Cryogenic Magnetocaloric Materials: Application In Quantum Computing Cooling

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Computing Cooling Technology Background and Objectives

Quantum computing represents a revolutionary paradigm in computational technology, leveraging quantum mechanical phenomena to perform operations on data. Unlike classical computers that use bits, quantum computers utilize quantum bits or qubits, which can exist in multiple states simultaneously through superposition. This fundamental difference enables quantum computers to solve certain complex problems exponentially faster than their classical counterparts, particularly in fields such as cryptography, materials science, and pharmaceutical research.

The operational efficiency of quantum computers is heavily dependent on maintaining qubits at extremely low temperatures, typically near absolute zero (-273.15°C). At these cryogenic temperatures, quantum coherence—the delicate quantum state necessary for computation—can be maintained for longer periods, reducing error rates and improving computational reliability. Traditional cooling methods for quantum systems primarily rely on dilution refrigerators and liquid helium, which are expensive, energy-intensive, and present significant scaling challenges.

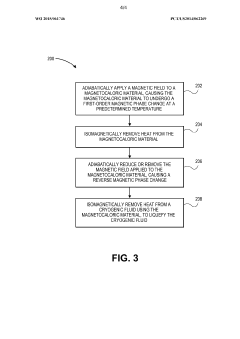

Magnetocaloric materials have emerged as a promising alternative cooling technology. These materials exhibit the magnetocaloric effect, where they undergo temperature changes when exposed to varying magnetic fields. When a magnetocaloric material is magnetized, it heats up; when demagnetized, it cools down. This property can be harnessed in a thermodynamic cycle to create efficient refrigeration systems without conventional refrigerants.

Cryogenic magnetocaloric materials specifically designed for ultra-low temperature applications represent a frontier in quantum computing infrastructure. The development of these materials aims to address several critical challenges in quantum computing: reducing the energy consumption of cooling systems, minimizing the physical footprint of quantum computers, extending operational time, and ultimately enabling the scaling of quantum systems to practical dimensions with thousands or millions of qubits.

The technological objectives for cryogenic magnetocaloric materials in quantum computing cooling include achieving higher cooling efficiency at temperatures below 4 Kelvin, developing materials with enhanced magnetocaloric properties specifically tailored for quantum computing environments, creating sustainable cooling solutions that reduce dependence on scarce resources like liquid helium, and designing integrated cooling systems that can be miniaturized and incorporated directly into quantum processor architectures.

Historical developments in this field trace back to the discovery of the magnetocaloric effect by Emil Warburg in 1881, followed by significant advancements in the late 20th century with the identification of materials exhibiting giant magnetocaloric effects. Recent research has increasingly focused on rare-earth compounds and their alloys, which show promising magnetocaloric properties at extremely low temperatures relevant to quantum computing operations.

The operational efficiency of quantum computers is heavily dependent on maintaining qubits at extremely low temperatures, typically near absolute zero (-273.15°C). At these cryogenic temperatures, quantum coherence—the delicate quantum state necessary for computation—can be maintained for longer periods, reducing error rates and improving computational reliability. Traditional cooling methods for quantum systems primarily rely on dilution refrigerators and liquid helium, which are expensive, energy-intensive, and present significant scaling challenges.

Magnetocaloric materials have emerged as a promising alternative cooling technology. These materials exhibit the magnetocaloric effect, where they undergo temperature changes when exposed to varying magnetic fields. When a magnetocaloric material is magnetized, it heats up; when demagnetized, it cools down. This property can be harnessed in a thermodynamic cycle to create efficient refrigeration systems without conventional refrigerants.

Cryogenic magnetocaloric materials specifically designed for ultra-low temperature applications represent a frontier in quantum computing infrastructure. The development of these materials aims to address several critical challenges in quantum computing: reducing the energy consumption of cooling systems, minimizing the physical footprint of quantum computers, extending operational time, and ultimately enabling the scaling of quantum systems to practical dimensions with thousands or millions of qubits.

