Carbon-negative Concrete: Strategies for Wide-scale Adoption

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Concrete, a fundamental building material in modern construction, has undergone significant evolution since its widespread adoption in the 20th century. Traditional concrete production is responsible for approximately 8% of global CO2 emissions, primarily due to the energy-intensive process of cement manufacturing. The concept of carbon-negative concrete represents a paradigm shift in construction materials, aiming not only to reduce emissions but to actively sequester carbon dioxide from the atmosphere during its lifecycle.

The evolution of carbon-negative concrete technologies can be traced through several key developmental phases. Initially, efforts focused on reducing the carbon footprint through partial replacement of Portland cement with supplementary cementitious materials (SCMs) like fly ash and slag. This approach, while beneficial, only achieved carbon reduction rather than carbon negativity. The breakthrough came with the development of alternative binding systems that could actively incorporate CO2 during the curing process, transforming concrete from a carbon source to a carbon sink.

Recent technological advancements have accelerated this evolution, particularly in the areas of carbon mineralization, alternative clinkers, and biomimetic approaches. Companies like Carbicrete, CarbonCure, and Solidia have pioneered commercial-scale implementations of carbon-sequestering concrete technologies, demonstrating the technical feasibility of these approaches beyond laboratory settings.

The primary objective of carbon-negative concrete development is to create a construction material that maintains or exceeds the performance characteristics of traditional concrete while actively removing CO2 from the atmosphere. This involves optimizing the carbon sequestration capacity without compromising structural integrity, durability, or economic viability. Specific technical targets include achieving a net carbon sequestration of at least 100 kg CO2 per cubic meter of concrete while maintaining compressive strength comparable to conventional concrete (30-50 MPa).

Secondary objectives include developing scalable production methods that can be integrated into existing concrete manufacturing infrastructure with minimal disruption, ensuring cost competitiveness with traditional concrete within a 10% premium threshold, and creating regulatory frameworks that incentivize the adoption of carbon-negative concrete through carbon credits or building code requirements.

The long-term vision for carbon-negative concrete extends beyond mere carbon neutrality to position the construction industry as an active participant in climate change mitigation. By transforming concrete from one of the largest sources of industrial carbon emissions to a significant carbon sink, the technology aims to revolutionize how we conceptualize sustainable construction materials in the context of global decarbonization efforts.

The evolution of carbon-negative concrete technologies can be traced through several key developmental phases. Initially, efforts focused on reducing the carbon footprint through partial replacement of Portland cement with supplementary cementitious materials (SCMs) like fly ash and slag. This approach, while beneficial, only achieved carbon reduction rather than carbon negativity. The breakthrough came with the development of alternative binding systems that could actively incorporate CO2 during the curing process, transforming concrete from a carbon source to a carbon sink.

Recent technological advancements have accelerated this evolution, particularly in the areas of carbon mineralization, alternative clinkers, and biomimetic approaches. Companies like Carbicrete, CarbonCure, and Solidia have pioneered commercial-scale implementations of carbon-sequestering concrete technologies, demonstrating the technical feasibility of these approaches beyond laboratory settings.

The primary objective of carbon-negative concrete development is to create a construction material that maintains or exceeds the performance characteristics of traditional concrete while actively removing CO2 from the atmosphere. This involves optimizing the carbon sequestration capacity without compromising structural integrity, durability, or economic viability. Specific technical targets include achieving a net carbon sequestration of at least 100 kg CO2 per cubic meter of concrete while maintaining compressive strength comparable to conventional concrete (30-50 MPa).

Secondary objectives include developing scalable production methods that can be integrated into existing concrete manufacturing infrastructure with minimal disruption, ensuring cost competitiveness with traditional concrete within a 10% premium threshold, and creating regulatory frameworks that incentivize the adoption of carbon-negative concrete through carbon credits or building code requirements.

