V4 Engine Piston Design: Weight vs Strength Considerations

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Piston Evolution and Design Objectives

The evolution of piston design in internal combustion engines represents a fascinating journey of engineering innovation spanning over a century. Early pistons from the 1900s were simple cast iron components, prioritizing durability over weight considerations. As automotive technology progressed through the mid-20th century, aluminum alloys began replacing cast iron, marking a significant shift in piston material technology that balanced strength requirements with substantial weight reduction.

The V4 engine configuration, though less common than inline-4 or V6 designs, presents unique piston design challenges due to its compact layout and specific firing sequence. Historical development of V4 pistons has been driven by the fundamental need to withstand extreme thermal and mechanical stresses while minimizing reciprocating mass to enhance engine performance and efficiency.

Modern V4 piston design objectives center around the critical balance between weight reduction and structural integrity. This balance directly impacts several key performance parameters: engine responsiveness, fuel efficiency, power output, and durability. Contemporary engineering targets typically aim for 15-20% weight reduction compared to previous generation designs without compromising strength characteristics.

The thermal management aspect of piston design has gained increasing importance, particularly as combustion pressures and temperatures continue to rise with advanced engine technologies. Current design objectives include optimizing heat dissipation pathways while maintaining dimensional stability under operating conditions exceeding 300°C at the piston crown.

Material science advancements have significantly influenced piston evolution, with current high-performance designs utilizing specialized aluminum-silicon alloys, often incorporating nickel, copper, and magnesium for enhanced properties. Some cutting-edge applications explore metal matrix composites and ceramic-reinforced materials to further optimize the weight-strength ratio.

Computer-aided engineering has revolutionized the design process, enabling finite element analysis to identify stress concentration points and optimize material distribution. This analytical approach has led to sophisticated topological designs featuring variable wall thicknesses, strategically placed reinforcement ribs, and complex cooling galleries that would have been impossible to conceptualize through traditional methods.

The trajectory of piston development continues toward increasingly lightweight designs that maintain or improve strength characteristics through material innovation and geometric optimization. Future objectives include further weight reduction of 5-10% while enhancing durability under higher combustion pressures anticipated in next-generation high-efficiency engines. This evolution represents the ongoing engineering challenge of balancing seemingly contradictory requirements through innovative design approaches.

The V4 engine configuration, though less common than inline-4 or V6 designs, presents unique piston design challenges due to its compact layout and specific firing sequence. Historical development of V4 pistons has been driven by the fundamental need to withstand extreme thermal and mechanical stresses while minimizing reciprocating mass to enhance engine performance and efficiency.

Modern V4 piston design objectives center around the critical balance between weight reduction and structural integrity. This balance directly impacts several key performance parameters: engine responsiveness, fuel efficiency, power output, and durability. Contemporary engineering targets typically aim for 15-20% weight reduction compared to previous generation designs without compromising strength characteristics.

The thermal management aspect of piston design has gained increasing importance, particularly as combustion pressures and temperatures continue to rise with advanced engine technologies. Current design objectives include optimizing heat dissipation pathways while maintaining dimensional stability under operating conditions exceeding 300°C at the piston crown.

Material science advancements have significantly influenced piston evolution, with current high-performance designs utilizing specialized aluminum-silicon alloys, often incorporating nickel, copper, and magnesium for enhanced properties. Some cutting-edge applications explore metal matrix composites and ceramic-reinforced materials to further optimize the weight-strength ratio.

Computer-aided engineering has revolutionized the design process, enabling finite element analysis to identify stress concentration points and optimize material distribution. This analytical approach has led to sophisticated topological designs featuring variable wall thicknesses, strategically placed reinforcement ribs, and complex cooling galleries that would have been impossible to conceptualize through traditional methods.

The trajectory of piston development continues toward increasingly lightweight designs that maintain or improve strength characteristics through material innovation and geometric optimization. Future objectives include further weight reduction of 5-10% while enhancing durability under higher combustion pressures anticipated in next-generation high-efficiency engines. This evolution represents the ongoing engineering challenge of balancing seemingly contradictory requirements through innovative design approaches.