The technological objectives for cryogenic magnetocaloric materials in quantum computing cooling include achieving higher cooling efficiency at temperatures below 4 Kelvin, developing materials with enhanced magnetocaloric properties specifically tailored for quantum computing environments, creating sustainable cooling solutions that reduce dependence on scarce resources like liquid helium, and designing integrated cooling systems that can be miniaturized and incorporated directly into quantum processor architectures.

Historical developments in this field trace back to the discovery of the magnetocaloric effect by Emil Warburg in 1881, followed by significant advancements in the late 20th century with the identification of materials exhibiting giant magnetocaloric effects. Recent research has increasingly focused on rare-earth compounds and their alloys, which show promising magnetocaloric properties at extremely low temperatures relevant to quantum computing operations.

Market Analysis for Quantum Computing Cooling Solutions

The quantum computing cooling solutions market is experiencing rapid growth, driven by the increasing adoption of quantum computing technologies across various industries. As of 2023, the global quantum computing market is valued at approximately $866 million, with projections suggesting it will reach $4.6 billion by 2027, representing a compound annual growth rate of 39.2%. The cooling systems segment constitutes roughly 15-20% of this market, highlighting the critical importance of thermal management in quantum computing infrastructure.

The demand for advanced cooling solutions is primarily fueled by the stringent temperature requirements of quantum processors, which typically operate at temperatures near absolute zero (10-15 millikelvin). Traditional cooling methods are increasingly proving inadequate for maintaining stable quantum states, creating a substantial market opportunity for cryogenic magnetocaloric materials-based solutions.

Market segmentation reveals distinct customer categories with varying needs. Research institutions and academic laboratories currently represent approximately 40% of the market, focusing on experimental quantum systems with flexible cooling requirements. Commercial quantum computing providers account for about 35% of the market, demanding reliable and scalable cooling solutions for their growing quantum infrastructure. Government and defense sectors constitute roughly 20% of the market, with emphasis on secure and high-performance quantum computing capabilities.

Geographically, North America leads the market with approximately 45% share, followed by Europe (30%) and Asia-Pacific (20%). The remaining 5% is distributed across other regions. Countries with significant quantum computing initiatives, such as the United States, China, Germany, Japan, and Canada, demonstrate particularly strong demand for advanced cooling technologies.

Key market drivers include the race for quantum supremacy among technology giants, increasing government investments in quantum technologies, and the growing application potential in fields like cryptography, drug discovery, and complex system optimization. The U.S. National Quantum Initiative Act and similar programs in China and the European Union have allocated substantial funding for quantum research, indirectly boosting the cooling solutions market.

Market challenges include the high cost of implementation, technical complexity of integration with existing systems, and limited awareness among potential end-users. Additionally, the specialized nature of quantum cooling solutions creates high barriers to entry, resulting in a concentrated market with few dominant players capable of delivering comprehensive solutions.

The forecast period (2023-2028) is expected to witness significant market expansion as quantum computing moves from research laboratories to commercial applications, creating sustained demand for more efficient, compact, and reliable cooling technologies based on advanced materials like cryogenic magnetocalorics.

The demand for advanced cooling solutions is primarily fueled by the stringent temperature requirements of quantum processors, which typically operate at temperatures near absolute zero (10-15 millikelvin). Traditional cooling methods are increasingly proving inadequate for maintaining stable quantum states, creating a substantial market opportunity for cryogenic magnetocaloric materials-based solutions.

Market segmentation reveals distinct customer categories with varying needs. Research institutions and academic laboratories currently represent approximately 40% of the market, focusing on experimental quantum systems with flexible cooling requirements. Commercial quantum computing providers account for about 35% of the market, demanding reliable and scalable cooling solutions for their growing quantum infrastructure. Government and defense sectors constitute roughly 20% of the market, with emphasis on secure and high-performance quantum computing capabilities.

Geographically, North America leads the market with approximately 45% share, followed by Europe (30%) and Asia-Pacific (20%). The remaining 5% is distributed across other regions. Countries with significant quantum computing initiatives, such as the United States, China, Germany, Japan, and Canada, demonstrate particularly strong demand for advanced cooling technologies.

