V4 Engine Coating Technologies: Heat and Corrosion Resistance

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Coating Evolution and Objectives

The evolution of coating technologies for V4 engines has undergone significant transformation over the past several decades, driven by increasing demands for engine performance, durability, and efficiency. Initially, engine coatings were primarily focused on basic corrosion protection, utilizing simple metallic layers and basic ceramic applications. The 1970s marked the beginning of more sophisticated approaches with the introduction of thermal barrier coatings (TBCs) derived from aerospace applications.

By the 1990s, the development of plasma spray techniques revolutionized the coating industry, enabling more uniform and durable protective layers for engine components. This period also witnessed the emergence of physical vapor deposition (PVD) and chemical vapor deposition (CVD) technologies, allowing for nanoscale precision in coating application. The early 2000s brought significant advancements in ceramic matrix composites and diamond-like carbon (DLC) coatings, substantially improving heat resistance properties.

The current technological landscape features multi-layered coating systems that combine different materials to address multiple challenges simultaneously. Modern V4 engine coatings typically consist of a bond coat for adhesion, a thermally grown oxide layer for oxidation resistance, and a ceramic top coat for thermal insulation. These sophisticated systems can withstand temperatures exceeding 1200°C while providing protection against various forms of corrosion.

The primary objectives of contemporary V4 engine coating research center around several key areas. First, enhancing thermal efficiency by developing coatings that can maintain structural integrity at increasingly higher operating temperatures, thereby improving fuel economy and reducing emissions. Second, extending component lifespan by providing superior protection against high-temperature oxidation, hot corrosion, and mechanical wear, particularly in critical areas such as combustion chambers and exhaust valves.

Additionally, researchers aim to develop environmentally sustainable coating solutions that eliminate toxic materials like hexavalent chromium while maintaining or improving performance characteristics. Cost-effectiveness remains another crucial objective, with efforts focused on streamlining application processes and reducing rare earth element dependencies in coating formulations.

Looking forward, the industry is moving toward smart coating systems with self-healing properties and in-situ monitoring capabilities. These advanced coatings will potentially incorporate nanomaterials and phase-change materials to provide adaptive thermal management. The ultimate goal is to develop coating technologies that can enable V4 engines to operate at higher temperatures with greater efficiency while simultaneously extending service intervals and reducing maintenance costs.

By the 1990s, the development of plasma spray techniques revolutionized the coating industry, enabling more uniform and durable protective layers for engine components. This period also witnessed the emergence of physical vapor deposition (PVD) and chemical vapor deposition (CVD) technologies, allowing for nanoscale precision in coating application. The early 2000s brought significant advancements in ceramic matrix composites and diamond-like carbon (DLC) coatings, substantially improving heat resistance properties.

The current technological landscape features multi-layered coating systems that combine different materials to address multiple challenges simultaneously. Modern V4 engine coatings typically consist of a bond coat for adhesion, a thermally grown oxide layer for oxidation resistance, and a ceramic top coat for thermal insulation. These sophisticated systems can withstand temperatures exceeding 1200°C while providing protection against various forms of corrosion.

The primary objectives of contemporary V4 engine coating research center around several key areas. First, enhancing thermal efficiency by developing coatings that can maintain structural integrity at increasingly higher operating temperatures, thereby improving fuel economy and reducing emissions. Second, extending component lifespan by providing superior protection against high-temperature oxidation, hot corrosion, and mechanical wear, particularly in critical areas such as combustion chambers and exhaust valves.

Additionally, researchers aim to develop environmentally sustainable coating solutions that eliminate toxic materials like hexavalent chromium while maintaining or improving performance characteristics. Cost-effectiveness remains another crucial objective, with efforts focused on streamlining application processes and reducing rare earth element dependencies in coating formulations.

Looking forward, the industry is moving toward smart coating systems with self-healing properties and in-situ monitoring capabilities. These advanced coatings will potentially incorporate nanomaterials and phase-change materials to provide adaptive thermal management. The ultimate goal is to develop coating technologies that can enable V4 engines to operate at higher temperatures with greater efficiency while simultaneously extending service intervals and reducing maintenance costs.

Market Demand for Advanced Engine Coating Solutions

The global market for advanced engine coating solutions has experienced significant growth in recent years, driven primarily by the automotive and aerospace industries' increasing demand for enhanced engine performance and durability. Current market valuations indicate that the thermal barrier coatings segment alone reached approximately 11 billion USD in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2030.