The long-term vision for carbon-negative concrete extends beyond mere carbon neutrality to position the construction industry as an active participant in climate change mitigation. By transforming concrete from one of the largest sources of industrial carbon emissions to a significant carbon sink, the technology aims to revolutionize how we conceptualize sustainable construction materials in the context of global decarbonization efforts.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the building sector. The global green building materials market was valued at approximately $256 billion in 2020 and is projected to reach $523 billion by 2027, growing at a CAGR of 10.7%. Within this broader market, carbon-negative concrete represents an emerging segment with substantial growth potential.

Construction activities account for nearly 40% of global carbon emissions, with traditional concrete production alone responsible for 8% of worldwide CO2 emissions. This environmental impact has created a pressing demand for alternative materials that can reduce or even reverse carbon footprints. Carbon-negative concrete solutions are positioned to address this critical market need by not only reducing emissions but potentially sequestering more carbon than they produce during manufacturing.

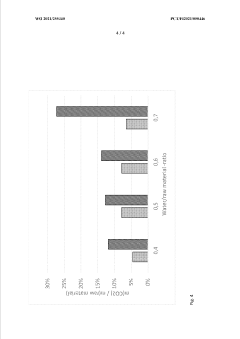

Market segmentation reveals varying adoption rates across regions. Europe leads in sustainable construction materials adoption, with countries like Germany, France, and the Nordic nations implementing stringent building codes that favor low-carbon alternatives. North America follows with growing demand particularly in urban centers and LEED-certified projects. The Asia-Pacific region represents the fastest-growing market, driven by rapid urbanization and increasing environmental regulations in China and India.

Customer analysis indicates three primary market segments: public infrastructure projects, commercial construction, and residential building. Government infrastructure projects currently represent the largest potential market for carbon-negative concrete due to public procurement policies increasingly incorporating sustainability criteria. Commercial construction follows closely, with corporate sustainability commitments driving adoption among large developers and multinational corporations.

Price sensitivity remains a significant market factor. Current carbon-negative concrete solutions typically command a 15-30% premium over traditional concrete, creating adoption barriers particularly in cost-sensitive sectors. However, this price differential is narrowing as production scales up and carbon pricing mechanisms become more widespread.

Market forecasts suggest that carbon-negative concrete could capture 5-10% of the global concrete market by 2030, representing a potential market value of $25-50 billion. This growth trajectory depends on several factors including regulatory developments, carbon pricing evolution, technological improvements, and supply chain maturation.

Competitive analysis reveals a market currently dominated by innovative startups and research institutions, with traditional cement and concrete manufacturers increasingly investing in sustainable alternatives through acquisitions and R&D partnerships. This market structure is expected to evolve toward consolidation as technologies mature and scale.

Construction activities account for nearly 40% of global carbon emissions, with traditional concrete production alone responsible for 8% of worldwide CO2 emissions. This environmental impact has created a pressing demand for alternative materials that can reduce or even reverse carbon footprints. Carbon-negative concrete solutions are positioned to address this critical market need by not only reducing emissions but potentially sequestering more carbon than they produce during manufacturing.

Market segmentation reveals varying adoption rates across regions. Europe leads in sustainable construction materials adoption, with countries like Germany, France, and the Nordic nations implementing stringent building codes that favor low-carbon alternatives. North America follows with growing demand particularly in urban centers and LEED-certified projects. The Asia-Pacific region represents the fastest-growing market, driven by rapid urbanization and increasing environmental regulations in China and India.

Customer analysis indicates three primary market segments: public infrastructure projects, commercial construction, and residential building. Government infrastructure projects currently represent the largest potential market for carbon-negative concrete due to public procurement policies increasingly incorporating sustainability criteria. Commercial construction follows closely, with corporate sustainability commitments driving adoption among large developers and multinational corporations.

Price sensitivity remains a significant market factor. Current carbon-negative concrete solutions typically command a 15-30% premium over traditional concrete, creating adoption barriers particularly in cost-sensitive sectors. However, this price differential is narrowing as production scales up and carbon pricing mechanisms become more widespread.

Market forecasts suggest that carbon-negative concrete could capture 5-10% of the global concrete market by 2030, representing a potential market value of $25-50 billion. This growth trajectory depends on several factors including regulatory developments, carbon pricing evolution, technological improvements, and supply chain maturation.

