Characterization Protocols For Magnetocaloric Entropy And Adiabatic Temperature Change

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetocaloric Effect Background and Research Objectives

The magnetocaloric effect (MCE), first discovered by Emil Warburg in 1881, represents a thermodynamic phenomenon where certain materials exhibit temperature changes when exposed to varying magnetic fields. This effect has evolved from a scientific curiosity to a promising technology for energy-efficient cooling applications. The fundamental principle relies on the alignment of magnetic moments in response to an applied magnetic field, resulting in entropy changes that manifest as temperature variations under adiabatic conditions.

Over the past decades, research in magnetocaloric materials has progressed through several distinct phases. Initial investigations focused primarily on rare-earth elements and their alloys, particularly gadolinium, which exhibits a significant magnetocaloric effect near room temperature. The discovery of giant magnetocaloric effect in Gd5(Si2Ge2) by Pecharsky and Gschneidner in 1997 marked a pivotal advancement, demonstrating entropy changes substantially larger than previously observed.

Recent technological evolution has shifted toward more sustainable and cost-effective materials, including transition metal-based alloys, Heusler alloys, and manganites. These materials offer comparable performance while reducing dependency on scarce rare-earth elements. Additionally, composite and nanostructured magnetocaloric materials have emerged as promising candidates for enhanced performance through interface engineering and dimensional effects.

The characterization of magnetocaloric materials presents unique challenges that necessitate standardized protocols. Current methodologies for measuring entropy changes and adiabatic temperature variations often yield inconsistent results across different laboratories, impeding meaningful comparisons and technological advancement. This research aims to establish robust, reproducible characterization protocols that accurately quantify these critical parameters.

Our primary objective is to develop comprehensive standardized procedures for measuring magnetocaloric entropy changes and adiabatic temperature variations across diverse material systems. These protocols will address variables including sample preparation, measurement conditions, data processing algorithms, and uncertainty quantification. Secondary objectives include creating reference materials for calibration purposes and establishing an international database of standardized measurements to facilitate collaborative research.

The successful implementation of these protocols will accelerate material discovery and optimization processes by enabling reliable comparisons between different material systems. Furthermore, it will bridge the gap between laboratory research and industrial applications by providing manufacturers with dependable performance metrics for material selection and device design. Ultimately, this research contributes to advancing magnetocaloric technology toward commercial viability in energy-efficient cooling systems.

Over the past decades, research in magnetocaloric materials has progressed through several distinct phases. Initial investigations focused primarily on rare-earth elements and their alloys, particularly gadolinium, which exhibits a significant magnetocaloric effect near room temperature. The discovery of giant magnetocaloric effect in Gd5(Si2Ge2) by Pecharsky and Gschneidner in 1997 marked a pivotal advancement, demonstrating entropy changes substantially larger than previously observed.

Recent technological evolution has shifted toward more sustainable and cost-effective materials, including transition metal-based alloys, Heusler alloys, and manganites. These materials offer comparable performance while reducing dependency on scarce rare-earth elements. Additionally, composite and nanostructured magnetocaloric materials have emerged as promising candidates for enhanced performance through interface engineering and dimensional effects.

The characterization of magnetocaloric materials presents unique challenges that necessitate standardized protocols. Current methodologies for measuring entropy changes and adiabatic temperature variations often yield inconsistent results across different laboratories, impeding meaningful comparisons and technological advancement. This research aims to establish robust, reproducible characterization protocols that accurately quantify these critical parameters.

Our primary objective is to develop comprehensive standardized procedures for measuring magnetocaloric entropy changes and adiabatic temperature variations across diverse material systems. These protocols will address variables including sample preparation, measurement conditions, data processing algorithms, and uncertainty quantification. Secondary objectives include creating reference materials for calibration purposes and establishing an international database of standardized measurements to facilitate collaborative research.

The successful implementation of these protocols will accelerate material discovery and optimization processes by enabling reliable comparisons between different material systems. Furthermore, it will bridge the gap between laboratory research and industrial applications by providing manufacturers with dependable performance metrics for material selection and device design. Ultimately, this research contributes to advancing magnetocaloric technology toward commercial viability in energy-efficient cooling systems.