The primary market drivers for V4 engine coating technologies stem from stringent environmental regulations worldwide that mandate reduced emissions and improved fuel efficiency. These regulations have compelled manufacturers to develop engines that operate at higher temperatures for better combustion efficiency, consequently increasing the need for advanced heat-resistant coatings. The European Union's Euro 7 standards and similar regulations in North America and Asia have accelerated this trend significantly.

Consumer demand patterns also reveal a growing preference for vehicles with extended warranty periods and lower maintenance costs. This has pushed manufacturers to implement coating solutions that extend engine life and maintain performance over longer operational periods. Market research indicates that consumers are willing to pay a premium of 3-5% for vehicles with demonstrably superior engine durability.

In the industrial sector, the demand for corrosion-resistant coatings has seen remarkable growth, particularly in marine applications, power generation, and heavy machinery. These industries require engines that can withstand harsh operating environments, including exposure to saltwater, chemical contaminants, and extreme temperature fluctuations. The market size for corrosion-resistant coatings in industrial engines exceeded 7 billion USD in 2022.

Regional market analysis shows that Asia-Pacific represents the fastest-growing market for advanced engine coating technologies, with China and India leading the demand due to rapid industrialization and automotive sector growth. North America and Europe maintain significant market shares, driven by their established automotive and aerospace industries and stringent environmental regulations.

The commercial vehicle segment has emerged as a particularly promising market, with fleet operators increasingly recognizing the long-term cost benefits of engines with advanced coating technologies. Studies indicate that properly coated engine components can reduce maintenance costs by up to 15% over the vehicle's operational lifetime and extend service intervals by 20-30%.

Market forecasts suggest that nano-ceramic coatings and multi-layer composite coatings will see the highest demand growth in the coming years, as these technologies offer superior heat resistance and anti-corrosion properties while maintaining relatively competitive production costs.

The primary market drivers for V4 engine coating technologies stem from stringent environmental regulations worldwide that mandate reduced emissions and improved fuel efficiency. These regulations have compelled manufacturers to develop engines that operate at higher temperatures for better combustion efficiency, consequently increasing the need for advanced heat-resistant coatings. The European Union's Euro 7 standards and similar regulations in North America and Asia have accelerated this trend significantly.

Consumer demand patterns also reveal a growing preference for vehicles with extended warranty periods and lower maintenance costs. This has pushed manufacturers to implement coating solutions that extend engine life and maintain performance over longer operational periods. Market research indicates that consumers are willing to pay a premium of 3-5% for vehicles with demonstrably superior engine durability.

In the industrial sector, the demand for corrosion-resistant coatings has seen remarkable growth, particularly in marine applications, power generation, and heavy machinery. These industries require engines that can withstand harsh operating environments, including exposure to saltwater, chemical contaminants, and extreme temperature fluctuations. The market size for corrosion-resistant coatings in industrial engines exceeded 7 billion USD in 2022.

Regional market analysis shows that Asia-Pacific represents the fastest-growing market for advanced engine coating technologies, with China and India leading the demand due to rapid industrialization and automotive sector growth. North America and Europe maintain significant market shares, driven by their established automotive and aerospace industries and stringent environmental regulations.

The commercial vehicle segment has emerged as a particularly promising market, with fleet operators increasingly recognizing the long-term cost benefits of engines with advanced coating technologies. Studies indicate that properly coated engine components can reduce maintenance costs by up to 15% over the vehicle's operational lifetime and extend service intervals by 20-30%.

Market forecasts suggest that nano-ceramic coatings and multi-layer composite coatings will see the highest demand growth in the coming years, as these technologies offer superior heat resistance and anti-corrosion properties while maintaining relatively competitive production costs.

Current Coating Technologies and Technical Barriers

The current landscape of V4 engine coating technologies presents a diverse array of solutions designed to address heat and corrosion resistance challenges. Thermal barrier coatings (TBCs) represent the most widely adopted technology, typically utilizing yttria-stabilized zirconia (YSZ) as the primary material due to its exceptional thermal insulation properties. These coatings can reduce metal surface temperatures by 100-300°C, significantly extending component lifespan in high-temperature environments. However, YSZ-based TBCs face limitations at temperatures exceeding 1200°C, where phase destabilization occurs.