Competitive analysis reveals a market currently dominated by innovative startups and research institutions, with traditional cement and concrete manufacturers increasingly investing in sustainable alternatives through acquisitions and R&D partnerships. This market structure is expected to evolve toward consolidation as technologies mature and scale.

Current Status and Barriers in Carbon-negative Concrete Technology

Carbon-negative concrete technology has made significant strides globally, with several pilot projects demonstrating its technical feasibility. Currently, multiple approaches exist, including carbon capture during cement production, alternative cementitious materials, and carbon-curing processes. Companies like CarbonCure, Solidia, and Carbicrete have developed commercial solutions that can reduce concrete's carbon footprint by 5-30%, with some claiming carbon-negative status under specific conditions.

Despite these advancements, wide-scale adoption faces substantial barriers. Technical challenges persist in ensuring that carbon-negative concrete maintains comparable strength, durability, and workability to conventional concrete. Long-term performance data remains limited, creating uncertainty about structural integrity over decades-long building lifespans. This lack of longitudinal studies hampers confidence among engineers, architects, and building code officials.

Economic barriers represent another significant obstacle. Carbon-negative concrete technologies typically command a 10-30% price premium over conventional concrete, making them less competitive in cost-sensitive construction markets. The capital expenditure required to retrofit existing concrete plants with carbon capture or alternative production technologies is substantial, often ranging from $1-5 million per facility, creating a significant barrier for small and medium-sized producers.

Regulatory frameworks present both challenges and opportunities. Building codes and standards in most countries have not been updated to specifically accommodate carbon-negative concrete, creating approval hurdles for innovative solutions. The lack of standardized carbon accounting methodologies for concrete also complicates verification of environmental claims and carbon credit opportunities.

Market awareness and acceptance remain problematic. Many stakeholders in the construction value chain—from architects to contractors to end clients—lack familiarity with carbon-negative concrete options. Conservative industry practices favor proven materials with extensive track records, creating resistance to adoption of novel solutions despite their environmental benefits.

Geographically, carbon-negative concrete development shows significant regional variation. North America and Europe lead in research and commercialization efforts, with companies in Canada, the United States, and Scandinavia at the forefront. Asia, despite being the largest concrete market globally, has fewer commercial-scale carbon-negative concrete initiatives, though research activities are accelerating in China, Japan, and Singapore.

Supply chain constraints further complicate adoption. Many carbon-negative concrete technologies require specialized additives, alternative materials, or carbon capture infrastructure that are not widely available. The limited production capacity of these inputs creates bottlenecks that restrict scaling potential in the near term.

Despite these advancements, wide-scale adoption faces substantial barriers. Technical challenges persist in ensuring that carbon-negative concrete maintains comparable strength, durability, and workability to conventional concrete. Long-term performance data remains limited, creating uncertainty about structural integrity over decades-long building lifespans. This lack of longitudinal studies hampers confidence among engineers, architects, and building code officials.

Economic barriers represent another significant obstacle. Carbon-negative concrete technologies typically command a 10-30% price premium over conventional concrete, making them less competitive in cost-sensitive construction markets. The capital expenditure required to retrofit existing concrete plants with carbon capture or alternative production technologies is substantial, often ranging from $1-5 million per facility, creating a significant barrier for small and medium-sized producers.

Regulatory frameworks present both challenges and opportunities. Building codes and standards in most countries have not been updated to specifically accommodate carbon-negative concrete, creating approval hurdles for innovative solutions. The lack of standardized carbon accounting methodologies for concrete also complicates verification of environmental claims and carbon credit opportunities.

Market awareness and acceptance remain problematic. Many stakeholders in the construction value chain—from architects to contractors to end clients—lack familiarity with carbon-negative concrete options. Conservative industry practices favor proven materials with extensive track records, creating resistance to adoption of novel solutions despite their environmental benefits.

Geographically, carbon-negative concrete development shows significant regional variation. North America and Europe lead in research and commercialization efforts, with companies in Canada, the United States, and Scandinavia at the forefront. Asia, despite being the largest concrete market globally, has fewer commercial-scale carbon-negative concrete initiatives, though research activities are accelerating in China, Japan, and Singapore.