Market Applications and Demand for Magnetocaloric Technologies

Magnetocaloric technologies are experiencing growing market demand across multiple sectors, primarily driven by the need for more energy-efficient and environmentally friendly cooling solutions. The global refrigeration market, valued at approximately $340 billion, is increasingly looking toward magnetocaloric-based systems as alternatives to conventional vapor-compression technologies that rely on harmful refrigerants with high global warming potential.

The residential refrigeration sector represents one of the most promising application areas, with household refrigerators and freezers accounting for nearly 17% of average home electricity consumption in developed countries. Magnetocaloric cooling systems could potentially reduce this energy consumption by 20-30%, creating significant consumer appeal and market opportunity. Major appliance manufacturers including Haier, Samsung, and Whirlpool have already invested in research partnerships to develop commercially viable magnetocaloric refrigerators.

Commercial refrigeration presents another substantial market, particularly in supermarkets and food retail where cooling systems account for up to 50% of total energy consumption. The ability of magnetocaloric technologies to operate more efficiently at varying cooling loads makes them especially attractive for these applications. Several pilot installations in European supermarkets have demonstrated energy savings of 25% compared to conventional systems.

The automotive industry has also shown increasing interest in magnetocaloric air conditioning systems. With electric vehicles gaining market share, efficient cooling technologies that minimize battery drain are becoming critical competitive advantages. Leading automotive manufacturers including BMW and Toyota have active research programs exploring magnetocaloric air conditioning to extend EV range while maintaining passenger comfort.

Medical and laboratory applications represent a high-value niche market for magnetocaloric technologies. Ultra-precise temperature control for biological sample storage, medical imaging equipment cooling, and pharmaceutical manufacturing processes could benefit from the fine temperature regulation capabilities of magnetocaloric systems. The healthcare cooling market alone is projected to reach $24 billion by 2028.

Industrial process cooling, particularly in data centers and electronics manufacturing, constitutes another emerging application area. As data centers continue to proliferate globally, their cooling requirements—which can represent up to 40% of their total energy consumption—present a significant opportunity for energy-efficient magnetocaloric solutions.

Market adoption faces challenges including high initial costs of rare-earth materials used in magnetocaloric alloys, system integration complexities, and competition from improving conventional technologies. However, recent advances in characterization protocols for magnetocaloric entropy and adiabatic temperature change are accelerating material development and system optimization, potentially addressing these barriers and expanding market opportunities.

The residential refrigeration sector represents one of the most promising application areas, with household refrigerators and freezers accounting for nearly 17% of average home electricity consumption in developed countries. Magnetocaloric cooling systems could potentially reduce this energy consumption by 20-30%, creating significant consumer appeal and market opportunity. Major appliance manufacturers including Haier, Samsung, and Whirlpool have already invested in research partnerships to develop commercially viable magnetocaloric refrigerators.

Commercial refrigeration presents another substantial market, particularly in supermarkets and food retail where cooling systems account for up to 50% of total energy consumption. The ability of magnetocaloric technologies to operate more efficiently at varying cooling loads makes them especially attractive for these applications. Several pilot installations in European supermarkets have demonstrated energy savings of 25% compared to conventional systems.

The automotive industry has also shown increasing interest in magnetocaloric air conditioning systems. With electric vehicles gaining market share, efficient cooling technologies that minimize battery drain are becoming critical competitive advantages. Leading automotive manufacturers including BMW and Toyota have active research programs exploring magnetocaloric air conditioning to extend EV range while maintaining passenger comfort.

Medical and laboratory applications represent a high-value niche market for magnetocaloric technologies. Ultra-precise temperature control for biological sample storage, medical imaging equipment cooling, and pharmaceutical manufacturing processes could benefit from the fine temperature regulation capabilities of magnetocaloric systems. The healthcare cooling market alone is projected to reach $24 billion by 2028.

Industrial process cooling, particularly in data centers and electronics manufacturing, constitutes another emerging application area. As data centers continue to proliferate globally, their cooling requirements—which can represent up to 40% of their total energy consumption—present a significant opportunity for energy-efficient magnetocaloric solutions.

Market adoption faces challenges including high initial costs of rare-earth materials used in magnetocaloric alloys, system integration complexities, and competition from improving conventional technologies. However, recent advances in characterization protocols for magnetocaloric entropy and adiabatic temperature change are accelerating material development and system optimization, potentially addressing these barriers and expanding market opportunities.