Metallic coatings, particularly MCrAlY (where M represents nickel, cobalt, or a combination), offer excellent oxidation resistance through the formation of protective alumina scales. These coatings demonstrate superior adhesion to substrate materials but suffer from thermal expansion mismatch issues that can lead to spallation during thermal cycling. The industry has attempted to address this through gradient-layered approaches, though complete resolution remains elusive.

Ceramic matrix composite (CMC) coatings have emerged as promising alternatives, offering both thermal and corrosion resistance while maintaining structural integrity. Silicon carbide (SiC) and silicon nitride (Si3N4) variants show particular promise for V4 engine applications. However, manufacturing complexity and high production costs currently limit widespread adoption, with deposition techniques requiring further refinement.

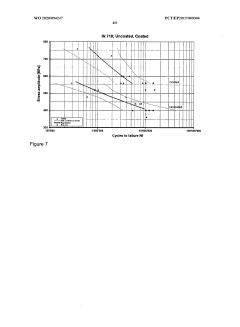

A significant technical barrier across all coating technologies is the challenge of maintaining coating integrity during thermal cycling. The repeated expansion and contraction of engine components create stress at coating-substrate interfaces, leading to cracking and eventual failure. Current solutions involving compliant layers show promise but require further development to achieve optimal performance in V4 engine operating conditions.

Deposition techniques present another critical challenge. While physical vapor deposition (PVD) offers excellent control over coating microstructure, it struggles with complex geometries common in V4 engine components. Thermal spray techniques provide better coverage but often result in higher porosity and reduced coating density. Emerging techniques like solution precursor plasma spray (SPPS) show promise in addressing these limitations but remain in developmental stages.

Corrosion resistance mechanisms in current coatings rely heavily on barrier protection rather than active corrosion inhibition. This approach proves insufficient in environments containing sulfur and vanadium contaminants common in certain fuel types. The development of self-healing coating systems represents a frontier technology that could address this limitation, though practical implementation faces significant challenges in terms of activation mechanisms and healing material reservoirs.

Metallic coatings, particularly MCrAlY (where M represents nickel, cobalt, or a combination), offer excellent oxidation resistance through the formation of protective alumina scales. These coatings demonstrate superior adhesion to substrate materials but suffer from thermal expansion mismatch issues that can lead to spallation during thermal cycling. The industry has attempted to address this through gradient-layered approaches, though complete resolution remains elusive.

Ceramic matrix composite (CMC) coatings have emerged as promising alternatives, offering both thermal and corrosion resistance while maintaining structural integrity. Silicon carbide (SiC) and silicon nitride (Si3N4) variants show particular promise for V4 engine applications. However, manufacturing complexity and high production costs currently limit widespread adoption, with deposition techniques requiring further refinement.

A significant technical barrier across all coating technologies is the challenge of maintaining coating integrity during thermal cycling. The repeated expansion and contraction of engine components create stress at coating-substrate interfaces, leading to cracking and eventual failure. Current solutions involving compliant layers show promise but require further development to achieve optimal performance in V4 engine operating conditions.

Deposition techniques present another critical challenge. While physical vapor deposition (PVD) offers excellent control over coating microstructure, it struggles with complex geometries common in V4 engine components. Thermal spray techniques provide better coverage but often result in higher porosity and reduced coating density. Emerging techniques like solution precursor plasma spray (SPPS) show promise in addressing these limitations but remain in developmental stages.

Corrosion resistance mechanisms in current coatings rely heavily on barrier protection rather than active corrosion inhibition. This approach proves insufficient in environments containing sulfur and vanadium contaminants common in certain fuel types. The development of self-healing coating systems represents a frontier technology that could address this limitation, though practical implementation faces significant challenges in terms of activation mechanisms and healing material reservoirs.

State-of-the-Art Engine Coating Solutions

01 Ceramic-based thermal barrier coatings

Ceramic-based coatings provide excellent thermal insulation for engine components exposed to high temperatures. These coatings typically consist of materials like yttria-stabilized zirconia (YSZ) that create a protective layer with low thermal conductivity. The ceramic layer acts as a barrier against heat transfer while maintaining structural integrity under extreme temperature conditions. These coatings are often applied using techniques such as plasma spraying or electron beam physical vapor deposition to achieve optimal adhesion and durability.- Ceramic-based thermal barrier coatings: Ceramic-based coatings provide excellent thermal insulation for engine components exposed to high temperatures. These coatings typically consist of materials like yttria-stabilized zirconia (YSZ) that create a protective barrier against heat transfer. The ceramic layer is often applied using techniques such as plasma spraying or electron beam physical vapor deposition, creating a microstructure that effectively reduces heat conduction while maintaining durability under thermal cycling conditions. These coatings can significantly extend the operational life of engine components by maintaining lower metal temperatures.

