Device Level Efficiency: Minimizing Hysteresis Losses In Magnetic Refrigerators

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnetic Refrigeration Technology Background and Objectives

Magnetic refrigeration represents a revolutionary cooling technology that leverages the magnetocaloric effect (MCE) to achieve refrigeration without traditional vapor-compression cycles. This technology has evolved significantly since its discovery in the late 19th century when German physicist Emil Warburg first observed temperature changes in iron when subjected to magnetic fields. The fundamental principle involves the alignment of magnetic moments in magnetocaloric materials when exposed to a magnetic field, resulting in heat release, followed by heat absorption when the field is removed.

The development trajectory of magnetic refrigeration has seen several pivotal advancements. In the 1930s, chemical demagnetization techniques enabled scientists to reach ultra-low temperatures approaching absolute zero. The 1970s marked a significant turning point with the discovery of gadolinium's strong magnetocaloric properties near room temperature, opening possibilities for practical applications beyond laboratory settings.

Recent decades have witnessed accelerated research into magnetic refrigeration, driven by environmental concerns and energy efficiency imperatives. Traditional refrigeration systems rely on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which contribute significantly to global warming. Magnetic refrigeration offers a compelling alternative with zero direct greenhouse gas emissions and potential energy efficiency improvements of 20-30% over conventional systems.

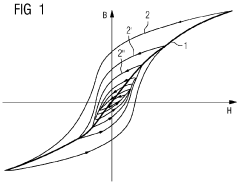

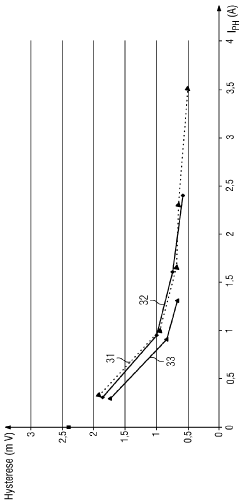

The primary technical objective in this field now centers on minimizing hysteresis losses in magnetic refrigerators. Hysteresis—the lag between magnetization and demagnetization processes—represents a critical inefficiency factor that diminishes the overall performance of these systems. Reducing these losses would substantially improve the coefficient of performance (COP) and make magnetic refrigeration commercially viable across broader applications.

Current research aims to develop advanced magnetocaloric materials with minimal hysteresis while maintaining strong magnetocaloric effects. The ideal material would exhibit sharp magnetic phase transitions, low thermal hysteresis, and mechanical stability through repeated magnetization cycles. Additionally, system-level design improvements seek to optimize magnetic field application and heat transfer mechanisms to minimize energy losses throughout the refrigeration cycle.

The technology aims to achieve market-ready solutions for residential refrigeration by 2025 and industrial cooling applications by 2030. These ambitious targets require overcoming significant materials science challenges while simultaneously addressing manufacturing scalability and cost considerations. Success in minimizing hysteresis losses represents perhaps the most critical milestone on this technological roadmap, potentially unlocking widespread commercial adoption of magnetic refrigeration systems.

The development trajectory of magnetic refrigeration has seen several pivotal advancements. In the 1930s, chemical demagnetization techniques enabled scientists to reach ultra-low temperatures approaching absolute zero. The 1970s marked a significant turning point with the discovery of gadolinium's strong magnetocaloric properties near room temperature, opening possibilities for practical applications beyond laboratory settings.

Recent decades have witnessed accelerated research into magnetic refrigeration, driven by environmental concerns and energy efficiency imperatives. Traditional refrigeration systems rely on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which contribute significantly to global warming. Magnetic refrigeration offers a compelling alternative with zero direct greenhouse gas emissions and potential energy efficiency improvements of 20-30% over conventional systems.

The primary technical objective in this field now centers on minimizing hysteresis losses in magnetic refrigerators. Hysteresis—the lag between magnetization and demagnetization processes—represents a critical inefficiency factor that diminishes the overall performance of these systems. Reducing these losses would substantially improve the coefficient of performance (COP) and make magnetic refrigeration commercially viable across broader applications.

Current research aims to develop advanced magnetocaloric materials with minimal hysteresis while maintaining strong magnetocaloric effects. The ideal material would exhibit sharp magnetic phase transitions, low thermal hysteresis, and mechanical stability through repeated magnetization cycles. Additionally, system-level design improvements seek to optimize magnetic field application and heat transfer mechanisms to minimize energy losses throughout the refrigeration cycle.