Current Challenges in Magnetocaloric Characterization Methods

Despite significant advancements in magnetocaloric materials research, the field faces several critical challenges in characterization methodologies that impede consistent evaluation and comparison of materials. One fundamental issue is the lack of standardized measurement protocols across research institutions, resulting in data inconsistencies when comparing magnetocaloric properties reported by different laboratories. This variability stems from differences in sample preparation, measurement conditions, and data processing algorithms.

The direct measurement of adiabatic temperature change (ΔTad) presents particular difficulties due to the requirement for truly adiabatic conditions, which are challenging to maintain in laboratory settings. Heat losses during measurement can significantly underestimate the true magnetocaloric effect, especially for materials with slower thermal response. Additionally, contact thermal sensors may introduce measurement artifacts through thermal mass effects and imperfect thermal coupling.

Entropy change (ΔSM) calculations derived from magnetization measurements using Maxwell relations face their own set of challenges. The indirect nature of these calculations introduces potential errors, particularly for materials exhibiting first-order phase transitions where the Maxwell relations may not be strictly valid due to hysteresis effects. The numerical integration procedures used in these calculations can further propagate measurement uncertainties.

Sample geometry and demagnetization effects represent another significant challenge, as non-standardized sample shapes lead to non-uniform internal magnetic fields that complicate data interpretation and comparison. This issue becomes particularly pronounced in materials with high magnetic susceptibility or in measurements conducted at lower applied fields.

Time-dependent effects in magnetocaloric measurements are often overlooked but critically important. Measurement rates that are too fast may not allow for thermal equilibrium, while rates that are too slow may miss dynamic magnetocaloric responses. This temporal dimension adds complexity to protocol standardization efforts.

Interlaboratory reproducibility remains problematic, with studies showing variations of up to 20% in measured magnetocaloric parameters for identical materials across different facilities. These discrepancies undermine confidence in reported values and complicate material selection for practical applications.

The characterization of thin films and nanostructured magnetocaloric materials presents additional challenges due to their small thermal mass and the difficulty in isolating their properties from substrate effects. Conventional bulk measurement techniques often prove inadequate for these emerging material formats, necessitating specialized approaches.

The direct measurement of adiabatic temperature change (ΔTad) presents particular difficulties due to the requirement for truly adiabatic conditions, which are challenging to maintain in laboratory settings. Heat losses during measurement can significantly underestimate the true magnetocaloric effect, especially for materials with slower thermal response. Additionally, contact thermal sensors may introduce measurement artifacts through thermal mass effects and imperfect thermal coupling.

Entropy change (ΔSM) calculations derived from magnetization measurements using Maxwell relations face their own set of challenges. The indirect nature of these calculations introduces potential errors, particularly for materials exhibiting first-order phase transitions where the Maxwell relations may not be strictly valid due to hysteresis effects. The numerical integration procedures used in these calculations can further propagate measurement uncertainties.

Sample geometry and demagnetization effects represent another significant challenge, as non-standardized sample shapes lead to non-uniform internal magnetic fields that complicate data interpretation and comparison. This issue becomes particularly pronounced in materials with high magnetic susceptibility or in measurements conducted at lower applied fields.

Time-dependent effects in magnetocaloric measurements are often overlooked but critically important. Measurement rates that are too fast may not allow for thermal equilibrium, while rates that are too slow may miss dynamic magnetocaloric responses. This temporal dimension adds complexity to protocol standardization efforts.

Interlaboratory reproducibility remains problematic, with studies showing variations of up to 20% in measured magnetocaloric parameters for identical materials across different facilities. These discrepancies undermine confidence in reported values and complicate material selection for practical applications.

The characterization of thin films and nanostructured magnetocaloric materials presents additional challenges due to their small thermal mass and the difficulty in isolating their properties from substrate effects. Conventional bulk measurement techniques often prove inadequate for these emerging material formats, necessitating specialized approaches.