- Multi-layer coating systems for combined protection: Multi-layer coating systems combine different materials to provide both heat and corrosion resistance. These systems typically include a bond coat that adheres to the metal substrate, a thermally grown oxide layer that forms during operation, and a top ceramic layer. The bond coat often contains aluminum to form a protective aluminum oxide scale, while the ceramic top coat provides thermal insulation. This layered approach creates a comprehensive protection system that addresses both thermal and chemical degradation mechanisms, making it ideal for severe operating environments in modern engines.

- Metal-based high-temperature resistant coatings: Metal-based coatings for engine components utilize specialized alloys that can withstand extreme temperatures while providing corrosion resistance. These coatings often incorporate elements such as nickel, cobalt, chromium, and aluminum to form protective oxide scales at high temperatures. MCrAlY (where M represents nickel, cobalt, or a combination) coatings are commonly used as they form stable aluminum oxide layers that protect against oxidation. These metallic coatings can be applied through various methods including thermal spraying, physical vapor deposition, or electroplating to achieve optimal adhesion and performance.

- Nanostructured and composite coatings: Nanostructured and composite coatings represent advanced solutions for engine protection, incorporating nanoscale materials or combining different materials to enhance performance. These coatings feature refined microstructures with grain sizes in the nanometer range, which improves mechanical properties and thermal stability. Nanocomposite coatings may combine ceramic particles within a metal matrix or utilize layered structures with nanoscale thickness. The unique properties of these coatings include improved toughness, better thermal shock resistance, and enhanced durability under cyclic thermal conditions, making them suitable for next-generation engine applications.

- Surface treatment and modification techniques: Surface treatment and modification techniques enhance the base material's resistance to heat and corrosion without necessarily applying a distinct coating layer. These processes include diffusion treatments, such as aluminizing or chromizing, where protective elements diffuse into the surface of the component. Other techniques involve surface hardening through nitriding or carburizing, or surface texturing to improve coating adhesion. These treatments can modify the chemical composition and microstructure of the surface layer, creating a gradient of properties that enhances both heat and corrosion resistance while maintaining strong integration with the base material.

02 Metal-matrix composite coatings

Metal-matrix composite coatings combine metallic materials with reinforcing particles or fibers to enhance both heat and corrosion resistance. These coatings typically incorporate aluminum, nickel, or cobalt as the matrix material with ceramic particles such as silicon carbide or aluminum oxide as reinforcement. The resulting composite structure provides superior mechanical properties at high temperatures while offering protection against oxidation and corrosion. These coatings can be applied through various methods including thermal spraying, electroplating, or powder metallurgy techniques.Expand Specific Solutions03 Multi-layer coating systems

Multi-layer coating systems consist of several functional layers designed to provide comprehensive protection against both heat and corrosion. These systems typically include a bond coat that adheres to the engine substrate, a thermally grown oxide layer that forms during operation, and a top ceramic layer for thermal insulation. Each layer serves a specific purpose: the bond coat provides oxidation resistance and adhesion, the oxide layer acts as a diffusion barrier, and the top coat provides thermal insulation. This layered approach creates a synergistic effect that significantly enhances the overall durability and performance of engine components.Expand Specific Solutions04 Nanostructured and nanocomposite coatings

Nanostructured and nanocomposite coatings utilize materials engineered at the nanoscale to achieve superior heat and corrosion resistance. These coatings incorporate nanoparticles or have nanoscale features that significantly enhance their protective properties. The nanoscale structure creates numerous interfaces that impede heat transfer and crack propagation while improving adhesion to the substrate. Additionally, these coatings can self-heal minor damage through the controlled release of corrosion inhibitors stored in nanocontainers within the coating matrix, extending the service life of engine components under extreme conditions.Expand Specific Solutions05 Environmental barrier coatings for advanced engines