Key market drivers include the race for quantum supremacy among technology giants, increasing government investments in quantum technologies, and the growing application potential in fields like cryptography, drug discovery, and complex system optimization. The U.S. National Quantum Initiative Act and similar programs in China and the European Union have allocated substantial funding for quantum research, indirectly boosting the cooling solutions market.

Market challenges include the high cost of implementation, technical complexity of integration with existing systems, and limited awareness among potential end-users. Additionally, the specialized nature of quantum cooling solutions creates high barriers to entry, resulting in a concentrated market with few dominant players capable of delivering comprehensive solutions.

The forecast period (2023-2028) is expected to witness significant market expansion as quantum computing moves from research laboratories to commercial applications, creating sustained demand for more efficient, compact, and reliable cooling technologies based on advanced materials like cryogenic magnetocalorics.

Current State and Challenges in Cryogenic Magnetocaloric Materials

The global landscape of cryogenic magnetocaloric materials has witnessed significant advancements in recent years, with research centers across North America, Europe, and Asia contributing to the field. The United States maintains leadership through institutions like NIST and national laboratories, while European research clusters in Germany, France, and the Netherlands focus on fundamental physics of these materials. China has rapidly expanded its research capacity, particularly in rare-earth-based magnetocaloric compounds.

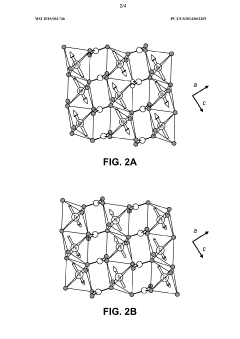

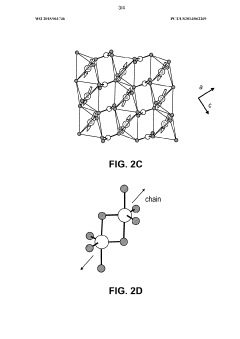

Current state-of-the-art materials include gadolinium-based alloys, which demonstrate substantial magnetocaloric effects near liquid helium temperatures. Rare-earth intermetallics such as RAl₂ (R = Ho, Dy, Er) compounds have shown promising entropy changes at sub-Kelvin temperatures critical for quantum computing applications. Holmium-based compounds have emerged as particularly effective for ultra-low temperature cooling, with recent developments in Ho₃Al₂ showing entropy changes exceeding 20 J/kg·K at temperatures below 4K.

Despite these advances, significant technical challenges persist in the development and application of magnetocaloric materials for quantum computing cooling systems. Material synthesis represents a primary obstacle, as producing high-purity, homogeneous samples with consistent magnetocaloric properties requires precise control of stoichiometry and crystal structure. Even minor impurities can dramatically reduce cooling efficiency at quantum-relevant temperatures.

Thermal hysteresis presents another major challenge, as it reduces cooling cycle efficiency and limits the frequency of operation in practical systems. This phenomenon becomes particularly problematic at the sub-Kelvin temperatures required for quantum bit stability. Additionally, mechanical stability issues arise as materials undergo significant strain during magnetization cycles, leading to microcracking and performance degradation over repeated cooling cycles.

Integration challenges with quantum computing architectures remain substantial. The proximity of magnetic materials to sensitive quantum bits can introduce unwanted magnetic fields and decoherence effects. Engineering solutions that maintain thermal contact while providing magnetic isolation are still in early development stages.

Scalability represents perhaps the most significant barrier to widespread implementation. Current laboratory demonstrations typically cool small volumes, while practical quantum computers require cooling across larger areas with multiple qubits. The thermal management systems necessary for efficient heat transfer from quantum processors to magnetocaloric elements remain underdeveloped.

Cost factors also limit adoption, as many effective magnetocaloric materials incorporate expensive rare-earth elements with supply chain vulnerabilities. Research into more abundant alternatives has shown promise but generally delivers lower performance at quantum-relevant temperatures.