The technology aims to achieve market-ready solutions for residential refrigeration by 2025 and industrial cooling applications by 2030. These ambitious targets require overcoming significant materials science challenges while simultaneously addressing manufacturing scalability and cost considerations. Success in minimizing hysteresis losses represents perhaps the most critical milestone on this technological roadmap, potentially unlocking widespread commercial adoption of magnetic refrigeration systems.

Market Analysis for Energy-Efficient Cooling Solutions

The global market for energy-efficient cooling solutions is experiencing unprecedented growth, driven by increasing environmental concerns, regulatory pressures, and rising energy costs. Conventional vapor-compression refrigeration systems, which dominate the current market, are facing scrutiny due to their high energy consumption and use of environmentally harmful refrigerants. This has created a significant opportunity for alternative cooling technologies, particularly magnetic refrigeration systems that minimize hysteresis losses.

The cooling and refrigeration market was valued at approximately $120 billion in 2022 and is projected to reach $180 billion by 2030, with energy-efficient solutions representing the fastest-growing segment at a CAGR of 8.7%. Magnetic refrigeration technology specifically is expected to grow at a CAGR of 23% through 2028, indicating strong market interest in this emerging technology.

Commercial refrigeration represents the largest potential application area, accounting for nearly 40% of energy consumption in retail establishments such as supermarkets and convenience stores. These businesses are actively seeking solutions to reduce operational costs, with energy expenses typically constituting 25-30% of their profit margins. Magnetic refrigeration systems with minimized hysteresis losses could potentially reduce energy consumption by 20-30% compared to conventional systems.

Residential applications present another substantial market opportunity, with household refrigeration accounting for approximately 7% of residential electricity consumption globally. Consumer awareness regarding energy efficiency has increased significantly, with 68% of consumers now considering energy efficiency ratings when purchasing new appliances. Premium-priced, energy-efficient cooling solutions have shown strong sales growth of 15% annually in developed markets.

Industrial cooling applications, particularly in data centers and manufacturing facilities, represent a high-value market segment. Data centers alone consumed 205 TWh of electricity globally in 2022, with cooling systems accounting for up to 40% of this energy use. The potential energy savings from advanced magnetic refrigeration systems make this an especially attractive market segment.

Geographically, North America and Europe currently lead in adoption of energy-efficient cooling technologies due to stringent regulations and higher energy costs. However, the Asia-Pacific region represents the fastest-growing market, with China and India investing heavily in sustainable cooling infrastructure to meet their climate commitments while addressing growing cooling demands from expanding middle classes.

Market barriers include higher initial costs compared to conventional systems, with magnetic refrigeration systems currently commanding a 30-50% premium. However, total cost of ownership analyses demonstrate potential payback periods of 3-5 years through energy savings, creating a compelling value proposition for commercial and industrial applications where operational costs are closely monitored.

The cooling and refrigeration market was valued at approximately $120 billion in 2022 and is projected to reach $180 billion by 2030, with energy-efficient solutions representing the fastest-growing segment at a CAGR of 8.7%. Magnetic refrigeration technology specifically is expected to grow at a CAGR of 23% through 2028, indicating strong market interest in this emerging technology.

Commercial refrigeration represents the largest potential application area, accounting for nearly 40% of energy consumption in retail establishments such as supermarkets and convenience stores. These businesses are actively seeking solutions to reduce operational costs, with energy expenses typically constituting 25-30% of their profit margins. Magnetic refrigeration systems with minimized hysteresis losses could potentially reduce energy consumption by 20-30% compared to conventional systems.

Residential applications present another substantial market opportunity, with household refrigeration accounting for approximately 7% of residential electricity consumption globally. Consumer awareness regarding energy efficiency has increased significantly, with 68% of consumers now considering energy efficiency ratings when purchasing new appliances. Premium-priced, energy-efficient cooling solutions have shown strong sales growth of 15% annually in developed markets.

Industrial cooling applications, particularly in data centers and manufacturing facilities, represent a high-value market segment. Data centers alone consumed 205 TWh of electricity globally in 2022, with cooling systems accounting for up to 40% of this energy use. The potential energy savings from advanced magnetic refrigeration systems make this an especially attractive market segment.

Geographically, North America and Europe currently lead in adoption of energy-efficient cooling technologies due to stringent regulations and higher energy costs. However, the Asia-Pacific region represents the fastest-growing market, with China and India investing heavily in sustainable cooling infrastructure to meet their climate commitments while addressing growing cooling demands from expanding middle classes.

