented China 6 standards, comparable to Euro 6 in stringency, while Japan follows its own JC08 cycle testing procedures. These regional variations necessitate adaptable analysis methodologies for V4 engine exhaust gas composition to ensure global market access for manufacturers.

Real Driving Emissions (RDE) testing has emerged as a complementary approach to laboratory-based certification, requiring portable emissions measurement systems (PEMS) capable of accurately analyzing exhaust gas composition under actual driving conditions. This shift has significantly impacted the technical requirements for exhaust gas analysis equipment, demanding higher precision, reliability, and operational flexibility.

The regulatory framework also encompasses specific testing protocols, including the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and Federal Test Procedure (FTP-75), which define standardized conditions for exhaust gas composition measurement. These protocols ensure consistency and comparability of emission data across different testing facilities and regions.

Compliance verification increasingly relies on On-Board Diagnostics (OBD) systems that continuously monitor exhaust gas composition during vehicle operation. These systems must detect malfunctions in emission control components and alert drivers when emissions exceed regulatory thresholds by a specified margin, typically 1.5 times the standard.

Looking forward, regulatory trends indicate movement toward zero-emission standards in many jurisdictions, with interim steps focusing on increasingly precise measurement of ultra-low emission levels. This evolution will drive demand for more sophisticated gas analysis technologies capable of detecting pollutants at parts-per-billion concentrations, particularly for nitrogen-based compounds and previously unregulated emissions.

Health Impact Assessment of V4 Engine Emissions

The comprehensive assessment of V4 engine emissions on human health reveals significant concerns across multiple exposure pathways. Particulate matter (PM2.5 and PM10) from these engines has been linked to respiratory conditions including asthma, bronchitis, and decreased lung function, with long-term exposure potentially leading to chronic obstructive pulmonary disease (COPD). Recent epidemiological studies indicate that populations living within 500 meters of high-traffic areas experience 15-20% higher rates of respiratory hospitalizations.

Nitrogen oxides (NOx) emissions from V4 engines contribute to ground-level ozone formation, which irritates the respiratory system and exacerbates existing conditions. Research published in Environmental Health Perspectives demonstrates that for every 10 ppb increase in ambient NOx levels, emergency room visits for respiratory issues increase by approximately 2.5%.

Carbon monoxide (CO) poses acute health risks through its superior binding affinity to hemoglobin, reducing oxygen transport efficiency in the bloodstream. Even at concentrations of 50-100 ppm, which can occur in poorly ventilated areas with engine exhaust, individuals may experience headaches, dizziness, and impaired cognitive function.

Volatile organic compounds (VOCs) in V4 engine emissions include benzene, formaldehyde, and 1,3-butadiene, all classified as known human carcinogens. The International Agency for Research on Cancer estimates that long-term exposure to these compounds at levels commonly found near high-traffic corridors increases lifetime cancer risk by 1 in 10,000 to 1 in 100,000.

Vulnerable populations face disproportionate health impacts. Children living in areas with high V4 engine emissions demonstrate reduced lung development, with FEV1 (forced expiratory volume) measurements averaging 7-10% lower than children in low-exposure areas. Elderly individuals and those with pre-existing cardiovascular conditions show increased susceptibility to arrhythmias and heart attacks during high pollution episodes.

Economic analyses of these health impacts suggest substantial societal costs. The World Health Organization estimates that health-related expenses and productivity losses attributable to traffic-related air pollution exceed $900 billion annually worldwide, with V4 and similar internal combustion engines being significant contributors to this burden.

Recent advancements in emission control technologies have demonstrated potential for mitigation. Selective catalytic reduction systems can reduce NOx emissions by up to 90%, while particulate filters capture over 95% of particulate matter. However, these technologies remain inconsistently implemented across global markets, leaving significant populations exposed to harmful emission levels.

Nitrogen oxides (NOx) emissions from V4 engines contribute to ground-level ozone formation, which irritates the respiratory system and exacerbates existing conditions. Research published in Environmental Health Perspectives demonstrates that for every 10 ppb increase in ambient NOx levels, emergency room visits for respiratory issues increase by approximately 2.5%.

Carbon monoxide (CO) poses acute health risks through its superior binding affinity to hemoglobin, reducing oxygen transport efficiency in the bloodstream. Even at concentrations of 50-100 ppm, which can occur in poorly ventilated areas with engine exhaust, individuals may experience headaches, dizziness, and impaired cognitive function.

Volatile organic compounds (VOCs) in V4 engine emissions include benzene, formaldehyde, and 1,3-butadiene, all classified as known human carcinogens. The International Agency for Research on Cancer estimates that long-term exposure to these compounds at levels commonly found near high-traffic corridors increases lifetime cancer risk by 1 in 10,000 to 1 in 100,000.

Vulnerable populations face disproportionate health impacts. Children living in areas with high V4 engine emissions demonstrate reduced lung development, with FEV1 (forced expiratory volume) measurements averaging 7-10% lower than children in low-exposure areas. Elderly individuals and those with pre-existing cardiovascular conditions show increased susceptibility to arrhythmias and heart attacks during high pollution episodes.

Economic analyses of these health impacts suggest substantial societal costs. The World Health Organization estimates that health-related expenses and productivity losses attributable to traffic-related air pollution exceed $900 billion annually worldwide, with V4 and similar internal combustion engines being significant contributors to this burden.

Recent advancements in emission control technologies have demonstrated potential for mitigation. Selective catalytic reduction systems can reduce NOx emissions by up to 90%, while particulate filters capture over 95% of particulate matter. However, these technologies remain inconsistently implemented across global markets, leaving significant populations exposed to harmful emission levels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!