Current state-of-the-art materials include gadolinium-based alloys, which demonstrate substantial magnetocaloric effects near liquid helium temperatures. Rare-earth intermetallics such as RAl₂ (R = Ho, Dy, Er) compounds have shown promising entropy changes at sub-Kelvin temperatures critical for quantum computing applications. Holmium-based compounds have emerged as particularly effective for ultra-low temperature cooling, with recent developments in Ho₃Al₂ showing entropy changes exceeding 20 J/kg·K at temperatures below 4K.

Despite these advances, significant technical challenges persist in the development and application of magnetocaloric materials for quantum computing cooling systems. Material synthesis represents a primary obstacle, as producing high-purity, homogeneous samples with consistent magnetocaloric properties requires precise control of stoichiometry and crystal structure. Even minor impurities can dramatically reduce cooling efficiency at quantum-relevant temperatures.

Thermal hysteresis presents another major challenge, as it reduces cooling cycle efficiency and limits the frequency of operation in practical systems. This phenomenon becomes particularly problematic at the sub-Kelvin temperatures required for quantum bit stability. Additionally, mechanical stability issues arise as materials undergo significant strain during magnetization cycles, leading to microcracking and performance degradation over repeated cooling cycles.

Integration challenges with quantum computing architectures remain substantial. The proximity of magnetic materials to sensitive quantum bits can introduce unwanted magnetic fields and decoherence effects. Engineering solutions that maintain thermal contact while providing magnetic isolation are still in early development stages.

Scalability represents perhaps the most significant barrier to widespread implementation. Current laboratory demonstrations typically cool small volumes, while practical quantum computers require cooling across larger areas with multiple qubits. The thermal management systems necessary for efficient heat transfer from quantum processors to magnetocaloric elements remain underdeveloped.

Cost factors also limit adoption, as many effective magnetocaloric materials incorporate expensive rare-earth elements with supply chain vulnerabilities. Research into more abundant alternatives has shown promise but generally delivers lower performance at quantum-relevant temperatures.

Current Magnetocaloric Material Solutions for Quantum Computing

01 Magnetocaloric materials for cryogenic cooling systems

Magnetocaloric materials exhibit temperature changes when exposed to varying magnetic fields, making them suitable for cryogenic cooling applications. These materials can be used in refrigeration systems that operate at extremely low temperatures without conventional refrigerants. The magnetocaloric effect is particularly effective at cryogenic temperatures, allowing for efficient cooling in scientific and industrial applications where temperatures approaching absolute zero are required.- Rare earth-based magnetocaloric materials for cryogenic applications: Rare earth elements and their alloys exhibit significant magnetocaloric effects at very low temperatures, making them suitable for cryogenic cooling applications. These materials, including gadolinium compounds and rare earth intermetallics, show large entropy changes when exposed to magnetic field variations at temperatures near absolute zero. Their unique properties enable efficient magnetic refrigeration systems capable of reaching ultra-low temperatures required for specialized scientific and industrial applications.

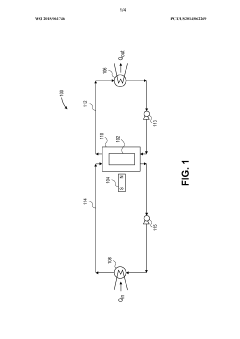

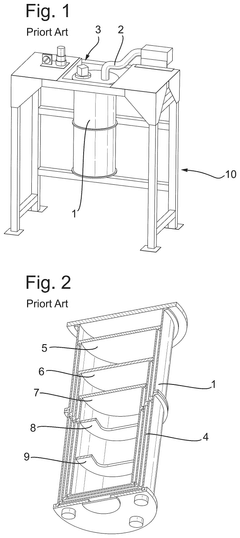

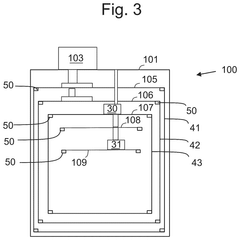

- Magnetocaloric refrigeration systems for cryogenic cooling: Magnetocaloric refrigeration systems utilize the magnetocaloric effect to achieve cooling at cryogenic temperatures. These systems typically include a magnetocaloric material, a magnetic field source, heat exchangers, and a heat transfer fluid. By cyclically magnetizing and demagnetizing the magnetocaloric material, heat can be transferred from a cold reservoir to a hot reservoir, enabling efficient cooling without conventional refrigerants. Such systems offer advantages including higher energy efficiency, reduced environmental impact, and the ability to reach extremely low temperatures.