Market barriers include higher initial costs compared to conventional systems, with magnetic refrigeration systems currently commanding a 30-50% premium. However, total cost of ownership analyses demonstrate potential payback periods of 3-5 years through energy savings, creating a compelling value proposition for commercial and industrial applications where operational costs are closely monitored.

Current Challenges in Magnetic Refrigeration Systems

Despite significant advancements in magnetic refrigeration technology, several critical challenges persist at the device level that impede widespread commercial adoption. The most prominent issue remains the management of hysteresis losses, which significantly reduce the efficiency of magnetic refrigeration systems. Hysteresis losses occur during the magnetization and demagnetization cycles, where energy is dissipated as heat rather than contributing to the cooling effect, resulting in decreased coefficient of performance (COP).

Material limitations constitute another major challenge. Current magnetocaloric materials, including gadolinium alloys and La-Fe-Si compounds, exhibit substantial hysteresis effects, particularly at higher operating frequencies. This creates a fundamental trade-off between operating speed and efficiency that engineers must navigate when designing practical systems.

Thermal management presents additional complications, as the heat transfer between the magnetocaloric material and the heat exchange fluid often becomes a bottleneck. Inefficient heat transfer mechanisms lead to temperature gradients within the active magnetic regenerator (AMR), exacerbating hysteresis effects and reducing overall system performance.

The mechanical design of magnetic refrigerators introduces further challenges. The moving parts required for the magnetization-demagnetization cycle create friction and wear issues, while also contributing to energy losses. Current permanent magnet arrangements, though improved, still struggle to provide the optimal magnetic field profiles needed to minimize hysteresis.

Control system limitations also impact efficiency, as many existing systems lack sophisticated algorithms to optimize the timing and intensity of magnetic field application. This results in sub-optimal utilization of the magnetocaloric effect and unnecessary energy expenditure during operation cycles.

Manufacturing constraints further complicate progress, with difficulties in producing magnetocaloric materials with consistent properties at scale. The complex geometries required for efficient heat exchangers add to production challenges and costs, limiting commercial viability.

Economic factors remain significant barriers, as the high cost of rare earth materials used in both magnetocaloric elements and permanent magnets drives up system costs. The current price-performance ratio makes magnetic refrigeration less competitive against conventional vapor-compression technologies despite its environmental advantages.

Standardization issues also persist across the industry, with various research groups and manufacturers employing different testing protocols and performance metrics, making direct comparisons between systems challenging and slowing collaborative progress toward solutions for hysteresis reduction.

Material limitations constitute another major challenge. Current magnetocaloric materials, including gadolinium alloys and La-Fe-Si compounds, exhibit substantial hysteresis effects, particularly at higher operating frequencies. This creates a fundamental trade-off between operating speed and efficiency that engineers must navigate when designing practical systems.

Thermal management presents additional complications, as the heat transfer between the magnetocaloric material and the heat exchange fluid often becomes a bottleneck. Inefficient heat transfer mechanisms lead to temperature gradients within the active magnetic regenerator (AMR), exacerbating hysteresis effects and reducing overall system performance.

The mechanical design of magnetic refrigerators introduces further challenges. The moving parts required for the magnetization-demagnetization cycle create friction and wear issues, while also contributing to energy losses. Current permanent magnet arrangements, though improved, still struggle to provide the optimal magnetic field profiles needed to minimize hysteresis.

Control system limitations also impact efficiency, as many existing systems lack sophisticated algorithms to optimize the timing and intensity of magnetic field application. This results in sub-optimal utilization of the magnetocaloric effect and unnecessary energy expenditure during operation cycles.

Manufacturing constraints further complicate progress, with difficulties in producing magnetocaloric materials with consistent properties at scale. The complex geometries required for efficient heat exchangers add to production challenges and costs, limiting commercial viability.

Economic factors remain significant barriers, as the high cost of rare earth materials used in both magnetocaloric elements and permanent magnets drives up system costs. The current price-performance ratio makes magnetic refrigeration less competitive against conventional vapor-compression technologies despite its environmental advantages.

Standardization issues also persist across the industry, with various research groups and manufacturers employing different testing protocols and performance metrics, making direct comparisons between systems challenging and slowing collaborative progress toward solutions for hysteresis reduction.