Market Requirements for Advanced Piston Technologies

The automotive industry is witnessing a significant shift towards more efficient, powerful, and environmentally friendly engines. This market evolution has created specific requirements for advanced piston technologies, particularly in V4 engine configurations where the balance between weight and strength is critical. Current market analysis indicates that OEMs are demanding pistons that can withstand higher combustion pressures while simultaneously reducing overall weight to improve fuel efficiency and reduce emissions.

Performance vehicle manufacturers require pistons capable of withstanding extreme thermal and mechanical stresses, with operational temperatures exceeding 300°C and combustion pressures reaching 200 bar in turbocharged applications. These manufacturers prioritize strength over weight, though they increasingly seek composite materials that can offer both properties without compromise.

In contrast, the mainstream automotive sector emphasizes fuel efficiency, with manufacturers targeting weight reductions of 15-20% compared to conventional pistons while maintaining adequate durability for standard driving conditions. This market segment represents the largest volume opportunity, with annual production exceeding millions of units.

The commercial vehicle sector presents unique requirements, demanding pistons with exceptional durability and longevity under constant high-load conditions. These applications typically prioritize service intervals of 500,000+ kilometers before major engine overhauls, necessitating materials and designs that resist wear and fatigue over extended periods.

Emerging markets show growing demand for cost-effective solutions that balance performance and efficiency, particularly in regions with less stringent emissions regulations but increasing consumer expectations for vehicle performance. These markets represent significant growth potential, with compound annual growth rates projected to outpace developed markets.

Regulatory pressures continue to shape market requirements, with emissions standards like Euro 7, China 6b, and US EPA Tier 3 driving innovation in piston design. Manufacturers must develop pistons that contribute to lower friction, improved combustion efficiency, and reduced oil consumption to meet these standards.

The aftermarket segment demonstrates distinct requirements, with performance enthusiasts seeking lightweight pistons that maximize power output, often willing to accept shorter service intervals as a trade-off. This niche market values innovative materials and designs that provide measurable performance improvements over OEM components.

Market research indicates growing interest in smart manufacturing capabilities, with customers increasingly valuing suppliers who can provide rapid prototyping, digital twins for simulation, and customization options to accelerate development cycles and reduce time-to-market for new engine designs.

Performance vehicle manufacturers require pistons capable of withstanding extreme thermal and mechanical stresses, with operational temperatures exceeding 300°C and combustion pressures reaching 200 bar in turbocharged applications. These manufacturers prioritize strength over weight, though they increasingly seek composite materials that can offer both properties without compromise.

In contrast, the mainstream automotive sector emphasizes fuel efficiency, with manufacturers targeting weight reductions of 15-20% compared to conventional pistons while maintaining adequate durability for standard driving conditions. This market segment represents the largest volume opportunity, with annual production exceeding millions of units.

The commercial vehicle sector presents unique requirements, demanding pistons with exceptional durability and longevity under constant high-load conditions. These applications typically prioritize service intervals of 500,000+ kilometers before major engine overhauls, necessitating materials and designs that resist wear and fatigue over extended periods.

Emerging markets show growing demand for cost-effective solutions that balance performance and efficiency, particularly in regions with less stringent emissions regulations but increasing consumer expectations for vehicle performance. These markets represent significant growth potential, with compound annual growth rates projected to outpace developed markets.

Regulatory pressures continue to shape market requirements, with emissions standards like Euro 7, China 6b, and US EPA Tier 3 driving innovation in piston design. Manufacturers must develop pistons that contribute to lower friction, improved combustion efficiency, and reduced oil consumption to meet these standards.

The aftermarket segment demonstrates distinct requirements, with performance enthusiasts seeking lightweight pistons that maximize power output, often willing to accept shorter service intervals as a trade-off. This niche market values innovative materials and designs that provide measurable performance improvements over OEM components.

Market research indicates growing interest in smart manufacturing capabilities, with customers increasingly valuing suppliers who can provide rapid prototyping, digital twins for simulation, and customization options to accelerate development cycles and reduce time-to-market for new engine designs.

Current Piston Design Limitations and Challenges

The current V4 engine piston design faces several critical limitations that impede optimal performance and efficiency. The fundamental challenge lies in the inherent trade-off between weight reduction and structural integrity. Conventional aluminum alloy pistons struggle to maintain sufficient strength when designers attempt to reduce mass for improved engine responsiveness and fuel efficiency. This compromise becomes particularly pronounced in high-performance applications where thermal loads exceed 300°C and mechanical stresses approach 100 MPa during operation.