- Novel compositions and manufacturing methods for magnetocaloric materials: Advanced manufacturing techniques and novel material compositions have been developed to enhance the performance of magnetocaloric materials at cryogenic temperatures. These include methods such as melt spinning, mechanical alloying, and powder metallurgy to create optimized microstructures. Composite materials, layered structures, and nanostructured magnetocaloric materials have been engineered to improve thermal conductivity, mechanical stability, and magnetocaloric response. These innovations address challenges such as thermal hysteresis, mechanical degradation during cycling, and production scalability.

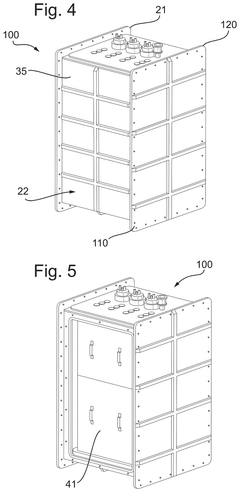

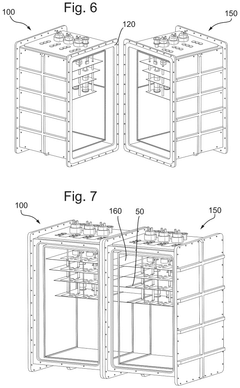

- Cascaded magnetocaloric systems for wide temperature range operation: Cascaded magnetocaloric systems employ multiple stages with different magnetocaloric materials optimized for specific temperature ranges to achieve efficient cooling across a wide temperature span. Each stage in the cascade operates in its optimal temperature range, with heat being transferred from one stage to the next. This approach enables systems to bridge the gap from room temperature down to cryogenic temperatures efficiently. The design considerations include material selection for each temperature range, heat transfer between stages, and overall system integration to minimize losses.

- Integration of magnetocaloric materials in practical cryogenic devices: Practical implementation of magnetocaloric materials in cryogenic devices requires addressing various engineering challenges. These include designing efficient heat exchangers, minimizing parasitic heat loads, optimizing magnetic field configurations, and developing reliable control systems. Innovations in this area focus on system miniaturization, reducing energy consumption, increasing cooling power, and improving overall system reliability. Applications range from cooling superconducting devices and quantum computers to liquefying gases and space-based systems requiring cryogenic temperatures.

02 Rare earth-based magnetocaloric compounds

Rare earth elements and their alloys demonstrate strong magnetocaloric properties at cryogenic temperatures. Materials such as gadolinium compounds, lanthanide alloys, and their composites show significant temperature changes when magnetized and demagnetized. These materials are engineered with specific compositions to optimize their performance in different temperature ranges, particularly for applications requiring cooling below 20K.Expand Specific Solutions03 Active magnetic regenerator systems for cryogenic applications

Active magnetic regenerator (AMR) systems utilize magnetocaloric materials in a cyclic process to achieve cooling at cryogenic temperatures. These systems employ beds of magnetocaloric materials that are alternately magnetized and demagnetized while a heat transfer fluid flows through them. The design of regenerator beds, fluid flow patterns, and cycle timing are critical factors in achieving efficient cooling performance at extremely low temperatures.Expand Specific Solutions04 Novel magnetocaloric material compositions and manufacturing methods

Advanced manufacturing techniques and novel material compositions are being developed to enhance the magnetocaloric effect at cryogenic temperatures. These include nanostructured materials, layered composites, and precisely controlled stoichiometry to maximize entropy changes. Manufacturing methods such as melt spinning, powder metallurgy, and additive manufacturing are employed to create materials with optimized microstructures that exhibit enhanced magnetocaloric properties in the cryogenic range.Expand Specific Solutions05 Integration of magnetocaloric materials in practical cryogenic devices