Current Approaches to Hysteresis Loss Reduction

01 Material selection to reduce hysteresis losses

Selecting appropriate magnetic materials can significantly reduce hysteresis losses in magnetic refrigeration systems. Materials with narrow hysteresis loops, such as certain rare earth alloys and advanced magnetocaloric materials, minimize energy losses during the magnetization-demagnetization cycles. These materials exhibit reduced magnetic friction and require less energy input to complete the thermodynamic cycle, thereby improving the overall efficiency of magnetic refrigeration systems.- Material selection for reducing hysteresis losses: Selecting appropriate magnetic materials is crucial for minimizing hysteresis losses in magnetic refrigeration systems. Materials with narrow hysteresis loops, such as certain rare earth alloys and advanced magnetocaloric materials, can significantly improve the efficiency of magnetic refrigerators. These materials exhibit reduced energy dissipation during magnetization cycles, leading to better cooling performance and lower energy consumption in magnetic refrigeration applications.

- Magnetic field optimization techniques: Optimizing the magnetic field configuration and application method can substantially reduce hysteresis losses in magnetic refrigeration systems. Techniques include using pulsed magnetic fields, graduated field application, and optimized field geometries. These approaches help to minimize the energy dissipated during magnetization and demagnetization cycles, improving the overall coefficient of performance of magnetic refrigerators while reducing operational energy requirements.

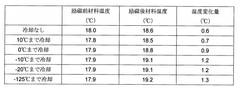

- Thermal management strategies: Effective thermal management strategies are essential for controlling hysteresis losses in magnetic refrigeration systems. These include optimized heat exchanger designs, improved thermal contact between components, and advanced heat transfer fluids. By enhancing heat exchange efficiency and managing temperature gradients within the system, these strategies help to minimize energy losses during the magnetocaloric effect cycle, resulting in improved cooling capacity and system performance.

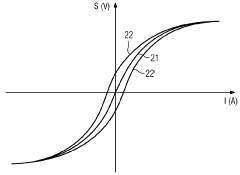

- Cycle optimization and control systems: Advanced control systems and cycle optimization techniques can significantly reduce hysteresis losses in magnetic refrigeration. These include precise timing of magnetization/demagnetization cycles, adaptive control algorithms that respond to changing operating conditions, and multi-stage refrigeration cycles. By optimizing the operational parameters and implementing sophisticated control strategies, the energy efficiency of magnetic refrigeration systems can be substantially improved.

- Novel device architectures and configurations: Innovative device architectures and system configurations offer promising approaches to minimize hysteresis losses in magnetic refrigeration. These include rotary magnetic refrigerators, cascaded systems, and hybrid designs that combine multiple cooling technologies. Novel geometrical arrangements of magnetocaloric materials and magnetic field sources can create more efficient thermodynamic cycles, reducing energy losses while enhancing cooling capacity and system performance.

02 Optimized magnetization-demagnetization cycles

Designing optimized magnetization-demagnetization cycles can minimize hysteresis losses in magnetic refrigerators. By carefully controlling the rate and pattern of field application and removal, the magnetic material can follow more reversible paths through its phase transitions. Advanced control algorithms and precise timing mechanisms help to reduce the irreversible processes that contribute to hysteresis losses, resulting in more efficient refrigeration cycles.Expand Specific Solutions03 Composite and layered magnetic structures

Utilizing composite and layered magnetic structures can help mitigate hysteresis losses in magnetic refrigeration systems. By combining different materials with complementary properties or creating graded structures, the magnetic transition can be spread over a wider temperature range, reducing the abruptness of phase changes that contribute to hysteresis. These engineered structures provide more gradual magnetic transitions while maintaining high magnetocaloric effect, resulting in reduced energy losses during operation.Expand Specific Solutions04 Thermal management techniques

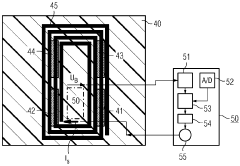

Implementing effective thermal management techniques can reduce hysteresis losses in magnetic refrigeration systems. By optimizing heat transfer between the magnetocaloric material and the heat exchange fluid, and ensuring uniform temperature distribution across the magnetic material, thermal gradients that exacerbate hysteresis can be minimized. Advanced heat exchanger designs and improved thermal contact between components help to maintain more consistent operating conditions, reducing the irreversible processes that contribute to energy losses.Expand Specific Solutions05 Field application geometry and uniformity