Material fatigue represents another significant constraint, with current designs exhibiting reduced service life under sustained high-temperature cycling. Laboratory testing reveals that after approximately 500 hours of operation at peak load conditions, micro-fractures begin to develop at stress concentration points, particularly around the piston pin bosses and ring grooves. These structural weaknesses progressively compromise performance and can ultimately lead to catastrophic failure.

Thermal management presents persistent challenges in current piston designs. The temperature gradient across the piston crown can exceed 200°C, creating thermal expansion differentials that induce mechanical stress and potential deformation. Existing cooling solutions, including oil jet cooling and internal cooling galleries, add complexity and weight while providing only marginal improvements in thermal stability.

Manufacturing limitations further constrain innovation in piston design. Traditional casting methods restrict geometric complexity, while more advanced techniques like forging impose constraints on material selection. The precision required for modern high-compression engines demands tolerances of ±0.005mm, which increases production costs and limits material options.

The integration of advanced materials faces significant hurdles. While ceramic composites and metal matrix materials offer theoretical advantages in weight-to-strength ratio, their implementation is hindered by joining difficulties, unpredictable failure modes, and prohibitive production costs. Current manufacturing processes struggle to economically incorporate these materials into mass-production environments.

Computational modeling limitations also impede progress. Current simulation tools cannot fully capture the complex interactions between thermal, mechanical, and tribological factors in real-world operating conditions. This modeling gap forces designers to rely on conservative safety factors, resulting in overengineered components that sacrifice potential weight reduction.

Emissions regulations create additional design constraints, as pistons must now accommodate increasingly complex combustion chamber geometries optimized for reduced emissions. These requirements often conflict with structural optimization goals, forcing compromises that impact both performance and durability.

Material fatigue represents another significant constraint, with current designs exhibiting reduced service life under sustained high-temperature cycling. Laboratory testing reveals that after approximately 500 hours of operation at peak load conditions, micro-fractures begin to develop at stress concentration points, particularly around the piston pin bosses and ring grooves. These structural weaknesses progressively compromise performance and can ultimately lead to catastrophic failure.

Thermal management presents persistent challenges in current piston designs. The temperature gradient across the piston crown can exceed 200°C, creating thermal expansion differentials that induce mechanical stress and potential deformation. Existing cooling solutions, including oil jet cooling and internal cooling galleries, add complexity and weight while providing only marginal improvements in thermal stability.

Manufacturing limitations further constrain innovation in piston design. Traditional casting methods restrict geometric complexity, while more advanced techniques like forging impose constraints on material selection. The precision required for modern high-compression engines demands tolerances of ±0.005mm, which increases production costs and limits material options.

The integration of advanced materials faces significant hurdles. While ceramic composites and metal matrix materials offer theoretical advantages in weight-to-strength ratio, their implementation is hindered by joining difficulties, unpredictable failure modes, and prohibitive production costs. Current manufacturing processes struggle to economically incorporate these materials into mass-production environments.

Computational modeling limitations also impede progress. Current simulation tools cannot fully capture the complex interactions between thermal, mechanical, and tribological factors in real-world operating conditions. This modeling gap forces designers to rely on conservative safety factors, resulting in overengineered components that sacrifice potential weight reduction.

Emissions regulations create additional design constraints, as pistons must now accommodate increasingly complex combustion chamber geometries optimized for reduced emissions. These requirements often conflict with structural optimization goals, forcing compromises that impact both performance and durability.

Contemporary Weight-Strength Balancing Solutions

01 Lightweight materials for V4 engine pistons

Various lightweight materials are used in V4 engine pistons to reduce weight while maintaining strength. These materials include aluminum alloys, titanium alloys, and composite materials. The reduced weight of the pistons helps to improve engine efficiency, reduce inertial forces, and enhance overall performance. The lightweight design also contributes to better fuel economy and reduced emissions while ensuring durability under high-temperature and high-pressure conditions.- Lightweight piston materials for V4 engines: Lightweight materials such as aluminum alloys, titanium, and composite materials are used in V4 engine pistons to reduce weight while maintaining structural integrity. These materials help improve engine performance by reducing reciprocating mass, which leads to better fuel efficiency and higher RPM capabilities. The reduced weight also decreases inertial forces, resulting in less stress on connecting rods and crankshafts.