Supply chain constraints further complicate adoption. Many carbon-negative concrete technologies require specialized additives, alternative materials, or carbon capture infrastructure that are not widely available. The limited production capacity of these inputs creates bottlenecks that restrict scaling potential in the near term.

Existing Carbon-negative Concrete Formulations and Methods

01 Carbon capture and sequestration in concrete

Technologies that enable concrete to absorb and permanently store carbon dioxide during the curing process, effectively turning concrete into a carbon sink. These methods involve introducing CO2 during manufacturing, which reacts with calcium compounds to form stable carbonates, reducing the carbon footprint of concrete production while enhancing material properties such as strength and durability.- Carbon capture and sequestration in concrete production: Technologies that capture and store carbon dioxide during the concrete manufacturing process, effectively reducing the carbon footprint of concrete production. These methods involve incorporating CO2 into the concrete mixture where it becomes permanently mineralized, transforming concrete from a carbon source to a carbon sink. This approach not only reduces emissions but can potentially make concrete carbon-negative by sequestering more carbon than is emitted during production.

- Alternative cementitious materials for reduced emissions: The use of alternative materials to replace traditional Portland cement, which is responsible for significant carbon emissions in concrete production. These alternatives include supplementary cementitious materials like fly ash, slag, silica fume, and natural pozzolans, as well as novel binders that require less energy to produce. By substituting these materials for a portion of the cement, the overall carbon footprint of concrete can be substantially reduced while maintaining or even improving performance characteristics.

- Carbon dioxide utilization in concrete curing: Methods that utilize CO2 in the concrete curing process, replacing traditional water-based curing with carbonation curing. This approach accelerates the hardening of concrete while simultaneously sequestering carbon dioxide. The CO2 reacts with calcium compounds in the concrete to form calcium carbonate, which enhances the strength and durability of the concrete while permanently storing the carbon dioxide in a stable mineral form.

- Monitoring and certification systems for carbon-negative concrete: Systems and methods for measuring, monitoring, and certifying the carbon footprint of concrete products throughout their lifecycle. These technologies include sensors, data analytics platforms, and blockchain-based verification systems that track carbon emissions and sequestration from raw material extraction through manufacturing, use, and end-of-life. Such systems enable accurate carbon accounting, verification of carbon-negative claims, and the potential development of carbon credit markets for concrete products.

- Biomass incorporation and biogenic materials in concrete: The integration of biomass and biogenic materials into concrete formulations to reduce carbon emissions and potentially create carbon sinks. These approaches include incorporating agricultural waste products, wood fibers, algae, or other plant-based materials that have sequestered carbon during their growth. When these materials are included in concrete, they can offset emissions from cement production while potentially improving properties such as thermal insulation, weight reduction, or crack resistance.

02 Alternative cementitious materials for reduced emissions

Development of cement alternatives that require less energy to produce and generate fewer emissions than traditional Portland cement. These include supplementary cementitious materials like fly ash, slag, silica fume, and novel binders based on alkali-activated materials or geopolymers. These alternatives can reduce the carbon footprint of concrete by up to 80% while maintaining or improving performance characteristics.Expand Specific Solutions03 CO2 utilization in concrete manufacturing processes

Innovative manufacturing processes that utilize carbon dioxide as a feedstock in concrete production. These technologies involve injecting CO2 into concrete mixtures during mixing or curing, where it becomes mineralized and permanently sequestered. This approach not only reduces emissions but can also improve concrete properties such as compressive strength and reduce curing time.Expand Specific Solutions04 Monitoring and certification systems for carbon-negative concrete

Development of systems and methodologies to accurately measure, report, and verify the carbon footprint of concrete products. These include life cycle assessment tools, carbon accounting frameworks, and certification standards specifically designed for carbon-negative concrete. Such systems enable transparent communication of environmental performance and facilitate carbon credit generation from concrete production.Expand Specific Solutions05 Biomass incorporation for carbon sequestration in concrete