Optimizing the geometry and uniformity of the applied magnetic field can significantly reduce hysteresis losses in magnetic refrigerators. By designing magnetic circuits that provide more uniform field distribution across the magnetocaloric material and minimizing field gradients, the material experiences more consistent magnetization conditions. This approach reduces localized stress and strain during phase transitions, which are major contributors to hysteresis losses, resulting in more efficient energy conversion during the refrigeration cycle.Expand Specific Solutions

Leading Companies and Research Institutions in Magnetic Refrigeration

Magnetic refrigeration technology is currently in the early commercialization phase, with a growing market estimated at $300-500 million and projected to expand significantly as energy efficiency demands increase. The technical challenge of minimizing hysteresis losses represents a critical barrier to widespread adoption. Leading players demonstrate varying levels of technological maturity: established industrial giants like TDK, Hitachi, and Siemens focus on material optimization and system integration, while specialized research institutions such as Baotou Rare Earth Research Institute and Huazhong University concentrate on fundamental materials science. Haier and Gree are advancing consumer applications, leveraging their appliance manufacturing expertise to address practical implementation challenges. The competitive landscape shows regional clusters of expertise in Japan, China, and Europe, with collaboration between academic and industrial partners accelerating development toward commercial viability.

TDK Corp.

Technical Solution: TDK has pioneered innovative approaches to magnetic refrigeration efficiency through their advanced material science expertise. Their technology focuses on developing specialized soft magnetic materials with engineered domain structures that significantly reduce hysteresis losses during magnetization cycles. TDK's solution incorporates nanostructured magnetic materials with precisely controlled grain sizes and interfaces that minimize domain wall pinning effects. They have developed proprietary manufacturing processes that create highly homogeneous materials with consistent magnetic properties throughout the volume, eliminating localized hysteresis hotspots. TDK's magnetic refrigeration components feature laminated structures with optimized thickness profiles that reduce eddy current losses while maintaining high thermal conductivity. Additionally, their systems employ sophisticated magnetic circuit designs that ensure uniform field distribution across the magnetocaloric material, preventing localized saturation effects that contribute to hysteresis losses.

Strengths: TDK's exceptional expertise in magnetic materials engineering allows for highly optimized material compositions specifically designed for magnetic refrigeration applications. Their manufacturing capabilities enable consistent production of high-performance materials at scale. Weaknesses: Their solutions may be less adaptable to varying operating conditions compared to some competitors, and integration with existing refrigeration infrastructure can be challenging.

Hitachi Ltd.

Technical Solution: Hitachi has developed advanced magnetic refrigeration systems that focus on minimizing hysteresis losses through their proprietary microstructure control technology. Their approach involves creating precisely engineered magnetocaloric materials with optimized grain boundaries and crystalline structures that reduce magnetic domain wall pinning effects. Hitachi's technology incorporates multi-layered composite materials with graded transitions between layers to minimize abrupt magnetic property changes that contribute to hysteresis. Their systems utilize pulsed magnetic field application techniques that follow optimized field profiles, allowing for more efficient magnetization and demagnetization cycles. Additionally, Hitachi has implemented advanced thermal management systems that maintain optimal operating temperatures for their magnetocaloric materials, further reducing hysteresis losses by preventing thermal gradients that can exacerbate magnetic hysteresis.

Strengths: Hitachi's extensive experience in materials science and precision manufacturing enables them to create highly optimized magnetocaloric materials with minimal hysteresis. Their integrated approach combining material design, field application techniques, and thermal management provides comprehensive efficiency improvements. Weaknesses: Their solutions tend to be more expensive than conventional refrigeration technologies, and the complexity of their systems may present maintenance challenges in some applications.

Key Patents and Research on Magnetocaloric Materials

Production method for magnetic refrigeration material

PatentWO2016104739A1

Innovation

- Cooling a manganese-based compound to a temperature below its Curie temperature, specifically to 25°C or lower, to enhance the magnetic refrigeration material's refrigeration performance by aligning magnetic spins and reducing thermal hysteresis, thereby improving the magnetocaloric effect and cooling efficiency.

Method for operating a magnetic field sensor and associated magnetic field sensor

PatentWO2008040659A2

Innovation

- A high-frequency magnetic field pulse with decaying amplitude is superimposed over the measuring current using an integrated conductor loop to reduce hysteresis in magnetoresistive elements, minimizing the magnetic memory and achieving a hysteresis-reduced characteristic.