- Reinforced piston designs for strength enhancement: Various structural reinforcement techniques are employed in V4 engine pistons to enhance strength without significantly increasing weight. These include ribbed designs, strut reinforcements, and optimized crown geometries. Such reinforcements are strategically placed at high-stress areas to withstand combustion pressures and thermal loads while maintaining the lightweight characteristics necessary for high-performance engines.

- Advanced manufacturing processes for piston weight reduction: Innovative manufacturing techniques such as precision forging, casting with controlled cooling, and advanced machining processes are used to create V4 engine pistons with optimized weight-to-strength ratios. These processes allow for more precise material distribution, thinner walls where possible, and reinforcement only where needed, resulting in pistons that are both lightweight and durable under high-stress engine conditions.

- Thermal management features affecting piston weight and strength: Thermal management features incorporated into V4 engine pistons, such as cooling galleries, thermal barriers, and specialized coatings, help maintain structural integrity under high-temperature conditions. These features allow for thinner piston designs without compromising strength, as they prevent thermal expansion issues and material weakening that could otherwise necessitate heavier designs to achieve the same durability.

- Composite and multi-material piston constructions: Hybrid and composite piston designs combine different materials to optimize the weight-strength balance in V4 engines. These may include steel inserts in aluminum pistons, ceramic thermal barriers, or fiber-reinforced components. By using stronger materials only where needed and lighter materials elsewhere, these designs achieve significant weight reduction while maintaining or even improving strength in critical areas exposed to high mechanical and thermal stresses.

02 Structural reinforcement techniques for V4 engine pistons

Various structural reinforcement techniques are employed to enhance the strength of V4 engine pistons. These include ribbed designs, reinforced skirt structures, and optimized crown geometries. The reinforcement structures are strategically placed to withstand the high combustion pressures and thermal stresses experienced during engine operation. These design enhancements improve the durability and reliability of the pistons while minimizing weight increase, resulting in better overall engine performance.Expand Specific Solutions03 Heat-resistant coatings and treatments for V4 engine pistons

Specialized coatings and surface treatments are applied to V4 engine pistons to enhance their heat resistance and durability. These include thermal barrier coatings, anodizing processes, and nitriding treatments. These surface modifications help to reduce thermal expansion, prevent wear, and increase the overall strength-to-weight ratio of the pistons. By improving heat management, these treatments allow for higher operating temperatures and increased engine efficiency while maintaining structural integrity.Expand Specific Solutions04 Advanced manufacturing processes for V4 engine pistons

Advanced manufacturing processes are utilized to produce V4 engine pistons with optimal weight and strength characteristics. These include precision forging, casting techniques with controlled cooling, and additive manufacturing methods. These processes enable the creation of complex internal structures and variable wall thicknesses that would be difficult to achieve with conventional manufacturing methods. The result is pistons with improved strength-to-weight ratios, better dimensional accuracy, and enhanced performance characteristics.Expand Specific Solutions05 Innovative piston designs for V4 engines

Innovative piston designs for V4 engines focus on optimizing the balance between weight and strength. These designs include articulated pistons, variable compression pistons, and pistons with cooling galleries. The designs incorporate features such as asymmetrical skirts, optimized ring lands, and strategically placed weight reduction pockets. These innovations help to reduce reciprocating mass while maintaining structural integrity, resulting in improved engine performance, reduced vibration, and enhanced durability under high-load conditions.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The V4 Engine Piston Design market is currently in a mature growth phase, with established players like MAHLE GmbH, KS Kolbenschmidt, and Federal-Mogul (Tenneco) dominating the technical landscape. The global market size for engine pistons is estimated at approximately $4-5 billion, with steady growth driven by automotive and industrial applications. Technical maturity varies significantly across competitors, with European manufacturers demonstrating advanced lightweight alloy technologies while Asian companies like Weichai Power and Chery Automobile focus on cost-effective manufacturing solutions. Major OEMs including GM, Honda, and Audi maintain significant in-house piston design capabilities, particularly for high-performance applications where the weight-strength ratio represents a critical competitive advantage.