Environmental barrier coatings are specifically designed to protect engine components from the combined effects of high temperature, corrosive gases, and particulate erosion. These coatings are particularly important for advanced engines using ceramic matrix composites or intermetallic materials. They typically consist of rare earth silicates or aluminosilicates that provide excellent chemical stability in combustion environments. The coatings create a protective layer that prevents the degradation of underlying materials by blocking the penetration of oxygen, water vapor, and other corrosive species while maintaining thermal protection at temperatures exceeding 1200°C.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The V4 Engine Coating Technologies market is currently in a growth phase, driven by increasing demands for enhanced heat and corrosion resistance in automotive and aerospace applications. The global market size is estimated to reach $3.5 billion by 2027, with a CAGR of 6.8%. Technologically, the field shows varying maturity levels across different coating types. Industry leaders like General Electric, Praxair S.T. Technology, and Oerlikon Surface Solutions have established advanced thermal barrier coatings, while companies such as Caterpillar, Southwest Research Institute, and IHI Corp are developing innovative ceramic-metallic composites. Chinese players including AVIC Shenyang Liming and FAW are rapidly advancing their capabilities, particularly in nano-structured coatings. Automotive manufacturers like Isuzu, Tata Motors, and Suzuki are increasingly integrating these technologies to meet stringent emission standards and performance requirements.

Praxair S.T. Technology, Inc.

Technical Solution: Praxair has pioneered thermal spray coating solutions for V4 engines with their HVOF (High Velocity Oxy-Fuel) and plasma spray technologies. Their proprietary MCrAlY (where M stands for Ni, Co, or combination) coating systems provide exceptional heat resistance up to 1200°C while maintaining structural integrity. The company has developed a specialized suspension plasma spray process that creates columnar microstructures with controlled porosity (7-15%) to enhance thermal insulation while maintaining mechanical strength. Their coatings incorporate rare earth elements like yttrium and hafnium to improve oxide scale adhesion during thermal cycling. Praxair's recent innovation includes nanostructured cermet coatings that combine ceramic hardness with metallic toughness, achieving 40% better thermal shock resistance than conventional coatings.

Strengths: Exceptional thermal barrier properties with controlled porosity; excellent resistance to thermal fatigue; proven track record in aerospace applications transferable to automotive V4 engines. Weaknesses: Relatively high application costs; requires precise control of spray parameters; may add weight to engine components compared to thinner coating alternatives.

Oerlikon Surface Solutions AG

Technical Solution: Oerlikon Surface Solutions has developed advanced PVD (Physical Vapor Deposition) and PACVD (Plasma-Assisted Chemical Vapor Deposition) coating technologies specifically for V4 engine components. Their BALINIT® CRONOS coating system utilizes a multi-layer approach combining chromium nitride and aluminum-based compounds to create thermal barrier coatings that can withstand temperatures up to 1100°C while providing exceptional corrosion resistance. The coating process involves precise control of plasma parameters to achieve optimal microstructure with nano-layered architecture that enhances both thermal insulation and wear resistance. Their proprietary technology allows for coating thicknesses between 2-10 μm with excellent adhesion properties even under thermal cycling conditions typical in V4 engines.

Strengths: Superior thermal cycling resistance with minimal coating degradation; excellent adhesion properties even at high temperatures; ability to coat complex geometries with uniform thickness. Weaknesses: Higher production costs compared to conventional coatings; requires specialized equipment for application; longer processing time than traditional methods.

Key Patents in Heat and Corrosion Resistant Coatings

Corrosion resistant coatings

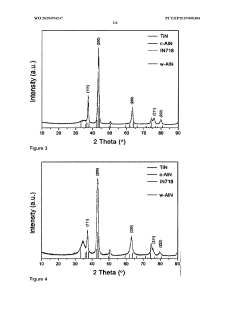

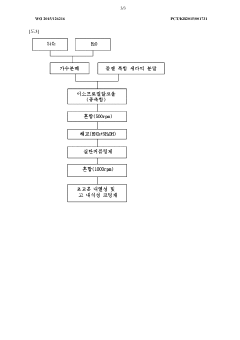

PatentWO2020094247A1

Innovation

- A physical vapor deposition (PVD) method, specifically cathodic arc deposition, is used to apply a titanium aluminum nitride (TiAIN) coating with a higher aluminum to titanium ratio, forming a wurtzite phase, which enhances corrosion and erosion resistance by suppressing diffusion and oxidation processes while maintaining mechanical properties.