Established Protocols for Entropy and Temperature Change Measurement

01 Composition of magnetocaloric materials for enhanced entropy change

Various compositions of magnetocaloric materials can be engineered to enhance entropy change during the magnetocaloric effect. These compositions include rare earth-based alloys, transition metal compounds, and composite materials with specific stoichiometric ratios. By optimizing the composition, researchers can achieve higher magnetic entropy changes, which directly correlates with improved cooling efficiency in magnetic refrigeration systems. These materials often exhibit first-order phase transitions that contribute to their enhanced magnetocaloric properties.- Magnetocaloric materials composition and properties: Various compositions of magnetocaloric materials exhibit different entropy changes and adiabatic temperature variations. These materials typically include rare earth elements, transition metals, and their alloys. The composition directly affects the Curie temperature, magnetic entropy change, and overall magnetocaloric effect. By optimizing the material composition, researchers can enhance the magnetocaloric effect for specific temperature ranges and applications.

- Refrigeration and cooling systems using magnetocaloric effect: Magnetocaloric materials are utilized in magnetic refrigeration systems that leverage the adiabatic temperature change during magnetization and demagnetization cycles. These systems offer energy-efficient alternatives to conventional vapor-compression refrigeration. The design incorporates heat exchangers, regenerators, and magnetic field sources to maximize the cooling capacity. The efficiency of these systems depends on the magnitude of entropy change and adiabatic temperature change of the magnetocaloric materials used.

- Enhancement techniques for magnetocaloric performance: Various methods can enhance the magnetocaloric effect in materials, including nanostructuring, creating composite materials, and introducing defects or dopants. These techniques aim to increase the entropy change and adiabatic temperature change by modifying the magnetic phase transition characteristics. Optimization of particle size, crystallinity, and microstructure can significantly improve the magnetocaloric performance for practical applications.

- First-order vs. second-order magnetic transitions in magnetocaloric materials: Magnetocaloric materials exhibit either first-order or second-order magnetic phase transitions, which significantly affect their entropy change and adiabatic temperature change characteristics. First-order transitions typically show larger magnetocaloric effects but often come with thermal and magnetic hysteresis. Second-order transitions generally provide smaller but more reversible magnetocaloric effects. Understanding and controlling these transition types is crucial for developing effective magnetocaloric materials for various applications.

- Measurement and characterization methods for magnetocaloric properties: Various techniques are employed to measure and characterize the entropy change and adiabatic temperature change in magnetocaloric materials. These include direct measurement methods using specialized calorimeters, magnetometers, and thermometers, as well as indirect methods based on magnetization measurements and thermodynamic relationships. Advanced characterization techniques help in understanding the relationship between material structure and magnetocaloric performance, enabling the development of improved materials.

02 Structural modifications to improve adiabatic temperature change

Structural modifications of magnetocaloric materials can significantly improve their adiabatic temperature change capabilities. Techniques such as nanostructuring, grain boundary engineering, and crystal structure optimization can enhance the magnetocaloric effect. By controlling the microstructure and crystallographic properties, researchers can reduce hysteresis losses and improve thermal conductivity, leading to larger adiabatic temperature changes during magnetic field application or removal. These structural modifications are crucial for developing more efficient magnetic cooling technologies.Expand Specific Solutions03 Magnetic refrigeration systems utilizing magnetocaloric effect

Magnetic refrigeration systems leverage the magnetocaloric effect to achieve cooling without conventional refrigerants. These systems utilize the entropy change and adiabatic temperature change of magnetocaloric materials when subjected to varying magnetic fields. Advanced designs incorporate regenerative cycles, heat exchangers, and optimized magnetic field generators to maximize cooling efficiency. The performance of these systems depends on the magnetocaloric properties of the materials used, particularly their entropy change and temperature response under adiabatic conditions.Expand Specific Solutions04 Novel magnetocaloric materials with reduced hysteresis

Developing novel magnetocaloric materials with reduced thermal and magnetic hysteresis is essential for improving overall system efficiency. Materials exhibiting minimal hysteresis demonstrate more reversible magnetocaloric effects, allowing for greater entropy changes and adiabatic temperature variations during cycling. Research focuses on creating materials with tuned phase transitions, optimized electron configurations, and controlled lattice parameters to minimize hysteresis while maintaining strong magnetocaloric responses. These advancements are critical for practical applications in energy-efficient cooling technologies.Expand Specific Solutions05 Measurement and characterization techniques for magnetocaloric properties

Advanced measurement and characterization techniques are essential for accurately determining the entropy change and adiabatic temperature change in magnetocaloric materials. These methods include direct and indirect measurement approaches such as calorimetry, magnetometry, and thermal analysis under controlled magnetic fields. Computational models and simulation techniques complement experimental measurements by predicting magnetocaloric behavior and guiding material design. Standardized protocols for characterization enable reliable comparison between different materials and support the development of more efficient magnetic cooling technologies.Expand Specific Solutions