KS Kolbenschmidt GmbH

Technical Solution: KS Kolbenschmidt has developed a proprietary "LiteKS" piston technology specifically for V4 engines that utilizes a steel reinforcement insert in the aluminum piston body. This design achieves weight reduction of approximately 25% compared to conventional pistons while maintaining strength parameters. Their pistons feature an innovative cooling gallery design with sodium filling that enhances heat dissipation from critical areas. The company employs a specialized casting process that creates a graduated material structure, with denser aluminum in high-stress regions. KS Kolbenschmidt's V4 pistons incorporate diamond-like carbon (DLC) coatings on skirt surfaces, reducing friction by up to 30% compared to conventional designs. Their patented "Silitec" process creates a hypereutectic aluminum-silicon alloy with superior wear resistance and thermal stability. The company has also developed specialized ring groove geometries that maintain sealing performance under extreme conditions while allowing for thinner, lighter overall piston designs.

Strengths: Exceptional weight reduction while maintaining mechanical integrity; superior thermal management through innovative cooling solutions; reduced friction leading to improved efficiency. Weaknesses: Higher initial manufacturing costs; specialized materials may limit repair options; potential challenges in scaling production for mass market applications.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered a dual-material piston design for V4 engines that combines a forged steel crown with an aluminum skirt. This hybrid approach addresses the critical weight-strength balance by placing stronger materials only where needed. Their patented "DuraBowl" process uses friction welding to reinforce the piston bowl rim, allowing for thinner overall designs while maintaining durability. GM's pistons incorporate variable wall thickness technology, with thicker sections in high-stress areas and thinner walls elsewhere to optimize weight distribution. The company utilizes advanced finite element analysis to simulate thermal and mechanical stresses throughout the engine cycle, resulting in designs that are up to 15% lighter than previous generations while handling 10% higher peak cylinder pressures. Their latest V4 pistons also feature integrated cooling channels that are precision-cast rather than drilled, improving cooling efficiency while maintaining structural integrity.

Strengths: Excellent balance of weight reduction and durability; proven performance in high-output applications; sophisticated thermal management. Weaknesses: Complex manufacturing process increases production costs; requires specialized assembly techniques; potential compatibility issues when integrating with third-party components.

Critical Patents and Innovations in Piston Materials

Optimized hub support

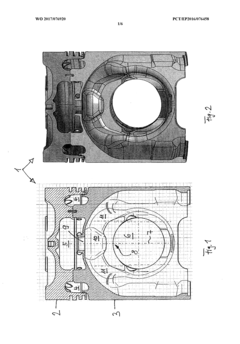

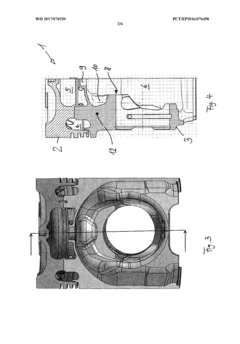

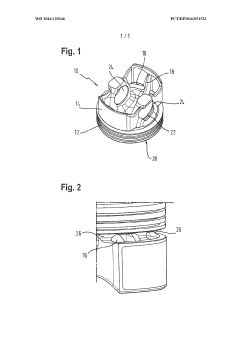

PatentWO2017076920A1

Innovation

- The piston design incorporates a recess in the lower part above the pin bore and a web around the outer circumference to reduce material where loads are reduced, with a web supporting the upper part during deformation, and additional recesses and rounded transitions to avoid weakening and crack formation.

Piston for an internal combustion engine and method for producing the piston for an internal combustion engine

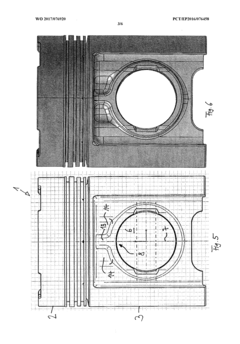

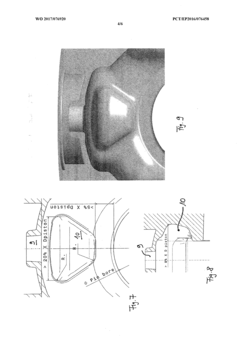

PatentWO2016120246A1

Innovation

- A piston design featuring an annular zone with openings between the ring zone and shaft, a central rib for added strength, and a locking groove with interruptions to reduce material usage, along with a specific skirt configuration for weight savings and stability, addresses the need for both low weight and high strength.