Integration of biomass-derived materials into concrete formulations to enhance carbon sequestration capabilities. These approaches include incorporating biochar, agricultural waste, or other plant-based materials that have already captured CO2 during their growth phase. When embedded in concrete, these materials provide long-term carbon storage while potentially improving insulation properties and reducing the overall weight of concrete products.Expand Specific Solutions

Leading Companies and Research Institutions in Green Concrete

Carbon-negative concrete adoption is currently in the early development stage, with the market expected to grow significantly as sustainability regulations tighten globally. The competitive landscape features established construction materials giants like China National Building Material Group and Taiheiyo Cement Corporation pursuing incremental improvements, alongside innovative startups such as Concrete4Change and Procarbon Bio developing disruptive technologies. Research institutions including Arizona State University, Southeast University, and Lawrence Livermore National Security are advancing fundamental breakthroughs in carbon sequestration techniques. Technical maturity varies widely, with conventional players like China West Construction and China Construction Commercial Concrete implementing moderate carbon reduction strategies, while X Development (formerly Google X) explores more experimental approaches that remain years from commercial viability.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Security (LLNS) has developed groundbreaking carbon-negative concrete technology through their "Carbon Initiative" program. Their approach centers on a novel process called "Carbonate Mineralization," which utilizes electrochemical methods to accelerate the natural carbonation process in concrete. This technology can sequester up to 300-400kg of CO2 per ton of cement used, effectively making concrete a significant carbon sink. LLNS has pioneered advanced computational modeling that optimizes concrete formulations for maximum CO2 absorption while maintaining or enhancing structural properties. Their system incorporates specialized catalysts that facilitate the conversion of gaseous CO2 into stable carbonate minerals within the concrete matrix. Additionally, LLNS has developed portable carbon capture units that can be deployed at construction sites, allowing for direct utilization of captured CO2 in concrete production. Their latest innovation includes self-healing concrete that uses carbonation reactions to automatically repair micro-cracks, simultaneously sequestering additional carbon while extending infrastructure lifespan.

Strengths: Cutting-edge scientific approach with strong theoretical foundation; technology can be applied to both new construction and existing infrastructure; significant carbon sequestration potential exceeding most competing technologies. Weaknesses: Currently at higher technology readiness levels for laboratory and pilot applications than for commercial-scale deployment; requires specialized expertise for implementation; higher initial costs compared to conventional concrete production methods.

China National Building Material Group Co., Ltd.

Technical Solution: China National Building Material Group (CNBM) has developed a comprehensive carbon-negative concrete strategy centered around their "Low Carbon Development Roadmap." Their approach includes innovative clinker substitution technologies that reduce the cement content in concrete by up to 60% while maintaining structural performance. CNBM has pioneered the use of industrial by-products like fly ash and slag as supplementary cementitious materials, significantly reducing the carbon footprint. Their carbon capture utilization and storage (CCUS) technology implemented at their Anhui plant captures approximately 50,000 tons of CO2 annually, which is then utilized for carbonation curing of precast concrete elements. This process not only sequesters carbon but also improves concrete strength by 10-15%. CNBM has also developed specialized admixtures that enhance CO2 absorption during concrete's service life, effectively turning structures into carbon sinks.

Strengths: Extensive manufacturing infrastructure allows for rapid scaling of new technologies; strong integration of CCUS with existing production processes; government backing facilitates implementation of carbon policies. Weaknesses: Heavy reliance on coal power in manufacturing operations partially offsets carbon benefits; implementation costs remain high for smaller projects; technology adoption varies significantly across different regional subsidiaries.

Key Patents and Innovations in CO2 Sequestration for Concrete

Controlling carbonation

PatentWO2021255340A1

Innovation

- A method for controlling carbonation by adjusting the total concentration of dissolved silicon and/or aluminium in a mix, which is cured with carbon dioxide, using an alkaline substance to activate the raw material, thereby increasing carbon dioxide uptake and reducing the need for cement in concrete production.