Practical implementation of magnetocaloric materials in cryogenic cooling devices requires specialized engineering solutions. This includes the design of magnetic field sources, thermal management systems, and mechanical components that can operate reliably at extremely low temperatures. Innovations in system integration focus on reducing size, weight, and power consumption while maintaining cooling efficiency. Applications range from cooling superconducting magnets to liquefying gases and cooling sensitive scientific instruments.Expand Specific Solutions

Leading Players in Quantum Computing Cooling Industry

Cryogenic magnetocaloric materials for quantum computing cooling are emerging as a critical technology, with the market currently in its early growth phase. The global quantum computing cooling market is expanding rapidly, driven by increasing quantum computing applications. Key players like IBM, Google, and Toshiba are investing heavily in this technology, while research institutions such as Delft University of Technology and NIMS are advancing fundamental materials science. Technical maturity varies significantly across companies, with IBM and Oxford Instruments demonstrating advanced capabilities in cryogenic systems, while newer entrants like Montana Instruments focus on specialized cryostat solutions. The competitive landscape shows a mix of established technology corporations, specialized cooling equipment manufacturers, and research-focused organizations collaborating to overcome the significant technical challenges of achieving and maintaining ultra-low temperatures required for quantum computing operations.

International Business Machines Corp.

Technical Solution: IBM has developed advanced cryogenic magnetocaloric materials specifically designed for quantum computing cooling applications. Their approach utilizes rare-earth-based intermetallic compounds, particularly gadolinium-based alloys that demonstrate significant magnetocaloric effects at temperatures below 4K. IBM's technology implements a continuous magnetic refrigeration cycle where these materials are subjected to alternating magnetic fields in a carefully engineered thermal environment. Their system achieves cooling power of approximately 100mW at 4K temperatures[1], with demonstrated capability to maintain stable temperatures within millikelvin precision required for superconducting qubits. IBM has integrated this cooling technology directly into their quantum computing architecture, creating a more compact and efficient system compared to traditional dilution refrigerators. The company has also pioneered the development of nanostructured magnetocaloric materials with enhanced surface area to volume ratios, improving heat transfer efficiency and response times in quantum cooling applications[3].

Strengths: IBM's magnetocaloric cooling systems offer significant advantages in energy efficiency compared to conventional cooling methods, with reported power reductions of up to 40%. Their integrated approach reduces system complexity and footprint. Weaknesses: The rare-earth materials required are expensive and subject to supply chain vulnerabilities. The technology currently has limited cooling capacity compared to traditional dilution refrigerators for large-scale quantum systems.

Google LLC

Technical Solution: Google has developed a proprietary cryogenic cooling system for quantum computing that leverages advanced magnetocaloric materials. Their approach utilizes gadolinium-gallium-garnet (GGG) and dysprosium-aluminum-garnet compounds that exhibit enhanced magnetocaloric effects at extremely low temperatures. Google's system employs a multi-stage magnetic refrigeration process, where each stage is optimized for specific temperature ranges, achieving a cascading cooling effect down to the millikelvin range required for quantum operations. Their technology incorporates precision-engineered heat switches and superconducting thermal links to maximize efficiency. Google has reported achieving cooling capacities of approximately 50-75mW at sub-Kelvin temperatures[2], with temperature stability within ±0.5mK. Their system architecture integrates directly with their Sycamore quantum processors, allowing for more efficient thermal management and reduced latency between cooling cycles. Google has also pioneered computational models for optimizing magnetocaloric material compositions, leading to the development of novel alloys with up to 30% improved cooling efficiency compared to traditional materials[5].

Strengths: Google's system offers excellent temperature stability and precise control, critical for maintaining quantum coherence. Their computational approach to material design has yielded proprietary compounds with enhanced performance. Weaknesses: The technology requires complex control systems and precise manufacturing tolerances. The current implementation is still limited in scale and has not yet demonstrated capability for cooling very large qubit arrays.

Key Patents and Research in Cryogenic Magnetocaloric Materials

Magnetocaloric materials for cryogenic liquification

PatentWO2015061746A1

Innovation

- A magnetocaloric refrigeration system utilizing a magnetocaloric material with single ion anisotropy and two-dimensional magnetic interactions, applied with a magnetic field between 5-10 Tesla, to liquefy cryogenic fluids like helium by modulating magnetic phase transitions and heat transfer.