Environmental Regulations Impact on Piston Design

Environmental regulations have become increasingly stringent worldwide, significantly influencing the design parameters of engine components, particularly pistons in V4 engines. The regulatory landscape has evolved from basic emissions standards to comprehensive frameworks addressing greenhouse gases, particulate matter, and NOx emissions. These regulations, such as Euro 7 in Europe, China 6 in Asia, and EPA Tier 3 in the United States, have fundamentally altered the approach to piston design.

The primary regulatory impact manifests in the demand for higher combustion efficiency and reduced emissions. This necessitates pistons that can withstand higher temperatures and pressures while maintaining structural integrity. Engineers must now design pistons that facilitate more complete combustion, which often means accommodating higher compression ratios and altered combustion chamber geometries.

Material selection for pistons has been directly influenced by these regulatory pressures. Traditional aluminum alloys are being enhanced with silicon, nickel, and copper to improve thermal stability and strength. Some manufacturers are exploring advanced materials like titanium alloys and ceramic composites that offer superior strength-to-weight ratios while withstanding the more extreme operating conditions required for emissions compliance.

Weight reduction remains a critical factor in meeting fleet-wide fuel efficiency standards. Regulations like the Corporate Average Fuel Economy (CAFE) standards indirectly push for lighter engine components. However, this weight reduction must not compromise the piston's ability to withstand the higher thermal and mechanical stresses associated with cleaner combustion. This has led to innovative design approaches such as variable wall thickness and topologically optimized structures.

The cooling requirements for pistons have also evolved in response to regulatory demands. Higher combustion temperatures necessitate more effective heat management strategies, including oil jet cooling systems and advanced thermal barrier coatings. These features add complexity to piston design but are essential for maintaining performance while meeting emissions targets.

Durability testing protocols have been expanded to ensure pistons can maintain their integrity throughout the vehicle's lifecycle while continuing to meet emissions standards. This includes accelerated aging tests that simulate the effects of thousands of hours of operation under varying conditions. The regulatory requirement for on-board diagnostics (OBD) systems to monitor emissions performance throughout the vehicle's life has further emphasized the need for consistent long-term piston performance.

Manufacturing processes for pistons are also adapting to regulatory pressures, with greater emphasis on precision and quality control. Tighter tolerances are necessary to ensure optimal combustion characteristics and minimize oil consumption, both of which directly impact emissions performance. Advanced manufacturing techniques like 3D printing and precision forging are being employed to achieve these exacting standards while maintaining economic viability.

The primary regulatory impact manifests in the demand for higher combustion efficiency and reduced emissions. This necessitates pistons that can withstand higher temperatures and pressures while maintaining structural integrity. Engineers must now design pistons that facilitate more complete combustion, which often means accommodating higher compression ratios and altered combustion chamber geometries.

Material selection for pistons has been directly influenced by these regulatory pressures. Traditional aluminum alloys are being enhanced with silicon, nickel, and copper to improve thermal stability and strength. Some manufacturers are exploring advanced materials like titanium alloys and ceramic composites that offer superior strength-to-weight ratios while withstanding the more extreme operating conditions required for emissions compliance.

Weight reduction remains a critical factor in meeting fleet-wide fuel efficiency standards. Regulations like the Corporate Average Fuel Economy (CAFE) standards indirectly push for lighter engine components. However, this weight reduction must not compromise the piston's ability to withstand the higher thermal and mechanical stresses associated with cleaner combustion. This has led to innovative design approaches such as variable wall thickness and topologically optimized structures.

The cooling requirements for pistons have also evolved in response to regulatory demands. Higher combustion temperatures necessitate more effective heat management strategies, including oil jet cooling systems and advanced thermal barrier coatings. These features add complexity to piston design but are essential for maintaining performance while meeting emissions targets.

Durability testing protocols have been expanded to ensure pistons can maintain their integrity throughout the vehicle's lifecycle while continuing to meet emissions standards. This includes accelerated aging tests that simulate the effects of thousands of hours of operation under varying conditions. The regulatory requirement for on-board diagnostics (OBD) systems to monitor emissions performance throughout the vehicle's life has further emphasized the need for consistent long-term piston performance.