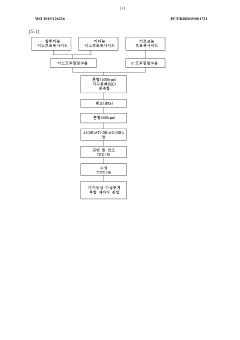

Composite ceramic prepared by using sol-gel method, thin film coating material with ultra-high temperature heat resistance and high corrosion resistance, containing same, and preparation method therefor

PatentWO2015126216A1

Innovation

- A method for producing a multi-functional composite ceramic powder using a modified sol-gel process with aluminum alkoxide, titanium alkoxide, and zirconium alkoxide, resulting in a thin film coating material with alumina, titania, and zirconia that exhibits excellent heat resistance, corrosion resistance, durability, and chemical resistance, achieved through specific steps of dissolving, mixing, gelling, peptizing, heating, and baking.

Environmental Impact and Sustainability Factors

The environmental impact of V4 engine coating technologies extends far beyond performance considerations, encompassing critical sustainability factors that influence both manufacturing processes and operational lifecycles. Traditional coating methods often involve hazardous materials such as hexavalent chromium and cadmium, which pose significant environmental and health risks. Recent regulatory frameworks, including REACH in Europe and similar initiatives globally, have accelerated the transition toward more environmentally responsible alternatives.

Modern thermal spray coatings and PVD (Physical Vapor Deposition) processes have demonstrated substantial reductions in toxic waste generation compared to conventional electroplating techniques. Quantitative assessments indicate that advanced ceramic coating processes can reduce hazardous waste by approximately 60-75% while decreasing water consumption by up to 40% during manufacturing.

The sustainability profile of coating technologies must also consider their contribution to engine efficiency and longevity. Enhanced thermal barrier coatings enable engines to operate at higher temperatures, improving fuel efficiency by 2-5% and consequently reducing carbon emissions. Furthermore, superior corrosion resistance extends component lifespan by 30-50%, significantly decreasing resource consumption associated with replacement parts manufacturing.

Life cycle assessment (LCA) studies reveal that the environmental footprint of advanced coating technologies demonstrates favorable outcomes when evaluated across the entire product lifecycle. While production of certain ceramic coatings may require higher initial energy inputs, this investment is typically offset by operational efficiency gains and extended service intervals. The net carbon reduction over a typical engine lifecycle can reach 15-20% when implementing optimized coating systems.

Emerging bio-inspired coating technologies represent a promising frontier for further sustainability improvements. Biomimetic approaches that replicate naturally occurring structures have shown potential for creating self-healing surfaces that minimize maintenance requirements while utilizing fewer toxic substances. Additionally, research into plant-derived precursors for ceramic coatings offers pathways to reduce dependence on energy-intensive mining operations for raw materials.

Circular economy principles are increasingly influencing coating technology development, with emphasis on recyclability and end-of-life considerations. Novel coating removal techniques enable more effective component reconditioning, while materials selection increasingly prioritizes elements with established recycling infrastructures. These approaches align with broader industry sustainability goals while maintaining the critical performance characteristics required for V4 engine applications.

Modern thermal spray coatings and PVD (Physical Vapor Deposition) processes have demonstrated substantial reductions in toxic waste generation compared to conventional electroplating techniques. Quantitative assessments indicate that advanced ceramic coating processes can reduce hazardous waste by approximately 60-75% while decreasing water consumption by up to 40% during manufacturing.

The sustainability profile of coating technologies must also consider their contribution to engine efficiency and longevity. Enhanced thermal barrier coatings enable engines to operate at higher temperatures, improving fuel efficiency by 2-5% and consequently reducing carbon emissions. Furthermore, superior corrosion resistance extends component lifespan by 30-50%, significantly decreasing resource consumption associated with replacement parts manufacturing.

Life cycle assessment (LCA) studies reveal that the environmental footprint of advanced coating technologies demonstrates favorable outcomes when evaluated across the entire product lifecycle. While production of certain ceramic coatings may require higher initial energy inputs, this investment is typically offset by operational efficiency gains and extended service intervals. The net carbon reduction over a typical engine lifecycle can reach 15-20% when implementing optimized coating systems.

Emerging bio-inspired coating technologies represent a promising frontier for further sustainability improvements. Biomimetic approaches that replicate naturally occurring structures have shown potential for creating self-healing surfaces that minimize maintenance requirements while utilizing fewer toxic substances. Additionally, research into plant-derived precursors for ceramic coatings offers pathways to reduce dependence on energy-intensive mining operations for raw materials.