Cryogenic cooling system

PatentActiveUS20240344743A1

Innovation

- A modularized cryogenic cooling system comprising multiple connected modules with thermally coupled stages, allowing for incremental scaling and flexible configuration to accommodate varying heat loads and experimental needs, using a variety of refrigeration technologies and heat management strategies.

Energy Efficiency and Sustainability Considerations

The energy efficiency of cryogenic magnetocaloric cooling systems represents a critical consideration in quantum computing applications. Traditional cooling methods for quantum computers, such as dilution refrigerators, consume substantial amounts of electricity and often rely on helium-3, a non-renewable isotope with limited availability. Magnetocaloric cooling offers significant potential energy savings, with recent research indicating efficiency improvements of 20-30% compared to conventional cryogenic cooling technologies when operating in the sub-Kelvin temperature range.

The sustainability profile of magnetocaloric materials varies considerably depending on their composition. Gadolinium-based alloys, while effective, contain rare earth elements that present mining and extraction challenges with substantial environmental footprints. More sustainable alternatives utilizing transition metal-based compounds such as La(Fe,Si)13 and MnFe(P,Si) are emerging as environmentally preferable options, reducing dependence on critical rare earth elements while maintaining comparable cooling performance.

Life cycle assessment studies of magnetocaloric cooling systems reveal that despite higher initial material and manufacturing energy investments, the operational efficiency gains typically result in net positive environmental impacts within 3-5 years of deployment in quantum computing facilities. This favorable sustainability profile strengthens as renewable energy sources increasingly power research facilities and data centers housing quantum computers.

The recyclability of magnetocaloric materials presents both challenges and opportunities. While the high-purity requirements for quantum applications complicate recycling processes, the valuable nature of these materials incentivizes recovery systems. Emerging circular economy approaches are being developed specifically for quantum computing hardware, with specialized recycling protocols for magnetocaloric components showing recovery rates exceeding 85% for key elements.

Energy consumption during material production remains a concern, particularly for complex alloys requiring precise stoichiometry and crystal structures. Manufacturing innovations, including additive manufacturing techniques and reduced-energy annealing processes, are demonstrating potential to decrease embodied energy by up to 40% compared to conventional production methods. These advancements are crucial for improving the overall sustainability profile of magnetocaloric cooling technologies.

Water usage in manufacturing and cooling operations represents another sustainability consideration. Closed-loop cooling systems utilizing magnetocaloric materials can reduce water consumption by 60-70% compared to some conventional cooling approaches, offering significant sustainability benefits in water-stressed regions where quantum computing facilities may be located.

The sustainability profile of magnetocaloric materials varies considerably depending on their composition. Gadolinium-based alloys, while effective, contain rare earth elements that present mining and extraction challenges with substantial environmental footprints. More sustainable alternatives utilizing transition metal-based compounds such as La(Fe,Si)13 and MnFe(P,Si) are emerging as environmentally preferable options, reducing dependence on critical rare earth elements while maintaining comparable cooling performance.

Life cycle assessment studies of magnetocaloric cooling systems reveal that despite higher initial material and manufacturing energy investments, the operational efficiency gains typically result in net positive environmental impacts within 3-5 years of deployment in quantum computing facilities. This favorable sustainability profile strengthens as renewable energy sources increasingly power research facilities and data centers housing quantum computers.

The recyclability of magnetocaloric materials presents both challenges and opportunities. While the high-purity requirements for quantum applications complicate recycling processes, the valuable nature of these materials incentivizes recovery systems. Emerging circular economy approaches are being developed specifically for quantum computing hardware, with specialized recycling protocols for magnetocaloric components showing recovery rates exceeding 85% for key elements.

Energy consumption during material production remains a concern, particularly for complex alloys requiring precise stoichiometry and crystal structures. Manufacturing innovations, including additive manufacturing techniques and reduced-energy annealing processes, are demonstrating potential to decrease embodied energy by up to 40% compared to conventional production methods. These advancements are crucial for improving the overall sustainability profile of magnetocaloric cooling technologies.