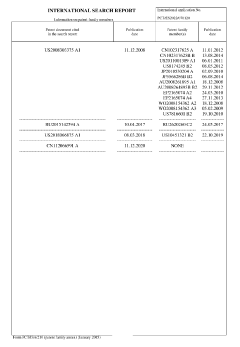

Leading Research Institutions and Industry Players

The magnetocaloric characterization protocols market is in a growth phase, driven by increasing interest in magnetic refrigeration as an energy-efficient alternative to conventional cooling. The global market is expanding with a projected size of several hundred million dollars by 2030. Technologically, the field shows moderate maturity with established measurement protocols, but significant innovation continues. Leading players include research institutions like Chinese Academy of Sciences and Centre National de la Recherche Scientifique, alongside commercial entities such as VACUUMSCHMELZE and BASF. Material manufacturers like Resonac Holdings and Delta Electronics are advancing practical applications, while specialized research centers in China, Europe, and North America are developing standardized characterization methods for magnetocaloric materials, focusing on entropy measurement accuracy and adiabatic temperature change protocols.

VACUUMSCHMELZE GmbH & Co. KG

Technical Solution: VACUUMSCHMELZE has developed comprehensive characterization protocols for magnetocaloric materials focusing on direct measurement techniques. Their approach combines differential scanning calorimetry (DSC) under applied magnetic fields with direct adiabatic temperature change measurements using custom-built apparatus. The company has pioneered standardized testing procedures that ensure reproducibility across different material batches, utilizing a modified Halbach array configuration to generate uniform magnetic fields up to 2T without superconducting magnets. Their protocols specifically address the challenge of measuring first-order phase transition materials where hysteresis effects significantly impact performance metrics. VACUUMSCHMELZE's characterization system incorporates simultaneous measurement of multiple parameters including magnetic field strength, temperature, heat capacity, and thermal conductivity to provide complete magnetocaloric property profiles.

Strengths: Industry-leading precision in direct measurement techniques with reported accuracy of ±0.05K for ΔTad measurements. Their integrated measurement approach reduces systematic errors common in separate characterization methods. Weaknesses: Their protocols require specialized equipment with high initial investment costs, and characterization of materials with very small magnetocaloric effects remains challenging due to signal-to-noise limitations.

Chinese Academy of Sciences Institute of Physics

Technical Solution: The Chinese Academy of Sciences Institute of Physics has established advanced characterization protocols for magnetocaloric materials that integrate both indirect and direct measurement methodologies. Their approach centers on a multi-parameter measurement system capable of simultaneously determining magnetic entropy change (ΔSM) and adiabatic temperature change (ΔTad) across wide temperature ranges (10-350K) and magnetic fields up to 5T. The Institute has developed proprietary algorithms for processing magnetization data to calculate entropy changes with minimal approximation errors, particularly addressing the challenges of first-order phase transition materials. Their protocols incorporate correction factors for demagnetization effects and thermal lag, which significantly improve measurement accuracy. The Institute's characterization system employs a combination of vibrating sample magnetometry, heat capacity measurements, and direct temperature monitoring during field changes, with all measurements conducted under precisely controlled environmental conditions to eliminate external thermal influences.

Strengths: Exceptional magnetic field range (up to 5T) and temperature range (10-350K) capabilities allow comprehensive characterization across diverse material systems. Their integrated data processing algorithms provide superior accuracy for complex phase transition materials. Weaknesses: The protocols require highly specialized equipment and expertise, limiting widespread adoption. The time-intensive nature of their comprehensive characterization approach makes rapid screening of multiple materials challenging.