Circular economy principles are increasingly influencing coating technology development, with emphasis on recyclability and end-of-life considerations. Novel coating removal techniques enable more effective component reconditioning, while materials selection increasingly prioritizes elements with established recycling infrastructures. These approaches align with broader industry sustainability goals while maintaining the critical performance characteristics required for V4 engine applications.

Material Science Breakthroughs for Engine Coatings

Recent advancements in material science have revolutionized engine coating technologies, particularly for V4 engines requiring superior heat and corrosion resistance. Ceramic matrix composites (CMCs) represent one of the most significant breakthroughs, combining ceramic reinforcements within a ceramic matrix to create coatings that maintain structural integrity at temperatures exceeding 1200°C while offering exceptional resistance to oxidation and corrosion.

Thermal barrier coatings (TBCs) have evolved substantially with the development of yttria-stabilized zirconia (YSZ) systems enhanced with rare earth elements. These advanced formulations demonstrate up to 30% improved thermal insulation properties compared to conventional coatings, allowing engine components to operate at higher temperatures without compromising mechanical integrity.

Nanostructured coatings represent another frontier in engine protection technology. By manipulating materials at the nanoscale, researchers have created multi-layered coatings with precisely engineered interfaces that effectively dissipate thermal energy and resist crack propagation. These nanocomposite coatings exhibit self-healing properties when minor damage occurs, significantly extending component lifespan in harsh operating environments.

Environmental barrier coatings (EBCs) have been developed specifically to address the challenges of water vapor and combustion byproducts in high-temperature environments. Recent breakthroughs in rare-earth silicates and hafnium-based compounds have produced EBCs capable of withstanding both thermal cycling and chemical attack from sulfur and vanadium contaminants common in various fuel types.

Physical vapor deposition (PVD) and chemical vapor deposition (CVD) techniques have undergone substantial refinement, enabling the creation of more uniform and adherent coatings. Hybrid deposition methods combining plasma-enhanced processes with traditional techniques have overcome previous limitations in coating complex geometries typical in V4 engine components.

Cold spray technology represents a paradigm shift in coating application, allowing the deposition of protective layers without subjecting the base material to high temperatures. This breakthrough preserves the microstructural integrity of the substrate while achieving excellent bonding strength and coating density, particularly valuable for aluminum and magnesium components in modern lightweight V4 engines.

Computational materials science has accelerated coating development through predictive modeling of coating performance under various operating conditions. Machine learning algorithms now enable the rapid screening of thousands of potential material combinations, identifying promising candidates for experimental validation and significantly reducing development timelines for next-generation engine coatings.

Thermal barrier coatings (TBCs) have evolved substantially with the development of yttria-stabilized zirconia (YSZ) systems enhanced with rare earth elements. These advanced formulations demonstrate up to 30% improved thermal insulation properties compared to conventional coatings, allowing engine components to operate at higher temperatures without compromising mechanical integrity.

Nanostructured coatings represent another frontier in engine protection technology. By manipulating materials at the nanoscale, researchers have created multi-layered coatings with precisely engineered interfaces that effectively dissipate thermal energy and resist crack propagation. These nanocomposite coatings exhibit self-healing properties when minor damage occurs, significantly extending component lifespan in harsh operating environments.

Environmental barrier coatings (EBCs) have been developed specifically to address the challenges of water vapor and combustion byproducts in high-temperature environments. Recent breakthroughs in rare-earth silicates and hafnium-based compounds have produced EBCs capable of withstanding both thermal cycling and chemical attack from sulfur and vanadium contaminants common in various fuel types.

Physical vapor deposition (PVD) and chemical vapor deposition (CVD) techniques have undergone substantial refinement, enabling the creation of more uniform and adherent coatings. Hybrid deposition methods combining plasma-enhanced processes with traditional techniques have overcome previous limitations in coating complex geometries typical in V4 engine components.

Cold spray technology represents a paradigm shift in coating application, allowing the deposition of protective layers without subjecting the base material to high temperatures. This breakthrough preserves the microstructural integrity of the substrate while achieving excellent bonding strength and coating density, particularly valuable for aluminum and magnesium components in modern lightweight V4 engines.

Computational materials science has accelerated coating development through predictive modeling of coating performance under various operating conditions. Machine learning algorithms now enable the rapid screening of thousands of potential material combinations, identifying promising candidates for experimental validation and significantly reducing development timelines for next-generation engine coatings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!