Material Science Advancements for Magnetic Refrigeration

Recent advancements in material science have significantly propelled the field of magnetic refrigeration forward, addressing one of its most persistent challenges: hysteresis losses. These losses, which occur during magnetization and demagnetization cycles, have historically limited the efficiency of magnetic cooling systems. The development of novel magnetocaloric materials with reduced hysteresis represents a critical breakthrough in making this technology commercially viable.

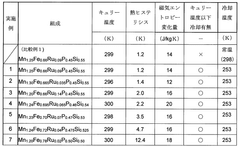

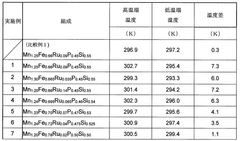

The evolution of magnetocaloric materials has progressed from first-generation gadolinium-based compounds to more sophisticated rare-earth alloys and composite structures. Researchers have achieved remarkable success with La-Fe-Si compounds and Heusler alloys, which demonstrate significantly reduced hysteresis while maintaining strong magnetocaloric effects. These materials exhibit phase transitions that are closer to ideal second-order behavior, minimizing the energy losses associated with first-order transitions.

Nanostructuring approaches have emerged as particularly promising for hysteresis reduction. By controlling grain size and interfaces at the nanoscale, scientists have created materials with smoother phase transitions and reduced magnetic and thermal hysteresis. Composite materials combining different magnetocaloric substances have shown synergistic effects, where the overall system exhibits lower hysteresis than its individual components.

Advanced manufacturing techniques, including rapid solidification, melt spinning, and powder metallurgy, have enabled precise control over material microstructure. These processes allow for the creation of materials with optimized crystallographic orientation and reduced structural defects, both of which contribute to lower hysteresis losses. Additionally, thin-film deposition methods have facilitated the development of layered structures with enhanced magnetocaloric properties.

Computational materials science has accelerated discovery in this field through predictive modeling of new magnetocaloric compounds. Machine learning algorithms, combined with density functional theory calculations, now allow researchers to screen thousands of potential material compositions before synthesis, identifying candidates with minimal hysteresis characteristics.

The integration of these advanced materials into device architectures requires careful consideration of thermal conductivity and mechanical stability. Recent innovations include functionally graded materials that optimize both magnetocaloric effect and heat transfer properties, addressing the system-level challenges of efficient refrigeration cycles.

Looking forward, emerging research directions include magnetoelectric multiferroic materials that could enable electrical control of the magnetocaloric effect, potentially eliminating mechanical moving parts in future refrigeration systems and further reducing energy losses associated with traditional magnetic field application methods.

The evolution of magnetocaloric materials has progressed from first-generation gadolinium-based compounds to more sophisticated rare-earth alloys and composite structures. Researchers have achieved remarkable success with La-Fe-Si compounds and Heusler alloys, which demonstrate significantly reduced hysteresis while maintaining strong magnetocaloric effects. These materials exhibit phase transitions that are closer to ideal second-order behavior, minimizing the energy losses associated with first-order transitions.

Nanostructuring approaches have emerged as particularly promising for hysteresis reduction. By controlling grain size and interfaces at the nanoscale, scientists have created materials with smoother phase transitions and reduced magnetic and thermal hysteresis. Composite materials combining different magnetocaloric substances have shown synergistic effects, where the overall system exhibits lower hysteresis than its individual components.

Advanced manufacturing techniques, including rapid solidification, melt spinning, and powder metallurgy, have enabled precise control over material microstructure. These processes allow for the creation of materials with optimized crystallographic orientation and reduced structural defects, both of which contribute to lower hysteresis losses. Additionally, thin-film deposition methods have facilitated the development of layered structures with enhanced magnetocaloric properties.

Computational materials science has accelerated discovery in this field through predictive modeling of new magnetocaloric compounds. Machine learning algorithms, combined with density functional theory calculations, now allow researchers to screen thousands of potential material compositions before synthesis, identifying candidates with minimal hysteresis characteristics.

The integration of these advanced materials into device architectures requires careful consideration of thermal conductivity and mechanical stability. Recent innovations include functionally graded materials that optimize both magnetocaloric effect and heat transfer properties, addressing the system-level challenges of efficient refrigeration cycles.

Looking forward, emerging research directions include magnetoelectric multiferroic materials that could enable electrical control of the magnetocaloric effect, potentially eliminating mechanical moving parts in future refrigeration systems and further reducing energy losses associated with traditional magnetic field application methods.