Critical Analysis of Advanced Characterization Techniques

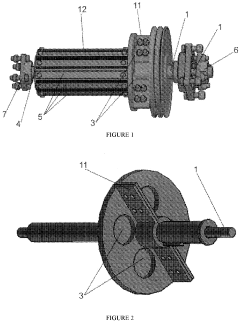

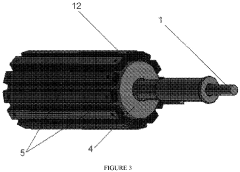

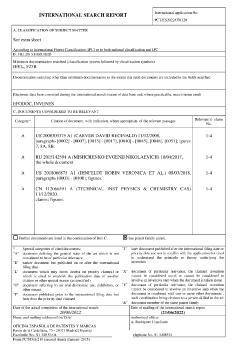

Device for converting thermal energy into electrical or mechanical energy using magnetocaloric effect

PatentPendingEP4303942A1

Innovation

- A device comprising a rotating drum of magnets and a drum of magnetocaloric sheets, where the magnetocaloric sheets generate electrical energy through the Thomson effect and mechanical energy through Lorentz's Law, allowing for high-performance energy conversion using a single heat source.

Porous materials embedded with nanoparticles, methods of fabrication and uses thereof

PatentInactiveEP2231756A2

Innovation

- A porous magnetic material with nanoparticles is created, allowing for the alignment of particles within a polymer or ceramic substrate using magnetic or electromagnetic fields to form a three-dimensional structure with a predetermined concentration gradient, enabling customizable electromagnetic properties for specific wave frequencies and applications.

Materials Science Considerations for Magnetocaloric Applications

The selection of appropriate materials for magnetocaloric applications requires careful consideration of several key factors that directly impact performance, efficiency, and practical implementation. Material composition plays a fundamental role, with rare earth elements like gadolinium and its alloys demonstrating superior magnetocaloric properties. However, these materials present sustainability challenges due to limited availability and high extraction costs, driving research toward more abundant alternatives.

Crystal structure significantly influences magnetocaloric performance, with specific lattice arrangements facilitating stronger magnetic coupling and enhanced entropy changes. Materials exhibiting first-order phase transitions generally produce larger magnetocaloric effects compared to those with second-order transitions, though they often suffer from thermal and magnetic hysteresis that can reduce cycling efficiency in practical applications.

Thermal conductivity represents another critical parameter, as efficient heat transfer is essential for rapid cooling cycles. Materials must balance strong magnetocaloric properties with adequate thermal transport capabilities to enable practical heat exchange in working devices. Additionally, mechanical stability during repeated magnetic field cycling is paramount, as magnetocaloric materials undergo dimensional changes during magnetic transitions that can lead to microstructural degradation over time.

Environmental stability and corrosion resistance must be considered for long-term applications, particularly in heat pump systems where materials may be exposed to various working fluids. The temperature range of operation is equally important, with different material compositions optimized for specific temperature windows, necessitating careful material selection based on the intended application temperature.

Manufacturing considerations also play a decisive role in material selection. The ability to process magnetocaloric materials into forms suitable for device integration—such as thin plates, particles, or complex geometries—directly impacts heat exchange efficiency and system design flexibility. Cost-effective production methods that maintain material performance while enabling scalable manufacturing represent a significant challenge in the field.

Recent advances in composite and multilayered magnetocaloric materials show promise for overcoming limitations of single-phase materials, allowing for tailored performance across broader temperature ranges and improved mechanical properties. These engineered material systems represent a frontier in magnetocaloric research, potentially enabling more efficient and practical cooling technologies.

Crystal structure significantly influences magnetocaloric performance, with specific lattice arrangements facilitating stronger magnetic coupling and enhanced entropy changes. Materials exhibiting first-order phase transitions generally produce larger magnetocaloric effects compared to those with second-order transitions, though they often suffer from thermal and magnetic hysteresis that can reduce cycling efficiency in practical applications.

Thermal conductivity represents another critical parameter, as efficient heat transfer is essential for rapid cooling cycles. Materials must balance strong magnetocaloric properties with adequate thermal transport capabilities to enable practical heat exchange in working devices. Additionally, mechanical stability during repeated magnetic field cycling is paramount, as magnetocaloric materials undergo dimensional changes during magnetic transitions that can lead to microstructural degradation over time.

Environmental stability and corrosion resistance must be considered for long-term applications, particularly in heat pump systems where materials may be exposed to various working fluids. The temperature range of operation is equally important, with different material compositions optimized for specific temperature windows, necessitating careful material selection based on the intended application temperature.

Manufacturing considerations also play a decisive role in material selection. The ability to process magnetocaloric materials into forms suitable for device integration—such as thin plates, particles, or complex geometries—directly impacts heat exchange efficiency and system design flexibility. Cost-effective production methods that maintain material performance while enabling scalable manufacturing represent a significant challenge in the field.