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Policy Frameworks and Incentives for Green Construction

The effective implementation of carbon-negative concrete technologies requires robust policy frameworks and incentives to drive adoption across the construction industry. Current regulatory landscapes in leading markets show a gradual shift toward carbon-conscious building codes. The European Union's Green Deal includes specific provisions for construction materials, with several member states implementing carbon taxes that directly impact concrete production. Similarly, California's Buy Clean California Act establishes maximum acceptable global warming potential limits for construction materials used in state projects.

Financial incentives have proven particularly effective in accelerating green construction adoption. Tax credits for buildings utilizing carbon-negative concrete, such as those implemented in Canada and parts of Scandinavia, have demonstrated measurable impact on market uptake. Direct subsidies for manufacturers transitioning to carbon-negative production methods have reduced implementation barriers, particularly for small and medium enterprises that might otherwise struggle with transition costs.

Green building certification systems like LEED, BREEAM, and the newer Carbon Leadership Forum have evolved to specifically recognize and reward the use of carbon-negative materials. These systems create market differentiation opportunities that developers increasingly leverage as sustainability becomes a competitive advantage in premium real estate markets.

Procurement policies represent another powerful lever for adoption. Government procurement requirements mandating carbon-negative materials for public infrastructure projects have created guaranteed markets that support industry transition. The Netherlands' Sustainable Public Procurement program and Singapore's Green Mark scheme exemplify how public sector purchasing power can drive industry innovation.

Performance-based regulations rather than prescriptive standards have proven more effective in stimulating innovation. By setting carbon performance targets without dictating specific technologies, these frameworks allow for continuous improvement and technological evolution. This approach has been successfully implemented in parts of Australia and New Zealand, resulting in accelerated development of locally appropriate carbon-negative concrete solutions.

International harmonization of standards remains a significant challenge. The International Organization for Standardization (ISO) has begun developing unified frameworks for measuring embodied carbon in building materials, but regional variations in implementation create market fragmentation. Cross-border carbon adjustment mechanisms, such as those proposed in the EU, may help level the playing field for producers adhering to stricter environmental standards.

Financial incentives have proven particularly effective in accelerating green construction adoption. Tax credits for buildings utilizing carbon-negative concrete, such as those implemented in Canada and parts of Scandinavia, have demonstrated measurable impact on market uptake. Direct subsidies for manufacturers transitioning to carbon-negative production methods have reduced implementation barriers, particularly for small and medium enterprises that might otherwise struggle with transition costs.

Green building certification systems like LEED, BREEAM, and the newer Carbon Leadership Forum have evolved to specifically recognize and reward the use of carbon-negative materials. These systems create market differentiation opportunities that developers increasingly leverage as sustainability becomes a competitive advantage in premium real estate markets.

Procurement policies represent another powerful lever for adoption. Government procurement requirements mandating carbon-negative materials for public infrastructure projects have created guaranteed markets that support industry transition. The Netherlands' Sustainable Public Procurement program and Singapore's Green Mark scheme exemplify how public sector purchasing power can drive industry innovation.

Performance-based regulations rather than prescriptive standards have proven more effective in stimulating innovation. By setting carbon performance targets without dictating specific technologies, these frameworks allow for continuous improvement and technological evolution. This approach has been successfully implemented in parts of Australia and New Zealand, resulting in accelerated development of locally appropriate carbon-negative concrete solutions.

International harmonization of standards remains a significant challenge. The International Organization for Standardization (ISO) has begun developing unified frameworks for measuring embodied carbon in building materials, but regional variations in implementation create market fragmentation. Cross-border carbon adjustment mechanisms, such as those proposed in the EU, may help level the playing field for producers adhering to stricter environmental standards.

Life Cycle Assessment of Carbon-negative Concrete Solutions

Life Cycle Assessment (LCA) provides a comprehensive framework for evaluating the environmental impacts of carbon-negative concrete solutions across their entire lifecycle. This assessment methodology examines impacts from raw material extraction through manufacturing, transportation, use, and end-of-life disposal or recycling. For carbon-negative concrete, LCA reveals significant advantages compared to traditional Portland cement concrete, particularly in greenhouse gas emissions reduction.