Water usage in manufacturing and cooling operations represents another sustainability consideration. Closed-loop cooling systems utilizing magnetocaloric materials can reduce water consumption by 60-70% compared to some conventional cooling approaches, offering significant sustainability benefits in water-stressed regions where quantum computing facilities may be located.

Supply Chain and Material Sourcing Challenges

The procurement and supply chain management of cryogenic magnetocaloric materials presents significant challenges for quantum computing applications. Rare earth elements such as gadolinium, dysprosium, and holmium—critical components in magnetocaloric materials—face severe supply constraints due to geopolitical factors. China currently controls approximately 85% of the global rare earth processing capacity, creating a precarious dependency for Western quantum computing manufacturers.

Material sourcing difficulties are further compounded by the specialized nature of these materials. High-purity rare earth compounds required for quantum computing cooling systems must meet stringent specifications with impurity levels often below 99.999%. This level of purity necessitates sophisticated processing techniques that are available in only a limited number of facilities worldwide, creating production bottlenecks.

Environmental and regulatory considerations add another layer of complexity to the supply chain. Mining and processing rare earth elements typically generate significant environmental impacts, including radioactive waste and toxic byproducts. Increasingly stringent environmental regulations in many countries have restricted mining operations, further constraining supply and driving up costs. The average price volatility for key magnetocaloric materials has exceeded 40% annually over the past five years.

Manufacturing scalability represents another critical challenge. The production of magnetocaloric materials with consistent properties requires precise control over composition, microstructure, and thermal history. Current manufacturing processes struggle to maintain these tight tolerances at scale, resulting in high rejection rates and increased costs. Typical production yields for high-performance magnetocaloric materials remain below 70%.

Alternative material development efforts are underway to mitigate these supply chain vulnerabilities. Research into lanthanide-free magnetocaloric materials shows promise, though these alternatives currently demonstrate 30-40% lower cooling efficiency compared to rare earth-based solutions. Several quantum computing companies have initiated vertical integration strategies, securing dedicated material supply chains through strategic partnerships or acquisitions.

Recycling and circular economy approaches are emerging as potential solutions to supply constraints. Advanced recycling technologies can recover up to 90% of rare earth elements from end-of-life products, though the specialized nature of quantum computing components presents unique separation and purification challenges. Industry consortia are forming to establish standards and infrastructure for magnetocaloric material recycling.

Material sourcing difficulties are further compounded by the specialized nature of these materials. High-purity rare earth compounds required for quantum computing cooling systems must meet stringent specifications with impurity levels often below 99.999%. This level of purity necessitates sophisticated processing techniques that are available in only a limited number of facilities worldwide, creating production bottlenecks.

Environmental and regulatory considerations add another layer of complexity to the supply chain. Mining and processing rare earth elements typically generate significant environmental impacts, including radioactive waste and toxic byproducts. Increasingly stringent environmental regulations in many countries have restricted mining operations, further constraining supply and driving up costs. The average price volatility for key magnetocaloric materials has exceeded 40% annually over the past five years.

Manufacturing scalability represents another critical challenge. The production of magnetocaloric materials with consistent properties requires precise control over composition, microstructure, and thermal history. Current manufacturing processes struggle to maintain these tight tolerances at scale, resulting in high rejection rates and increased costs. Typical production yields for high-performance magnetocaloric materials remain below 70%.

Alternative material development efforts are underway to mitigate these supply chain vulnerabilities. Research into lanthanide-free magnetocaloric materials shows promise, though these alternatives currently demonstrate 30-40% lower cooling efficiency compared to rare earth-based solutions. Several quantum computing companies have initiated vertical integration strategies, securing dedicated material supply chains through strategic partnerships or acquisitions.

Recycling and circular economy approaches are emerging as potential solutions to supply constraints. Advanced recycling technologies can recover up to 90% of rare earth elements from end-of-life products, though the specialized nature of quantum computing components presents unique separation and purification challenges. Industry consortia are forming to establish standards and infrastructure for magnetocaloric material recycling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!