Recent advances in composite and multilayered magnetocaloric materials show promise for overcoming limitations of single-phase materials, allowing for tailored performance across broader temperature ranges and improved mechanical properties. These engineered material systems represent a frontier in magnetocaloric research, potentially enabling more efficient and practical cooling technologies.

Environmental Impact and Energy Efficiency of Magnetocaloric Technologies

Magnetocaloric technologies represent a significant advancement in cooling systems with potentially lower environmental impact compared to conventional vapor-compression refrigeration. The environmental benefits stem primarily from the elimination of harmful refrigerants such as hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which contribute substantially to global warming and ozone depletion. Magnetocaloric cooling systems utilize solid refrigerants and water-based heat transfer fluids, substantially reducing direct greenhouse gas emissions associated with refrigerant leakage.

Energy efficiency analyses of prototype magnetocaloric refrigeration systems demonstrate promising results, with some experimental units achieving coefficient of performance (COP) values between 2-5, comparable to conventional systems. However, these values are highly dependent on the characterization protocols used to measure magnetocaloric entropy changes and adiabatic temperature variations. Accurate protocols are essential for realistic efficiency assessments and environmental impact calculations.

Life cycle assessments (LCA) of magnetocaloric technologies indicate potential energy savings of 20-30% compared to conventional refrigeration when operating at optimal conditions. This efficiency advantage translates directly to reduced indirect carbon emissions from electricity generation. The environmental payback period for magnetocaloric systems is estimated at 3-7 years, depending on usage patterns and local electricity generation profiles.

Material considerations also factor significantly into the environmental profile of these technologies. Rare earth elements commonly used in magnetocaloric materials, particularly gadolinium and its alloys, present sustainability challenges due to environmentally intensive mining and processing operations. Recent research has focused on developing rare-earth-lean or rare-earth-free magnetocaloric materials to mitigate these concerns while maintaining performance characteristics.

Manufacturing processes for magnetocaloric devices currently require more energy than conventional refrigeration system production, partially offsetting operational environmental benefits. However, as manufacturing scales and techniques improve, this initial environmental cost is expected to decrease substantially. Standardized characterization protocols for magnetocaloric properties would enable more accurate comparisons between different material systems and their respective environmental footprints.

End-of-life considerations for magnetocaloric systems present both challenges and opportunities. The solid-state nature of the refrigerant materials potentially allows for easier recovery and recycling compared to gaseous refrigerants, though specialized recycling infrastructure would need development. Proper reclamation of rare earth elements from decommissioned systems could significantly reduce the life-cycle environmental impact.

Energy efficiency analyses of prototype magnetocaloric refrigeration systems demonstrate promising results, with some experimental units achieving coefficient of performance (COP) values between 2-5, comparable to conventional systems. However, these values are highly dependent on the characterization protocols used to measure magnetocaloric entropy changes and adiabatic temperature variations. Accurate protocols are essential for realistic efficiency assessments and environmental impact calculations.

Life cycle assessments (LCA) of magnetocaloric technologies indicate potential energy savings of 20-30% compared to conventional refrigeration when operating at optimal conditions. This efficiency advantage translates directly to reduced indirect carbon emissions from electricity generation. The environmental payback period for magnetocaloric systems is estimated at 3-7 years, depending on usage patterns and local electricity generation profiles.

Material considerations also factor significantly into the environmental profile of these technologies. Rare earth elements commonly used in magnetocaloric materials, particularly gadolinium and its alloys, present sustainability challenges due to environmentally intensive mining and processing operations. Recent research has focused on developing rare-earth-lean or rare-earth-free magnetocaloric materials to mitigate these concerns while maintaining performance characteristics.

Manufacturing processes for magnetocaloric devices currently require more energy than conventional refrigeration system production, partially offsetting operational environmental benefits. However, as manufacturing scales and techniques improve, this initial environmental cost is expected to decrease substantially. Standardized characterization protocols for magnetocaloric properties would enable more accurate comparisons between different material systems and their respective environmental footprints.

End-of-life considerations for magnetocaloric systems present both challenges and opportunities. The solid-state nature of the refrigerant materials potentially allows for easier recovery and recycling compared to gaseous refrigerants, though specialized recycling infrastructure would need development. Proper reclamation of rare earth elements from decommissioned systems could significantly reduce the life-cycle environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!