Manufacturing processes for pistons are also adapting to regulatory pressures, with greater emphasis on precision and quality control. Tighter tolerances are necessary to ensure optimal combustion characteristics and minimize oil consumption, both of which directly impact emissions performance. Advanced manufacturing techniques like 3D printing and precision forging are being employed to achieve these exacting standards while maintaining economic viability.

Thermal Management Considerations in Modern Pistons

Thermal management represents a critical aspect of modern piston design, particularly in V4 engines where the balance between weight and strength must be carefully optimized. As engine performance demands increase, pistons are subjected to increasingly extreme thermal conditions, with temperatures potentially exceeding 300°C at the crown and thermal gradients of over 200°C across the piston body during operation.

Modern pistons employ sophisticated cooling strategies to maintain structural integrity while minimizing weight. Oil jet cooling systems direct pressurized oil to the underside of the piston crown, effectively reducing peak temperatures by 20-40°C. This targeted cooling approach allows designers to reduce material thickness without compromising durability, directly addressing the weight-strength compromise.

Material selection has evolved significantly to enhance thermal management capabilities. Advanced aluminum alloys incorporating silicon, copper, and nickel offer superior heat dissipation properties while maintaining strength at elevated temperatures. These specialized alloys can maintain up to 70% of their room temperature strength at operating temperatures, compared to just 40-50% for conventional alloys.

Thermal barrier coatings (TBCs) represent another significant advancement in piston thermal management. Ceramic-based coatings with thicknesses of 100-300 microns create an insulating layer that reduces heat transfer into the piston body by 15-25%. This thermal isolation allows for higher combustion temperatures and improved efficiency while protecting the underlying aluminum structure.

Finite Element Analysis (FEA) has revolutionized thermal management design by enabling precise modeling of heat distribution throughout the piston structure. Engineers can now identify and address thermal hotspots before physical prototyping, optimizing material distribution to maintain strength where temperatures are highest while reducing weight in less thermally stressed areas.

The geometry of cooling galleries within pistons has become increasingly sophisticated, with computer-optimized flow patterns ensuring maximum heat extraction with minimal weight penalty. Modern designs incorporate asymmetric cooling channels that direct more cooling capacity to areas experiencing the highest thermal loads, particularly on the exhaust side of the piston.

Thermal expansion management represents another critical consideration, as uneven heating can cause piston deformation and potential failure. Contemporary designs incorporate variable wall thicknesses and strategic reinforcement to control expansion patterns, maintaining optimal piston-to-cylinder clearances throughout the operating temperature range.

Modern pistons employ sophisticated cooling strategies to maintain structural integrity while minimizing weight. Oil jet cooling systems direct pressurized oil to the underside of the piston crown, effectively reducing peak temperatures by 20-40°C. This targeted cooling approach allows designers to reduce material thickness without compromising durability, directly addressing the weight-strength compromise.

Material selection has evolved significantly to enhance thermal management capabilities. Advanced aluminum alloys incorporating silicon, copper, and nickel offer superior heat dissipation properties while maintaining strength at elevated temperatures. These specialized alloys can maintain up to 70% of their room temperature strength at operating temperatures, compared to just 40-50% for conventional alloys.

Thermal barrier coatings (TBCs) represent another significant advancement in piston thermal management. Ceramic-based coatings with thicknesses of 100-300 microns create an insulating layer that reduces heat transfer into the piston body by 15-25%. This thermal isolation allows for higher combustion temperatures and improved efficiency while protecting the underlying aluminum structure.

Finite Element Analysis (FEA) has revolutionized thermal management design by enabling precise modeling of heat distribution throughout the piston structure. Engineers can now identify and address thermal hotspots before physical prototyping, optimizing material distribution to maintain strength where temperatures are highest while reducing weight in less thermally stressed areas.

The geometry of cooling galleries within pistons has become increasingly sophisticated, with computer-optimized flow patterns ensuring maximum heat extraction with minimal weight penalty. Modern designs incorporate asymmetric cooling channels that direct more cooling capacity to areas experiencing the highest thermal loads, particularly on the exhaust side of the piston.

Thermal expansion management represents another critical consideration, as uneven heating can cause piston deformation and potential failure. Contemporary designs incorporate variable wall thicknesses and strategic reinforcement to control expansion patterns, maintaining optimal piston-to-cylinder clearances throughout the operating temperature range.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!