Environmental Impact and Sustainability Considerations

Magnetic refrigeration technology represents a significant advancement in cooling systems with potentially lower environmental impacts compared to conventional vapor-compression refrigeration. The reduction of hysteresis losses in magnetic refrigerators not only improves energy efficiency but also contributes substantially to environmental sustainability through multiple pathways.

The elimination of hydrofluorocarbons (HFCs) and other refrigerant gases constitutes one of the most significant environmental benefits of magnetic refrigeration. Conventional cooling systems rely on refrigerants with high global warming potentials (GWPs), some exceeding 1,000 times that of CO2. By utilizing solid refrigerants and water-based heat transfer fluids, magnetic refrigeration systems avoid these harmful emissions entirely, aligning with global initiatives like the Kigali Amendment to the Montreal Protocol.

Energy consumption reduction resulting from minimized hysteresis losses directly translates to decreased greenhouse gas emissions from power generation. Research indicates that optimized magnetic refrigeration systems could potentially reduce energy consumption by 20-30% compared to conventional technologies. This efficiency improvement becomes particularly significant considering that cooling systems account for approximately 17% of global electricity consumption.

The materials used in magnetic refrigeration also present important sustainability considerations. While rare earth elements like gadolinium are commonly employed for their magnetocaloric properties, their mining and processing carry substantial environmental impacts. Recent advances in minimizing hysteresis losses have enabled the use of more abundant materials such as manganese-based alloys and iron-silicon compounds, reducing dependence on environmentally problematic rare earth extraction.

Life cycle assessment (LCA) studies comparing optimized magnetic refrigerators with conventional systems demonstrate favorable environmental profiles when hysteresis losses are minimized. The extended operational lifespan resulting from reduced mechanical wear and fewer moving parts further enhances sustainability through decreased manufacturing frequency and associated resource consumption.

The recyclability of magnetic refrigerator components presents another environmental advantage. Unlike conventional refrigeration systems requiring specialized disposal procedures for refrigerants, magnetic refrigeration materials can be more readily recovered and recycled. This characteristic supports circular economy principles and reduces end-of-life environmental impacts.

Water consumption represents a less obvious but important environmental consideration. Efficient magnetic refrigeration systems with minimized hysteresis losses require less cooling water in their operation compared to conventional systems, potentially reducing water stress in regions where cooling demands and water scarcity intersect.

The elimination of hydrofluorocarbons (HFCs) and other refrigerant gases constitutes one of the most significant environmental benefits of magnetic refrigeration. Conventional cooling systems rely on refrigerants with high global warming potentials (GWPs), some exceeding 1,000 times that of CO2. By utilizing solid refrigerants and water-based heat transfer fluids, magnetic refrigeration systems avoid these harmful emissions entirely, aligning with global initiatives like the Kigali Amendment to the Montreal Protocol.

Energy consumption reduction resulting from minimized hysteresis losses directly translates to decreased greenhouse gas emissions from power generation. Research indicates that optimized magnetic refrigeration systems could potentially reduce energy consumption by 20-30% compared to conventional technologies. This efficiency improvement becomes particularly significant considering that cooling systems account for approximately 17% of global electricity consumption.

The materials used in magnetic refrigeration also present important sustainability considerations. While rare earth elements like gadolinium are commonly employed for their magnetocaloric properties, their mining and processing carry substantial environmental impacts. Recent advances in minimizing hysteresis losses have enabled the use of more abundant materials such as manganese-based alloys and iron-silicon compounds, reducing dependence on environmentally problematic rare earth extraction.

Life cycle assessment (LCA) studies comparing optimized magnetic refrigerators with conventional systems demonstrate favorable environmental profiles when hysteresis losses are minimized. The extended operational lifespan resulting from reduced mechanical wear and fewer moving parts further enhances sustainability through decreased manufacturing frequency and associated resource consumption.

The recyclability of magnetic refrigerator components presents another environmental advantage. Unlike conventional refrigeration systems requiring specialized disposal procedures for refrigerants, magnetic refrigeration materials can be more readily recovered and recycled. This characteristic supports circular economy principles and reduces end-of-life environmental impacts.

Water consumption represents a less obvious but important environmental consideration. Efficient magnetic refrigeration systems with minimized hysteresis losses require less cooling water in their operation compared to conventional systems, potentially reducing water stress in regions where cooling demands and water scarcity intersect.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!