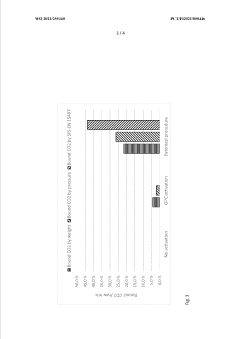

Current LCA studies indicate that carbon-negative concrete solutions can sequester between 50-300 kg CO2 per cubic meter, depending on the specific technology employed. This contrasts sharply with conventional concrete, which typically emits 300-400 kg CO2 per cubic meter. The carbon negativity is achieved through various mechanisms, including carbonation processes, alternative binders, and incorporation of carbon-capturing materials.

When examining the production phase, carbon-negative concrete demonstrates substantial benefits through reduced calcination emissions and lower energy requirements. Many formulations utilize industrial byproducts like fly ash and slag, further reducing the embodied carbon footprint. However, transportation impacts remain significant, particularly when specialized materials must be sourced from distant locations.

The use phase of carbon-negative concrete presents interesting dynamics in LCA modeling. Some formulations continue to absorb CO2 throughout their service life, enhancing their carbon-negative profile over time. This progressive carbonation must be accurately modeled to reflect the true environmental performance. Additionally, durability characteristics affect maintenance requirements and service life expectations, which significantly impact long-term environmental performance.

End-of-life considerations reveal further advantages for many carbon-negative concrete formulations. Enhanced recyclability reduces waste and allows for continued carbon sequestration in secondary applications. Some technologies even enable increased carbon uptake during the crushing and recycling process, creating additional environmental benefits.

Comprehensive LCA studies must also consider other environmental impact categories beyond carbon footprint, including water consumption, ecotoxicity, resource depletion, and land use changes. Some carbon-negative technologies may present trade-offs in these areas that require careful evaluation. For instance, certain mineral carbonation processes may require significant water inputs or land disturbance for raw material extraction.

Standardization of LCA methodologies specifically for carbon-negative concrete remains an ongoing challenge. Current efforts focus on developing consistent functional units, system boundaries, and allocation methods to enable fair comparisons between different technologies. This standardization is essential for regulatory acceptance and market adoption of these innovative materials.

Current LCA studies indicate that carbon-negative concrete solutions can sequester between 50-300 kg CO2 per cubic meter, depending on the specific technology employed. This contrasts sharply with conventional concrete, which typically emits 300-400 kg CO2 per cubic meter. The carbon negativity is achieved through various mechanisms, including carbonation processes, alternative binders, and incorporation of carbon-capturing materials.

When examining the production phase, carbon-negative concrete demonstrates substantial benefits through reduced calcination emissions and lower energy requirements. Many formulations utilize industrial byproducts like fly ash and slag, further reducing the embodied carbon footprint. However, transportation impacts remain significant, particularly when specialized materials must be sourced from distant locations.

The use phase of carbon-negative concrete presents interesting dynamics in LCA modeling. Some formulations continue to absorb CO2 throughout their service life, enhancing their carbon-negative profile over time. This progressive carbonation must be accurately modeled to reflect the true environmental performance. Additionally, durability characteristics affect maintenance requirements and service life expectations, which significantly impact long-term environmental performance.

End-of-life considerations reveal further advantages for many carbon-negative concrete formulations. Enhanced recyclability reduces waste and allows for continued carbon sequestration in secondary applications. Some technologies even enable increased carbon uptake during the crushing and recycling process, creating additional environmental benefits.

Comprehensive LCA studies must also consider other environmental impact categories beyond carbon footprint, including water consumption, ecotoxicity, resource depletion, and land use changes. Some carbon-negative technologies may present trade-offs in these areas that require careful evaluation. For instance, certain mineral carbonation processes may require significant water inputs or land disturbance for raw material extraction.

Standardization of LCA methodologies specifically for carbon-negative concrete remains an ongoing challenge. Current efforts focus on developing consistent functional units, system boundaries, and allocation methods to enable fair comparisons between different technologies. This standardization is essential for regulatory acceptance and market adoption of these innovative materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!